Patents

Literature

629 results about "Copper catalyzed" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

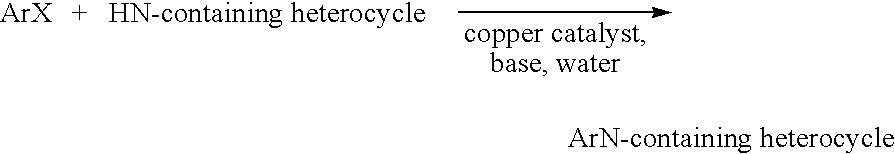

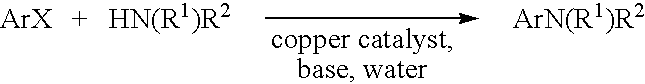

Copper-catalyzed amination refers to the coupling of an amine with an aryl or alkenyl electrophile in the presence of a copper catalyst and base to form a new carbon-nitrogen bond.

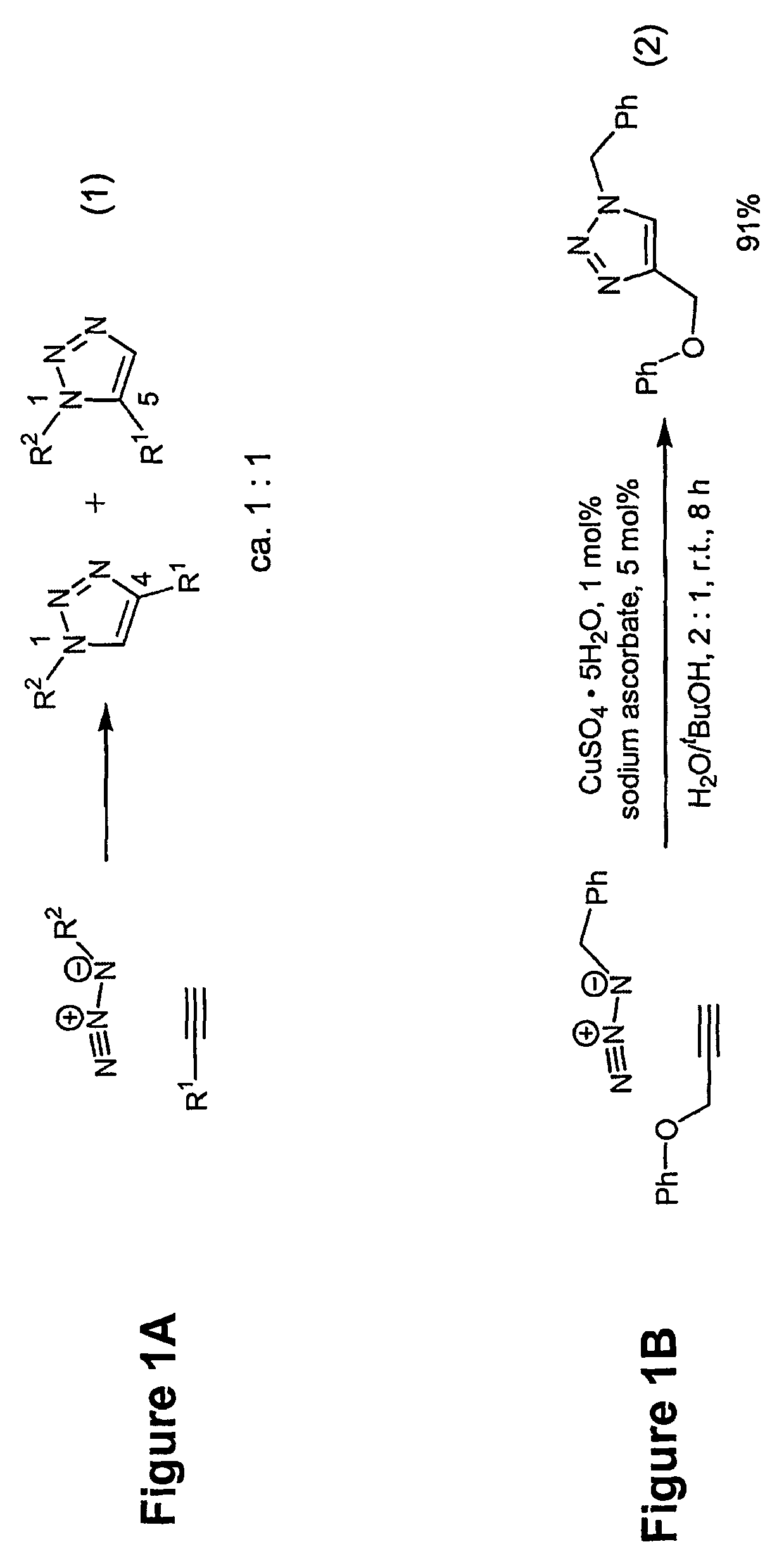

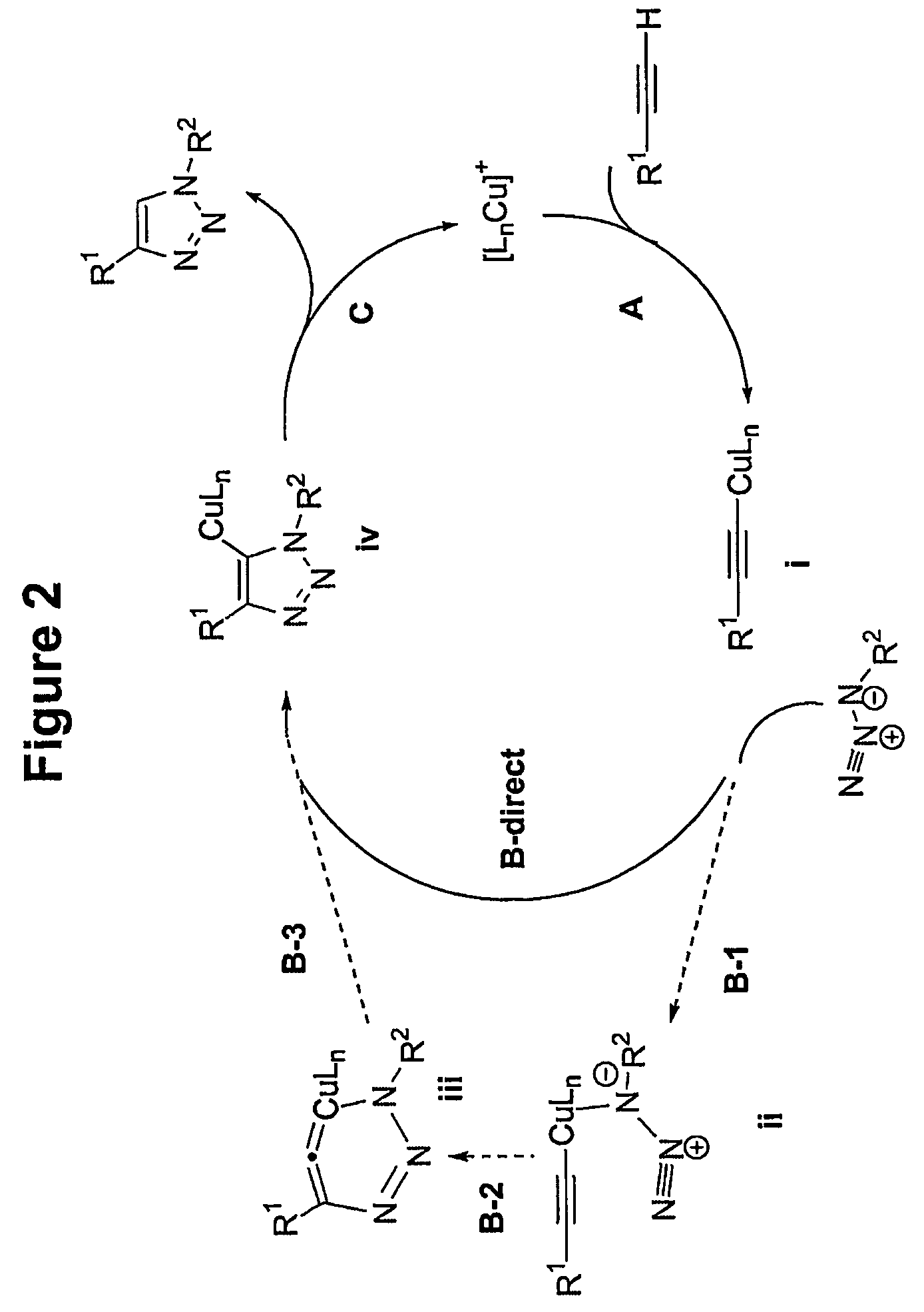

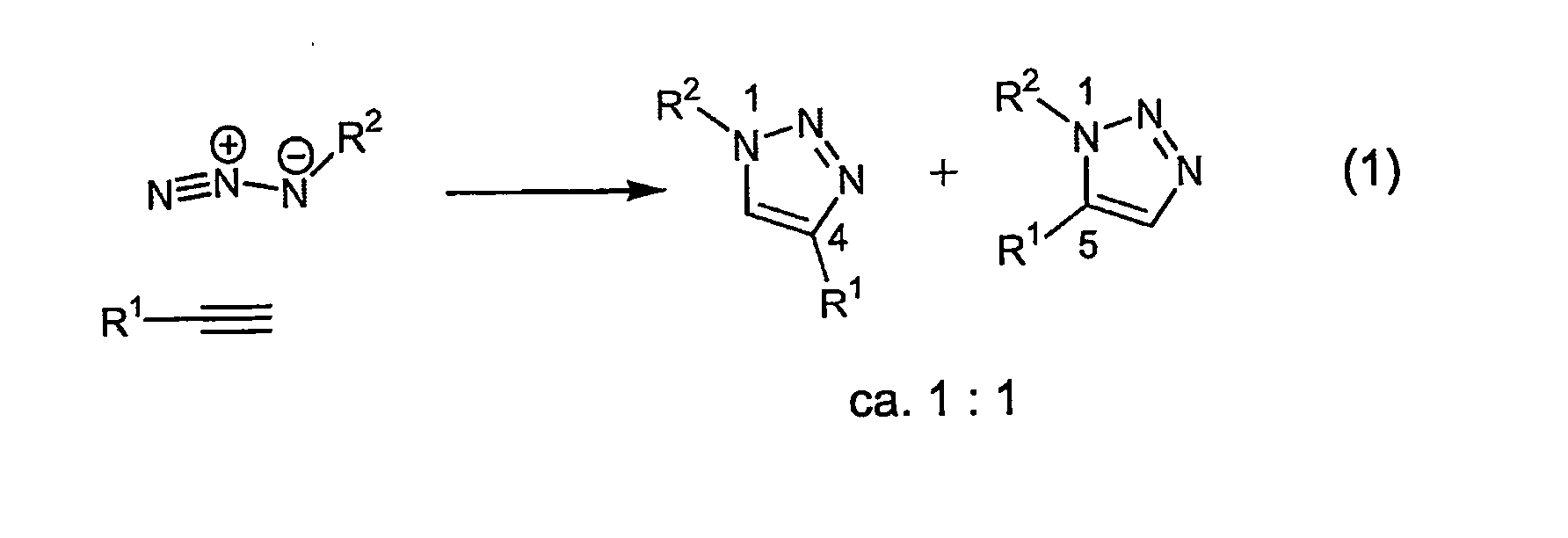

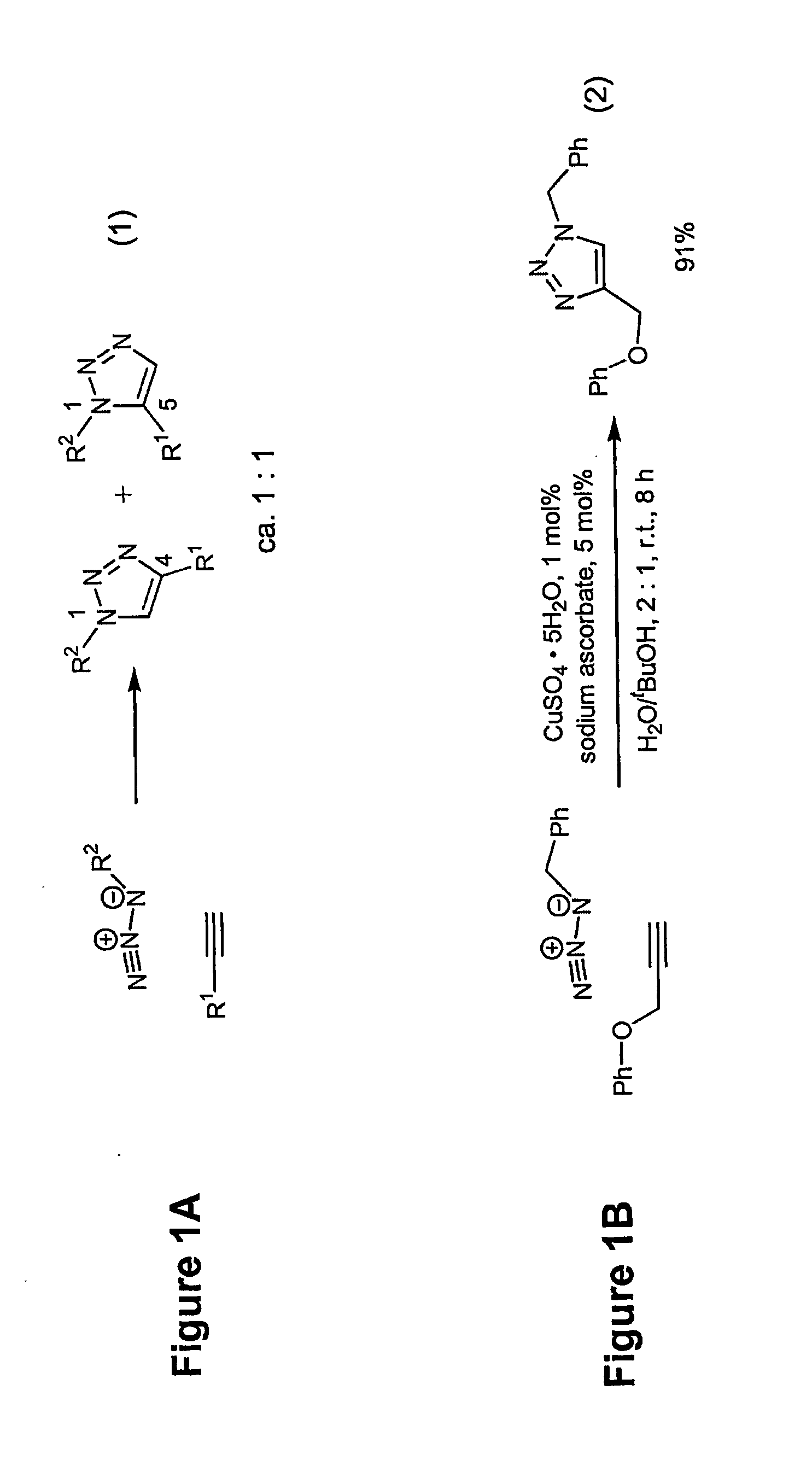

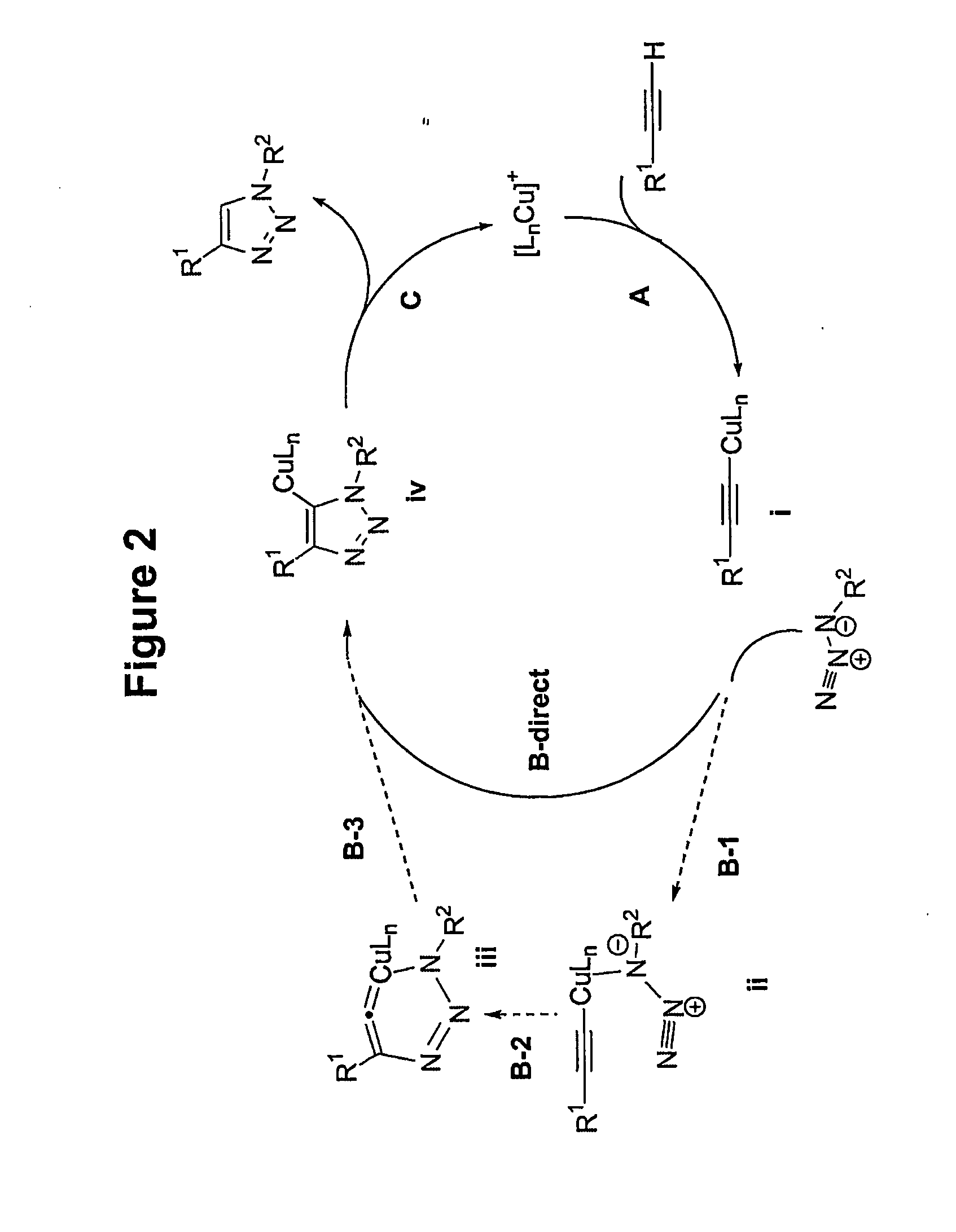

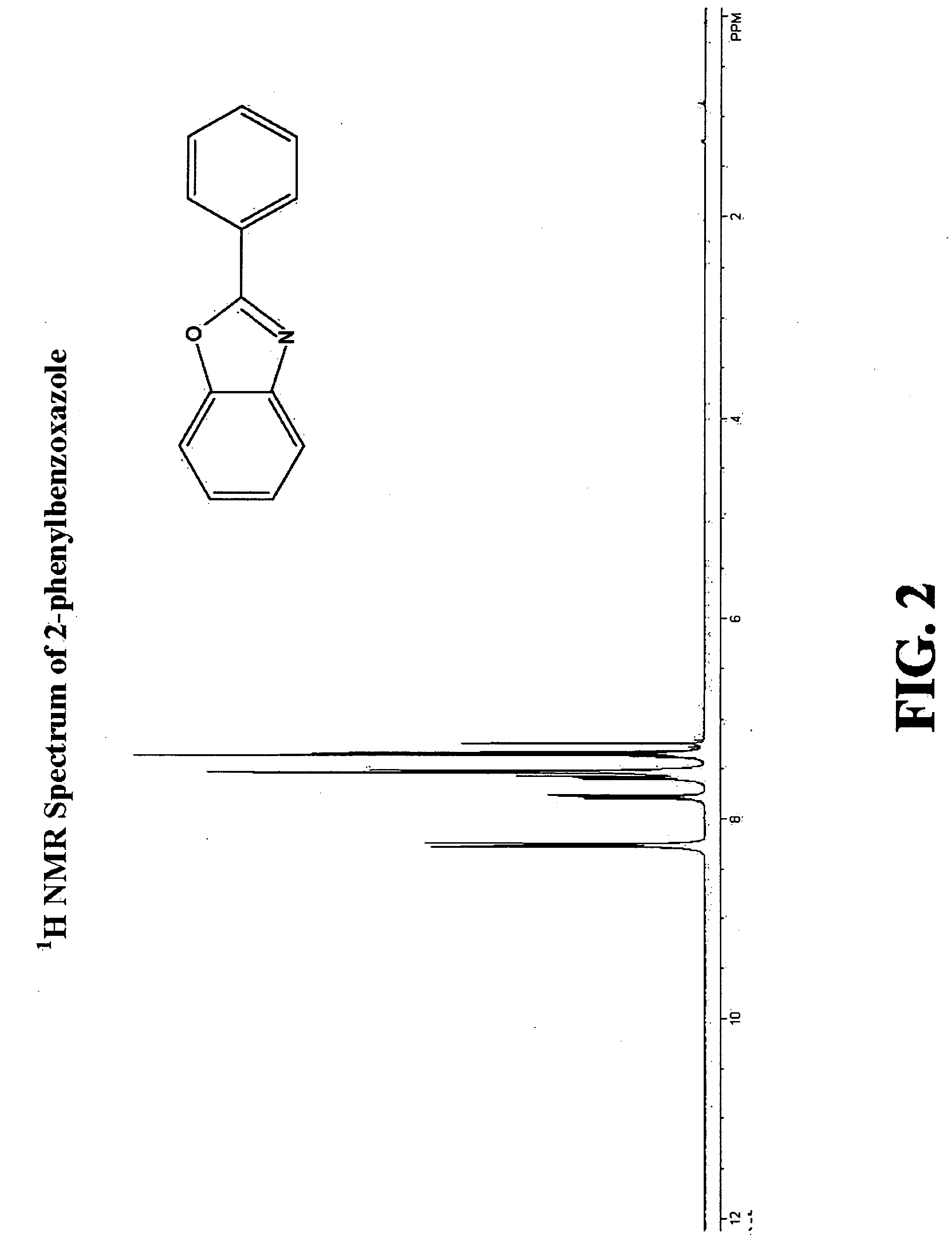

Copper-catalysed ligation of azides and acetylenes

InactiveUS7763736B2Organic chemistryOrganic-compounds/hydrides/coordination-complexes catalystsChemical ligationAqueous alcohol

