Low-nitrogen fluidized bed combustor for biomass

A fluidized bed and biomass technology, which is applied to fluidized bed combustion equipment, fuels burned in a molten state, combustion methods, etc., can solve the problems of unreasonable combustion chamber structure, unreasonable fire distribution and insufficient combustion, etc. , to reduce the production of nitrogen oxides, control emissions, and enhance the effect of combustion temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

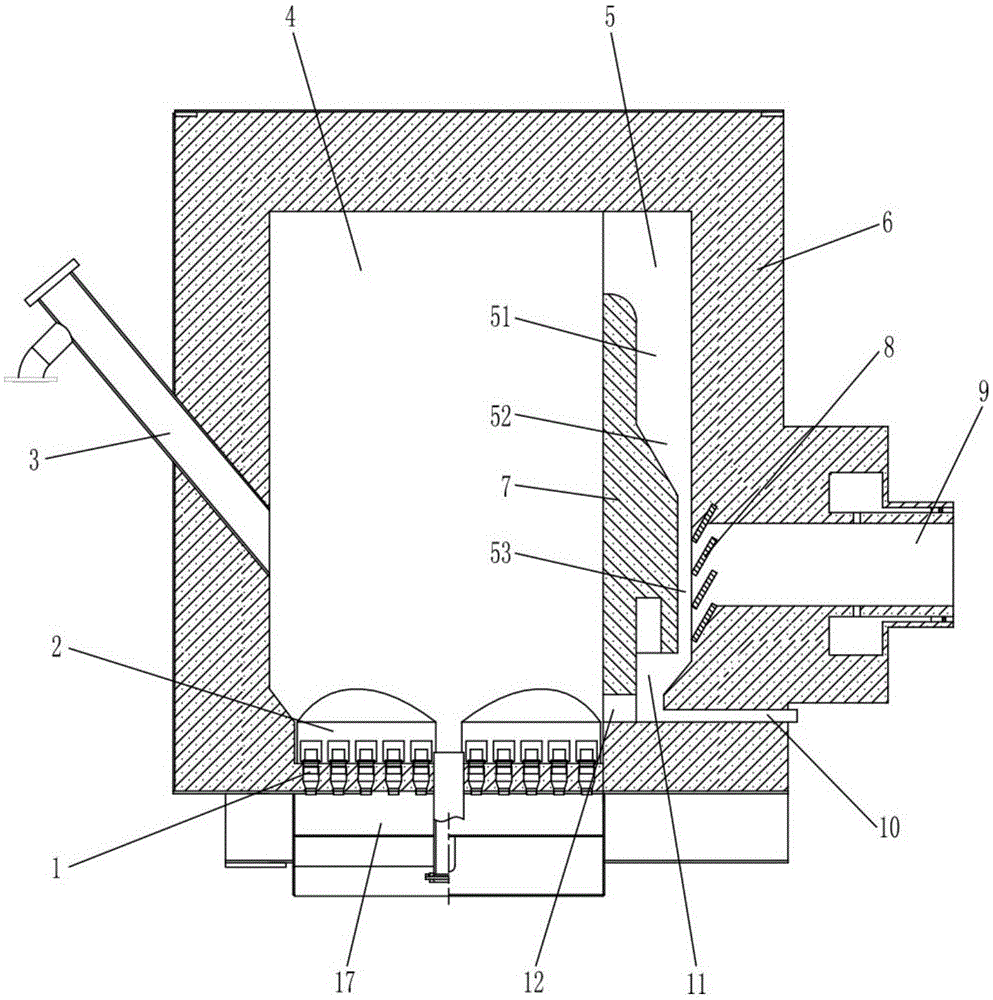

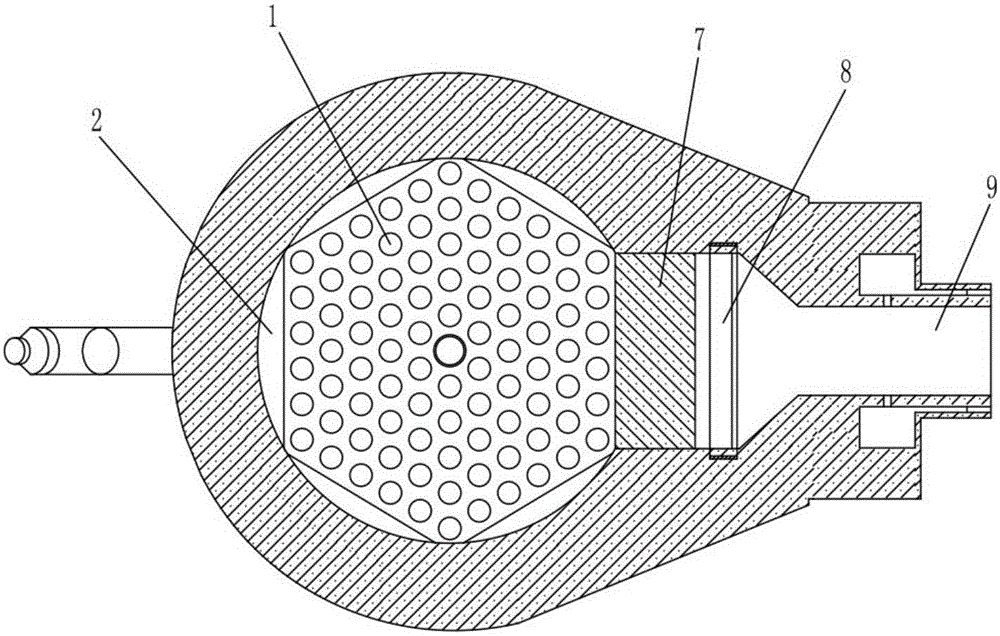

[0025] Such as figure 1 and figure 2 As shown, the biomass low-nitrogen fluidized bed burner includes a furnace body 6, a feed pipe 3, an air distribution plate 2, an equal pressure air box 17, an air cap 2, a partition wall 7, a material stopper 8 and a flame nozzle 9.

