Preparation method of copper phosphide (Cu3P) catalyst with hypophosphite by prosoma pyrolytic process

A hypophosphite and catalyst technology, applied in the direction of physical/chemical process catalysts, catalyst activation/preparation, phosphide, etc., can solve the problems of restricting the application of copper phosphide, the inability to prepare copper phosphide, and restricting large-scale industrial production , to achieve the effect of low equipment cost, cheap price and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

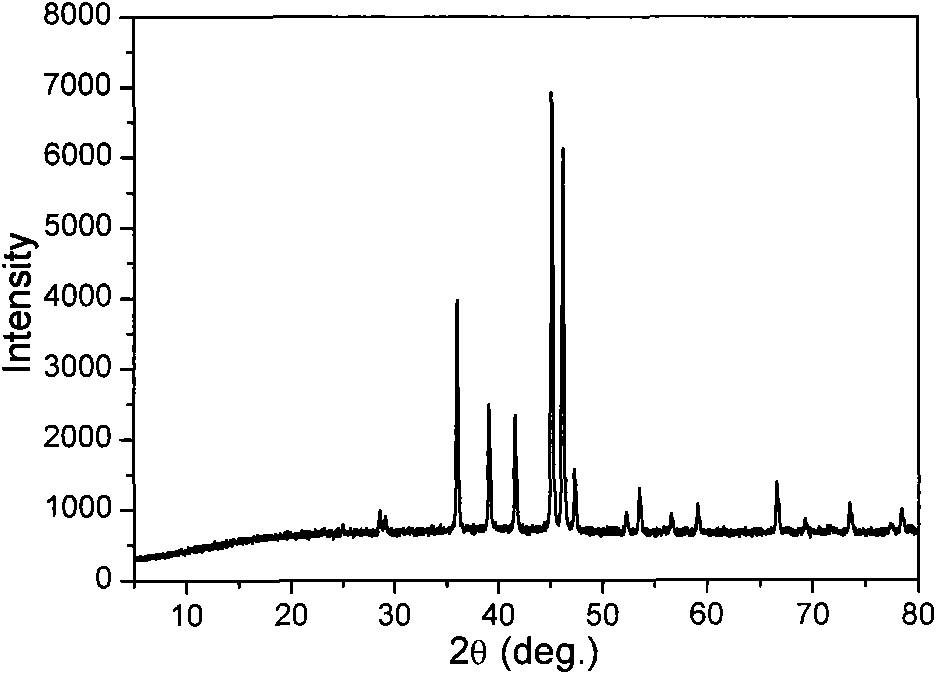

[0017] First, 6.89 g of CuCl was stirred at room temperature 2 .2H 2 O and 8.56 g NaH 2 PO 2 .H 2 O was added to 50ml of deionized water respectively, and after dissolving for 10 minutes, the resulting solution was put into a petri dish and dried at 60°C. Then put the dried precursor powder into the reactor, heat treatment at 300°C for 10 minutes under the protection of static nitrogen, and then wash the product with water and then dry it. The obtained sample is named A, and A has attached figure 1 Characteristics.