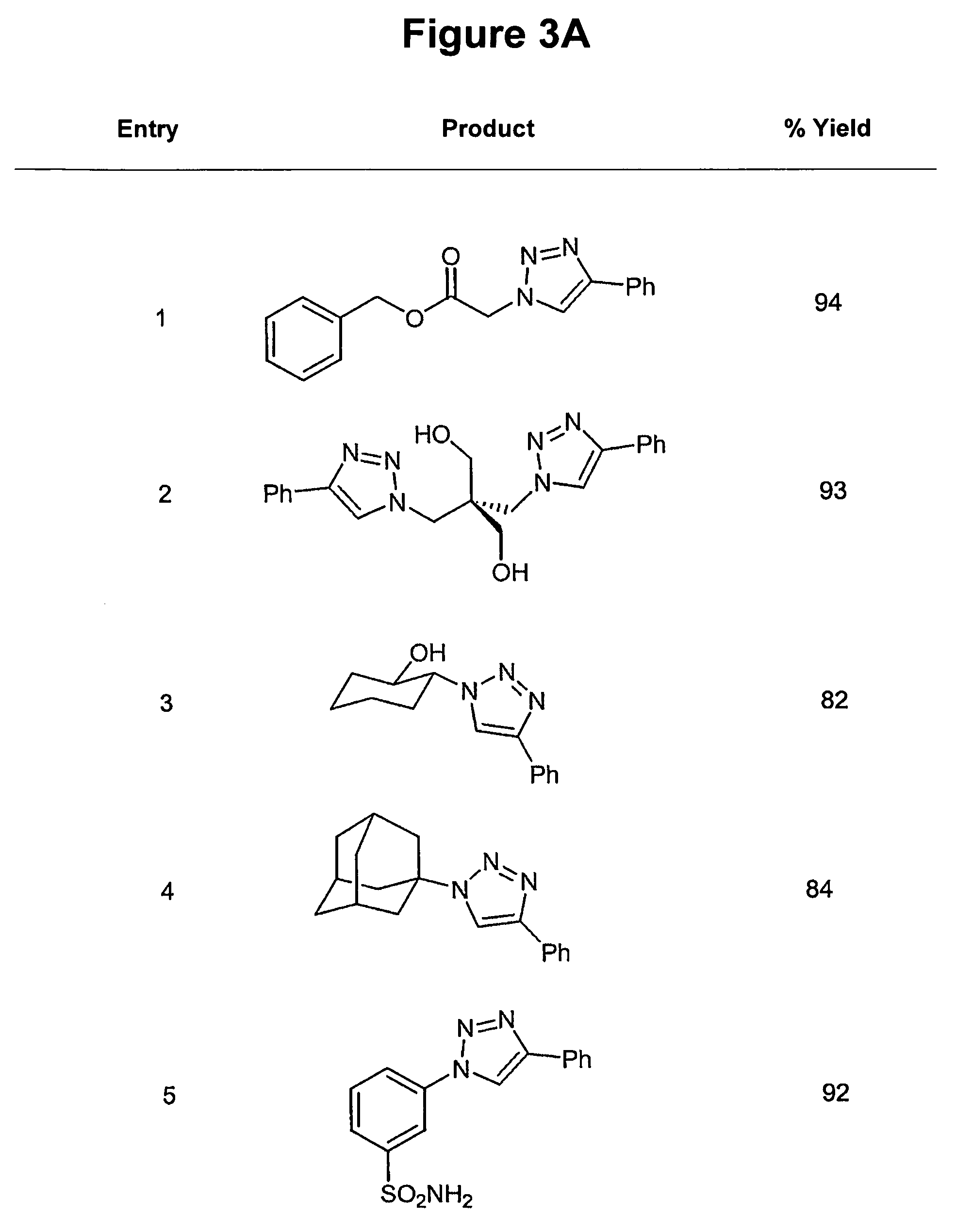

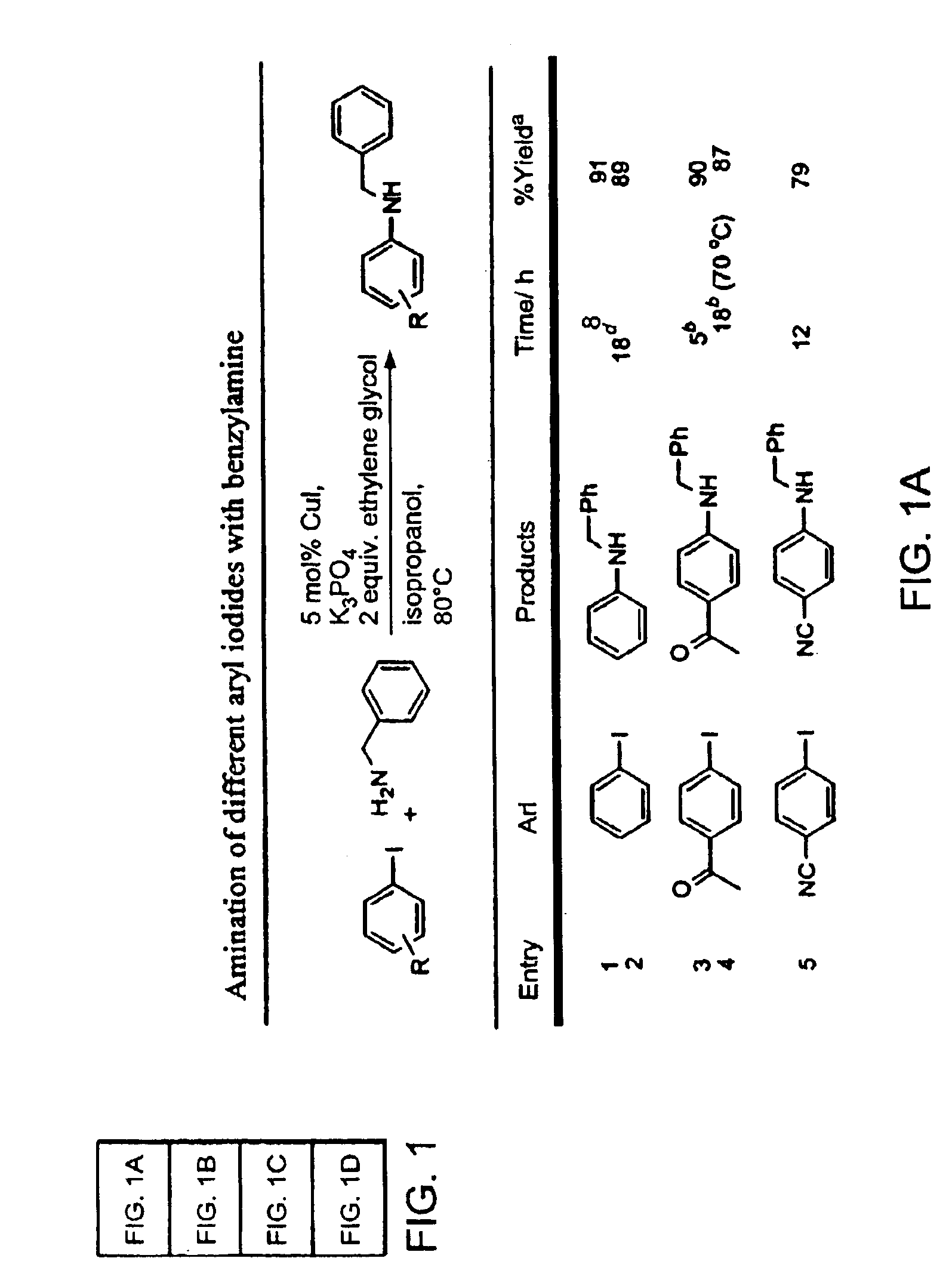

A copper catalyzed click chemistry ligation process is employed to bind azides and terminal acetylenes to provide 1,4-disubstituted 1,2,3-triazole triazoles. The process comprises contacting an organic azide and a terminal alkyne with a source of reactive Cu(I) ion for a time sufficient to form by cycloaddition a 1,4-disubstituted 1,2,3-triazole. The source of reactive Cu(I) ion can be, for example, a Cu(I) salt or copper metal. The process is preferably carried out in a solvent, such as an aqueous alcohol. Optionally, the process can be performed in a solvent that comprises a ligand for Cu(I) and an amine.

Owner:TETARD INC

Copper-catalyzed formation of carbon-heteroatom and carbon-carbon bonds

InactiveUS6867298B2Cheap and practicalLow costUrea derivatives preparationCarbamic acid derivatives preparationCarbon–oxygen bondHydrazine compound

The present invention relates to copper-catalyzed carbon-heteroatom and carbon-carbon bond-forming methods. In certain embodiments, the present invention relates to copper-catalyzed methods of forming a carbon-nitrogen bond between the nitrogen atom of an amide or amine moiety and the activated carbon of an aryl, heteroaryl, or vinyl halide or sulfonate. In additional embodiments, the present invention relates to copper-catalyzed methods of forming a carbon-nitrogen bond between a nitrogen atom of an acyl hydrazine and the activated carbon of an aryl, heteroaryl, or vinyl halide or sulfonate. In other embodiments, the present invention relates to copper-catalyzed methods of forming a carbon-nitrogen bond between the nitrogen atom of a nitrogen-containing heteroaromatic, e.g., indole, pyrazole, and indazole, and the activated carbon of an aryl, heteroaryl, or vinyl halide or sulfonate. In certain embodiments, the present invention relates to copper-catalyzed methods of forming a carbon-oxygen bond between the oxygen atom of an alcohol and the activated carbon of an aryl, heteroaryl, or vinyl halide or sulfonate. The present invention also relates to copper-catalyzed methods of forming a carbon-carbon bond between a reactant comprising a nucleophilic carbon atom, e.g., an enolate or malonate anion, and the activated carbon of an aryl, heteroaryl, or vinyl halide or sulfonate. Importantly, all the methods of the present invention are relatively inexpensive to practice due to the low cost of the copper comprised by the catalysts.

Owner:MASSACHUSETTS INST OF TECH

Copper-catalysed ligation of azides and acetylenes

InactiveUS20080214831A1Organic chemistryOrganic-compounds/hydrides/coordination-complexes catalystsMetalloleSufficient time

A copper catalyzed click chemistry ligation process is employed to bind azides and terminal acetylenes to provide 1,4-disubstituted 1,2,3-triazole triazoles. The process comprises contacting an organic azide and a terminal alkyne with a source of reactive Cu(I) ion for a time sufficient to form by cycloaddition a 1,4-disubstituted 1,2,3-triazole. The source of reactive Cu(I) ion can be, for example, a Cu(I) salt or copper metal. The process is preferably carried out in a solvent, such as an aqueous alcohol. Optionally, the process can be performed in a solvent that comprises a ligand for Cu(I) and an amine.

