Biomass double fluidized bed indirect gasification system and control method thereof

A dual-fluidized bed gasification system technology, which is applied in the gasification of granular/powdered fuels, the manufacture of combustible gases, and the petroleum industry, can solve the problem of limited catalytic cracking tar capacity, reduced gasification efficiency of gasifiers, and bed materials. single problem, to achieve the effect of increasing gasification temperature and gasification efficiency, reducing tar content, and increasing calorific value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1)

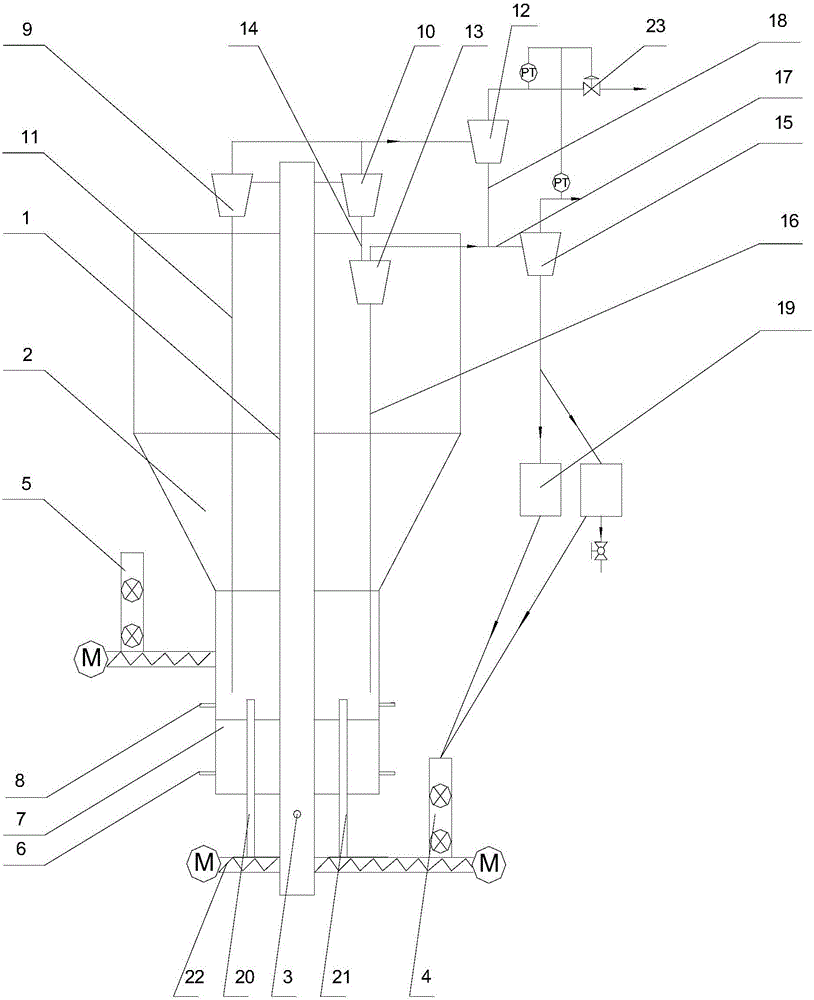

[0038] This embodiment includes that the fluidized bed burner 1 is a fast fluidized bed burner, the fluidized bed gasifier 2 is a bubbling fluidized bed gasifier, and the air adding unit 3 of the burner is three air inlets. Burner bed material feed unit 4 at the bottom of bed burner 1, gasifier biomass feed unit 5 at the middle and lower part of fluidized bed gasifier 2, steam pipeline 6 of gasifier, steam at the bottom of gasifier Chamber 7, steam or CO on the side of the gasifier bed 2 Injection port 8, more than two-thirds of the fluidized bed burner 1 is placed in the fluidized bed gasifier 2, and its top is connected with the relative burner primary cyclone separator 9 and the burner primary cyclone Separator two 10; the feed pipe one 11 of the primary cyclone separator one 9 of the burner extends downwards and penetrates into the bed layer at the lower part of the fluidized bed gasifier 2, and the primary cyclone separator one 9 of the burner and the combustion The outp...

Embodiment 2)

[0041] This embodiment includes that the fluidized bed burner 1 is a fast fluidized bed burner, the fluidized bed gasifier 2 is a bubbling fluidized bed gasifier, and the air adding unit 3 of the burner is three air inlets. Burner bed material feed unit 4 at the bottom of bed burner 1, gasifier biomass feed unit 5 at the middle and lower part of fluidized bed gasifier 2, steam pipeline 6 of gasifier, steam at the bottom of gasifier Chamber 7, steam or CO on the side of the gasifier bed 2Injection port 8, more than two-thirds of the fluidized bed burner 1 is placed in the fluidized bed gasifier 2, and its top is connected with the relative burner primary cyclone separator 9 and the burner primary cyclone Separator two 10; the feed pipe one 11 of the primary cyclone separator one 9 of the burner extends downwards and penetrates into the bed layer at the lower part of the fluidized bed gasifier 2, and the primary cyclone separator one 9 of the burner and the combustion The outpu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com