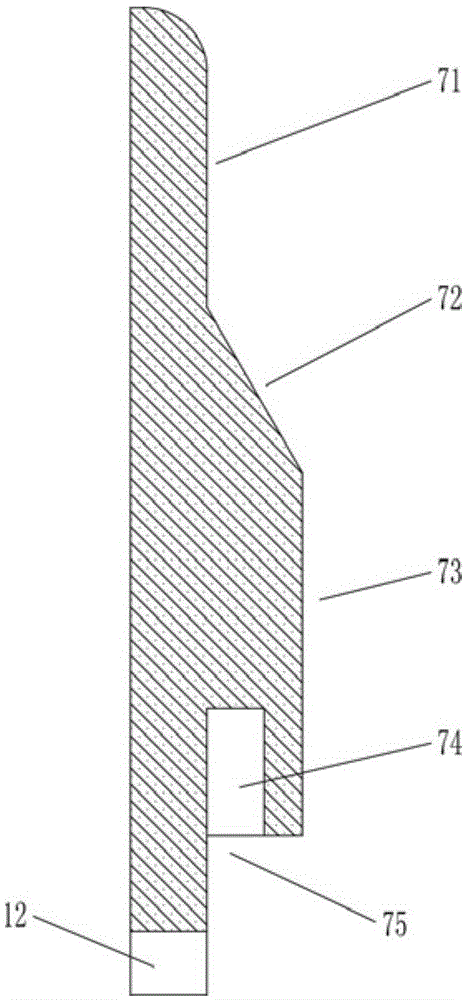

[0026] The cross-section of the inner cavity of the furnace body 6 has a C-shaped structure. The inner cavity of the furnace body 6 is provided with a partition wall 7, which divides the inner cavity into a combustion chamber 4 and a flue 5, and the upper part of the combustion chamber 4 communicates with the inlet of the flue 5. The combustion chamber 4 is used as the combustion area, which is in the form of a cylinder. The bottom of the combustion chamber 4 is set as the air distribution plate 2. The air distribution plate is hexagonal. Install the hood 2. Below the air distribution plate 2 is an equal pressure air box 17, the air distribution hole communicates with the equal pressure air box, and the e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com