Owner:TETARD INC

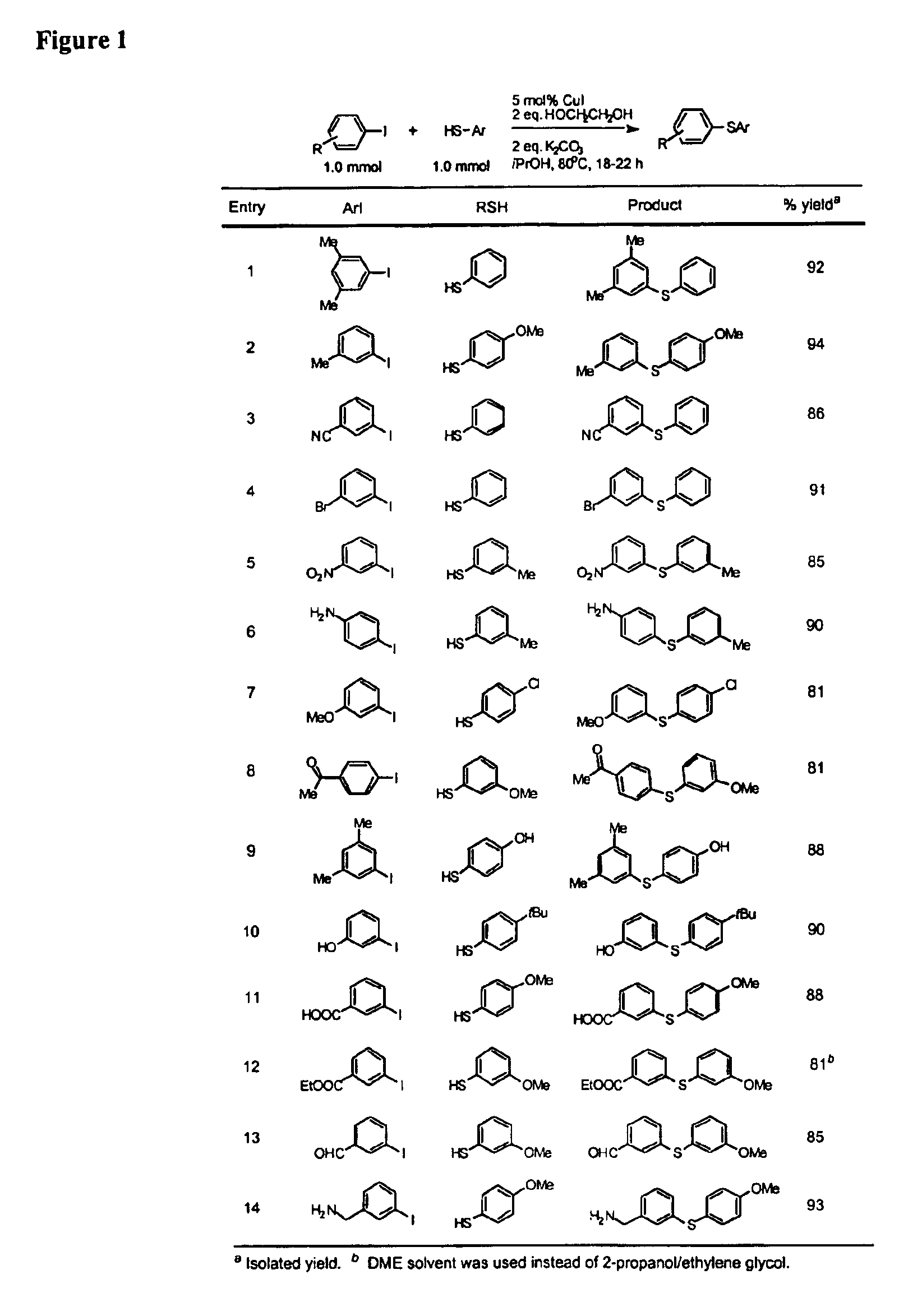

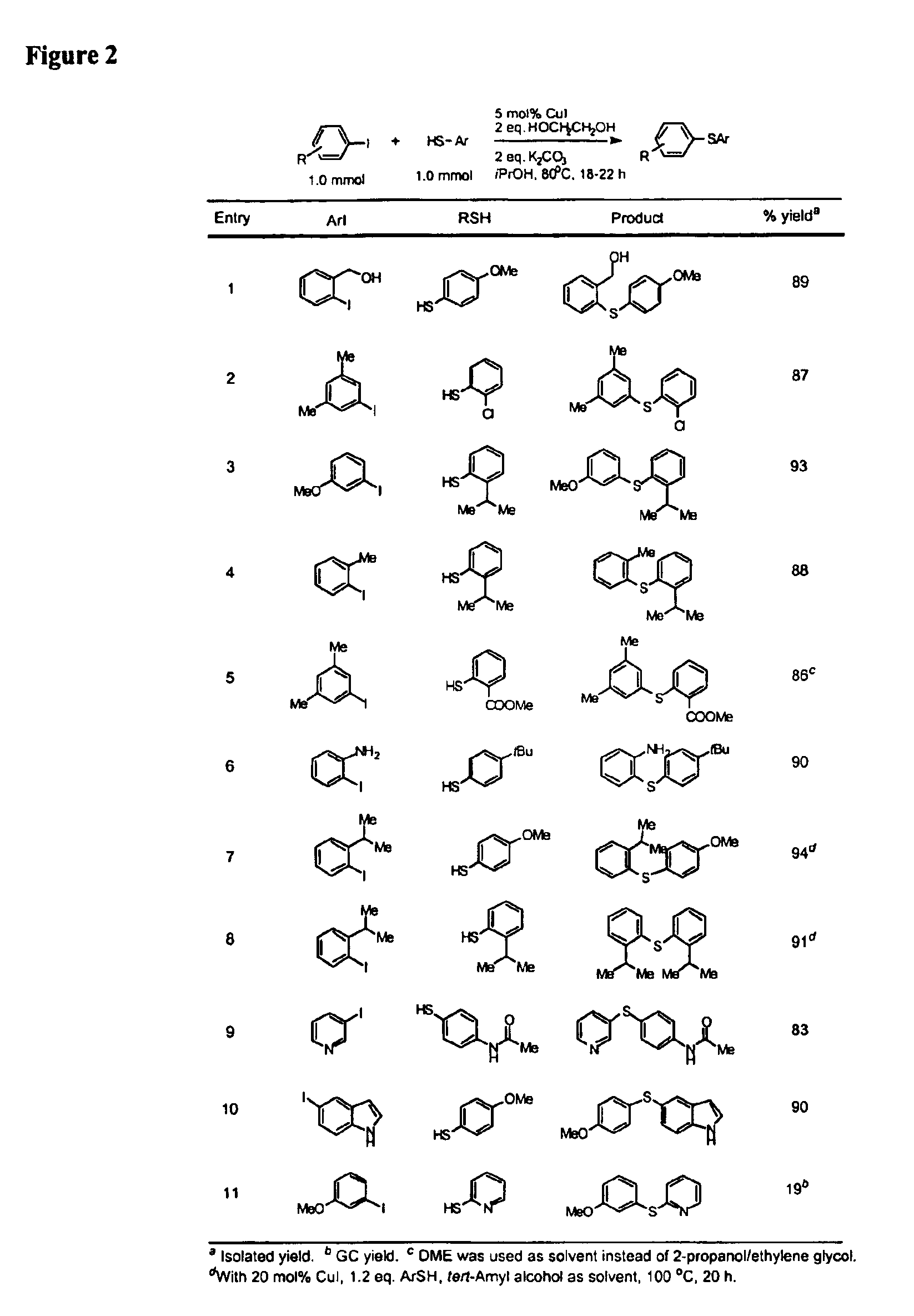

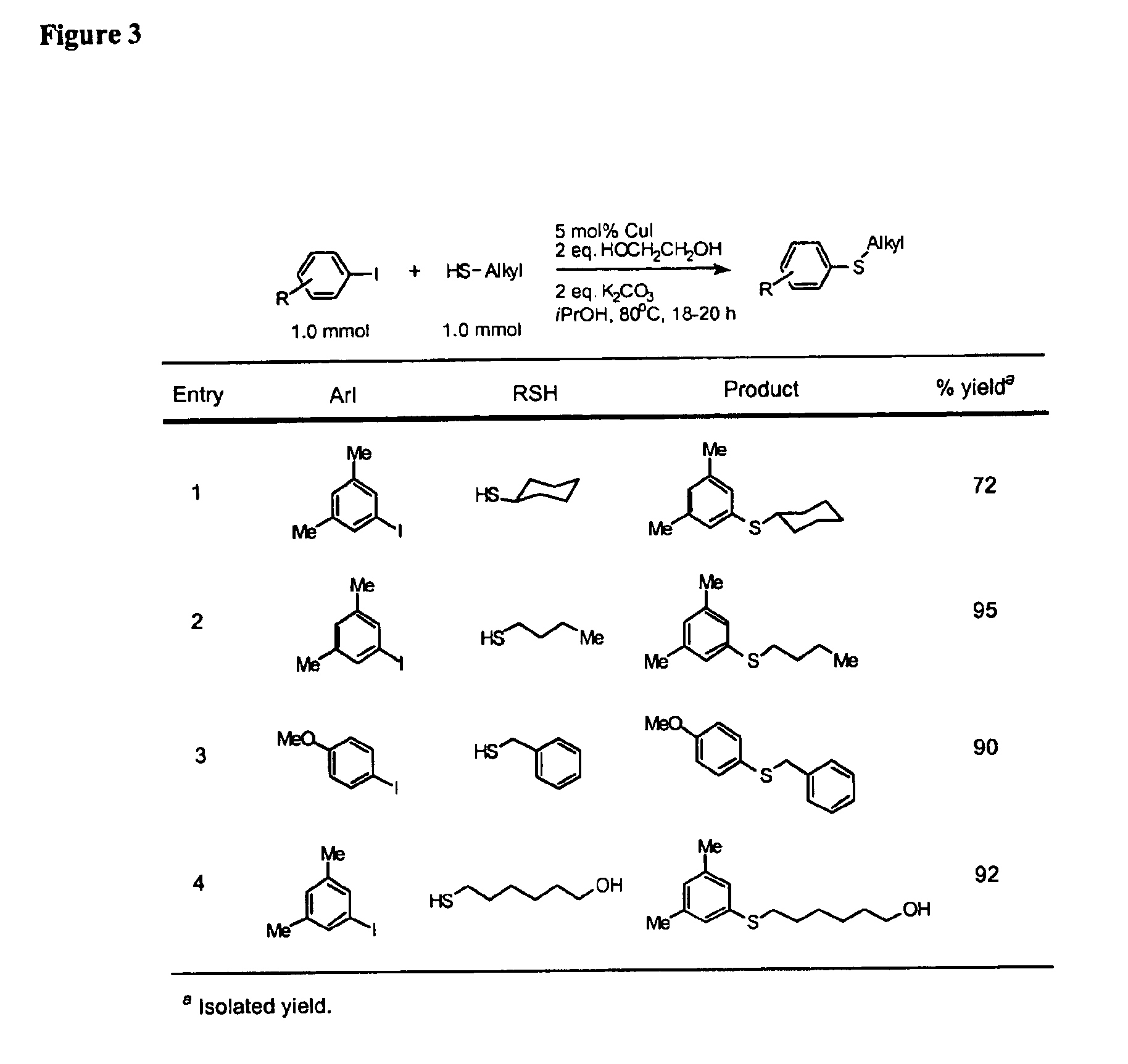

Copper-catalyzed formation of carbon-heteroatom and carbon-carbon bonds

InactiveUS6888032B2Cheap and practicalLow costOrganic compound preparationThiol preparationCarbon–carbon bondSulfide

One aspect of the present invention relates to copper-catalyzed carbon-heteroatom and carbon-carbon bond-forming methods. In certain embodiments, the present invention relates to copper-catalyzed methods of forming a carbon-sulfur bond between the sulfur atom of a thiol moiety and the activated carbon of an aryl, heteroaryl, or vinyl halide or sulfonate. In other embodiments, the present invention relates to copper(II)-catalyzed methods of forming a carbon-nitrogen bond between the nitrogen atom of an amide and the activated carbon of an aryl, heteroaryl, or vinyl halide or sulfonate. In certain embodiments, the present invention relates to copper-catalyzed methods of forming a carbon-carbon bond between the carbon atom of cyanide ion and the activated carbon of an aryl, heteroaryl, or vinyl halide or sulfonate. In another embodiment, the present invention relates to a copper-catalyzed method of transforming an aryl, heteroaryl, or vinyl chloride or bromide into the corresponding aryl, heteroaryl, or vinyl iodide. Yet another embodient of the present invention relates to a tandem method, which may be practiced in a single reaction vessel, wherein the first step of the method involves the copper-catalyzed formation of an aryl, heteroaryl, or vinyl iodide from the corresponding aryl, heteroaryl, or vinyl chloride or bromide; and the second step of the method involves the copper-catalyzed formation of an aryl, heteroaryl, or vinyl nitrile, amide or sulfide from the aryl, heteroaryl, or vinyl iodide formed in the first step.

Owner:MASSACHUSETTS INST OF TECH

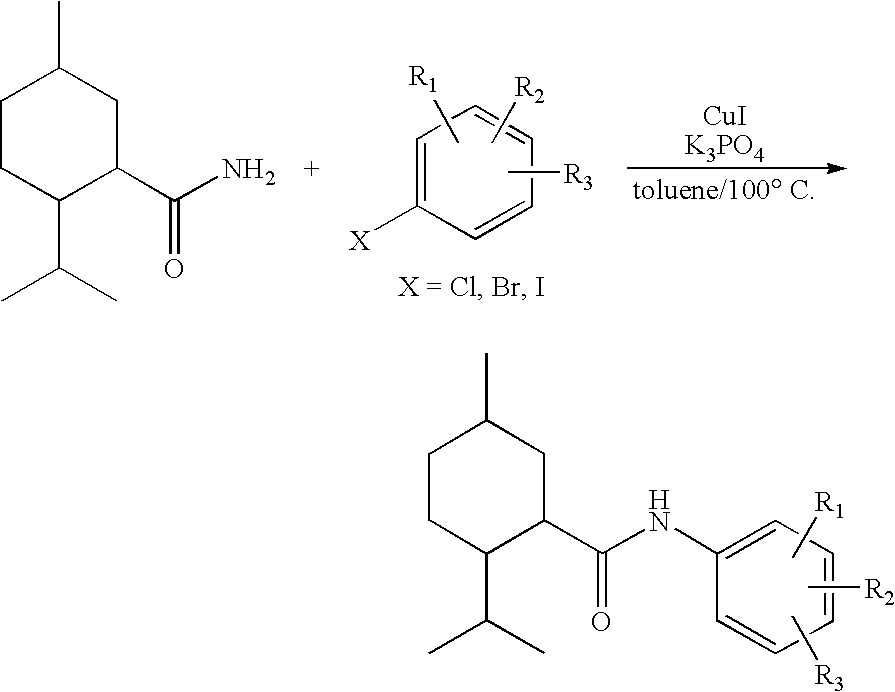

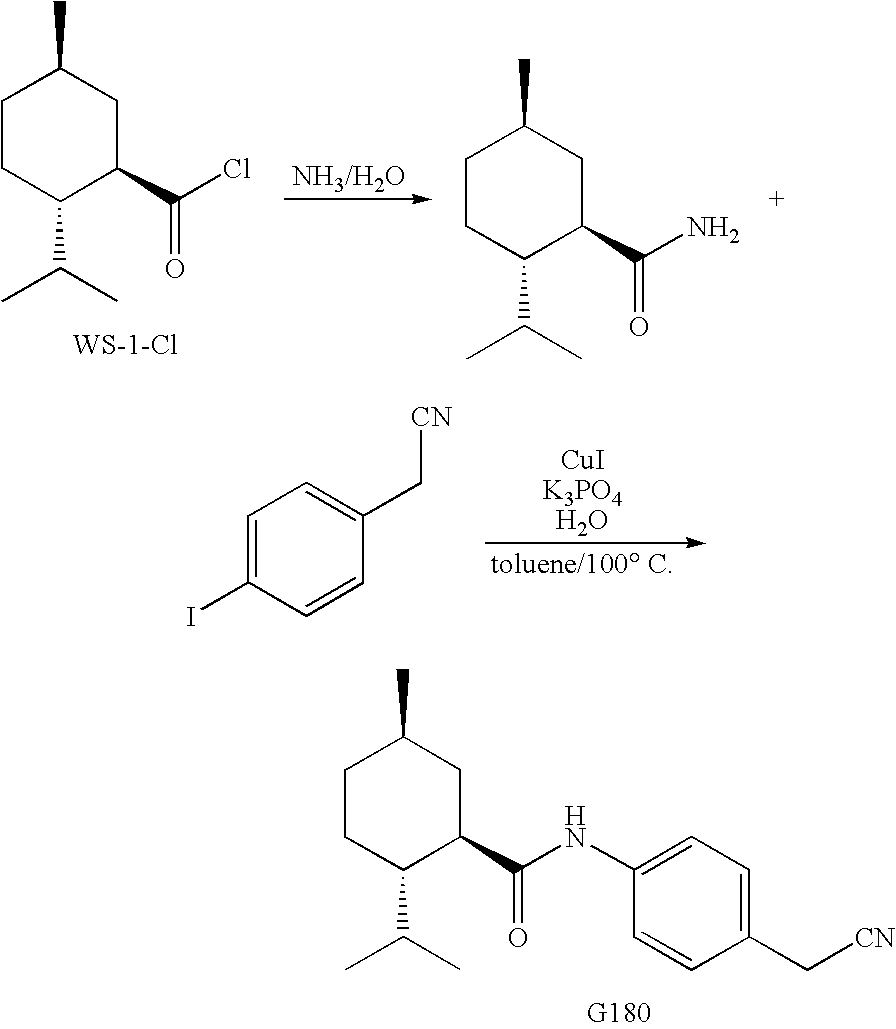

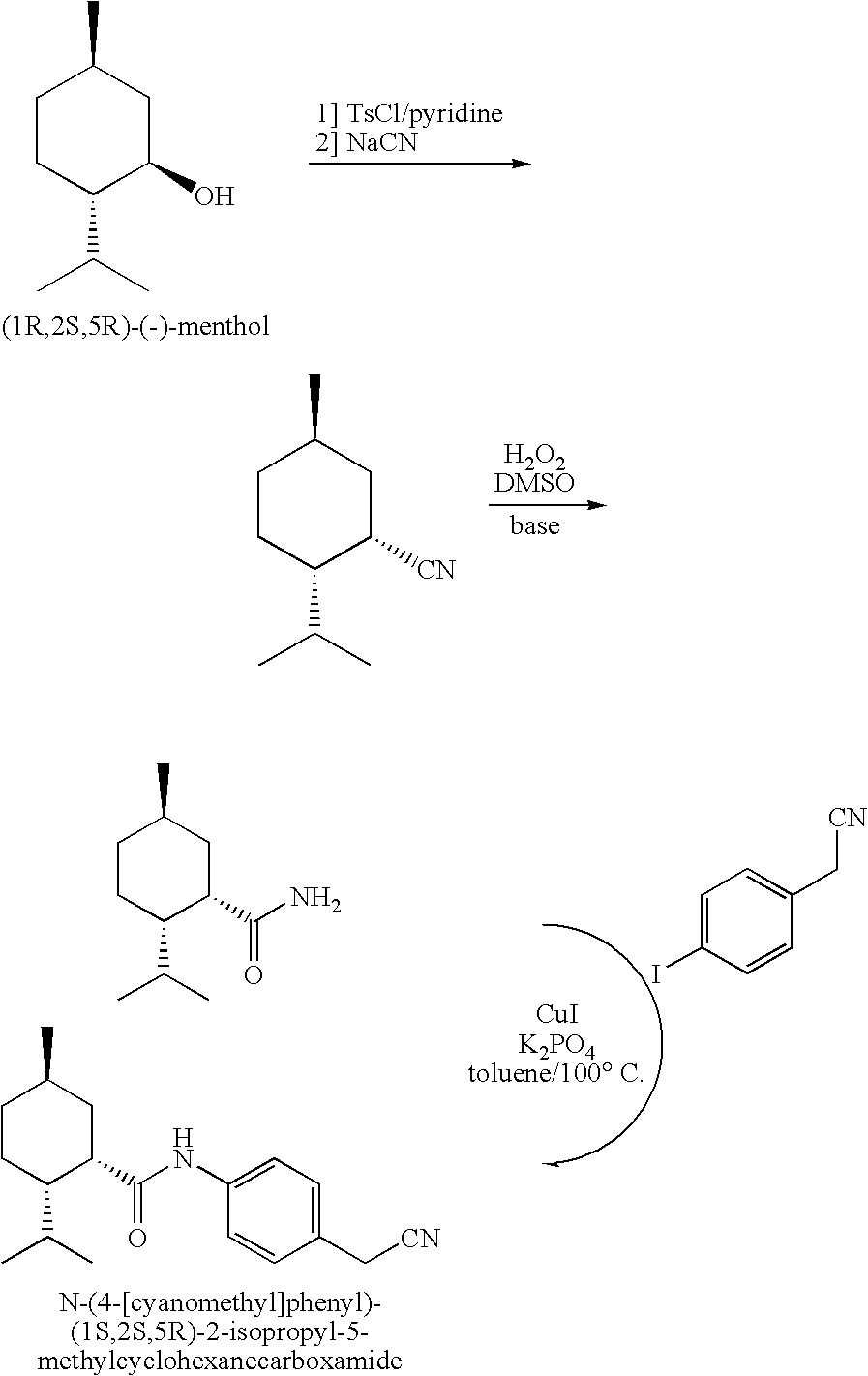

Synthesis of Cyclohexane Derivatives Useful as Sensates in Consumer Products

ActiveUS20100076080A1Improve cooling effectPotent and long lasting cooling effectBiocideCosmetic preparationsCooling effectL menthol

The present invention provides synthetic routes for preparing various isomers of cyclohexane-based coolants, such as menthyl esters and menthanecarboxamide derivatives, in particular those substituted at the amide nitrogen, for example with an aromatic ring or aryl moiety. Such structures have high cooling potency and long lasting sensory effect, which make them useful in a wide variety of consumer products. One synthetic route involves a copper catalyzed coupling of a primary menthanecarboxamide with an aryl halide, such reaction working best in the presence of potassium phosphate and water. Using this synthetic route, specific isomers can be prepared including the menthanecarboxamide isomer having the same configuration as l-menthol and new isomers such as a neoisomer having opposite stereochemistry at the carboxamide (C-1) position. The neoisomer unexpectedly has potent and long lasting cooling effect. Preparation schemes for neoisomers of other menthyl derivatives which are useful as coolants, including esters, ethers, carboxy esters and other N-substituted carboxamides are also provided.

Owner:THE PROCTER & GAMBLE COMPANY

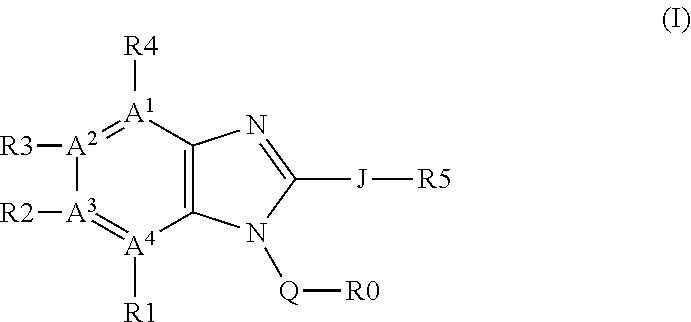

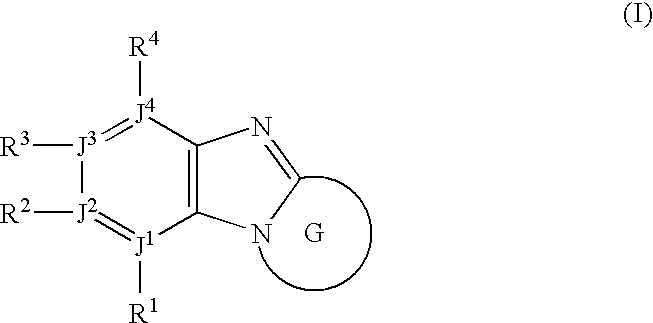

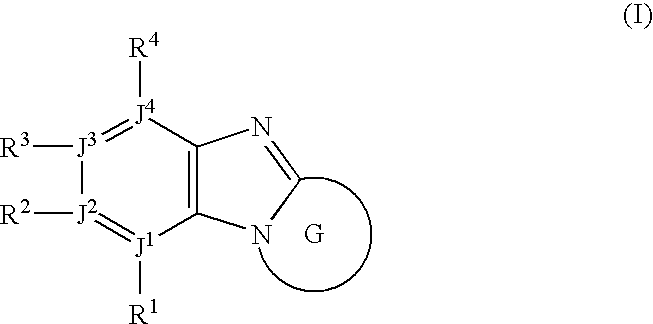

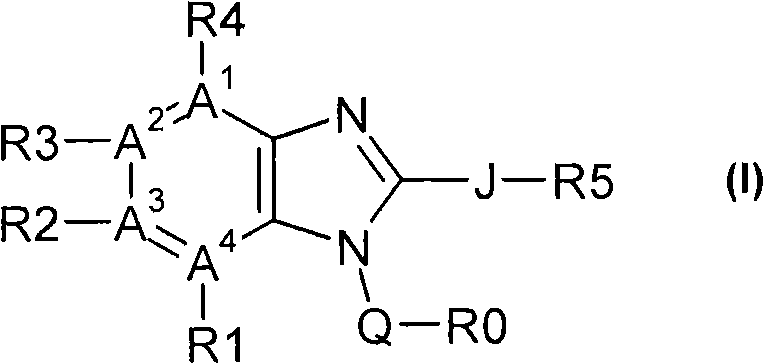

Regioselective copper catalyzed synthesis of benzimidazoles and azabenzimidazoles