Embodiment 2

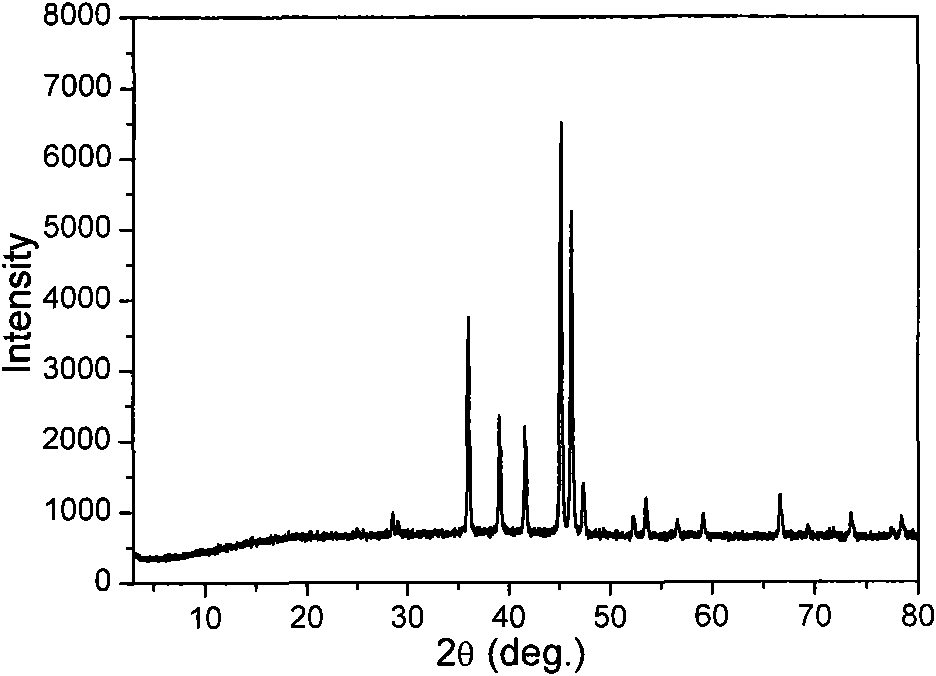

[0019] The preparation process is the same as that of sample A, only changing the NaH 2 PO 2 .H 2 The amount of O is 12.85g, and other conditions remain unchanged. The resulting sample is named B, B has attached figure 2 Characteristics.

Embodiment 3

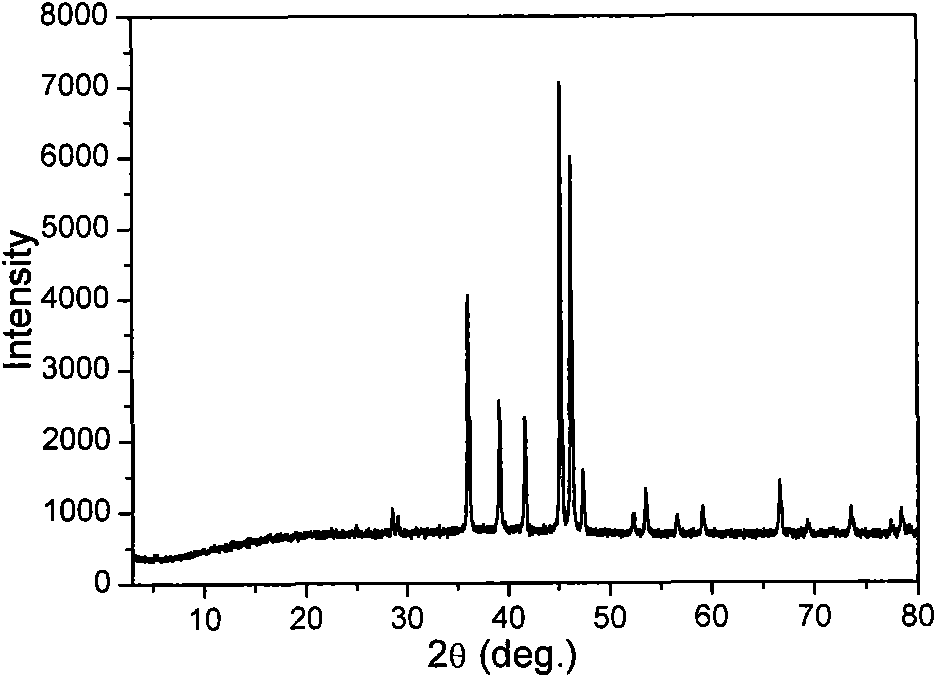

[0021] The preparation process is the same as that of sample A, only the heat treatment temperature is changed to 500°C, and other conditions remain unchanged. The obtained sample is named C, C has attached image 3 Characteristics.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com