Patents

Literature

45results about How to "Save coal resources" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Thermal power plant generator set varying duty energy consumption analysis method based on approach method

InactiveCN103678915AReduce coal consumption for power generationSave coal resourcesSpecial data processing applicationsProcess engineeringAnalysis method

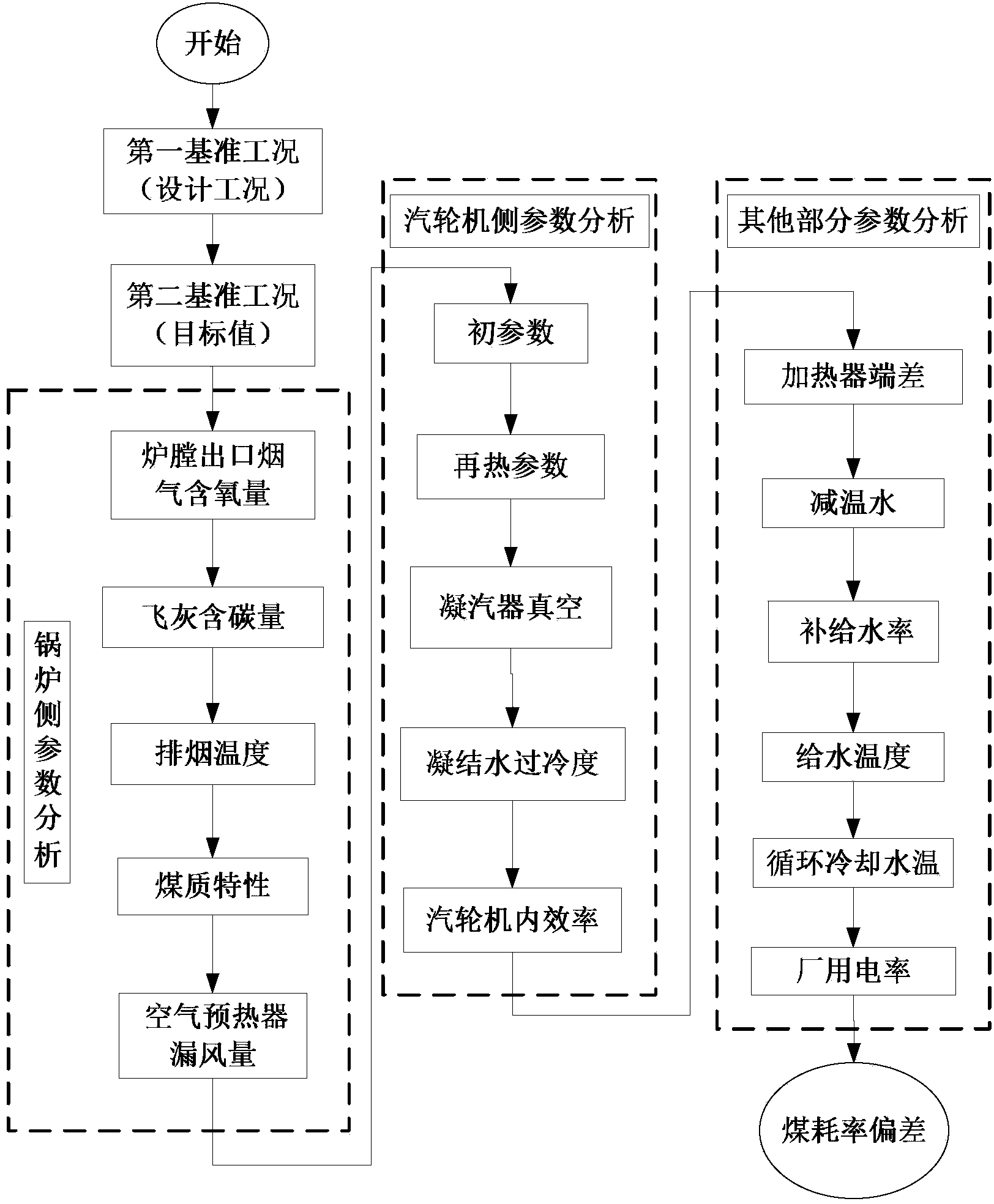

The invention discloses a thermal power plant generator set varying duty energy consumption analysis method based on an approach method. According to the method, 18 operating parameters with large influence on economical efficiency of generator sets are selected as analyzing objects according to long-tern operation experience, an operation statistic optimum value is used as an operation reference value, a series of working conditions is hypothesized between a stable operation condition and an actual operation condition, the 18 operating parameters are made to approach an actual operation value from the operation reference value one by one, energy consumption analysis of varying duty is carried out according to coal consumption difference values in the approaching process, parameters having large influences on coal consumption levels in the varying duty process are obtained through ranking, guide bases are provided for the determination of duty varying speed, duty varying scope and the time of a stabilization section in varying duty operation of a million-level set, the purpose of reducing coal consumption for electricity generation in the duty varying operation of a power plant is achieved, the task of duty varying is completed, and coal resources are saved at the same time.