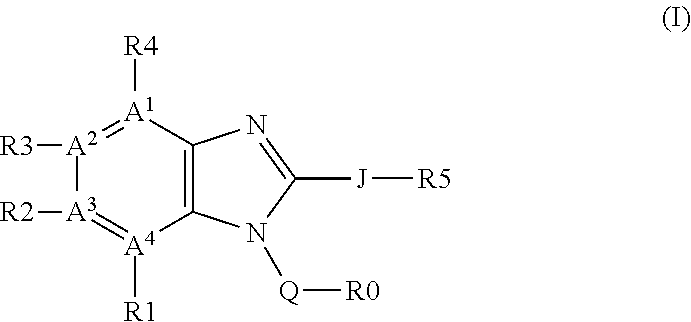

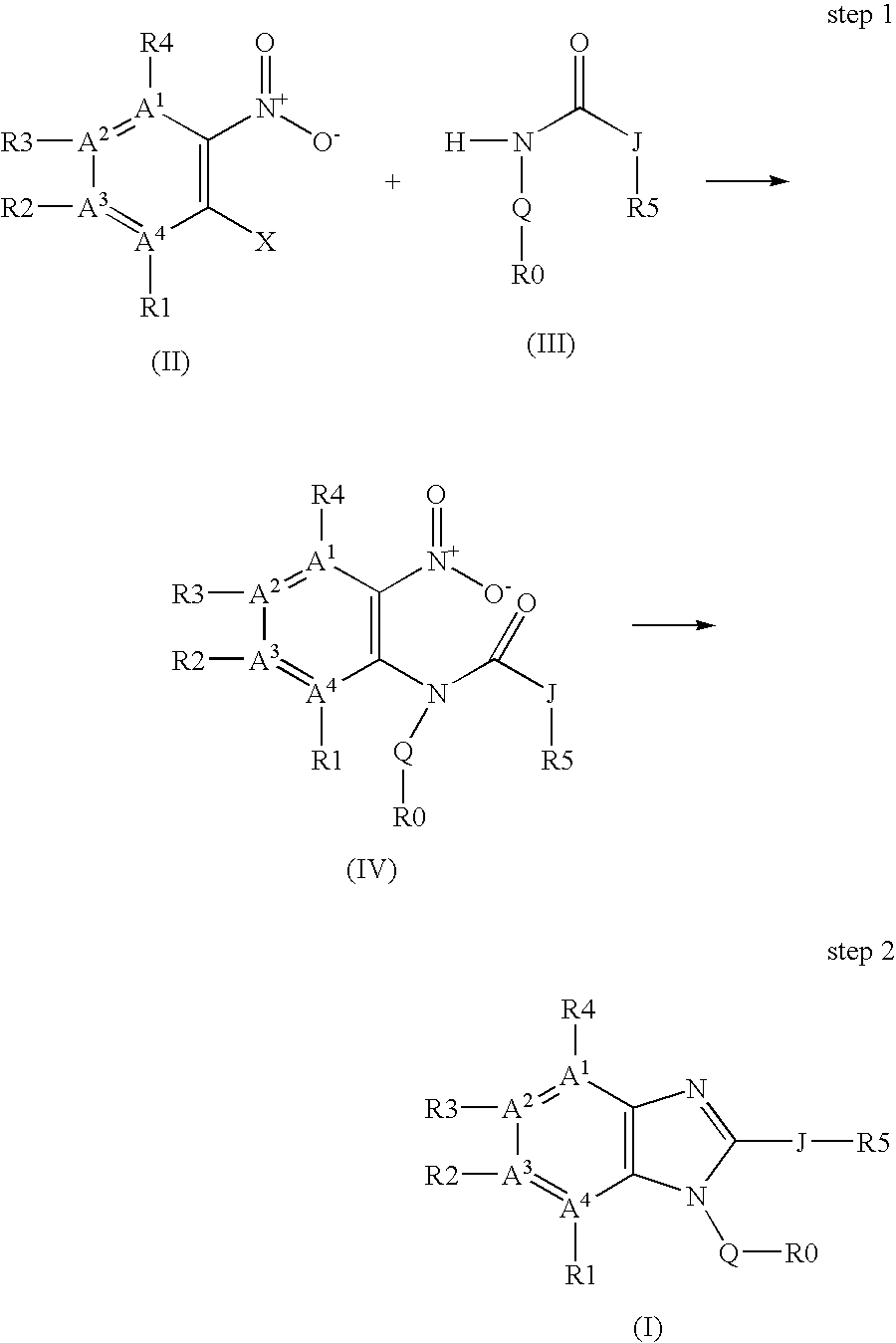

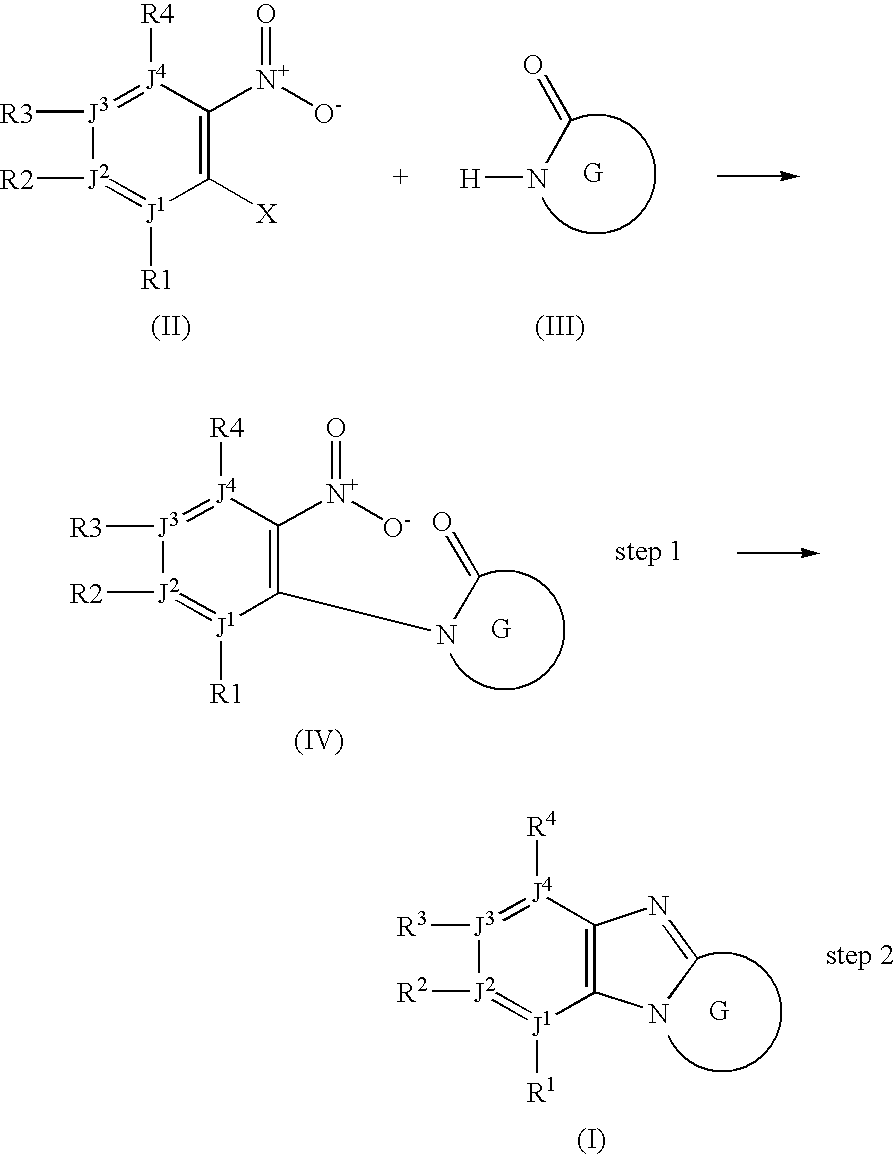

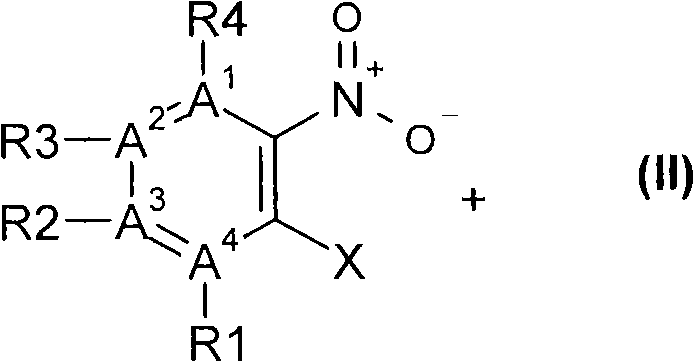

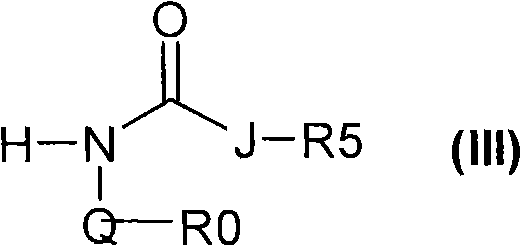

The present invention relates to a process for the regioselective synthesis of compounds of the formula I,wherein R0; R1; R2; R3; R4; R5; A1; A2; A3; A4, Q and J have the meanings indicated in the claims. The present invention provides a direct copper catalyzed regioselective process to a wide variety of unsymmetrical, multifunctional N-substituted benzimidazoles or azabenzimidazoles of formula I starting from 2-halo-nitroarenes and N-substituted amides.

Owner:SANOFI SA

Copper-catalyzed c-h bond arylation

ActiveUS20090076266A1Carboxylic acid nitrile preparationOrganic compound preparationHydrogenOrganic synthesis

The present invention is a one-step method for efficiently converting carbon-hydrogen bonds into carbon-carbon bonds using a combination of aryl halides, a substrate, and a copper salt as catalyst. This method allows faster introduction of complex molecular entities, a process that would otherwise require many more steps. This invention is particularly relevant for the organic synthesis of complex molecules such as, but not limited to, pharmacophores and explosives.

Owner:UNIV HOUSTON SYST

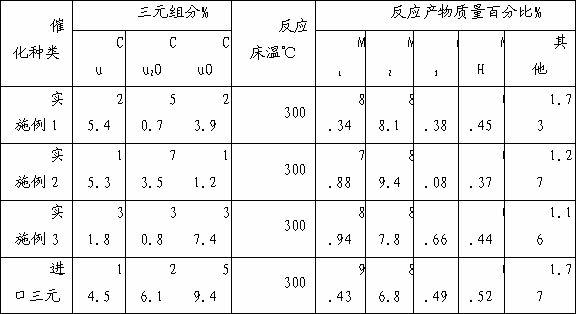

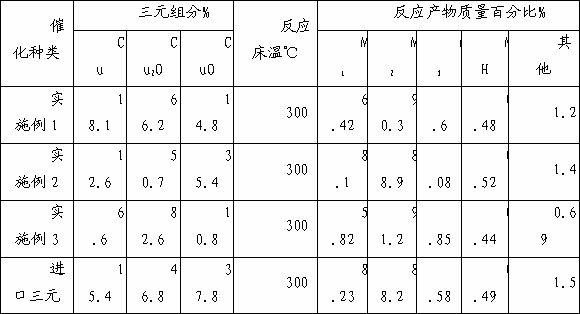

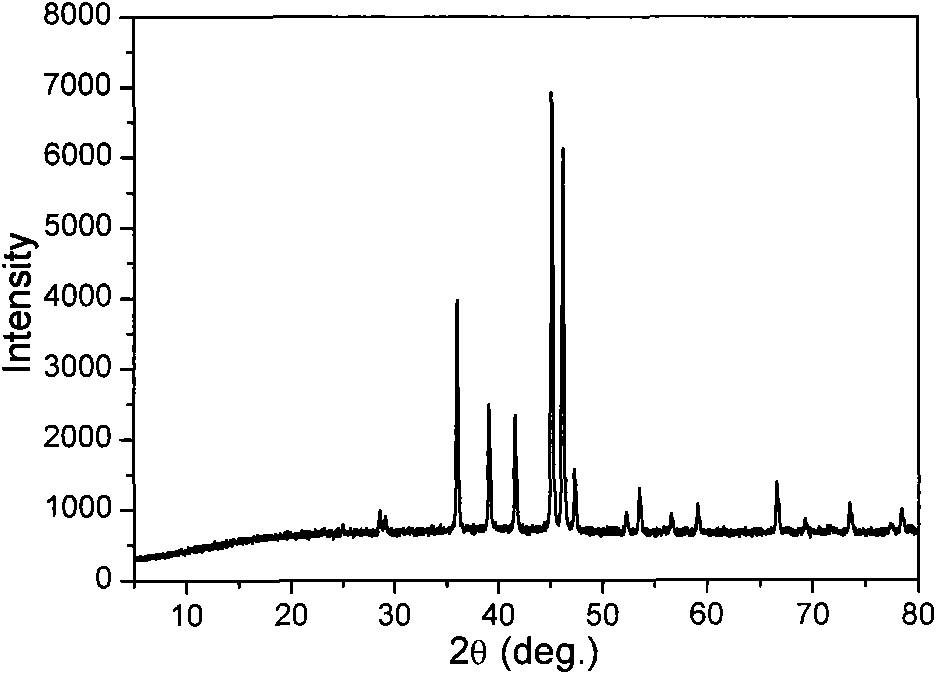

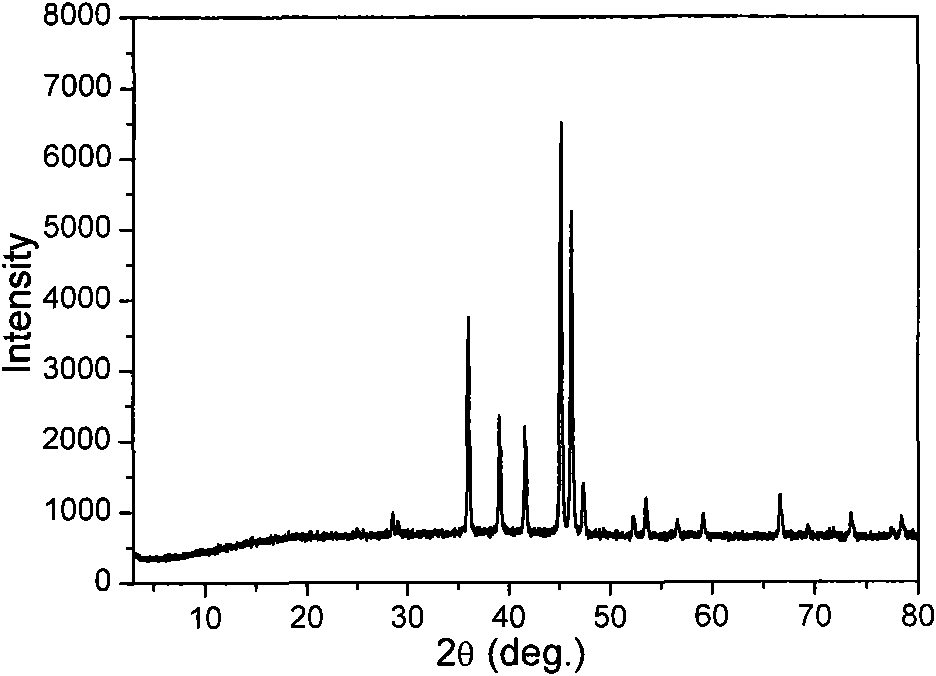

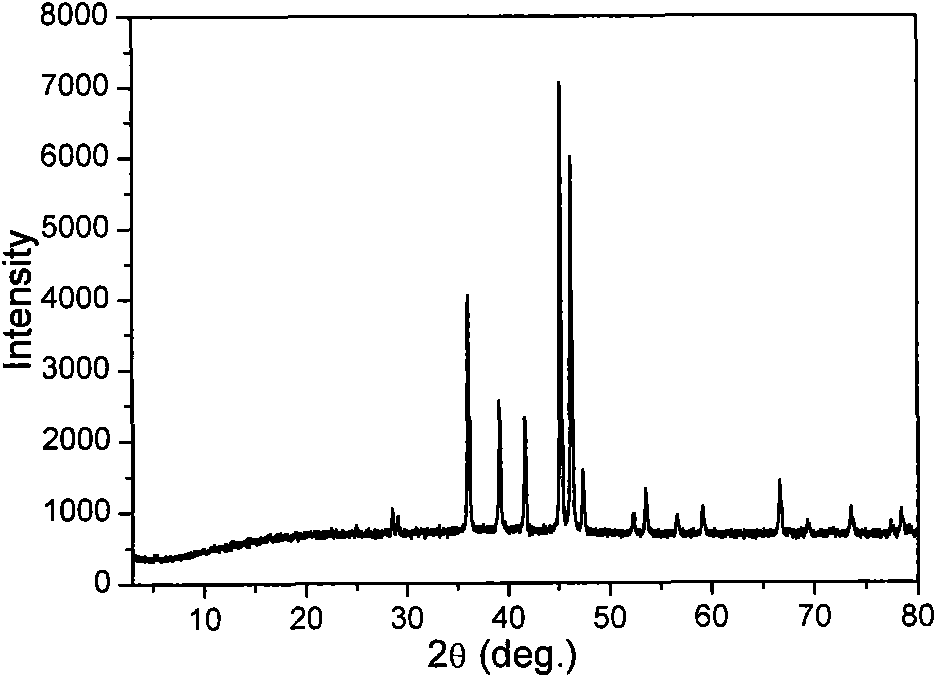

Catalyst produced by using copper oxide powder and production method thereof

InactiveCN102441381AHigh selectivityHigh reactivityGroup 4/14 element organic compoundsMetal/metal-oxides/metal-hydroxide catalystsPorosityElectrolysis

The invention discloses a catalyst produced by using copper oxide powder and a production method thereof. The catalyst comprises copper oxide powder and electrolytic copper powder as initial raw materials, and produced by mixing, reducing, crushing, oxidating, sieving, and grinding. The catalyst has the characteristics of porosity and large specific surface area, and has the properties of metal copper, cuprous oxide, and copper oxide. The catalyst containing metal copper, cuprous oxide, and copper oxide has high binary selectivity and high reaction activity. According to the invention, the problems of unstable quality of raw material CuSO4.5H2O used in ternary copper catalyst produced by using chemical method, complicated production technology, unstable quality of finished products and the like are solved, and the adverse factors of containing high content of S in the product of ternary copper catalyst produced by using chemical method, and causing damage to producer and user and environment are overcome.

