Fluidized bed reactor

A fluidized bed reactor and reaction zone technology, applied in the field of desulfurization, can solve problems such as affecting the stable operation of the device and being unable to discharge the reactor.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

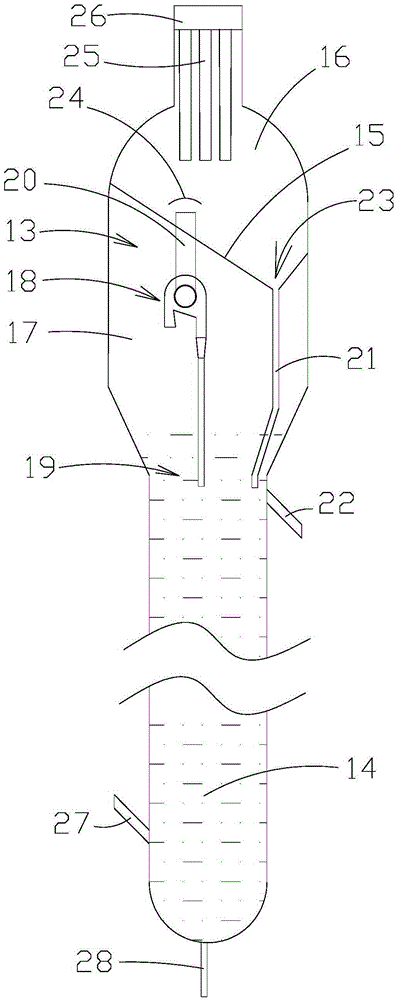

[0062] In this embodiment 1, if figure 1 As shown, the structure of the fluidized bed reactor is as follows:

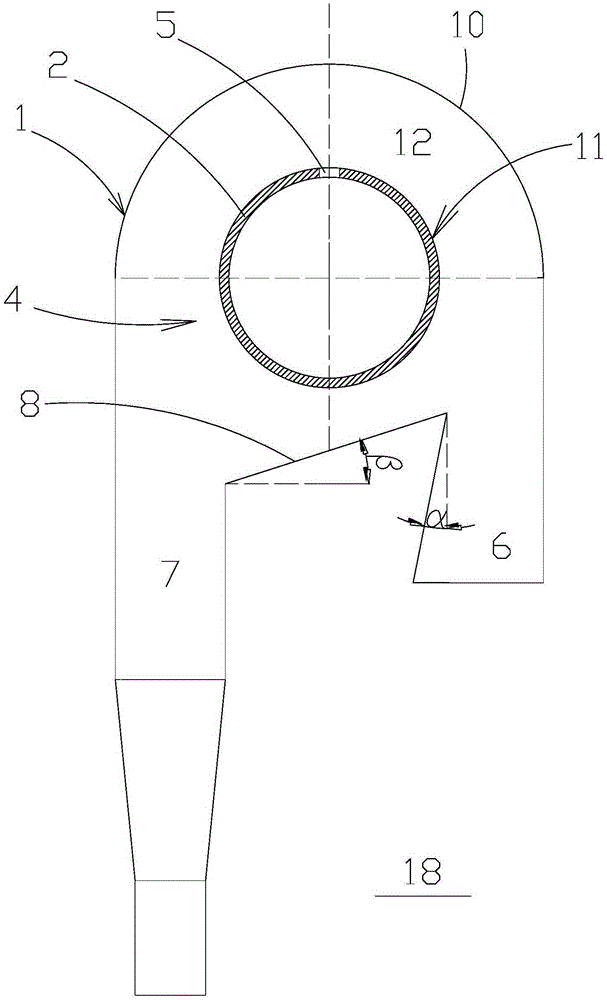

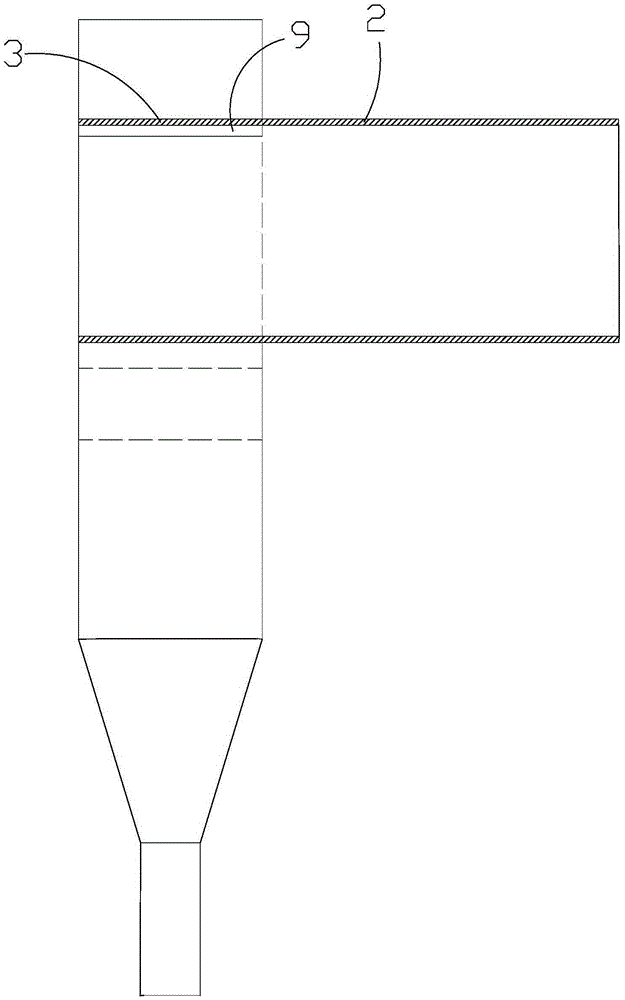

[0063] A partition body 15 is provided in the settling area 13, and the inclination angle of the partition body 15 is 20°. The upper part of the settling zone is provided with a metal filter tube filter, and the lower part of the settling zone is provided with 3 parallel gas-solid separation devices of the present invention uniformly distributed along the circumference, and the gas outlets of each gas-solid separation device are brought together to enter the upper chamber of the settling zone Chamber 16. At the same time, the angle α between the inner wall plate of the gas-solid mixed phase inlet section 6 of the gas-solid separation device and the vertical plane is 10°, and the angle β between the lower shell section 8 of the gas-solid separation device and the horizontal plane is 15°.

[0064] In this embodiment 1, the specific process is as follows.

[0065] The ...

Embodiment 2

[0071] Example 2 adopts the same method as Example 1 to carry out adsorption desulfurization, the difference is that only one gas-solid separation device 18 is provided in the lower chamber 17 of the settling zone.

[0072] Continuously for 500 hours. During the reaction process, the following indicators were monitored: (1) the composition of the obtained oil and gas product; (2) the dilute phase density in the upper space of the fluidized bed reactor settling zone, and the results are listed in Table 4.

[0073] Table 4

[0074] time / h 100 200 300 400 500 Product sulfur content / wppm 4.6 3.4 5.7 4.5 3.5 Antiknock Index Reduction Value* 0.59 0.5 0.61 0.64 0.57 Dilute phase density in the settlement zone / kg m -3

[0075] *: Based on the antiknock index of sulfur-containing gasoline as a hydrocarbon feedstock, where antiknock index=(RON+MON) / 2

Embodiment 3

[0077] Example 3 adopts the same method as Example 2 to carry out adsorption desulfurization, the difference is that: the angle α between the inner wall plate and the vertical plane of the gas-solid mixed phase inlet section 6 of the gas-solid separation device is 5°, and the gas-solid separation device The angle β between the lower casing section 8 and the horizontal plane is 10°.

[0078] Adsorption desulfurization conditions include: the contact temperature is 420°C, the pressure is 4MPa in absolute pressure, the sulfur-containing hydrocarbon feedstock enters the reactor at a speed of 0.3m / s, and the oil mixture in the settling zone flows at a speed of 3.5m / s Enter the guide air intake channel.

[0079] Continuously for 500 hours. During the reaction, the following indicators were monitored: (1) the composition of the obtained oil and gas product; (2) the density of the dilute phase in the settling zone of the fluidized bed reactor, and the results are listed in Table 7. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com