Composite catalyst used for catalytic combustion of organic waste gas as well as preparation method and application thereof

A composite catalyst and catalytic combustion technology are applied in the fields of cordierite honeycomb ceramic catalysts and composite organic waste gas catalytic combustion catalysts, which can solve the problems of decreased catalytic activity, high catalyst cost, difficult adsorption, etc., so as to increase the surface area of the coating and reduce the production cost. , to ensure the effect of sufficient adsorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

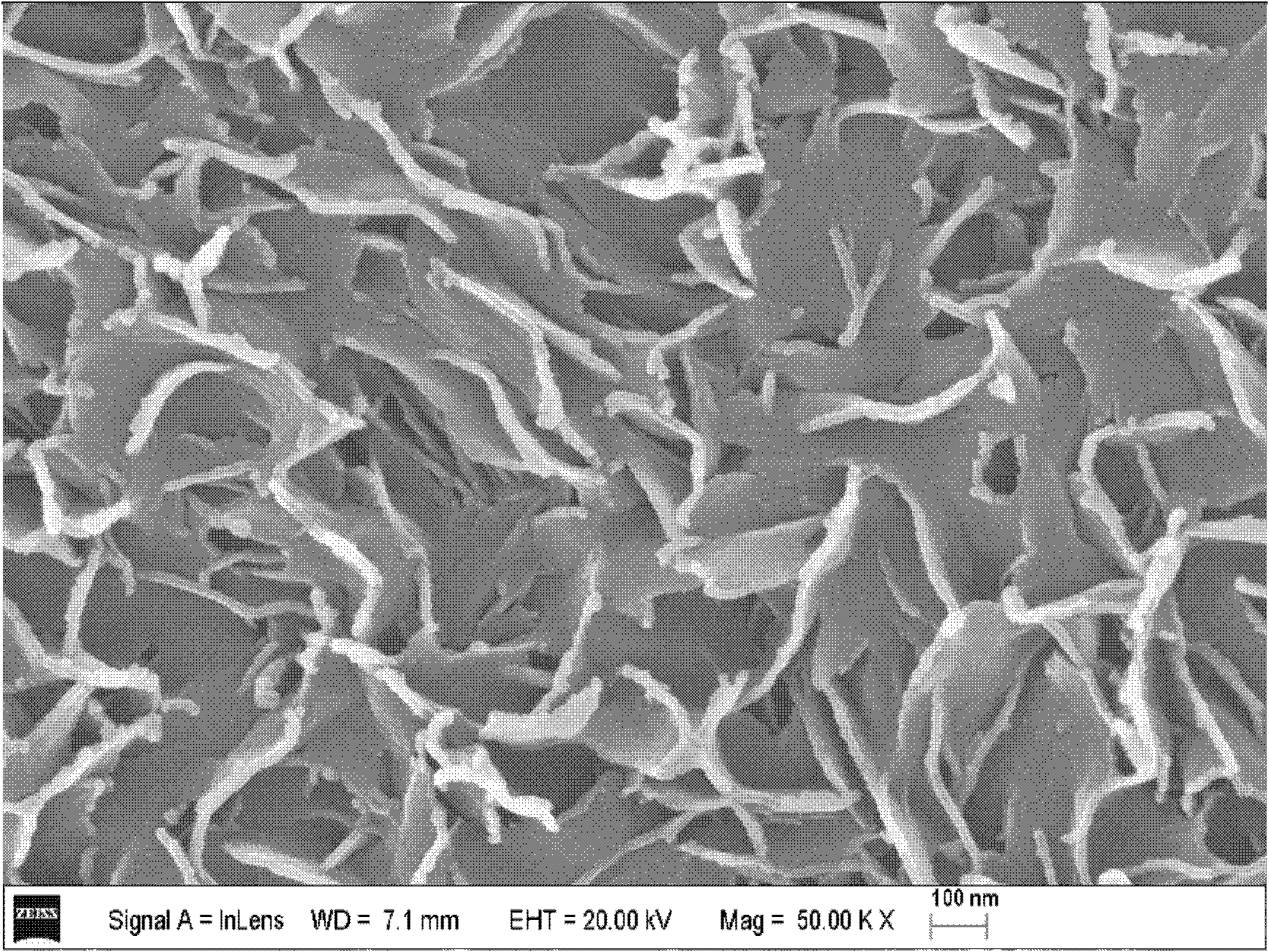

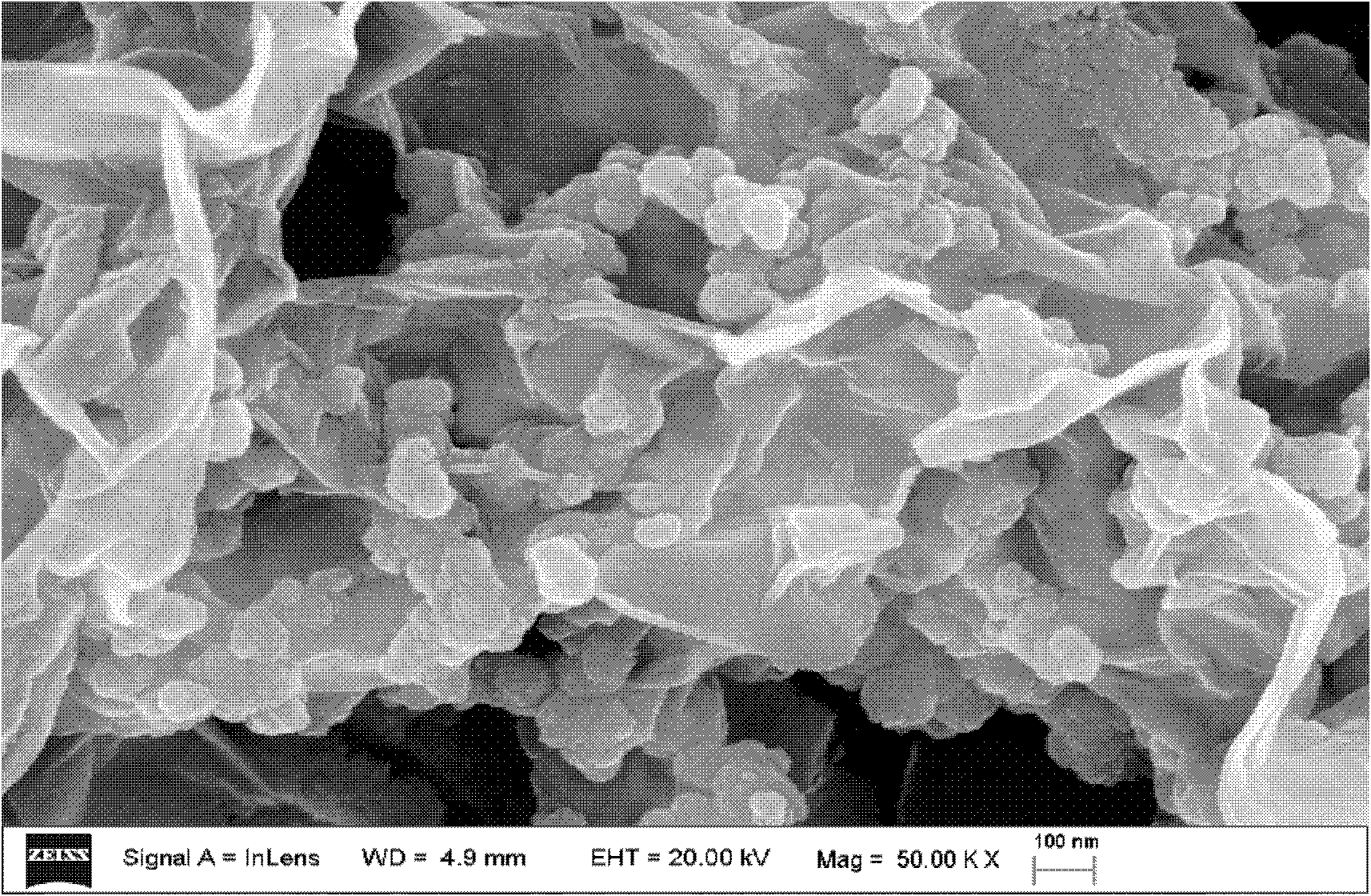

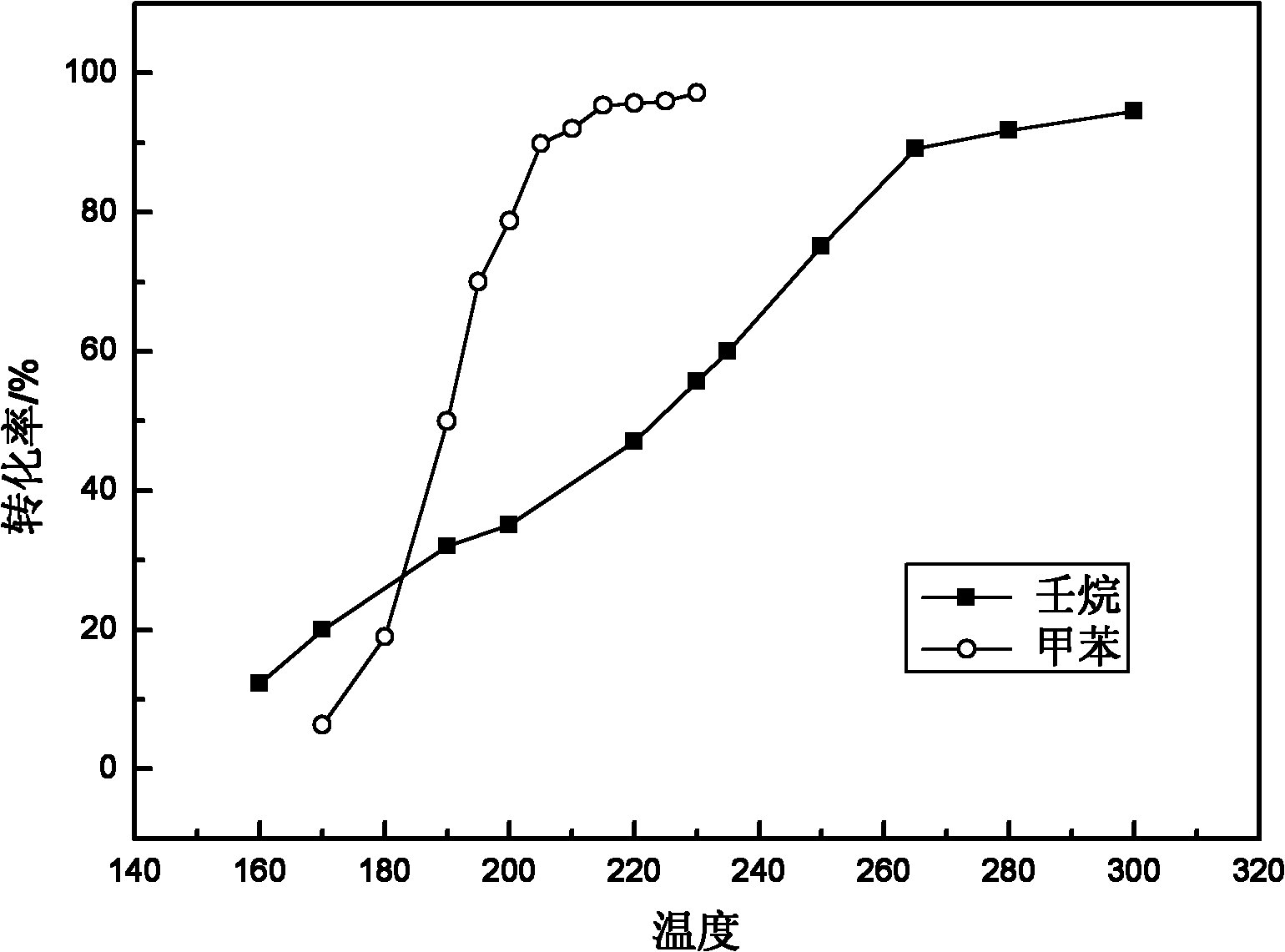

[0031] Cordierite honeycomb ceramics (200cell / in 2 ), put it into 1% dilute nitric acid solution, carry out acid etching pretreatment for 1h, wash it with water, and dry it in a blast drying oven at 