Owner:KUN SHAN DOTOP METAL TECH CO LTD

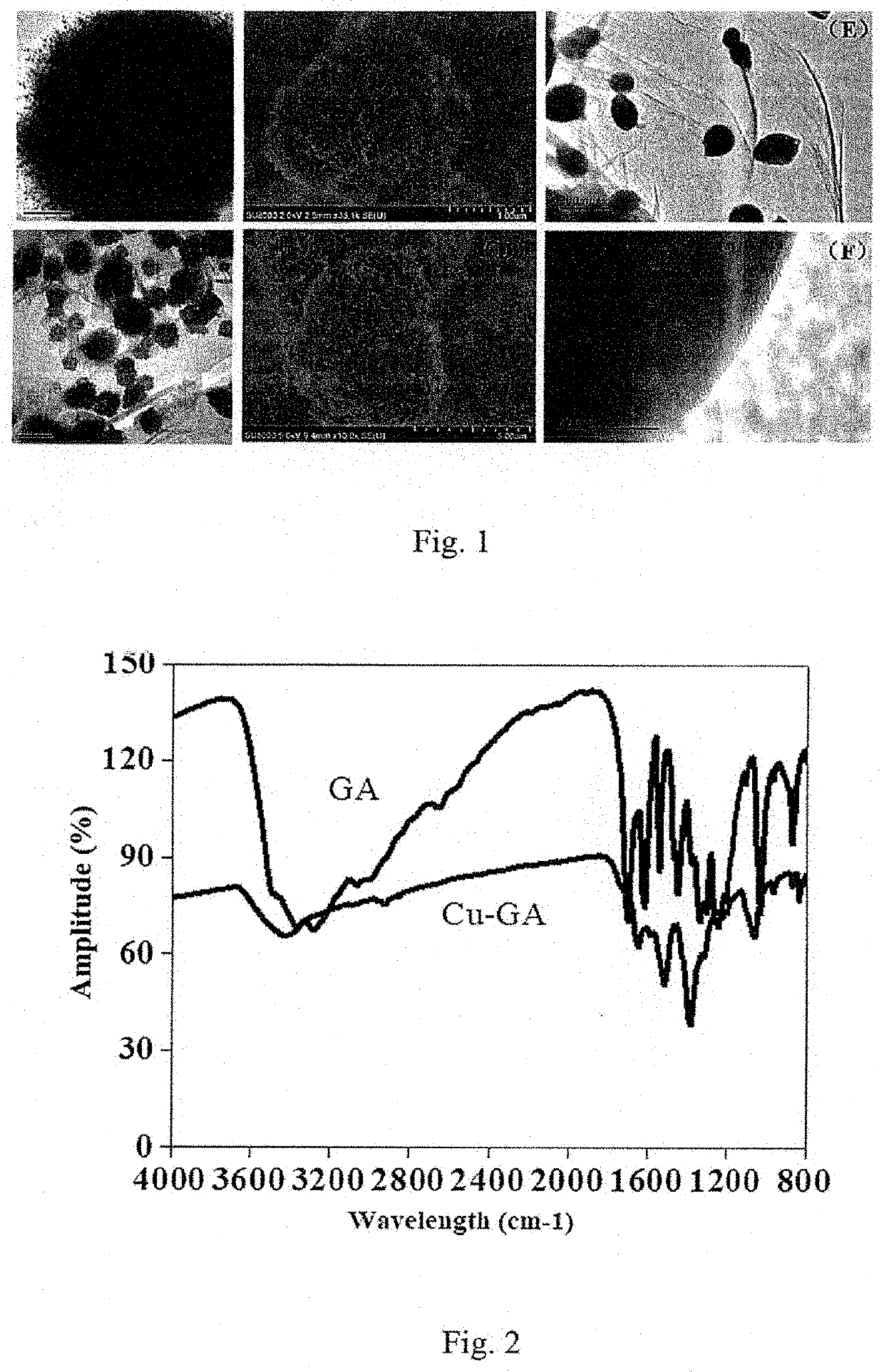

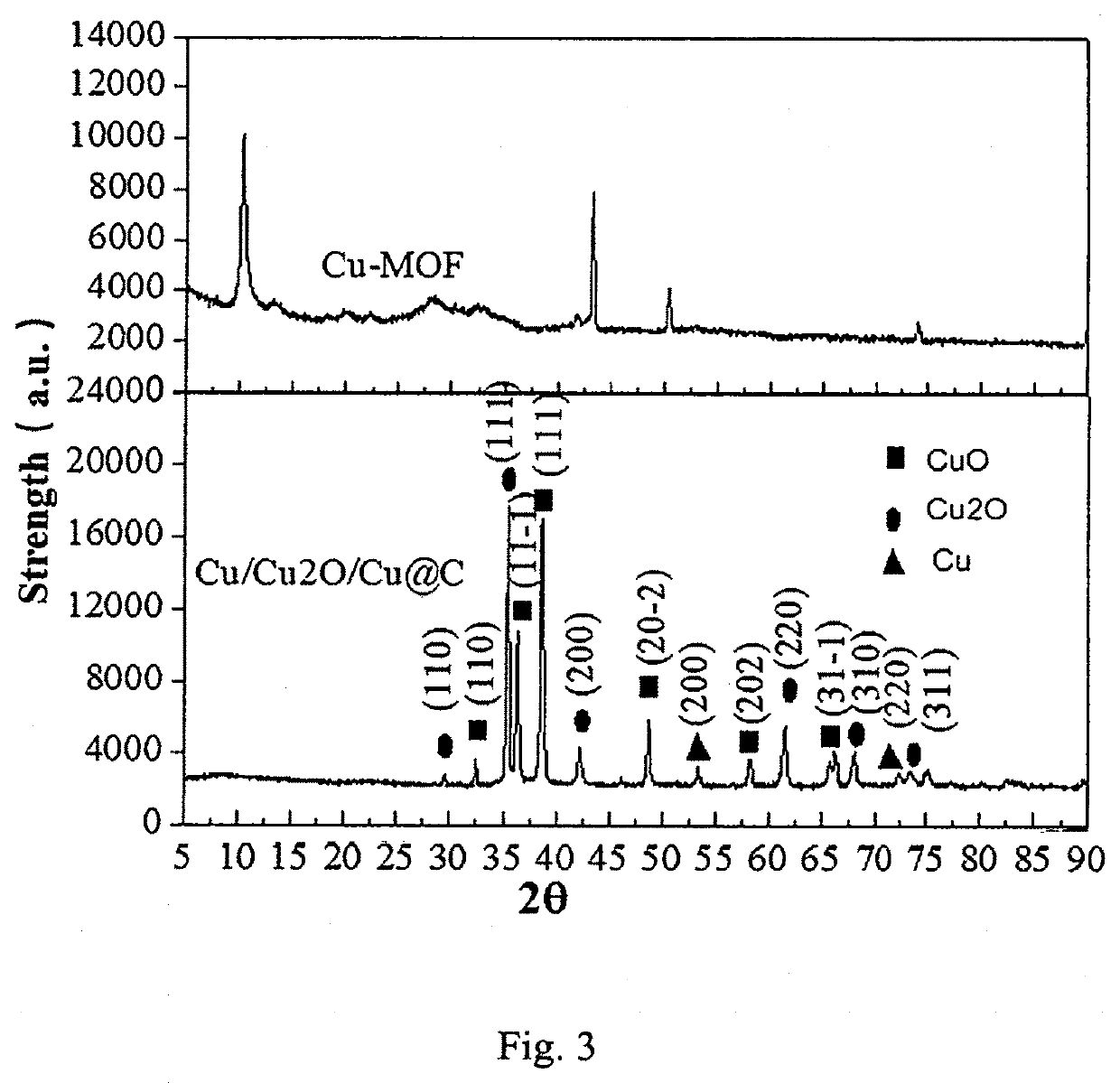

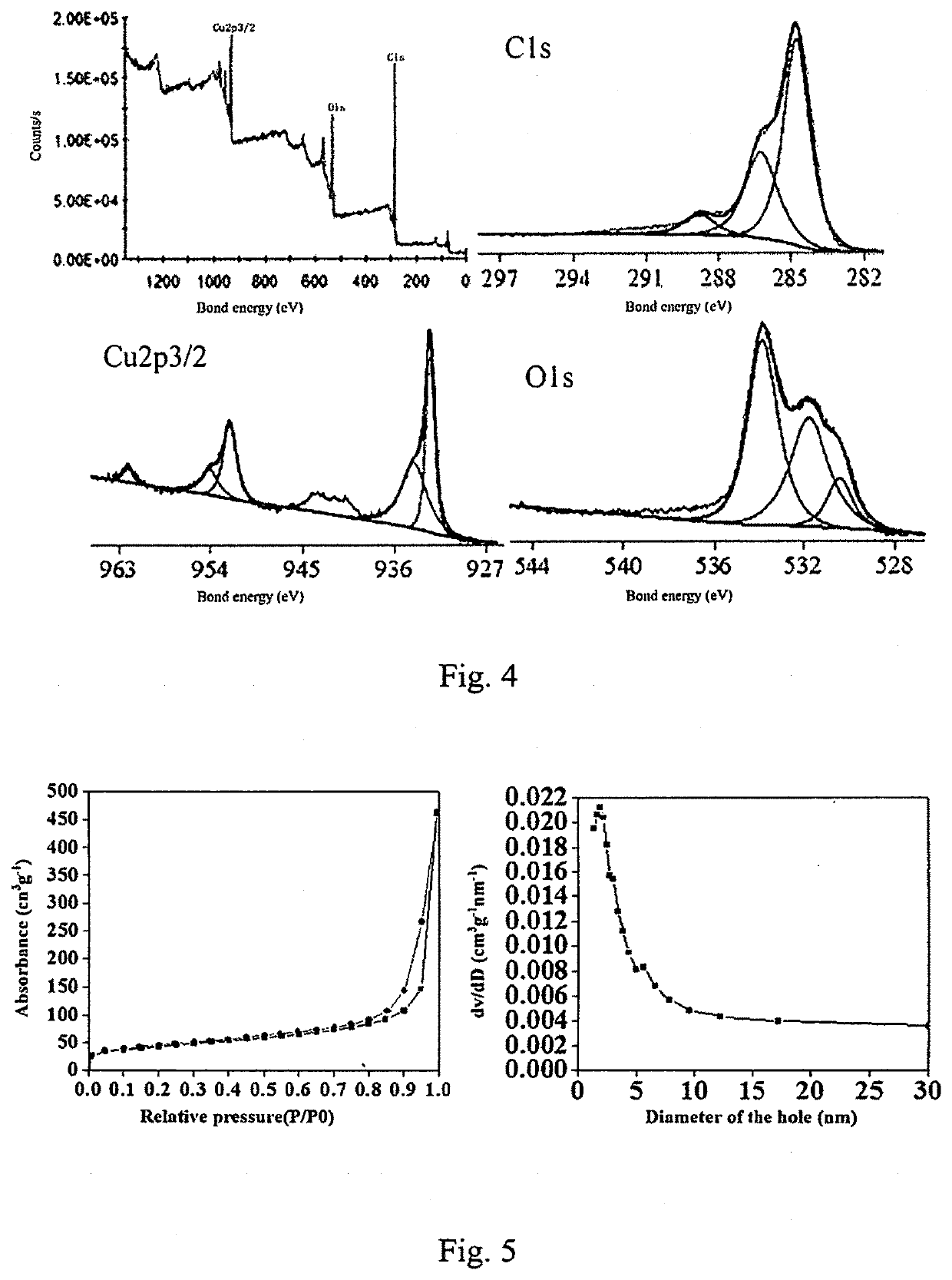

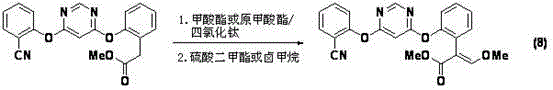

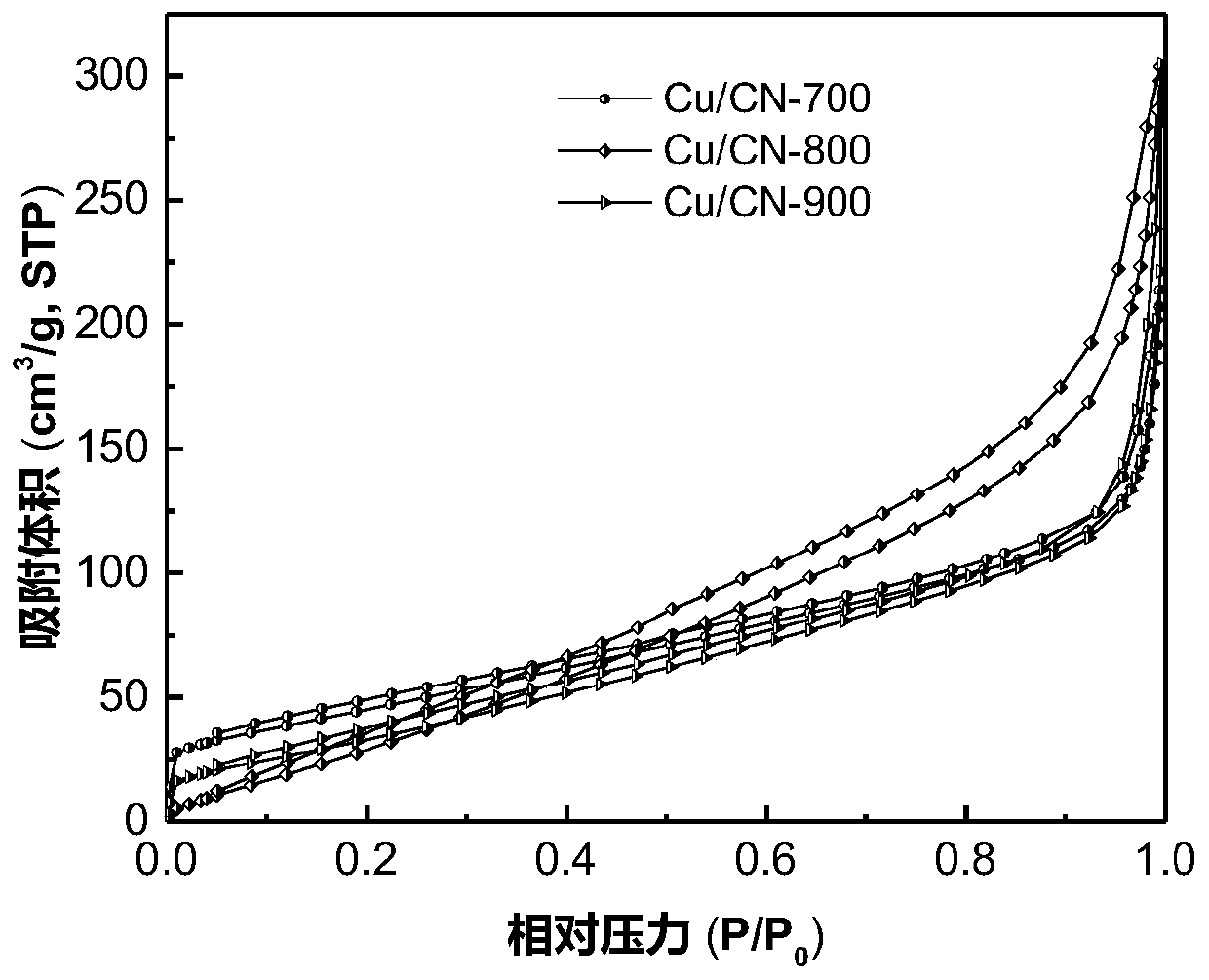

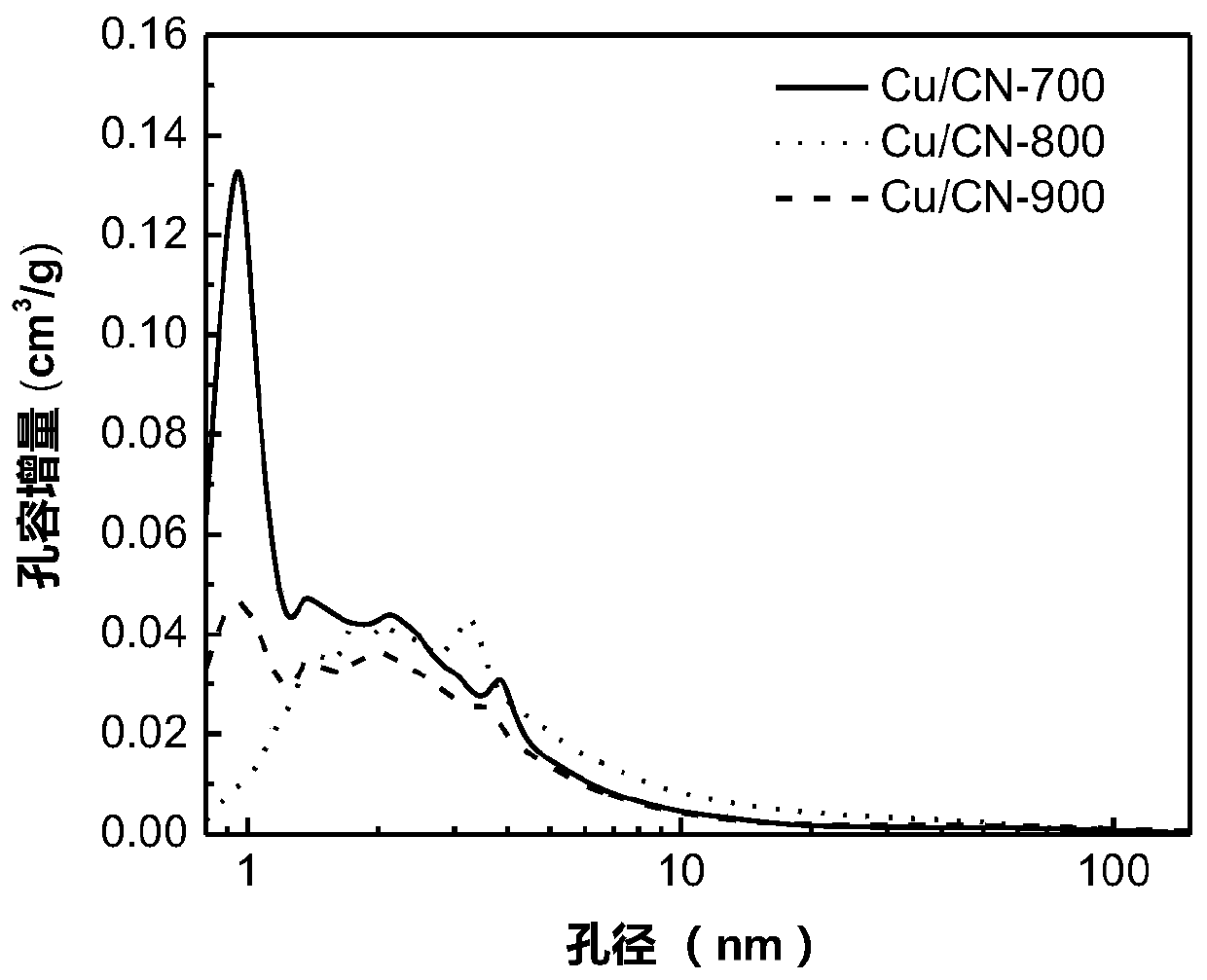

Cu CATALYST BASED ON METAL ORGANIC FRAMEWORK, PREPARATION METHOD AND USE THEREOF

ActiveUS20200129971A1Low costReduce and decompose pollutantOrganic-compounds/hydrides/coordination-complexes catalystsWater contaminantsPtru catalystPorous carbon

A Cu catalyst based on a metal organic framework as well as a preparation method and a use thereof is provided. The Cu catalyst based on a metal organic framework comprises composite particles with catalytic activity sites composed of copper in different oxidization states and a porous carbonized layer with a supporting effect. The method for preparing the catalyst includes the following steps: 1) preparing a metal organic framework Cu-MOF; and 2) carbonizing the metal organic framework Cu-MOF. The Cu catalyst can be used in aqueous phase catalysis to catalytically decompose organic pollutants in water.

Owner:CHINESE RES ACAD OF ENVIRONMENTAL SCI

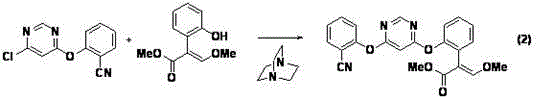

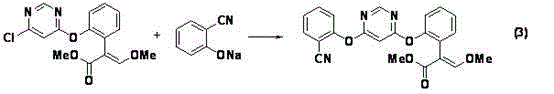

Azoxystrobin synthesis method

The invention relates to an azoxystrobin synthesis method which comprises the following synthesis steps: performing coupling reaction on 2-chlorobenzonitrile and 4,6-dihydroxypyrimidine in high-boiling-point aprotic solvent in the presence of a palladium or copper catalyst under alkaline conditions to generate 4-hydroxy-6-(2-cyanophenoxy)pyrimidine; chlorinating to obtain 4-chloro-6-(2-cyanophenoxy)pyrimidine; coupling the 4-chloro-6-(2-cyanophenoxy)pyrimidine with methyl (E)-2-(2-hydroxyphenyl)-3-methoxyacrylate in high-boiling-point aprotic solvent in the presence of a copper catalyst or a tertiary amine catalyst under alkaline conditions to generate methyl (E)-2-{2-[6-(2-cyanophenoxy)pyrimidine-4-yloxy]phenyl}-3-methoxyacrylate. The invention optimizes the reaction conditions, shortens the reaction time, avoids the generation of impurities, simplifies the separation and after treatment process, and is high in product yield and good in quality. Besides, the raw materials in the invention are cheap and accessible, thereby achieving low cost and being suitable for large-scale industrial production.

Owner:HEBEI VEYONG BIO CHEM

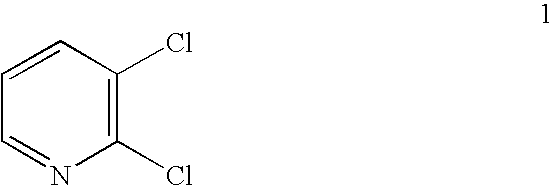

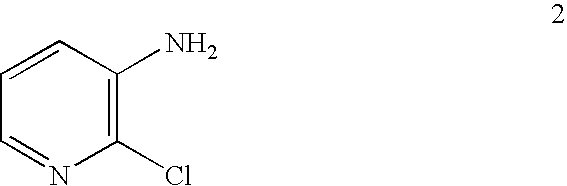

Process for the manufacture of 2,3-dichloropyridine

A method for preparing 2,3-dichloropyridine is disclosed in which 3-amino-2-chloropyridine is contacted with an alkali metal nitrite in the presence of aqueous hydrochloric acid to form a diazonium salt; and the diazonium salt is subsequently decomposed in the presence of copper catalyst wherein at least about 50% of the copper is the copper(II) oxidation state.