Owner:ELECTRIC POWER RES INST OF GUANGDONG POWER GRID +1

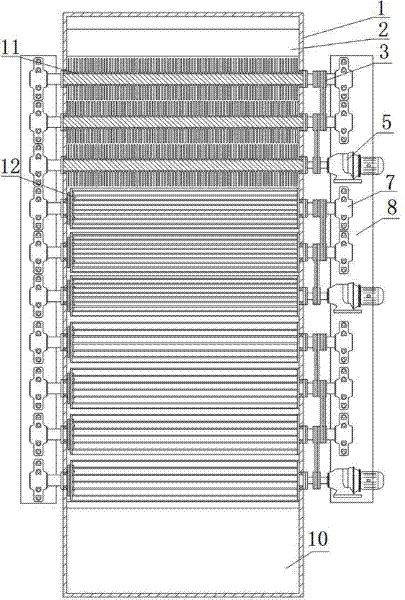

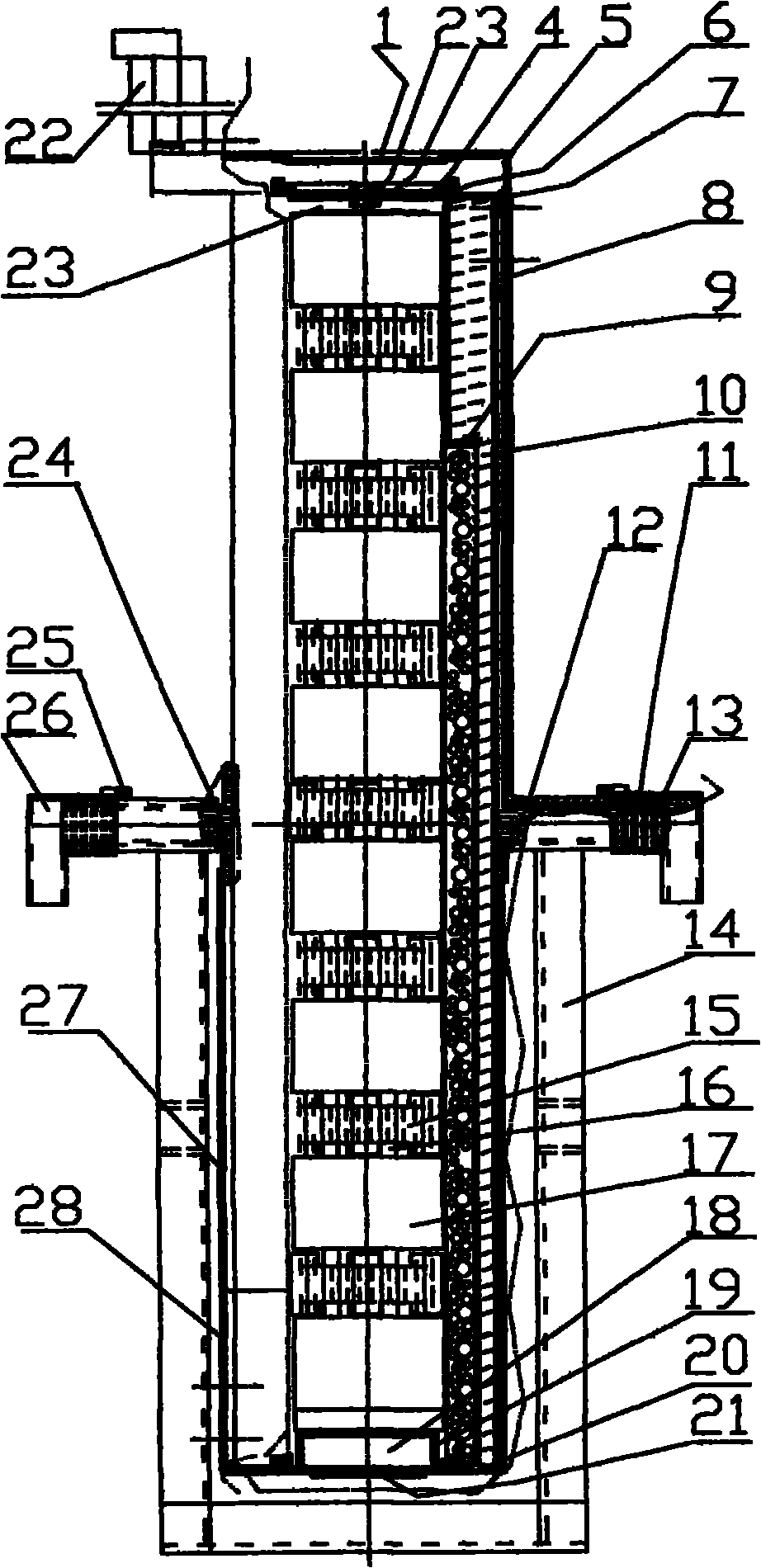

