Portable nozzle and fluidized bed reactor with same

A nozzle and nozzle body technology, applied in the field of carrying nozzles, can solve the problems of lack of carrying capacity, complex structure and equipment, cumbersome process, etc., and achieve good catalyst fluidization effect and gas-liquid distribution effect, which is beneficial to the reaction process and bed layer The effect of temperature uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

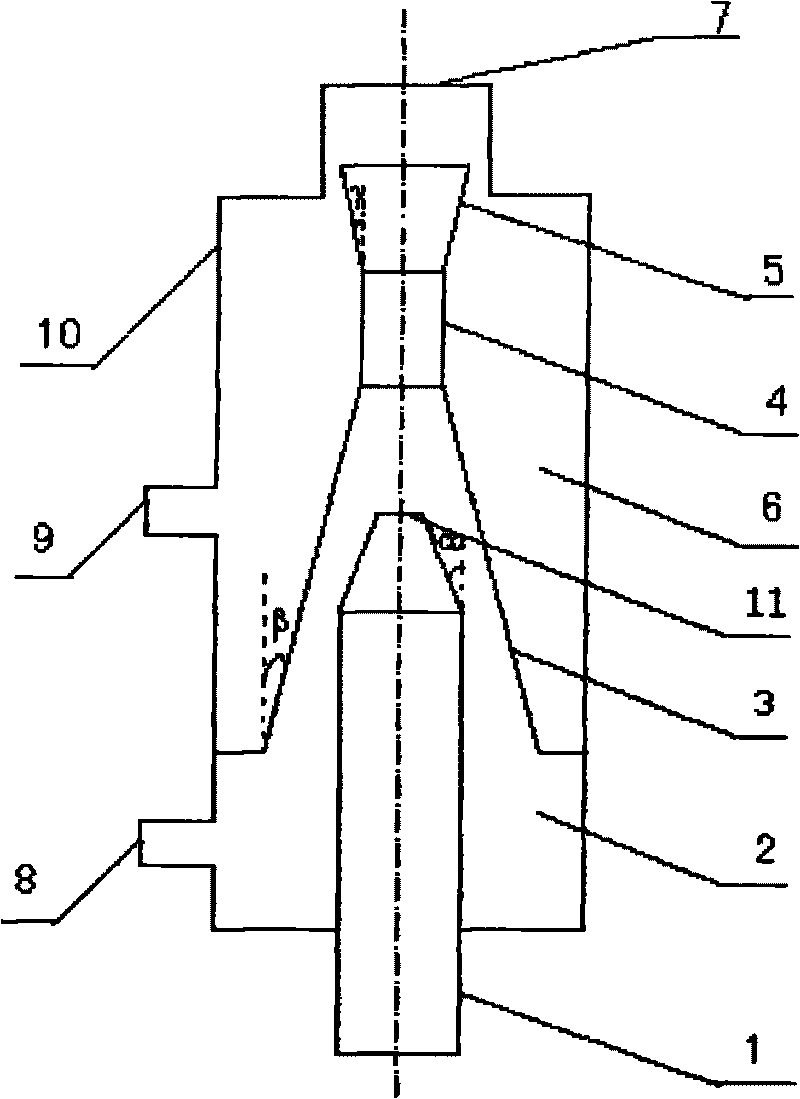

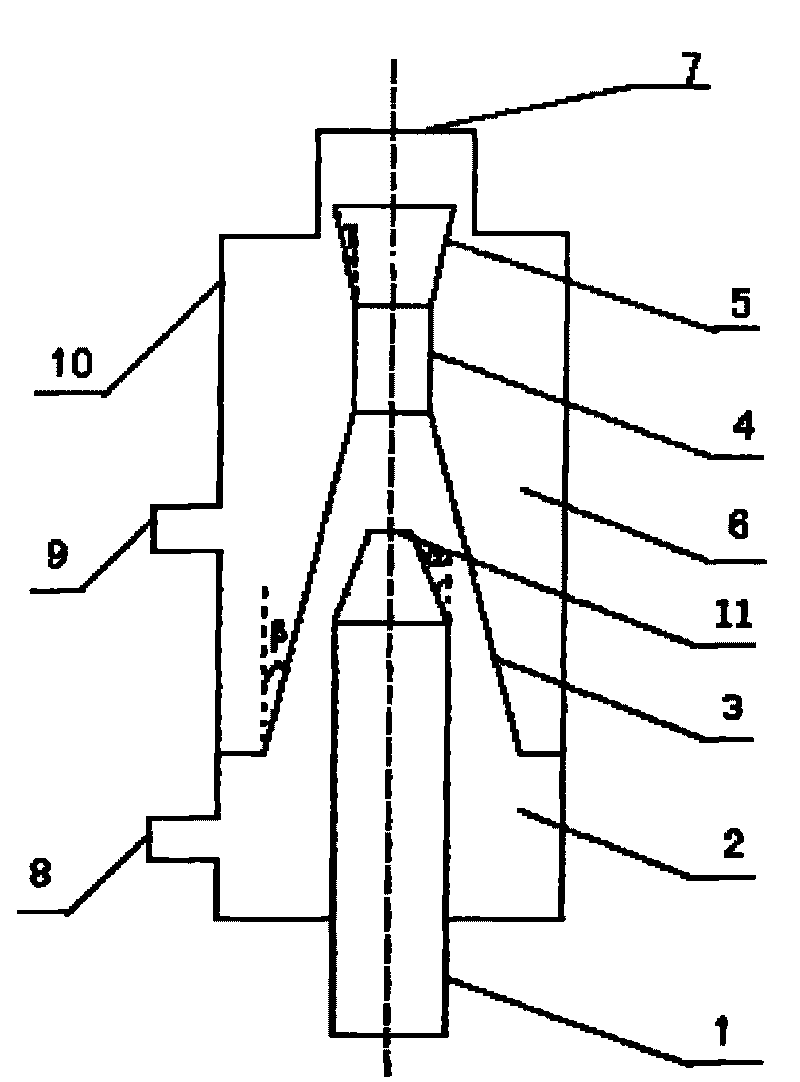

[0015] The structure of the carrying nozzle of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0016] Such as figure 1 Shown, the mouth body 10 of carrying nozzle of the present invention is tubular cylinder, and its one end is provided with mixture outlet 7, and the other end is feed end; Oil ascending section 2, constricting section 3, throat pipe 4, diffusing section 5 and gas ascending section 6; the feed end of the nozzle is provided with a raw oil feed pipe 1 and a circulating oil inlet 8, and a gas inlet 9 is provided at the gas ascending section; The raw material oil feed pipe 1 is coaxial with the nozzle body 10, and the nozzle 11 extends into the constriction section 3 all the time.

[0017] In order to obtain a higher linear velocity of raw material oil, the nozzle 11 is set in a contracted shape, and the contraction angle (expressed by α) of the nozzle is generally selected from 5 to 30 degrees, preferably 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Contraction angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com