Owner:EI DU PONT DE NEMOURS & CO

Catalyst produced through water atomization and manufacturing method thereof

InactiveCN102441382AImprove adsorption capacityHigh reactivityGroup 4/14 element organic compoundsCatalyst activation/preparationElectrolysisCompound (substance)

The invention discloses a catalyst produced through water atomization and a manufacturing method thereof. The catalyst is prepared by melting a cathode electrolytic copper plate serving as a primary raw material at high temperature, performing high water pressure spray atomization, precipitation, high-temperature drying oxidization, selection and ball milling oxidization on the copper plate. Besides the characteristics of multiple pores, and large specific surface area of a traditional elemental sheet copper powder catalyst, the catalyst also has the property of containing three element components, namely copper, cuprous oxide and copper oxide. Due to the characteristics of multiple pores, sheet shape and large specific surface area, absorption and contact area between the catalyst and silica powder are increased, more Si and Cu alloy and eta phase can be formed, and the reaction activity of a contact is improved. The disadvantages that the content of S in the three-element copper catalyst produced by a chemical method using CuSO4.5H2O as a raw material is relatively high and the S does harm to producers, users and environments are overcome. The catalyst is continuous in production way, good in controllability and stable in quality.

Owner:KUN SHAN DOTOP METAL TECH CO LTD

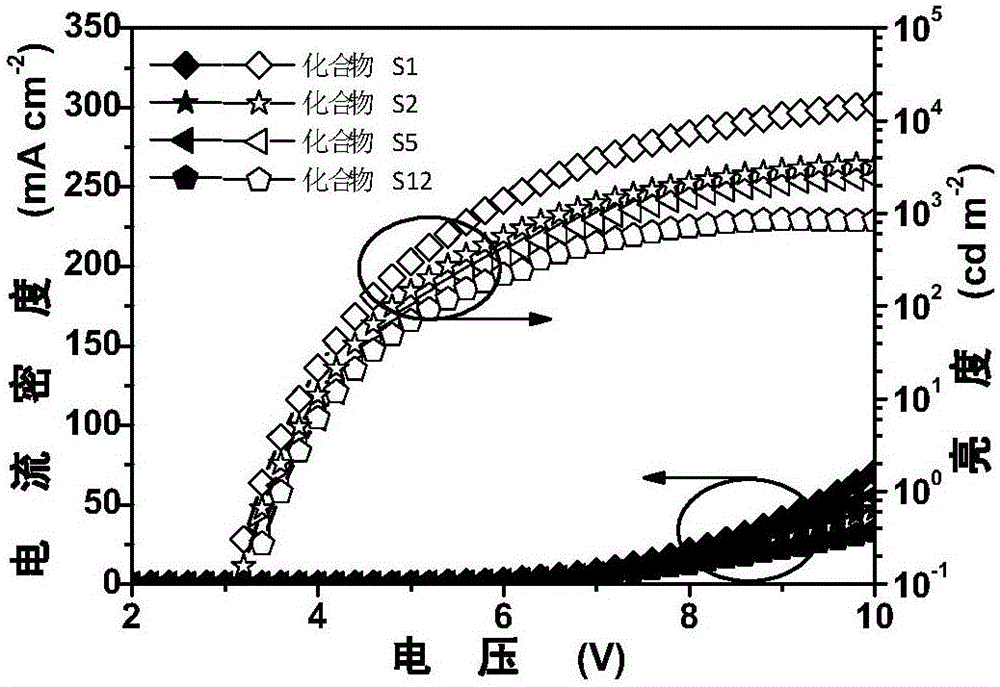

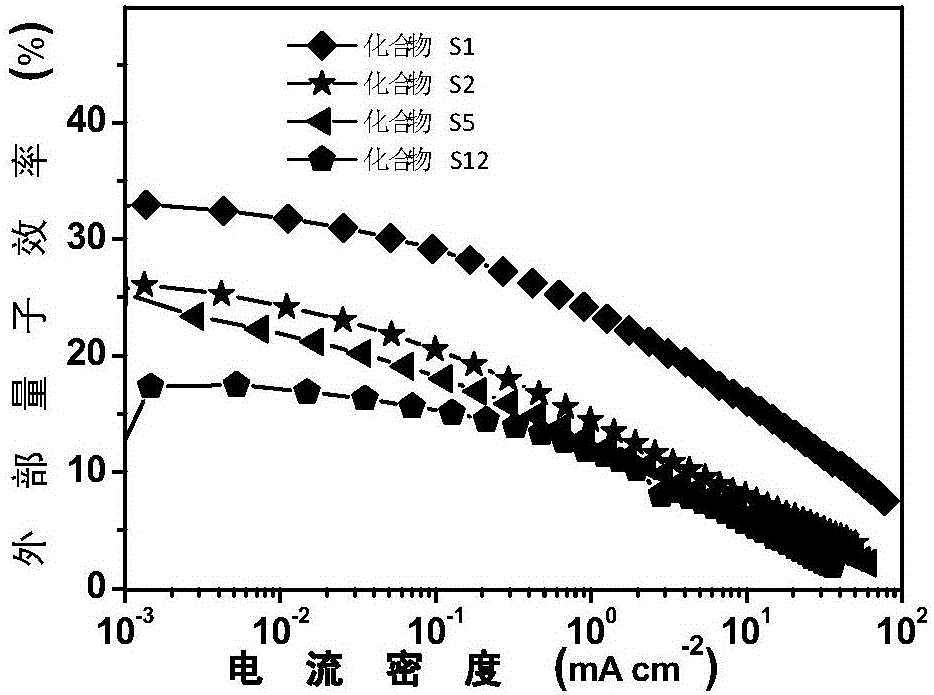

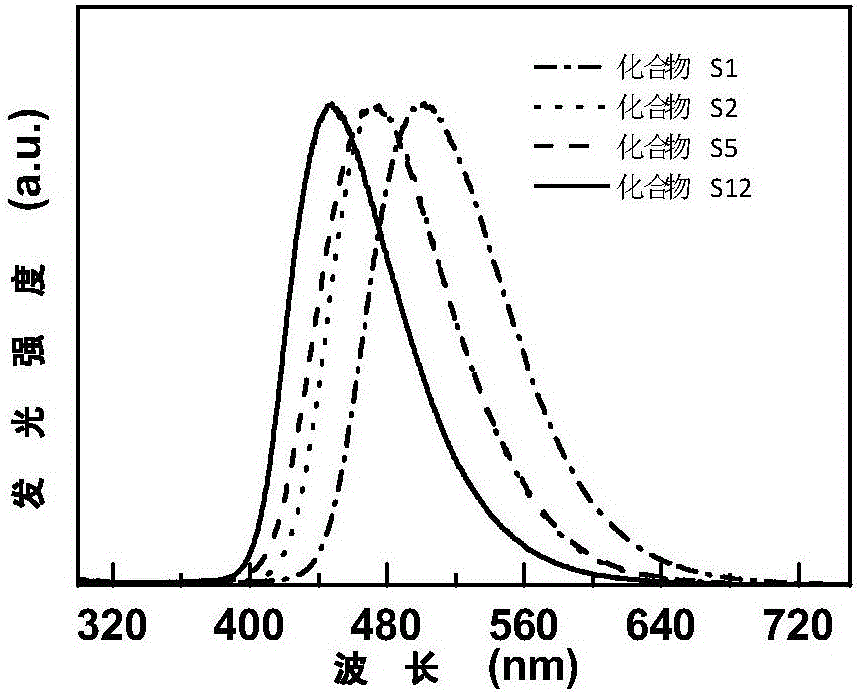

9,9'-spiral acridine-containing compound and preparation method and application thereof

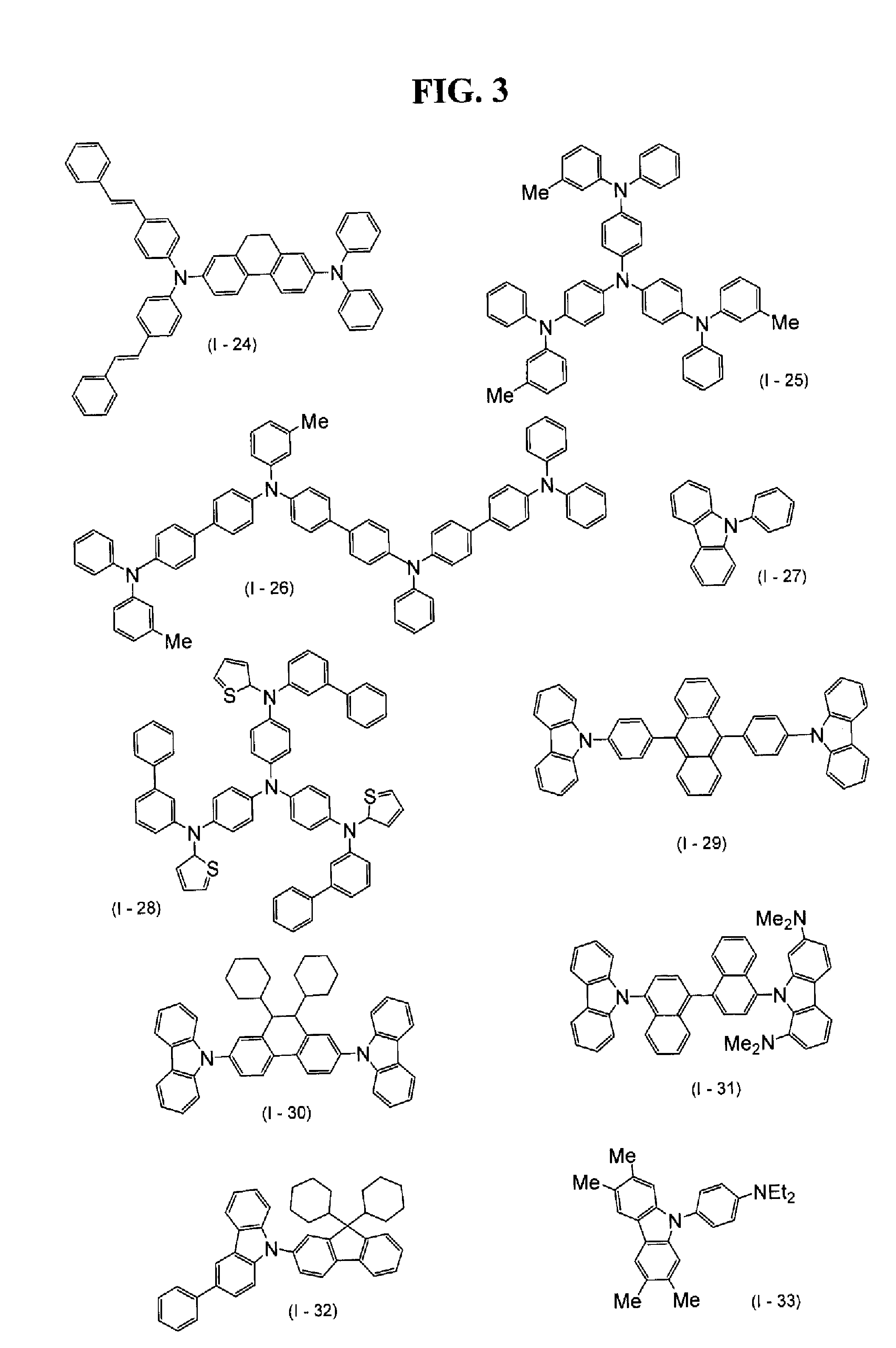

InactiveCN106831773ALow singlet-triplet energy level differenceImprove exciton utilizationOrganic chemistrySolid-state devicesAcridineHalogen

The invention discloses a 9,9'-spiral acridine-containing compound. 9,9'-spiral acridine is taken as a core and the 9,9'-spiral acridine is combined with peripheral electrophilic Ar and Ar' units. The invention further discloses a preparation method of the 9,9'-spiral acridine-containing compound. The 9,9'-spiral acridine-containing compound is obtained through selecting different halogen-substituted Ar unit and Ar' unit, carrying out Buchwald-Hartwig coupled reaction on 10H, 10'H-9,9'-spiral acridine, carrying out copper-catalyzed aryl halide amination reaction or carrying out nucleophilic substitution reaction under a strong alkaline condition. The invention further discloses an application of the 9,9'-spiral acridine-containing compound. The 9,9'-spiral acridine-containing compound has high fluorescence and certain conductivity, and can be used for fabricating a light-emitting layer of an organic light-emitting diode as a luminous body.

Owner:SOUTH CHINA UNIV OF TECH +1

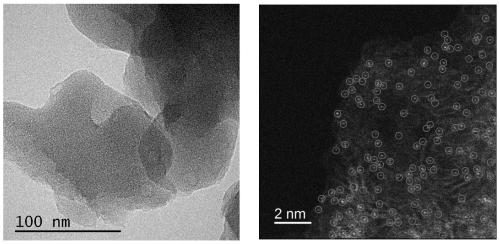

Biomass-based carbon material loaded monatomic copper catalyst as well as preparation method and application thereof

ActiveCN111068682AEasy to prepareAvoid gatheringCarboxylic acid nitrile preparationOrganic compound preparationArylPtru catalyst

The invention discloses a biomass-based carbon material loaded monatomic copper catalyst and a preparation method thereof, and a method for synthesizing a 1, 3-diyne compound by oxidative coupling ofthe catalyst. The catalyst is composed of 0.01 wt%-3 wt% of metal monatomic copper, 70 wt%-90 wt% of a carbon-based carrier and 5 wt%-20 wt% of heteroatoms. The preparation method of the biomass-basedcarrier-loaded monatomic copper catalyst is simple, mild in condition and low in cost, and does not need a common subsequent pickling process. The cheap metal salt and self-doped heteroatom N are used for synergistic coordination, aggregation of metal in the high-temperature pyrolysis process is avoided, and monodispersion of metal atoms is achieved. The metal monatomic content is high, the dispersion is uniform, and the physicochemical structure is stable. The catalyst can take air as an oxidizing agent in oxidative coupling reaction, achieves high conversion rate and excellent substrate universality under alkali-free and ligand-free conditions, and realizes an oxidative cross-coupling reaction among aryl-aryl, aryl-alkyl and alkyl-alkyl differently substituted substrates.

Owner:QINGDAO INST OF BIOENERGY & BIOPROCESS TECH CHINESE ACADEMY OF SCI

Copper catalyzed arylation

InactiveUS20060149076A1Minimizing reactor agitationMinimizing capacity issueUrea derivatives preparationOrganic compound preparationCopper atomAryl

Owner:SHASUN PHARMA SOLUTIONS LTD

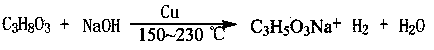

Method for preparing lactic acid through catalyzing glycerol by nano copper

InactiveCN104045543AIncrease concentrationImprove conversion ratePreparation from carboxylic acid saltsCarboxylic acid salt preparationPtru catalystReaction rate

The invention relates to the technical field of lactic acid preparation and particularly relates to a method for preparing lactic acid through catalyzing glycerol by nano copper. According to the method provided by the invention, reaction is carried out on glycerol which serves as a raw material for 0.5-4 hours in a high-pressure reactor at the temperature of 150-230 DEG C under anaerobic alkaline conditions in the presence of nano copper, thereby obtaining lactic acid. The method has the advantages that the reaction temperature and reaction pressure are low, the catalyst activity is high, the selectivity is good, the reaction rate is high, the process flow is safe and environmental-friendly, and the like, so that the industrial prospect is good.

Owner:JIANGSU UNIV

Regioselective metal catalyzed synthesis of annelated benzimidazoles and azabenzimidazoles

The present invention relates to a process for the regioselective synthesis of compounds of the formula I,wherein R1; R2; R3; R4; J1; J2; J3; J4 and G have the meanings indicated in the claims. The present invention provides a direct metal, e.g. palladium or copper, catalyzed, regioselective process to a wide variety of unsymmetrical, multifunctional N-substituted benzimidazoles or azabenzimidazoles of formula I starting from 2-halo-nitroarenes and N-substituted amides.