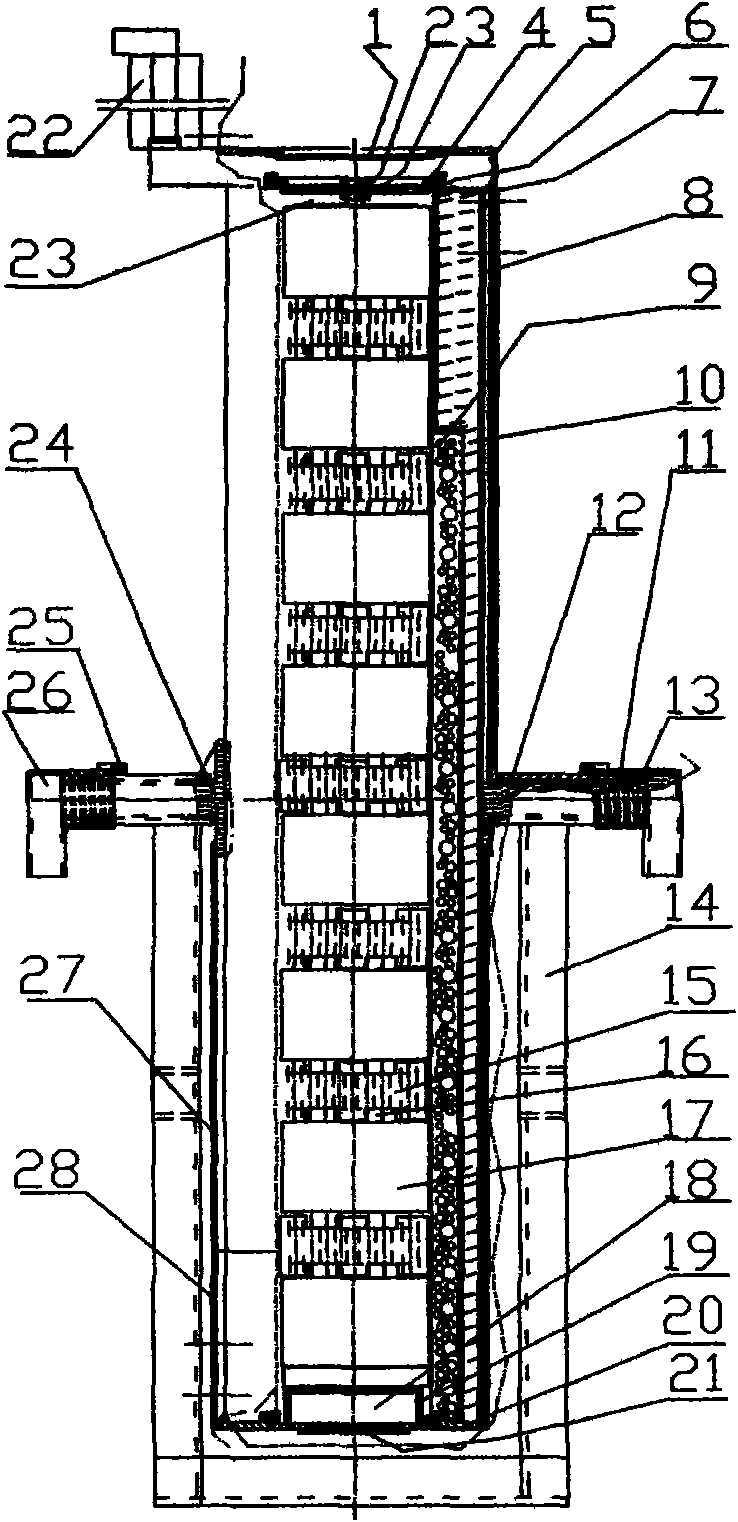

