Method of and apparatus for controlling the temperature of a fluidized bed reactor

A fluidized bed reactor and equipment technology, applied in fluidized bed combustion equipment, chemical instruments and methods, steam generation methods using heat carriers, etc., can solve the problems of reducing oil production and undesired chemical reactions, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

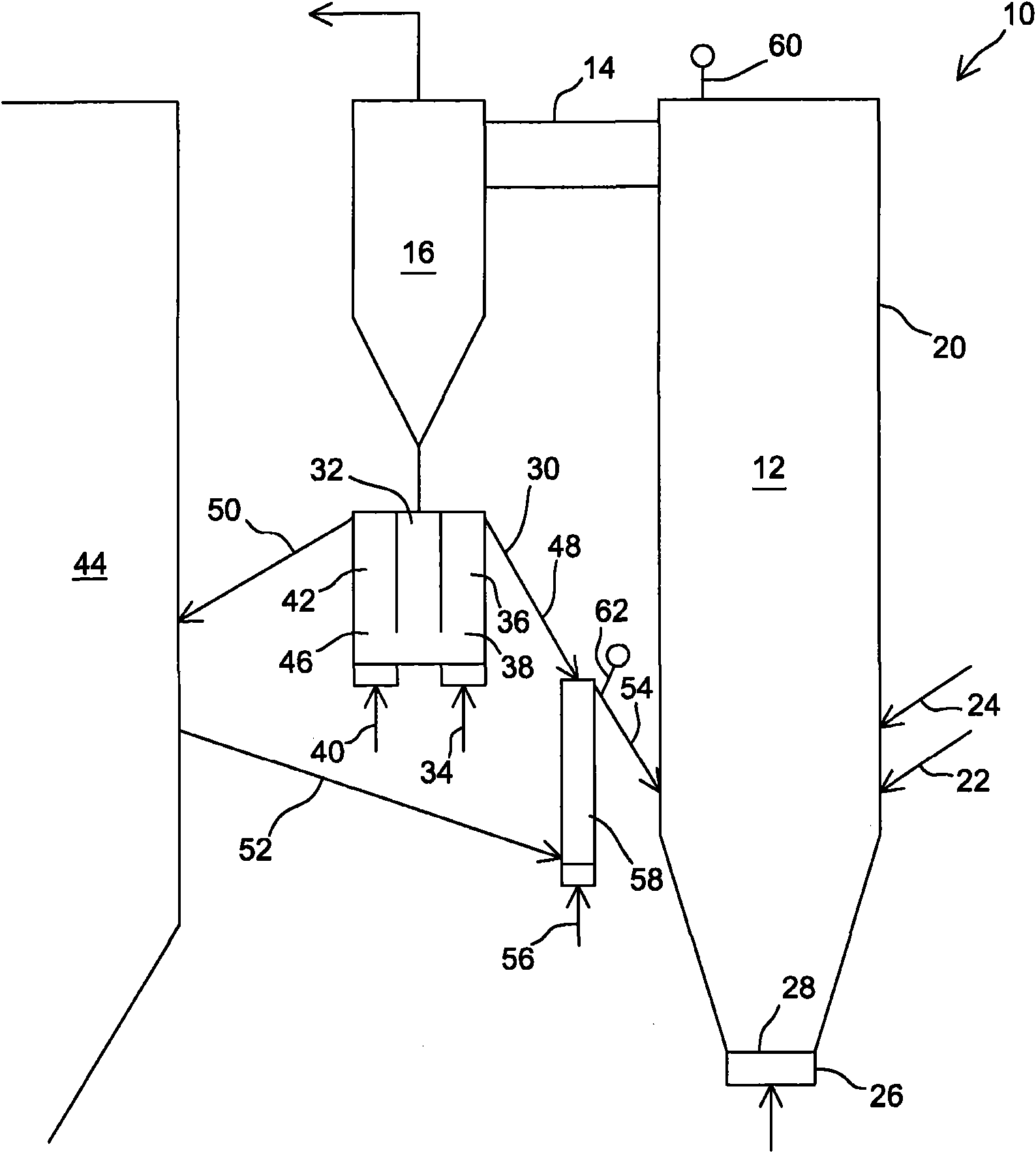

[0027] figure 1 Shown is a circulating fluidized bed pyrolyzer 10 according to a preferred embodiment of the present invention, said fluidized bed pyrolyzer comprising a reaction chamber 12, a gas discharge conduit 14 connected to the upper part of the reaction chamber and connected to Particle separator 16 to conduit 14 . Solid particles, in particular coke particles, are separated from the pyrolysis gas by means of a particle separator 16 . From the particle separator the pyrolysis gas is directed through a filter to a gas cooler ( figure 1 not shown in ), in which the pyrolysis oil is condensed from the pyrolysis gas. The uncondensed gaseous products are directed from the gas cooler for other uses, for example to be combusted or used as fluidization gas for a pyrolyzer. Conventional conduits 22, 24 are connected to the side wall 20 of the reaction chamber 12, for example to conduct fuel and inert bed material. Also arranged below the reaction chamber is a wind box 26 fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com