Color-coating waste gas heat recovery method

A technology of waste gas heat recovery and color coating, which is applied to heating devices, drying gas layout, lighting and heating equipment, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

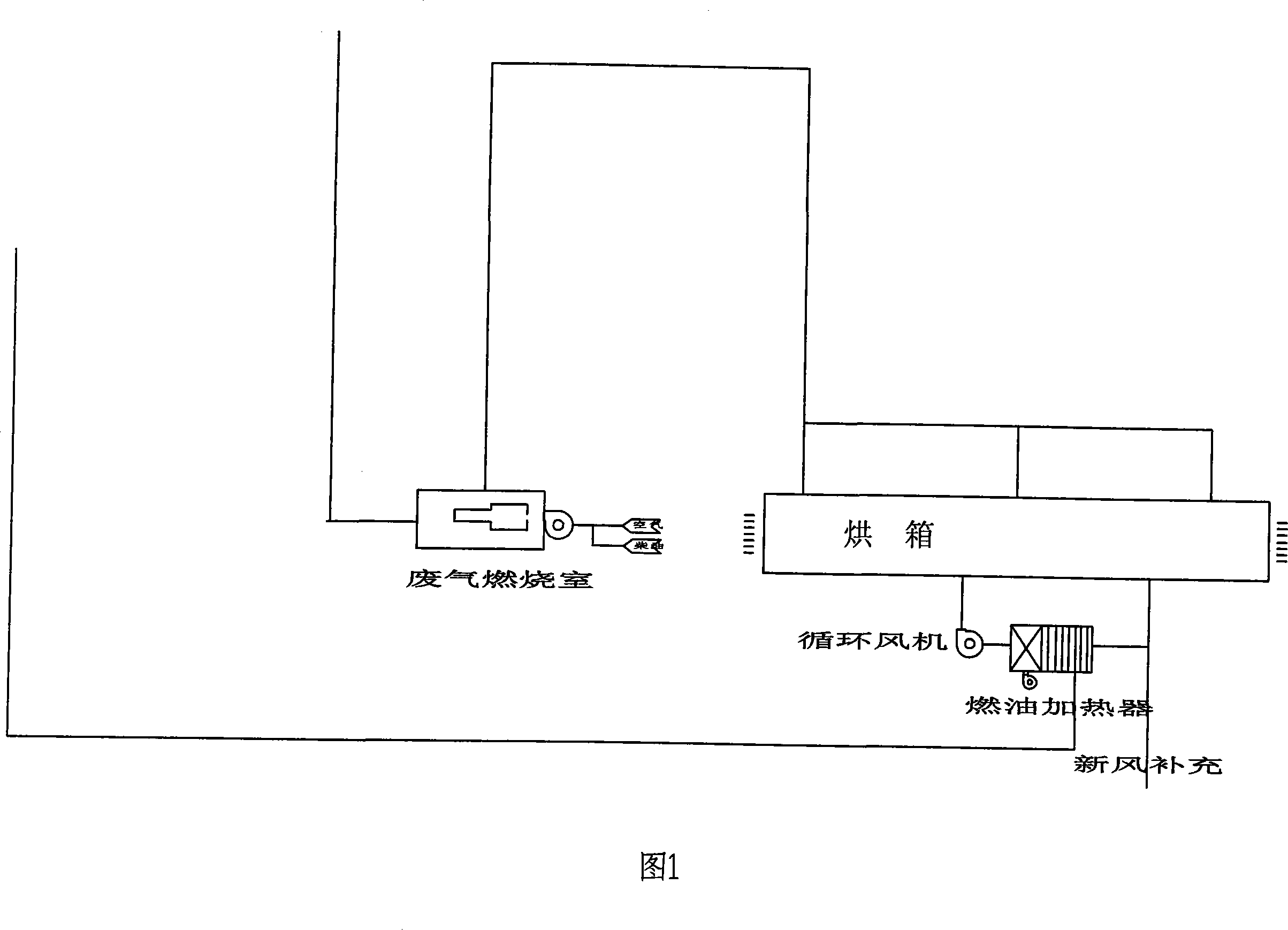

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Embodiment 1: A kind of color coating waste gas heat recovery method of this example, its steps are:

[0025] a. The exhaust gas from the oven passes through the heat exchanger of the machine, passes through the exhaust gas preheating chamber and the catalytic bed, and then passes into the heat exchanger of the machine; the exhaust gas exchanges heat with the catalyzed high-temperature gas and heats it to 300-400°C Catalytic light-off temperature;

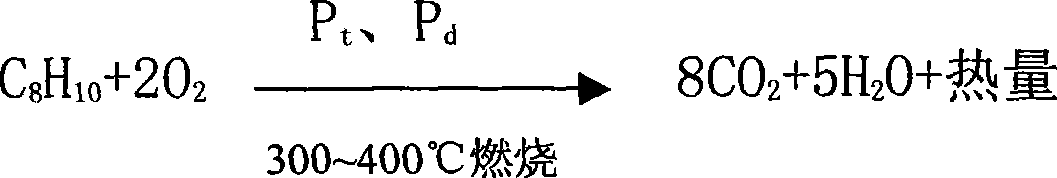

[0026] b. The exhaust gas heated to the catalytic light-off temperature enters the catalytic bed for catalytic reaction, and the catalyst P t ,P d Under the action of oxidizing and converting harmful organic benzene into harmless water and carbon dioxide, the purpose of purifying waste gas is achieved. The waste gas contains organic benzene, and its main component is C 8 h 10 , the reaction formula is:

[0027]

[0028] c. After the catalyzed high-temperature gas is exchanged with the fresh air from the air filter...

