Fluidized bed combustion furnace and control method thereof

A technology of fluidized bed and temperature control method, applied in the field of fluidized bed combustion furnace and its control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0071] In order to have a further cognition and understanding of the features, purpose and functions of the present invention, the relevant detailed structure and design concept of the device of the present invention will be described below so that the characteristics of the present invention can be understood. The detailed description is as follows :

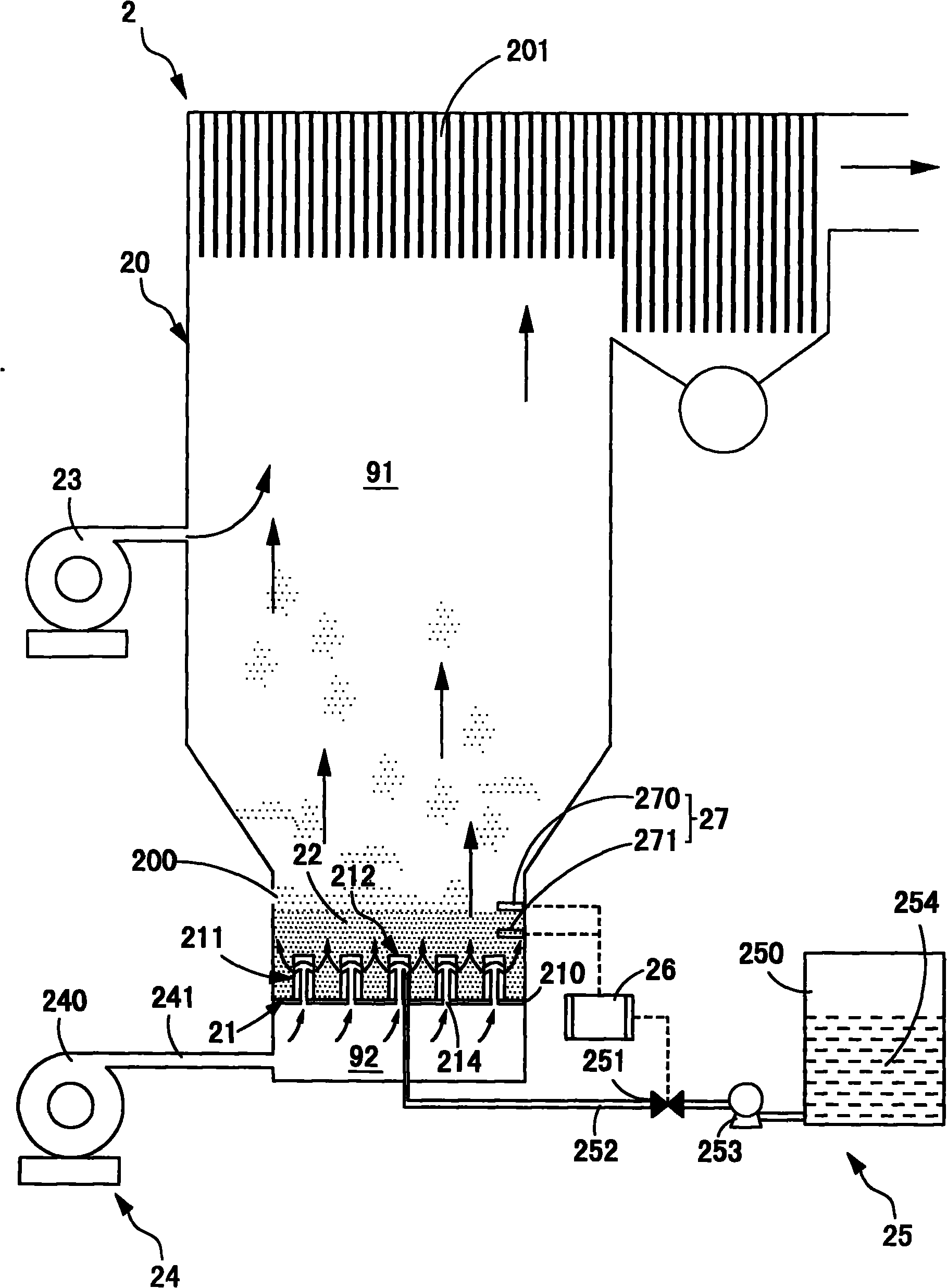

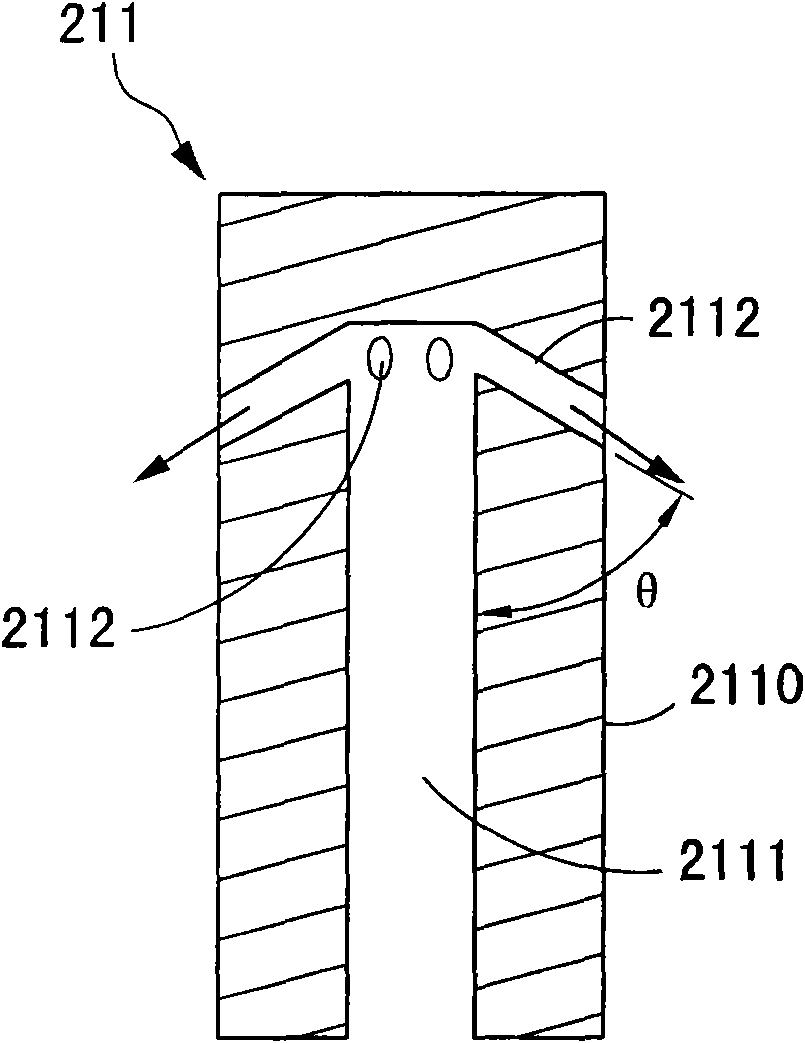

[0072] see figure 2 As shown, this figure is a schematic diagram of an embodiment of the fluidized bed combustion furnace of the present invention. The fluidized bed combustion furnace 2 has a furnace body 20, and a gas distributor 21 is arranged in the furnace body 20 to divide the furnace body 20 into two areas, which are respectively the freeboard area 91 and the wind box 92, wherein the gas A bed of sand 22 is laid on the freeboard area 91 above the distributor 21, and the bed of sand 22 can be quartz sand, but not limited thereto. There is also a fuel supply opening 200 on the furnace body 20 to provide fuel, such as wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com