Owner:SANOFI SA

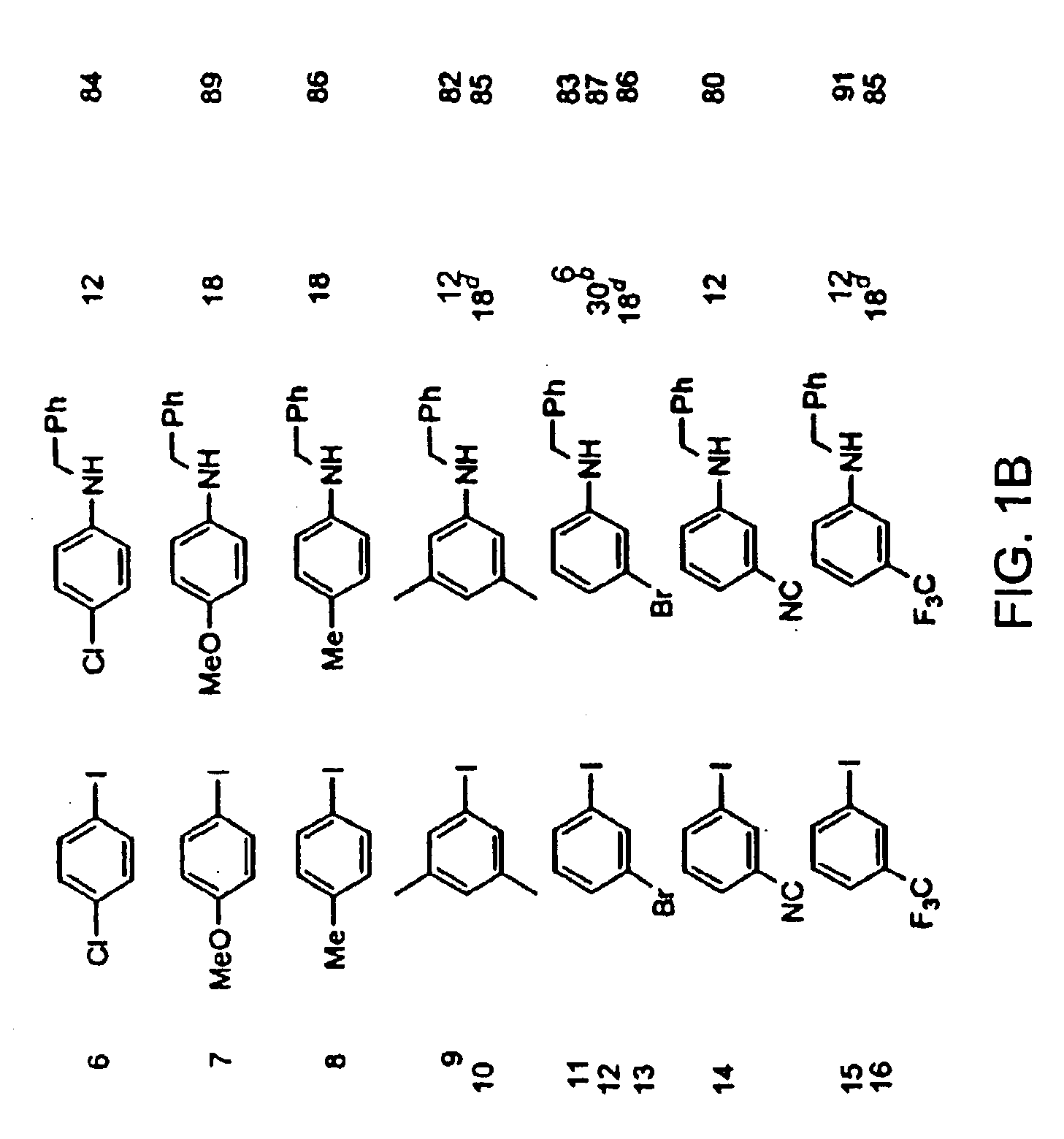

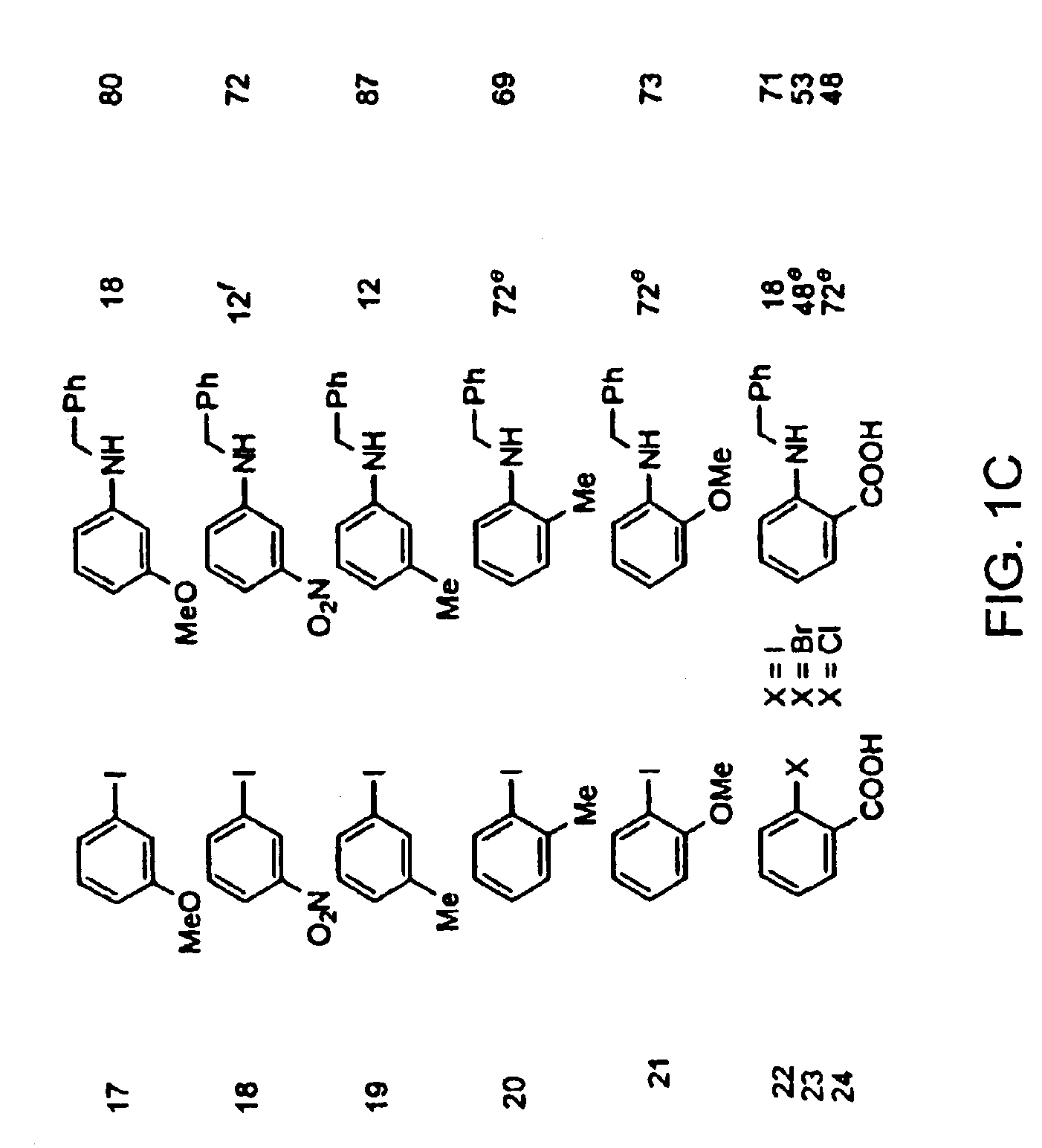

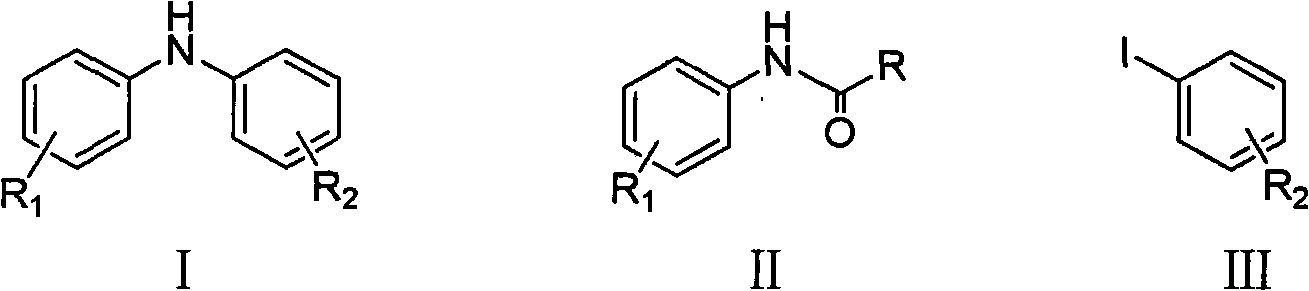

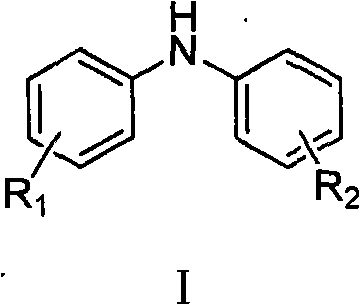

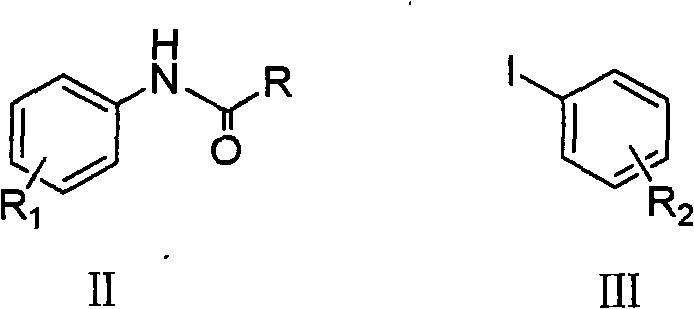

Method for synthesizing copper-catalyzed substituted diphenylamine

InactiveCN101570490ALow toxicitySimple reaction conditionsOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsOrganic solventNitrogen

The invention relates to a method for preparing substituted diphenylamine. The preparation method mainly comprises the following steps: heating a compound shown in a formula II and a compound shown in a formula III in an organic solvent in the presence of a catalytic amount of copper compounds, a nitrogen-containing ligand, and alkali, generating a coupling reaction, and using an acid or alkali for a hydrolysis reaction to obtain a target compound shown in a formula I. Compared with the prior method for preparing the substituted diphenylamine, the preparation method has the advantages of low cost, mild reaction conditions, high yield and easy industrialized production.

Owner:EAST CHINA UNIV OF SCI & TECH +1

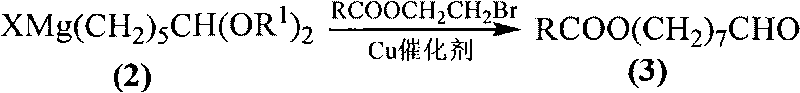

Synthetic method of effective component-royaljelly acid of royal jelly

InactiveCN101747181AAvoid purification difficultiesAvoid Yield ProblemsOrganic compound preparationCarboxylic compound preparation2-PyrrolidoneCopper

The invention provides a synthetic method of an effective component-royaljelly acid of royal jelly, comprising the following steps: allowing (1,1-bialkoxy-6-hexyl magnesiumhalide) to react with bromoethanol alkyl acid ester in the solvent in the presence of an auxiliary agent N-methyl-2-pyrrolidone under catalysis of catalytic amount of a copper catalyst; removing acetal protection under acid conditions to obtain 8-alkyl acyloxy caprylicaldehyde; and then adopting Knoevenagel condensation method to obtain the royaljelly acid in formula (1). The method adopted by the invention is characterized by mild reaction conditions, simple operation ('one pot method'), high yield and the like, and avoids the problems of difficult purification, low yield and the like encountered by the traditional synthetic technology of the compound, thus greatly reducing production cost. The reagent used in the whole reaction is available, thus being convenient for industrial implementation.

Owner:邵阳市科瑞化学品有限公司

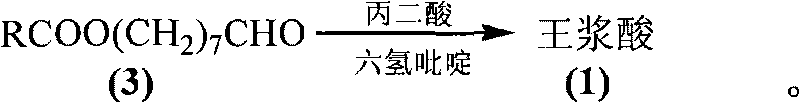

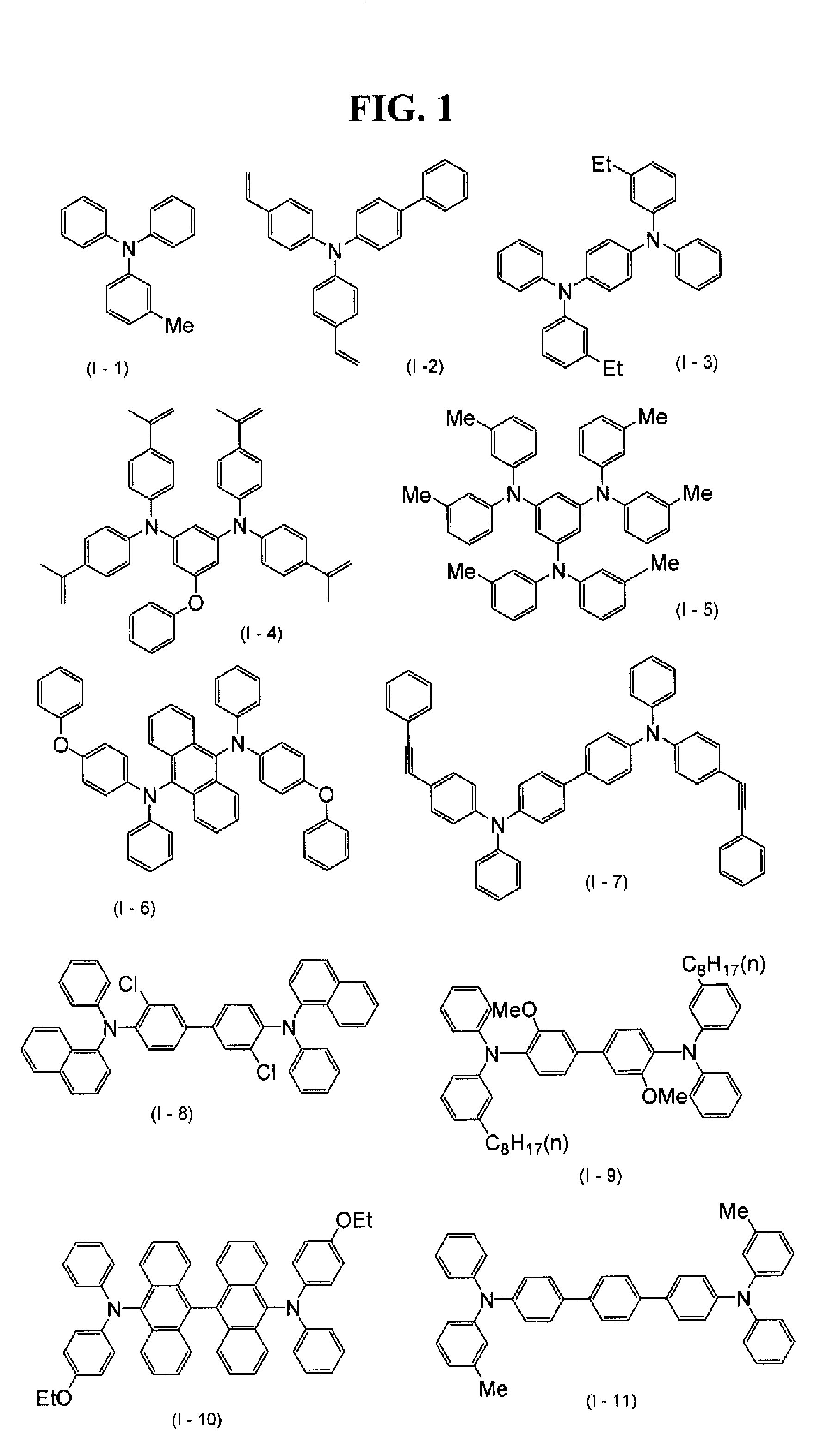

Process for producing arylamine

InactiveUS7273953B2High purityLow costOrganic compound preparationAmino compound preparationArylPyridinium

A process for producing an arylamine is provided which is characterized by reacting an aromatic halogen compound with an aromatic amine in the presence of an organic salt selected from specific pyridinium salts, imidazolium salts and quaternary onium salts, a copper catalyst, and a base. Thus, the reaction of even an aromatic halogen compound substituted by an electron-donating group proceeds efficiently, and an inexpensive chlorinated aromatic compound or brominated aromatic compound is usable, and an arylamine, in particular a triarylamine or diarylamine, having a high purity can be produced at low cost.

Owner:FUJIFILM FINECHEM

Method for preparing lactic acid through catalyzing glycerol by supported copper catalyst

InactiveCN104045544ALow reaction temperatureLow reaction pressurePreparation from carboxylic acid saltsCarboxylic preparation by oxidationPtru catalystReaction rate

The invention relates to the technical field of lactic acid preparation and particularly relates to a method for preparing lactic acid through catalyzing glycerol by a supported copper catalyst. According to the method, the selectivity of lactic acid can reach 70-90%, and the conversion ratio of glycerol can reach 72-100%. The method is characterized in that reaction is carried out on glycerol which serves as a raw material in a high-pressure reactor under anaerobic and alkali source provided alkaline conditions in the presence of supported copper oxide which serves as a catalyst, thereby obtaining lactic acid, wherein a support of the supported copper oxide catalyst contains metal oxides, including MgO, ZrO2, TiO2, CeO2 and ZnO, activated charcoal or hydroxyapatite; the supported copper catalyst is easy to prepare, low in cost and relatively long in service life. The method has the advantages that the reaction temperature and reaction pressure are low, the catalyst activity is high, the selectivity is good, the reaction rate is high, and the process flow is safe and environmental-friendly and the like, so that the industrial prospect is good.

Owner:JIANGSU UNIV

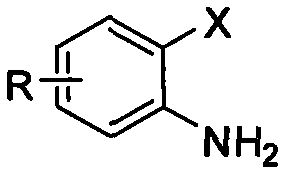

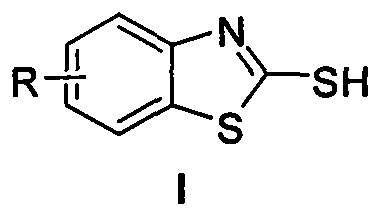

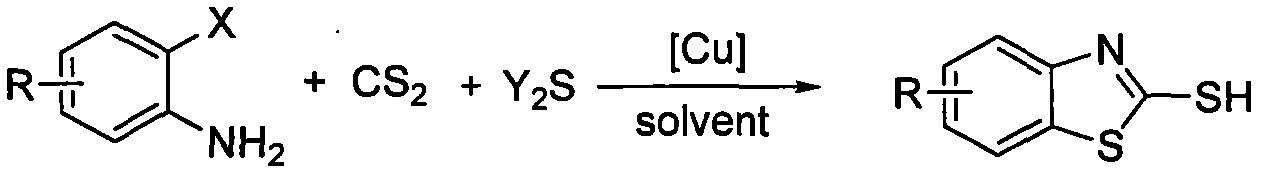

2-mercapto benzothiazole derivative synthetic method with copper-catalyzed carbon disulfide

InactiveCN104098528ANo pollution in the processSave raw materialsOrganic chemistryRecreationMetallic sulfide

The invention relates to the technical field of agriculture, industry and pharmacy and provides a 2-mercapto benzothiazole derivative synthetic method. According to the 2-mercapto benzothiazole derivative synthetic method, 2-mercapto benzothiazole derivatives are synthesized by take 2-halogen phenylamine, carbon disulfide and inorganic metal sulfide as the raw materials and through catalysis of copper salt. The method comprises dissolving the 2-halogen phenylamine, the inorganic metal sulfide and copper salt catalyst inside an appropriate solvent, adding the carbon disulfide inside the mixture for recreation under 50-110 DEG C for a certain time and performing purification treatment to obtain the 2-mercapto benzothiazole derivatives. The 2-mercapto benzothiazole derivative synthetic method with the copper-catalyzed carbon disulfide is rapid and efficiency, by taking the nontoxic, cheap and easily-obtained copper salt as the catalyst, omits ligand for recreations, and has the advantages of being high in yield rate, mild in conditions, low in the amount of by-products and the like.

