Preparation method of ternary copper catalyst with high specific surface area

A high specific surface area, ternary copper technology, applied in the direction of catalyst activation/preparation, chemical instruments and methods, physical/chemical process catalysts, etc. Small and other problems, to achieve excellent catalytic effect, suitable for popularization and use, and high specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

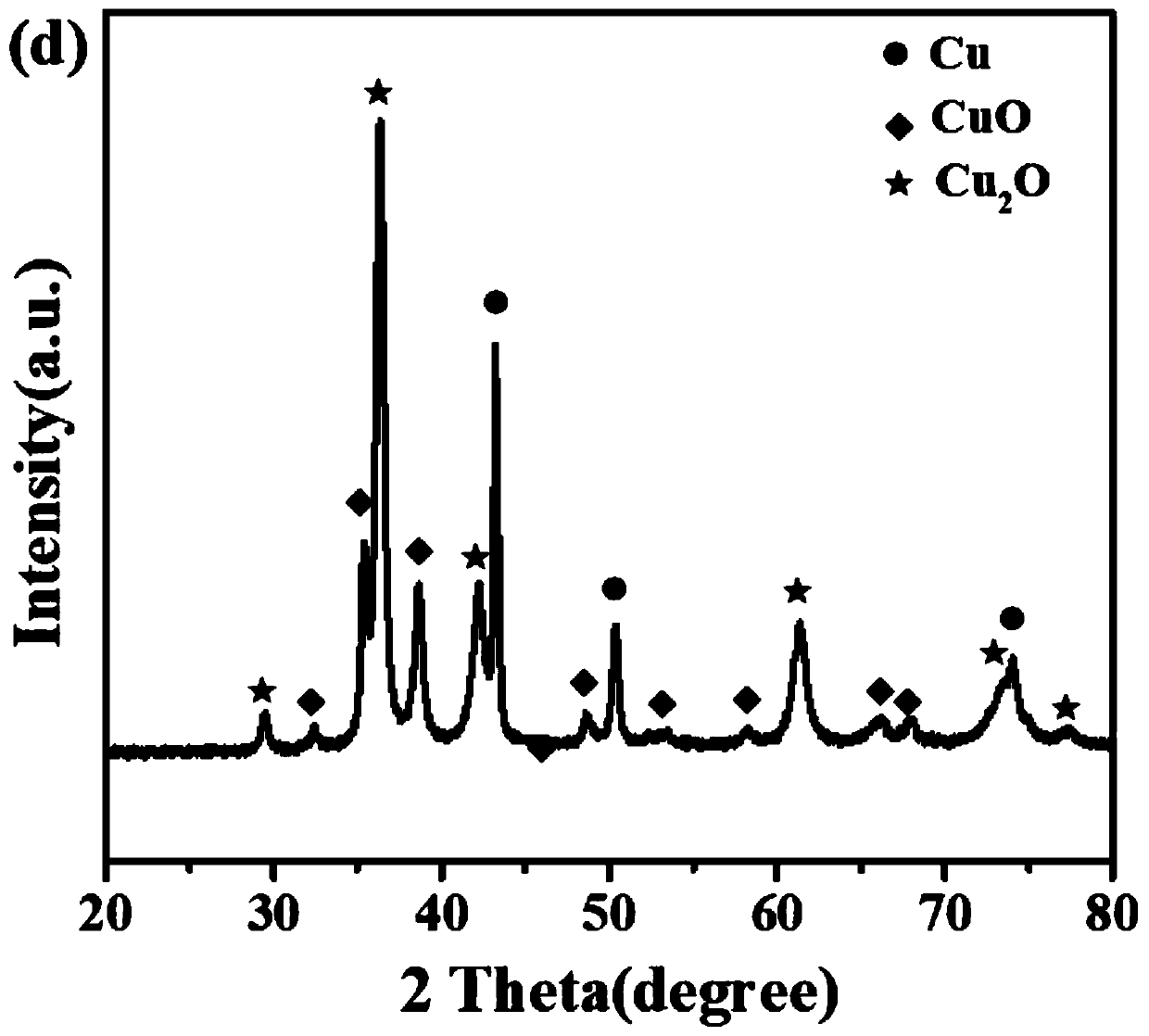

Image

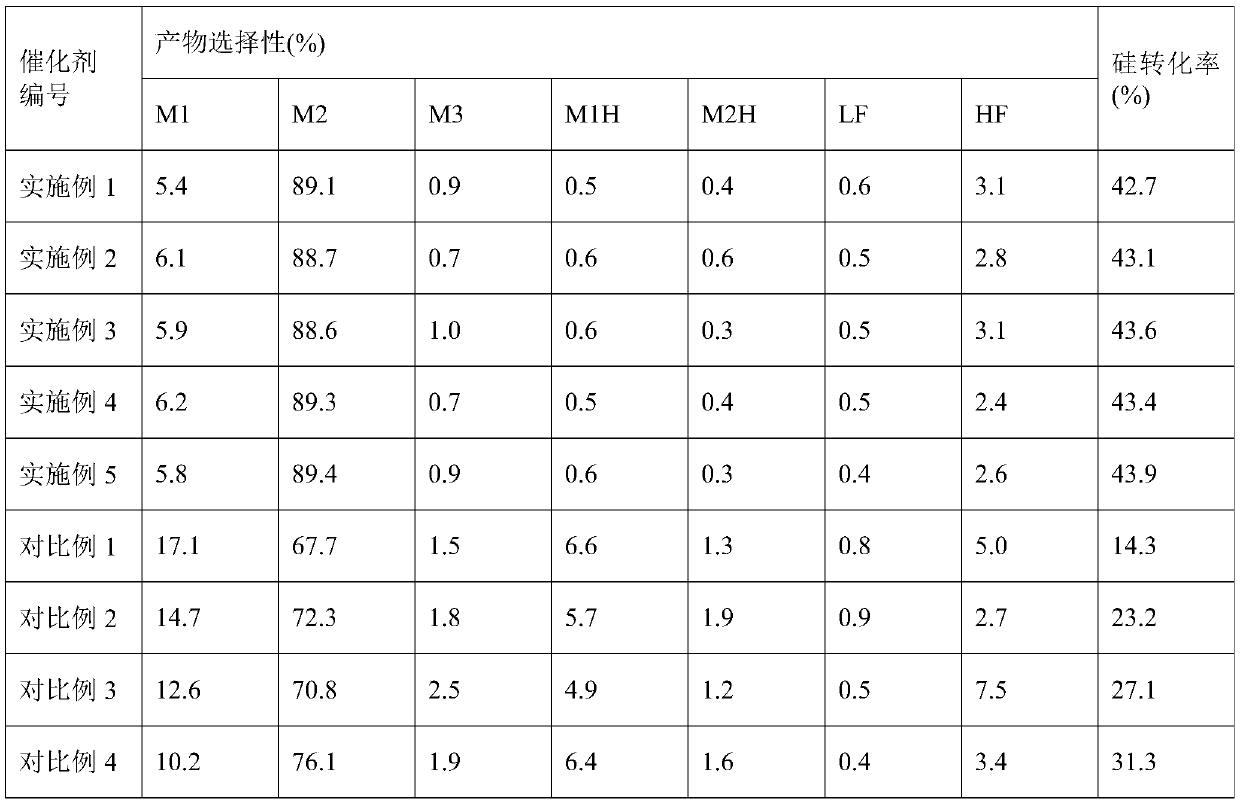

Examples

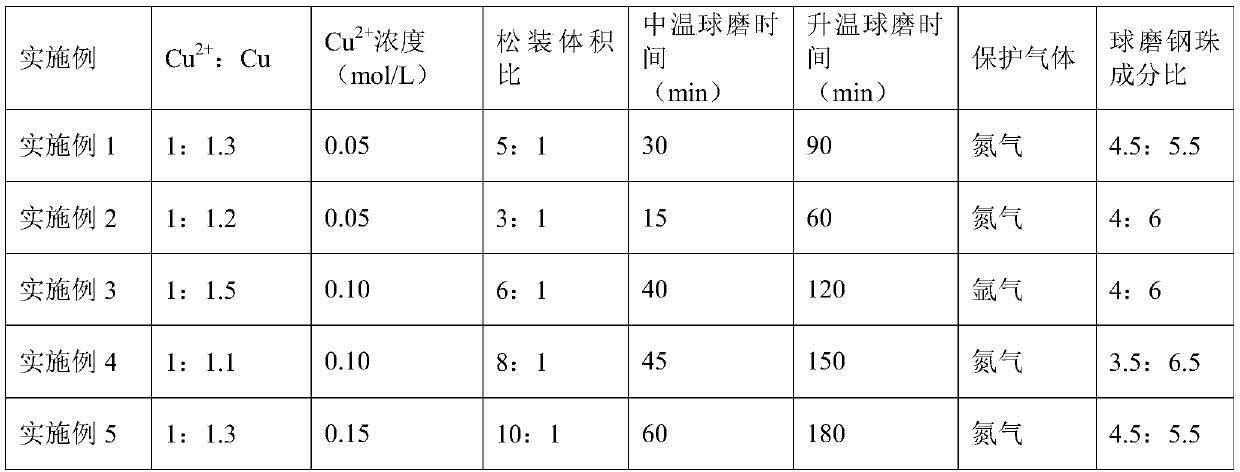

Embodiment 1~5

[0035] A kind of preparation method of high specific surface area ternary copper catalyst, described method comprises the following steps:

[0036] 1) Add excessive metal copper micropowder to the copper solution, add sodium hydroxide to adjust the pH value to ≥6.7 after a period of time after the reaction, precipitate and filter to separate to obtain solid particles;

[0037] 2) A layer of insulating foam plastic interlayer is coated on the outside of the ball mill tank of the ball mill. The interlayer has airtightness, and hot water is continuously fed into the interlayer to control the temperature of the ball mill tank. The temperature during ball milling is always 60-80°C. In addition, the protective gas is introduced into the ball mill to form a protective atmosphere, and the obtained solid particles and carbonic acid are co-placed in the ball mill tank for medium-temperature ball milling, and the intermediate is obtained after medium-temperature ball milling;

[0038] 3)...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com