Recycling process for waste furnace slag in fluidized bed boiler combustion system

A fluidized bed boiler and combustion system technology, applied in fluidized bed combustion equipment, fuels burned in a molten state, combustion methods, etc., can solve problems such as energy waste, environmental pollution, and high carbon content in slag, and achieve increased Effectiveness, saving coal resources, reducing environmental pollution and resource waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

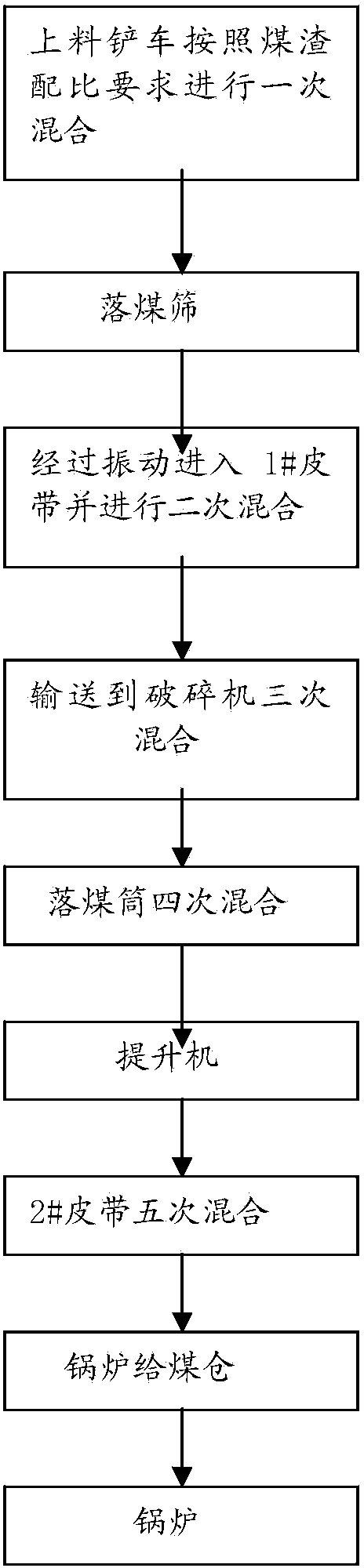

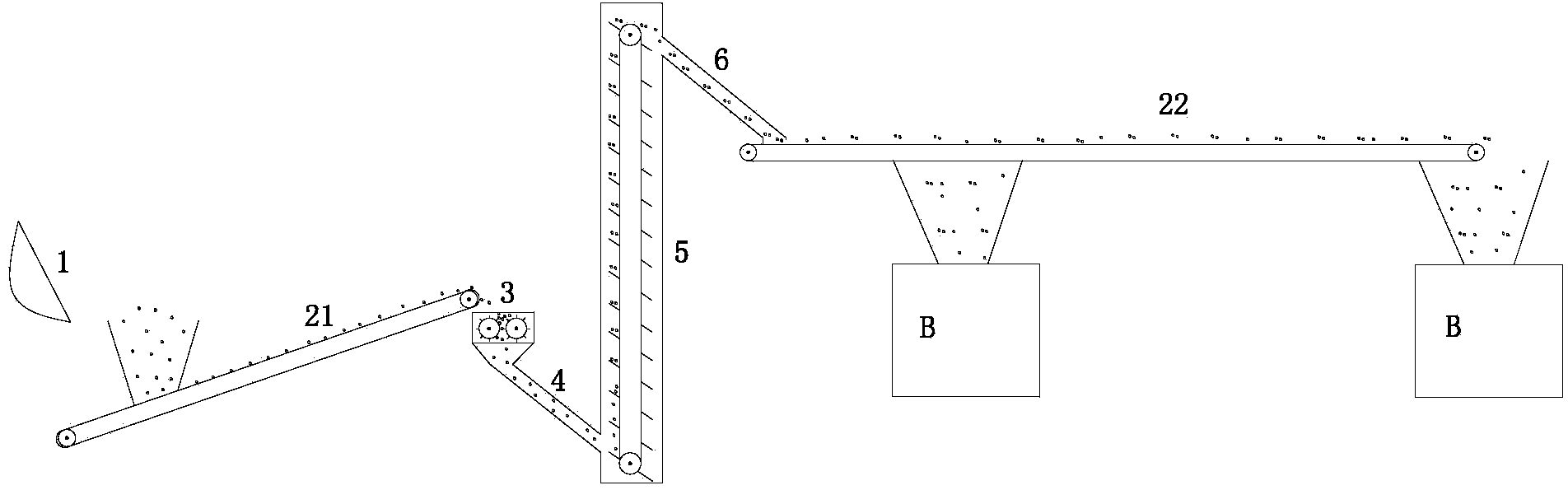

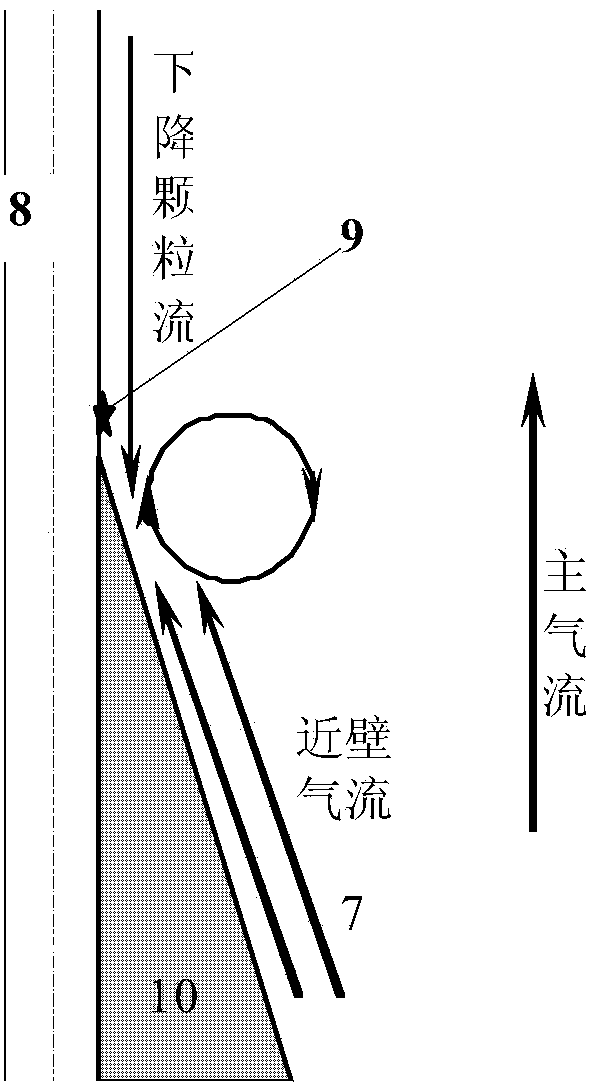

[0027] In order to better understand the purpose, structural features and functions of the present invention, the process of reusing waste slag in the combustion system of the fluidized bed boiler described in the present invention will be described in detail below in conjunction with the background of the present invention, drawings and actual working conditions describe.

[0028] First, analyze the combustibility of waste coal slag to determine the feasibility of burning and reusing slag. Generally, those skilled in the art regard waste slag with a low calorific value lower than 2200 kcal as non-reburnable slag; Table 1 below Table 2 and Table 2 respectively show the calorific value analysis results of the 10-ton chain boiler slag and the 20-ton chain boiler slag by the iron ore metrology and inspection department. The average calorific value of the boiler slag is 2924.1 kcal, that is, the calorific value of the 10-ton chain boiler slag and the 20-ton chain boiler slag are b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com