Photocatalytic internal-circulation anaerobic fluidized membrane bioreactor and working method thereof

A membrane bioreactor, anaerobic fluidization technology, applied in the direction of chemical instruments and methods, chemical/physical processes, physical/chemical process catalysts, etc., can solve problems such as easy clogging, to overcome easy clogging, realize treatment, simplify Effect of Reactor Structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0058] The preparation method of the titanium dioxide light particles comprises the following steps:

[0059] (1) Using a magnetic constant temperature stirrer, add analytically pure butyl titanate and analytically pure glacial acetic acid to absolute ethanol in sequence at 25°C, and stir for 15-20 minutes to obtain a uniform and transparent light yellow solution; the titanic acid The parts by volume of butyl ester, glacial acetic acid and dehydrated alcohol are respectively:

[0060] Butyl titanate: 5 parts;

[0061] Glacial acetic acid: 1 part;

[0062] Anhydrous ethanol: 15 parts;

[0063] (2) Continue to stir, add the nitric acid solution that accounts for 1-2% by volume of the light yellow solution obtained in the step (1), the concentration of the nitric acid solution is 65-68wt%; add the light yellow solution obtained in the step (1) An ethanol solution with a volume percentage of 25-27% of the yellow solution, the concentration of the ethanol solution is 90-95wt%, a...

Embodiment 1

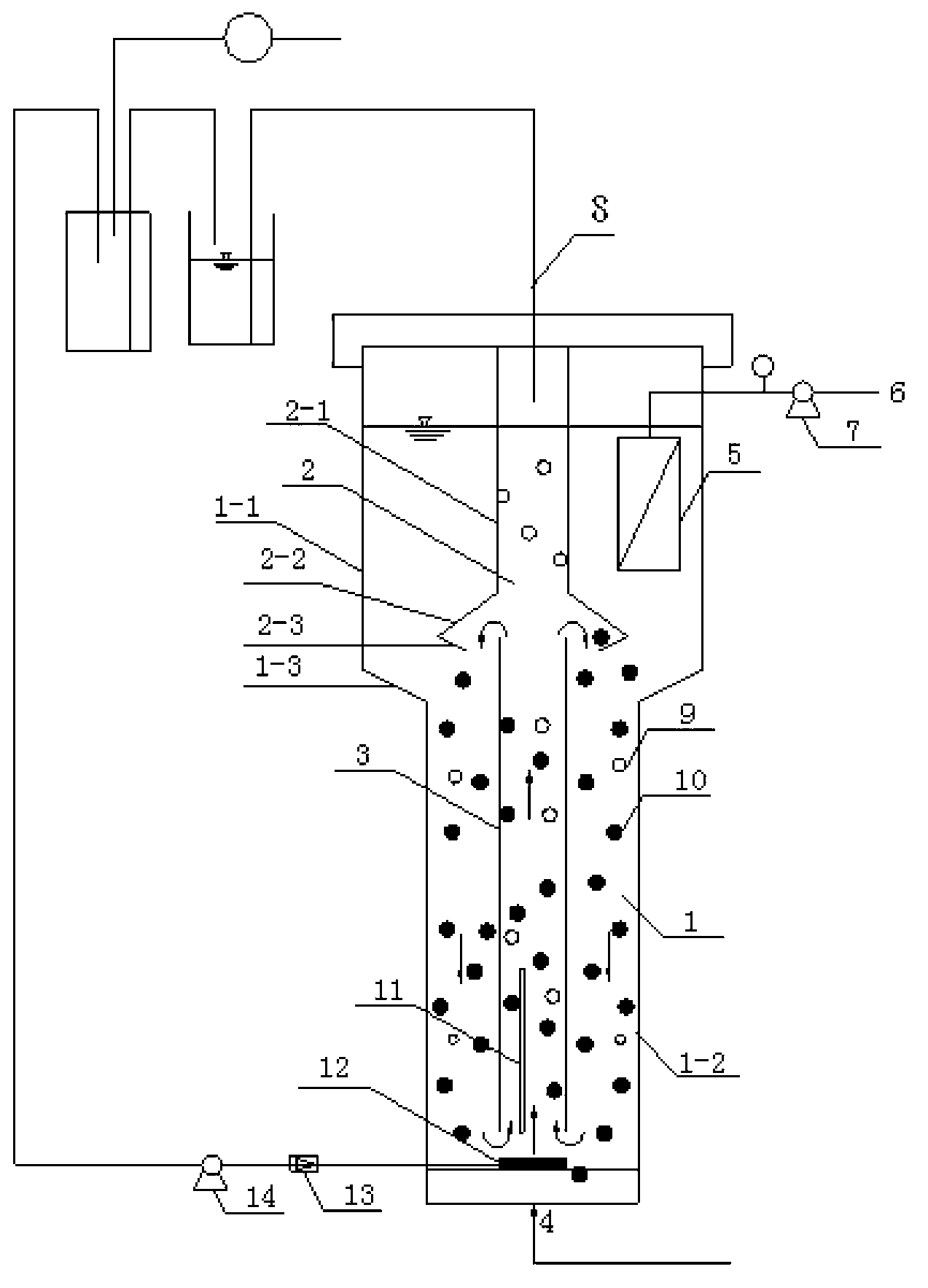

[0070] A photocatalytic, internal circulation anaerobic fluidized membrane bioreactor, including a reaction cylinder 1, a stripping cylinder 3, a three-phase separator 2 and a membrane module 5, and a water inlet pipe 4 is arranged at the bottom of the reaction cylinder 1 With the inlet pipe, light particles 10 loaded with titanium dioxide are placed in the reaction cylinder 1; a biogas aeration disc 12, a stripping cylinder 3 and a three-phase separator are arranged axially in the interior of the reaction cylinder 1 from bottom to top. Said airlift tube 3 is provided with an ultraviolet light source 11; a three-phase separator 2 is covered above said airlift tube 3, and said three-phase separator 2 includes a draft guide tube 2- 1 and an umbrella-shaped flow guide cover 2-2, an inwardly folded flow guide edge 2-3 is provided on the outer edge of the umbrella-shaped flow guide cover, and the upper end of the flow guide tube 2-1 passes through the reaction tube 1 The top cover ...

Embodiment 2

[0073] A kind of utilizing as embodiment 1 described reactor to process certain azo reactive blue printing and dyeing wastewater, COD in the wastewater Cr The content is 600-800mg / L, BOD / COD<0.18; the temperature in the reactor is maintained at 35±1°C; the specific method includes the following steps:

[0074](1) After the wastewater enters the reaction cylinder 1 through the water inlet pipe at the bottom of the reaction cylinder 1, the circulating methane gas enters the stripping cylinder through the inlet pipe at the bottom of the reaction cylinder. Titanium dioxide light particles are mixed into mixed wastewater;

[0075] (2) The mixed wastewater in the step (1) enters the stripper 3, and under the irradiation of the ultraviolet light source 11 and the catalytic action of titanium dioxide, the refractory organic matter in the mixed wastewater is degraded into biodegradable compounds;

[0076] (3) The mixed wastewater flows upwards along the airlift cylinder 3 to the umbre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com