120°C for 2h. Macropores and high-viscosity pseudo-boehmite were mixed in a mass ratio of 1:3 (total mass 30 grams), and a mixture of 3 g of cerium nitrate and zirconium nitrate (molar ratio of 3: 1) was added, dissolved in 90 ml of deionized water, After fully stirring, use 1mol·L -1 The pH value of the dilute nitric acid preparation solution is 2, and the transition coating solution after hydrolysis is continuously stirred for 2 hours. Immerse the pretreated cordierite carrier in the transition coating, take it out after impregnating saturation, blow off the excess solution in the channel with compressed air, then put it in an oven for 2 hours at 120°C, and bake it at 400°C for 4 hours to obtain a cordierite composite carrier. According to Cu, Mn, Zn, Fe mass ratio 3: 1: 1: 1,...

Embodiment 2

[0033] Cordierite honeycomb ceramics (200cell / in 2 ), put it into 1% dilute nitric acid solution, carry out acid etching pretreatment for 1h, wash it with water, and dry it in a blast drying oven at 120°C for 2h. Macropores and high-viscosity pseudo-boehmite are mixed in a mass ratio of 1: 1 (total mass 30 grams), and a mixture of 3 g of lanthanum nitrate and yttrium nitrate (molar ratio is 3: 1) is added, dissolved in 90 ml of deionized water, After fully stirring, use 1mol·L -1The pH value of the diluted nitric acid preparation solution was 2, and the hydrolyzed gel was stirred for 2 hours. Immerse the treated cordierite carrier in the transition coating, take it out after impregnation saturation, blow off the excess solution in the channel with compressed air, then put it in an oven at 120°C, dry it for 2 hours, and bake it at 400°C for 4 hours to obtain a cordierite composite carrier. Dissolve the nitrates of Cu, Mn, Zn, and Fe four non-precious metal elements in a mass...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com