Circulating system of combustion gasification materiel for double fluidized bed

A dual-fluidized bed and circulating system technology is applied in the directions of fluidized bed combustion equipment, fuel burning in a molten state, and combustion methods, which can solve the problems of complex system and poor reliability, and achieve simple operation, guaranteed reliability, and reasonable Effective use of the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

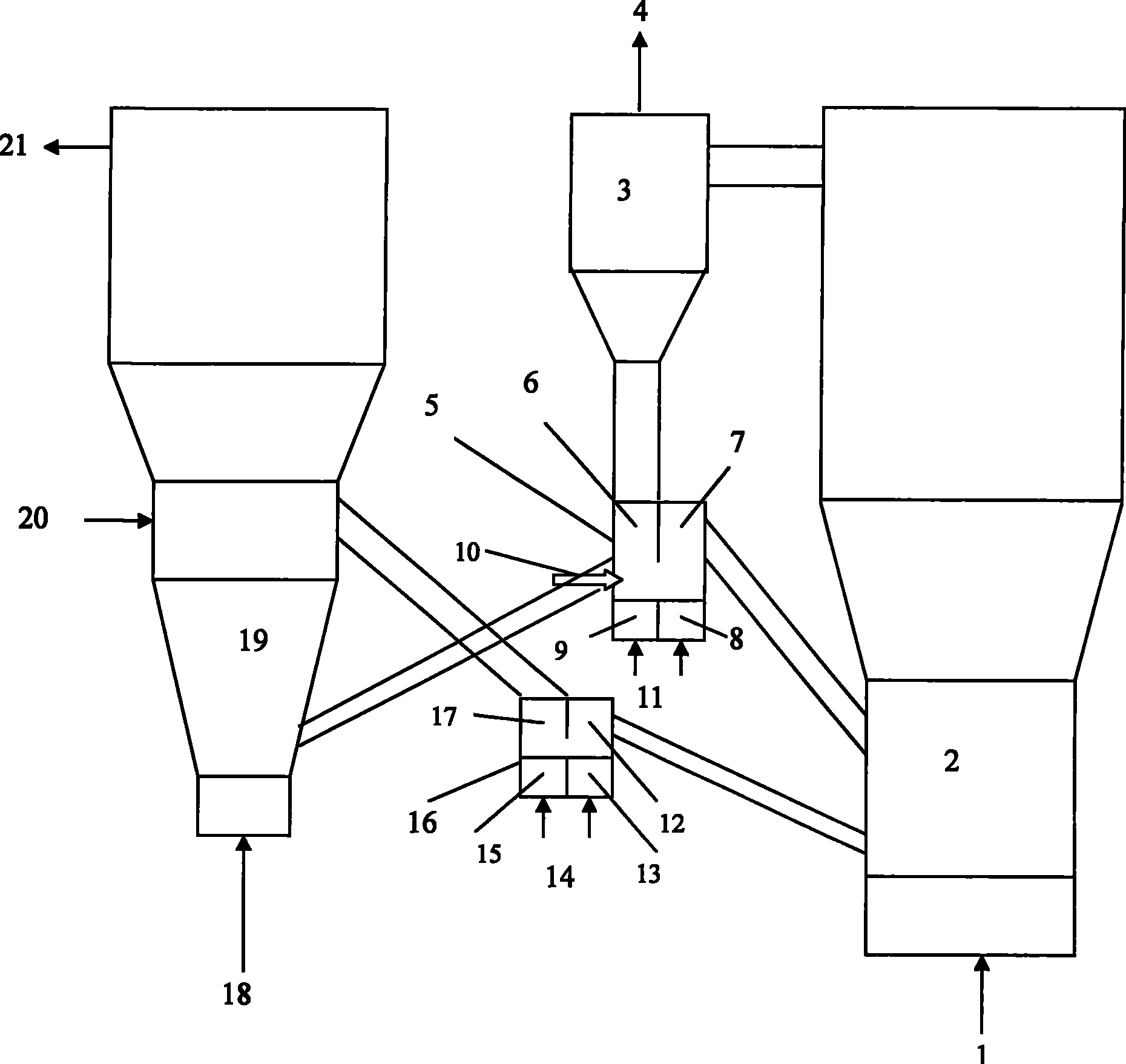

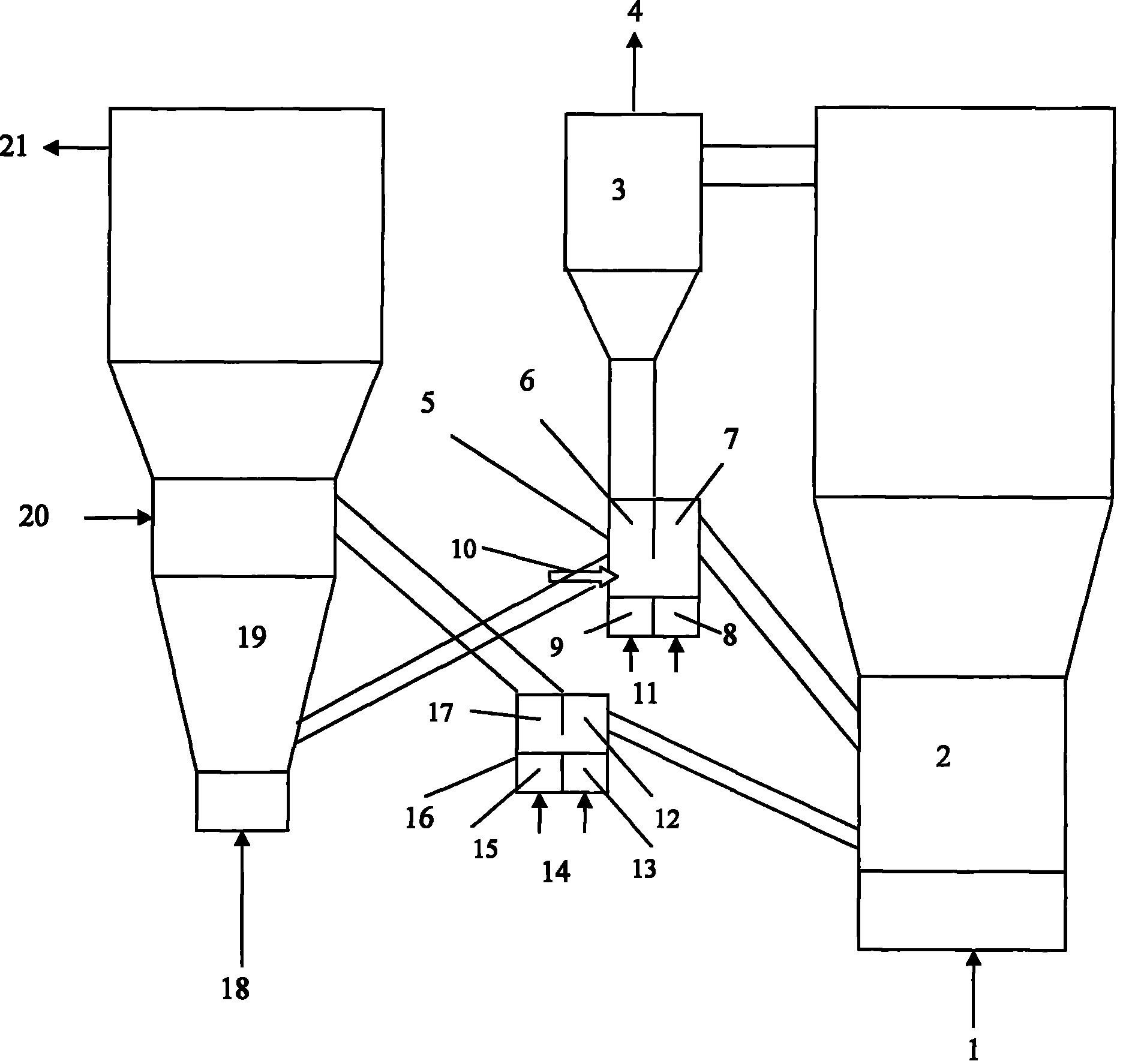

[0014] As shown in the drawings, the double fluidized bed combustion gasification material circulation system includes a fluidized bed gasification furnace 19 and a circulating fluidized bed combustion furnace 2; The feed chamber 17 is connected, and then the discharge chamber 12 of the feeder is connected with the lower part 2 of the circulating fluidized bed combustion furnace; 6 phases are connected, and then divided into two paths, one path is connected to the lower part of the fluidized bed gasification furnace 19 through the high-temperature cone valve 10 on the side of the feed chamber of the two-way feeder controller, and the other path is passed through the return chamber of the two-way feeder controller 7 is connected with the bottom of circulating fluidized bed combustion furnace 2. Thus forming a double fluidized bed high temperature material circulation system.

[0015] The upper part of the two-way feeder 5 is provided side by side with a feed chamber 6 and a re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com