Owner:INNER MONGOLIA UNIV OF TECH

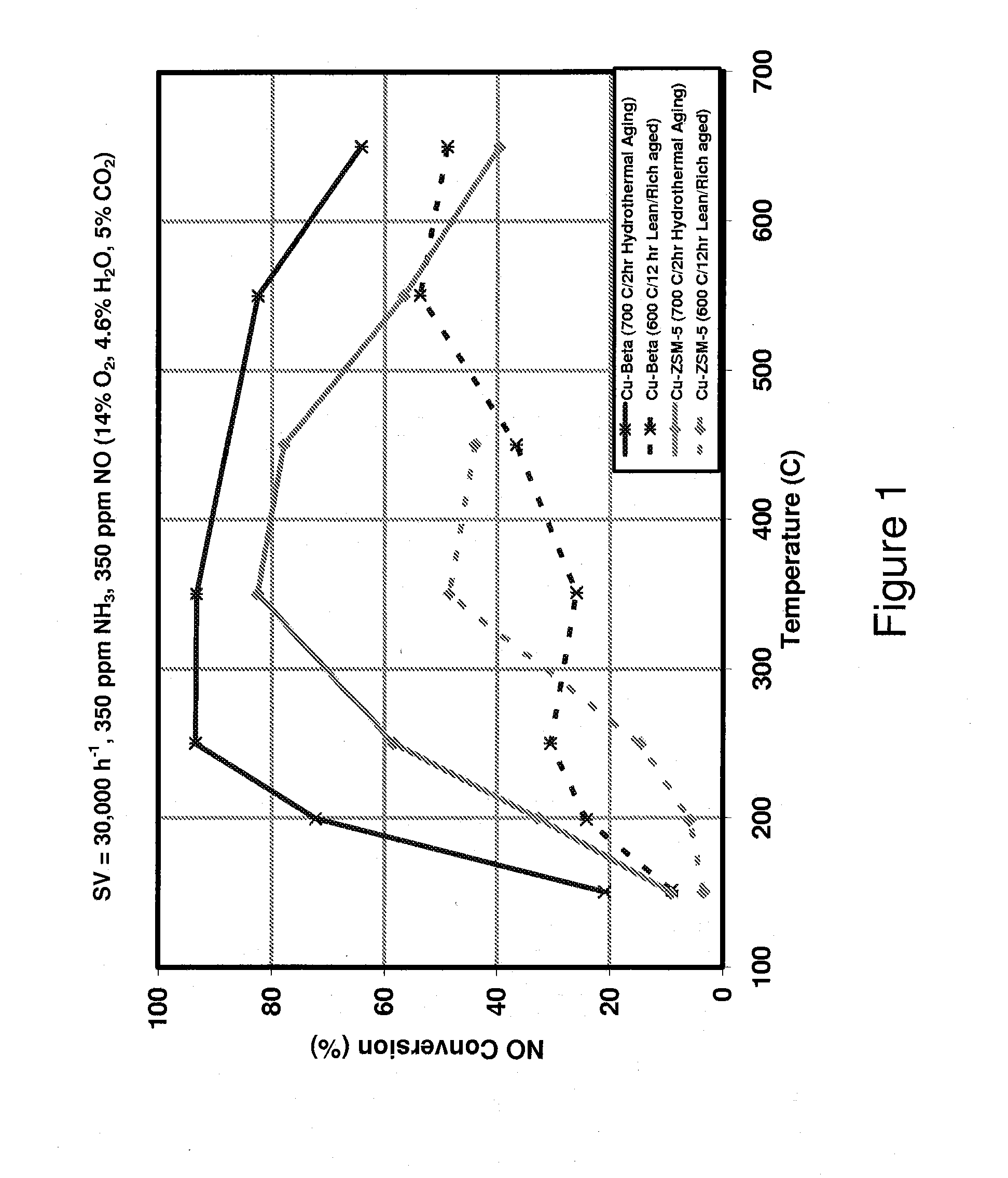

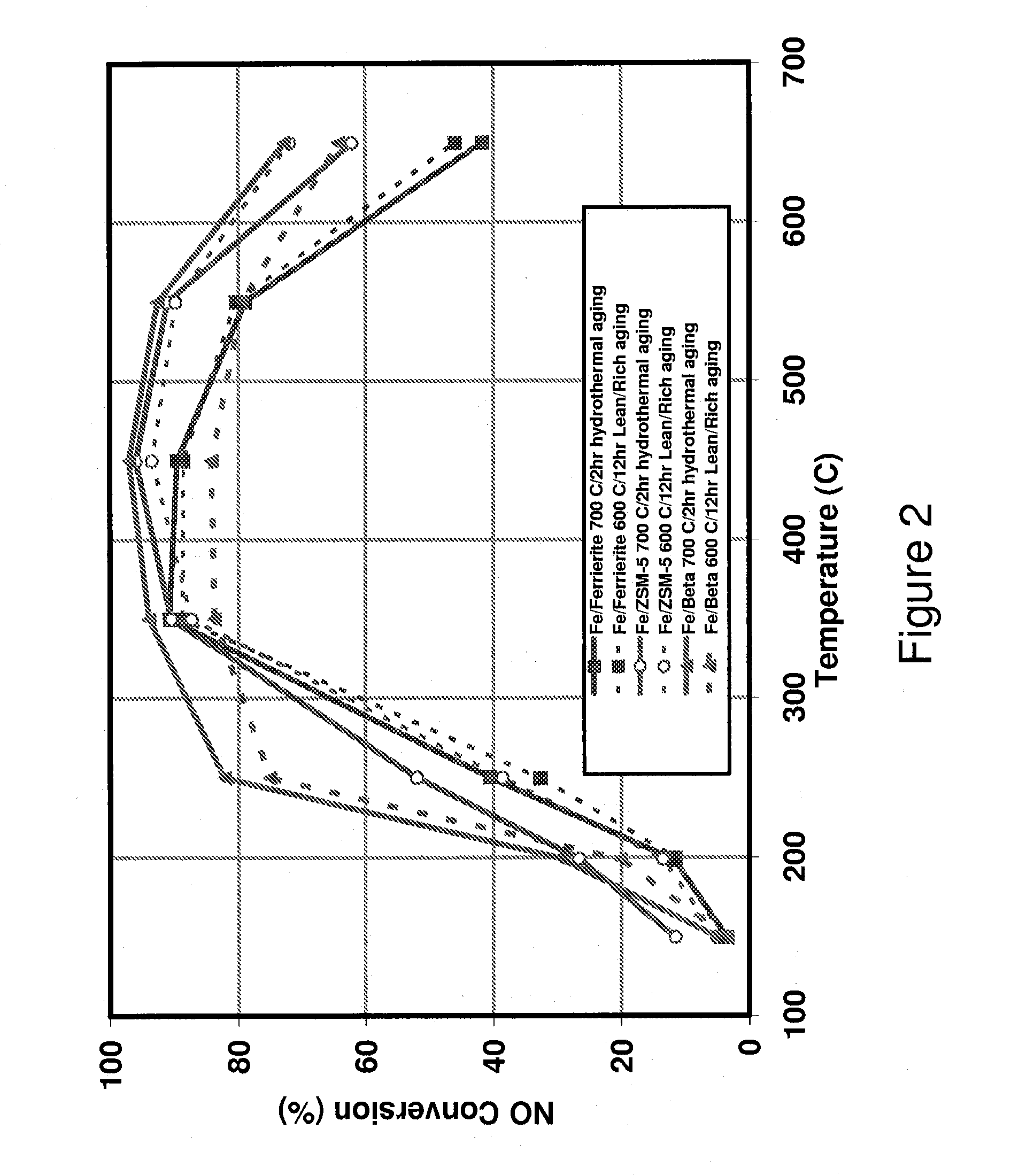

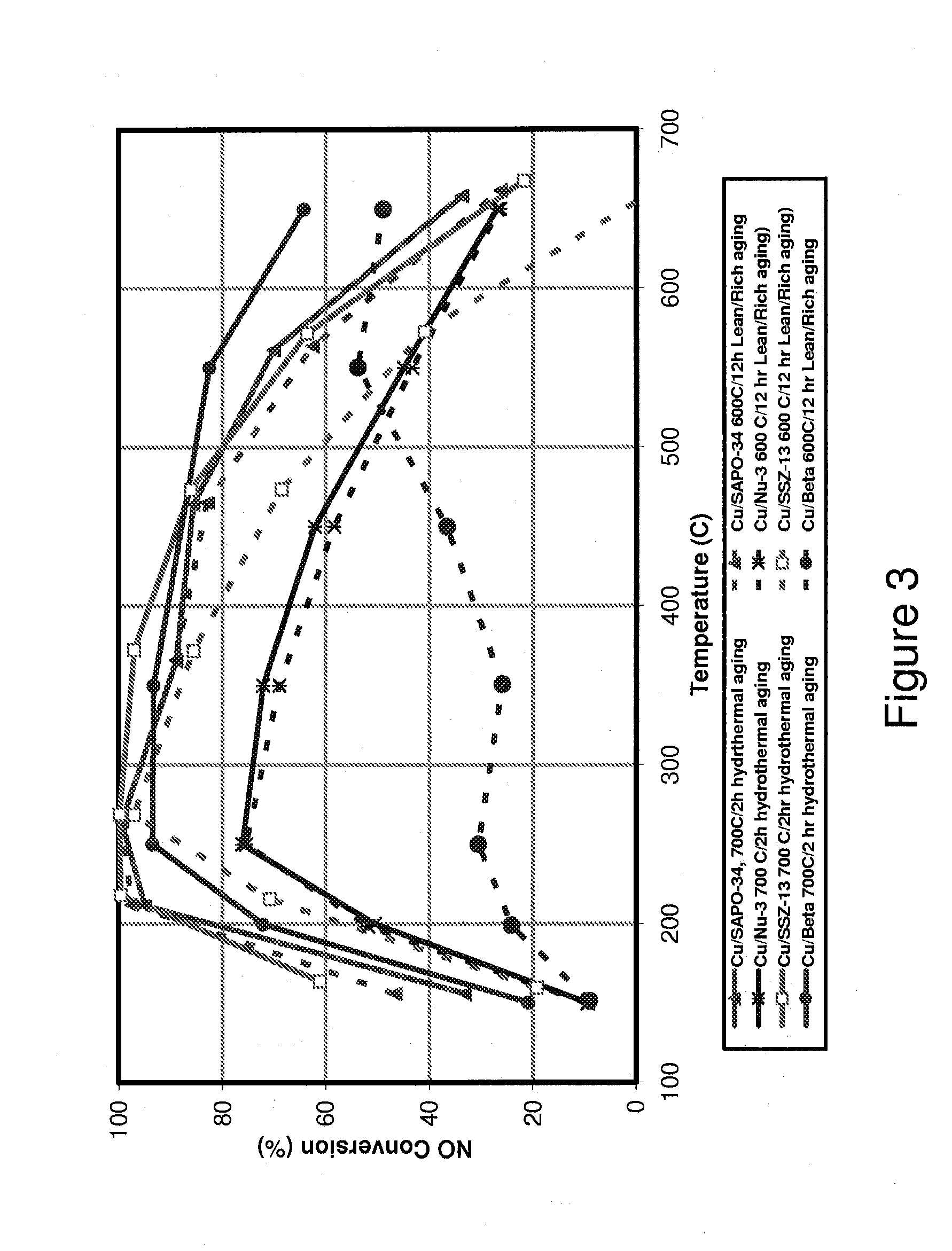

Small pore molecular sieve supported copper catalysts durable against lean/rich aging for the reduction of nitrogen oxides

ActiveUS20110281720A1Nitrogen compoundsInternal combustion piston enginesMolecular sieveReducing atmosphere

A method of using a catalyst comprises exposing a catalyst to at least one reactant in a chemical process. The catalyst comprises copper and a small pore molecular sieve having a maximum ring size of eight tetrahedral atoms. The chemical process undergoes at least one period of exposure to a reducing atmosphere. The catalyst has an initial activity and the catalyst has a final activity after the at least one period of exposure to the reducing atmosphere. The final activity is within 30% of the initial activity at a temperature between 200 and 500° C.

Owner:JOHNSON MATTHEY PLC

Preparation method of copper phosphide (Cu3P) catalyst with hypophosphite by prosoma pyrolytic process

InactiveCN101574663ALow pricePrice securityCatalyst activation/preparationPhosphidesCopperHigh pressure

The invention provides a new method for preparing a catalyst of supported copper phosphide or non-supported copper phosphide (Cu3P) by the prosoma pyrolytic process of hypophosphite. The invention is characterized in that: the process adopted is simple; complicated steps such as high temperature, high pressure and temperature programming are not necessary; and the supported copper phosphide or non-supported copper phosphide can be prepared only under normal pressure by the pyrolytic process. The materials are low in cost and safe and the cost of equipment is low. Therefore, the method is very suitable for large-scale production. Copper phosphide can improve the clinkering performance of 316L stainless steel and can serve as a reinforcing agent in the production of high speed steel (HSS) composite materials. Due to the good performances of circulation and reversibility, copper phosphide can serve as the potential electrode material for cathode of the lithium ion battery.

Owner:NANKAI UNIV

Synthesis of 2-aryl quinazolone from benzyl halide and 2-amobenzamide

The invention provides a new process for synthesizing 2-aryl quinazolone compounds by catalyzing reaction between benzyl halide and 2-aminobenzamide compounds with copper in air. In the method, benzyl halide with rich industrial sources is used as a reaction raw material, and the cost is lower; and more importantly, the 2-aryl quinazolone compounds which are difficult to synthesize by other methods can be synthesized, such as products containing iodine or bromine substituent on an aromatic ring.

Owner:CHENGDU UNIVERSITY OF TECHNOLOGY

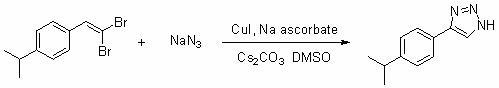

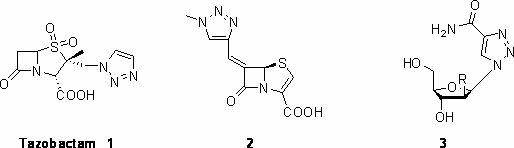

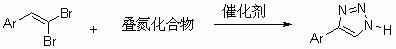

Method for synthesizing 4-aryl-1H-1,2,3-triazole by using 1,1-dibromo-1-olefin

InactiveCN102127024AEasy to operateRaw material economyOrganic chemistryOrganic synthesisSodium azide

The invention belongs to the technical fields of medicaments and organic synthetic intermediates and in particular relates to a method for synthesizing 4-aryl-1H-1,2,3-triazole by using 1,1-dibromo-1-olefin. A 4-aryl-1,2,3-triazole compound is synthesized by using a sodium azide or organic nitrine compound and cheap and readily-available 1,1-dibromo-1-olefin as raw materials in the presence of alkali in dimethylsulfoxide through copper catalysis conveniently. The compound comprises a 1,2,3-triazole structure unit with bioactivity and can be used for synthesizing and modifying the organic synthetic intermediates and the medicaments. A novel and effective synthetic method is provided for medicament screening.

Owner:TONGJI UNIV

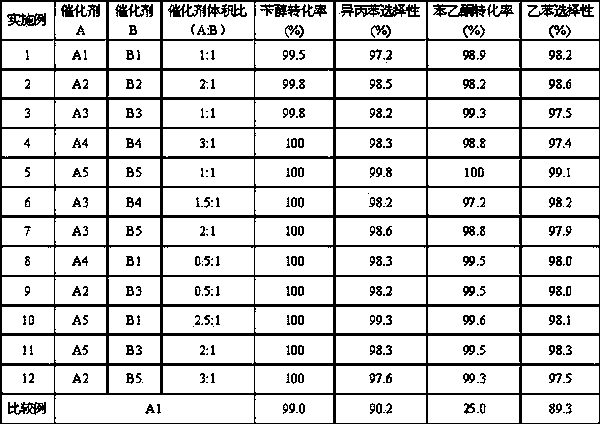

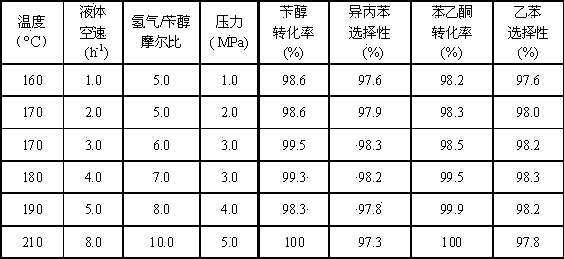

Preparation method of isopropyl benzene

ActiveCN104230643AImprove stabilityLow costHydrocarbon from oxygen organic compoundsHydrocarbonsPtru catalystReaction temperature

The invention relates to a preparation method of isopropyl benzene, and mainly solves the problem of poor stability of catalyst in the processes of benzyl alcohol hydrogenolysis and acetophenone hydrogenation. The invention adopts hydrogen and hydrocarbons containing alpha, alpha-dimethyl benzylalcohol and acetophenone as raw materials. The raw materials successively contact with a catalyst A and a catalyst B for reaction under the conditions of molar ratio of alpha, alpha-dimethyl benzylalcohol in the hydrogen / hydrocarbon material being 5-15:1, reaction temperature of 160-240 DEG C, reaction pressure of 0.5-5.0 MPa and volume space velocity of hydrocarbon material of 1.0-10.0 / h. The catalyst A and B catalyst are in the volume ratio of 0.5-3:1, the catalyst A is a Pd catalyst, and the catalyst B is a copper catalyst. The technical scheme can well solve the problem and can be used in industrial production of epoxypropane through dicumyl peroxide method.

Owner:CHINA PETROLEUM & CHEM CORP +1

A regioselective copper catalyzed synthesis of benzimidazoles and azabenzimidazoles

The present invention relates to a process for the regioselective synthesis of compounds of the formula (I), wherein R0; R1; R2; R3; R4; R5; A1; A2; A3; A4; Q and J have the meanings indicated in theclaims. The present invention provides a direct copper catalyzed regioselective process to a wide variety of unsymmetrical, multifunctional N / -substituted benzimidazoles or azabenzimidazoles of formula I starting from 2-halo-nitroarenes and N / -substituted amides. The process is useful for the production of pharmaceuticals, diagnostic agents, liquid crystals, polymers, herbicides, fungicidals, nematicidals, parasiticides, insecticides, acaricides and arthropodicides.

Owner:SANOFI AVENTIS SA

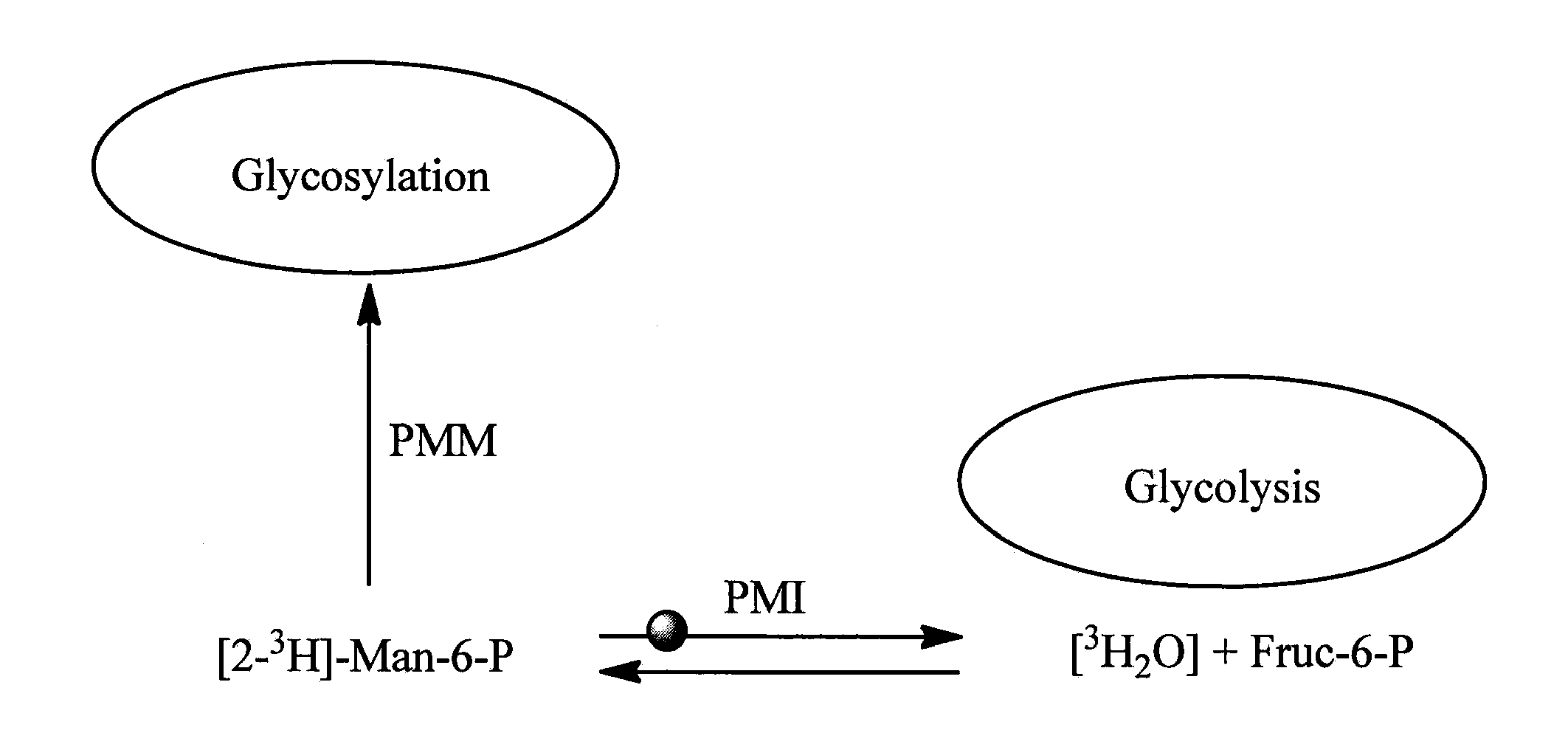

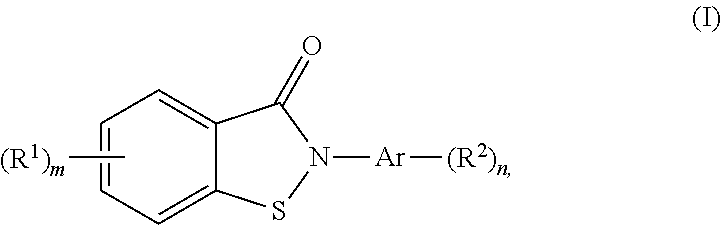

Benzoisothiazolones as inhibitors of phosphomannose isomerase

InactiveUS20110257233A1Promote accumulationAntibacterial agentsBiocideDiseasePhosphomannose Isomerase

The disclosure provides new compounds and compositions thereof, and methods for treating or ameliorating a disorder relating to CDG-Ia. In particular, the disclosure provides benzoisothiazolone inhibitors of PMI, which have been synthesized and their ability to drive glycosylation has been demonstrated. The disclosure provides two synthetic routes for these compounds, including a new copper-catalyzed N-arylation reaction amenable to parallel derivitization. The disclosed compounds represent potent inhibitors of PMI, and their dose-dependent efficacy in cell-based models of glycosylation have been demonstrated. In addition, the disclosed compounds are selective over PMM and therefore, are useful in treating or ameliorating a disorder relating to CDG-Ia.

Owner:SANFORD BURNHAM MEDICAL RES INST

Raney copper catalyst, method for preparing same and application of Raney copper catalyst

ActiveCN106475115AHigh selectivityLower alkyne contentHydrocarbon purification/separationHydrocarbonsPtru catalystMetallic aluminum

The invention relates to the field of petrochemical engineering, and discloses a Raney copper catalyst, a method for preparing the same and application of the Raney copper catalyst. The Raney copper catalyst comprises carbon and main active components. The carbon is used as a carrier, the main active components are dispersed in the carrier and comprise Zn-doped Raney copper, organic matters capable of being carbonized are carbonized to obtain the carbon used as the carrier, and mixtures with metal copper, metal aluminum and metal zinc are sequentially calcined, alloyed and activated to obtain the main active components; the content of the metal zinc in the Zn-doped Raney copper is 0.01-30% on the basis of the total weight of the Raney copper catalyst. The Raney copper catalyst, the method and the application have the advantage that the content of alkyne in C4 fractions can be effectively lowered when the alkyne in the C4 fractions is removed by means of selective hydrogenation.

Owner:CHINA PETROLEUM & CHEM CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com