Embodiment 2

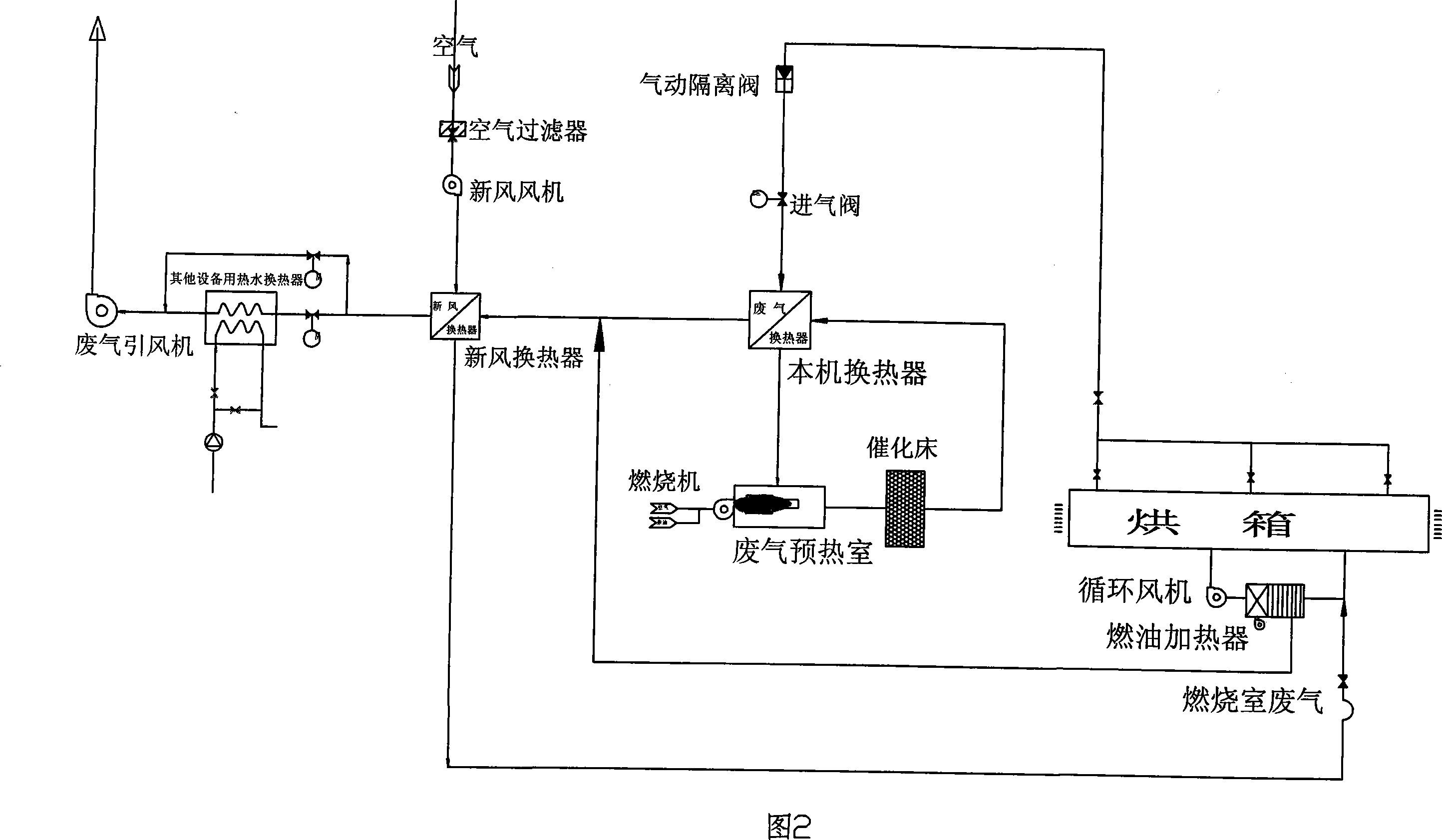

[0030] Embodiment 2: A kind of color coating waste gas heat recovery method of this example, as shown in Figure 2, its steps are:

[0031] a. The exhaust gas from the oven passes through the heat exchanger of the machine, passes through the exhaust gas preheating chamber and the catalytic bed, and then passes into the heat exchanger of the machine; the exhaust gas exchanges heat with the catalyzed high-temperature gas and heats it to 300-400°C Catalytic light-off temperature; when the exhaust gas after heat exchange by the exhaust gas heat exchanger does not reach the design-controlled catalytic light-off temperature of 300-400°C, the burner uses light oil as fuel to heat up to the designed catalytic light-off temperature , the burner stops working when it is reached, and the system relies on the reaction heat of the exhaust gas to maintain the thermal balance of the system and achieve the best reactive power operation state;

[0032] b. The exhaust gas heated to the catalytic...

Embodiment 3

[0036] Embodiment 3: A kind of color coating waste gas heat recovery method of this example, as shown in Figure 2, its steps are:

[0037] a. The exhaust gas from the oven passes through the heat exchanger of the machine, passes through the exhaust gas preheating chamber and the catalytic bed, and then passes into the heat exchanger of the machine; the exhaust gas exchanges heat with the catalyzed high-temperature gas and heats it to 300-400°C Catalytic light-off temperature;

[0038]b. The exhaust gas heated to the catalytic light-off temperature enters the catalytic bed for catalytic reaction, and the catalyst P t ,P d Under the action of oxidizing and converting harmful organic benzene into harmless water and carbon dioxide, the purpose of purifying waste gas is achieved. The waste gas contains organic benzene, and its main component is C 8 h 10 , the reaction formula is:

[0039]

[0040] c. After the catalyzed high-temperature gas is exchanged with the fresh ai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com