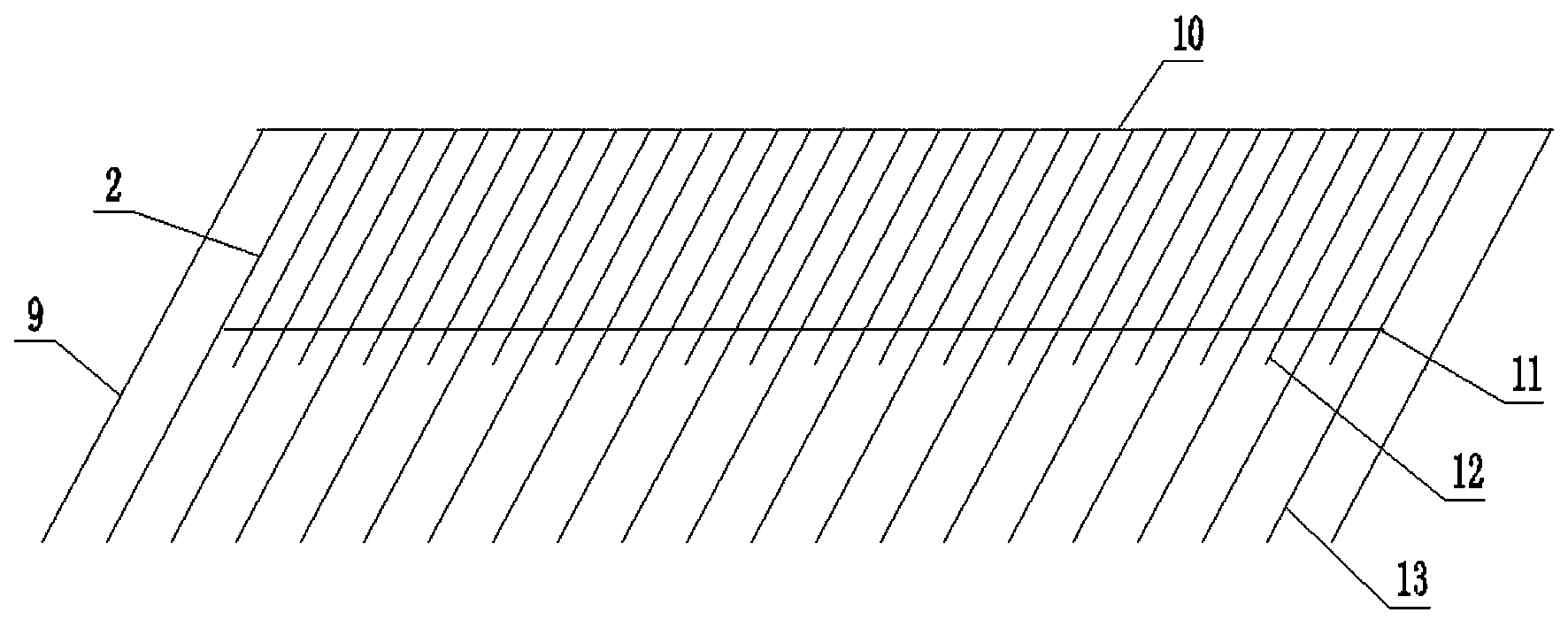

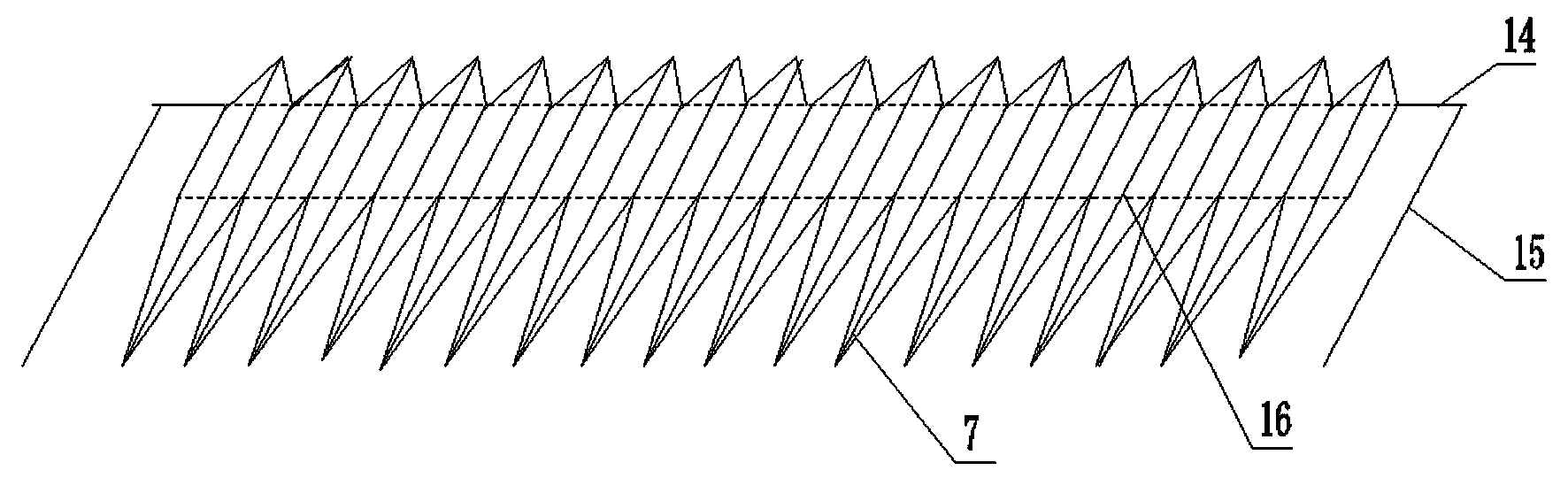

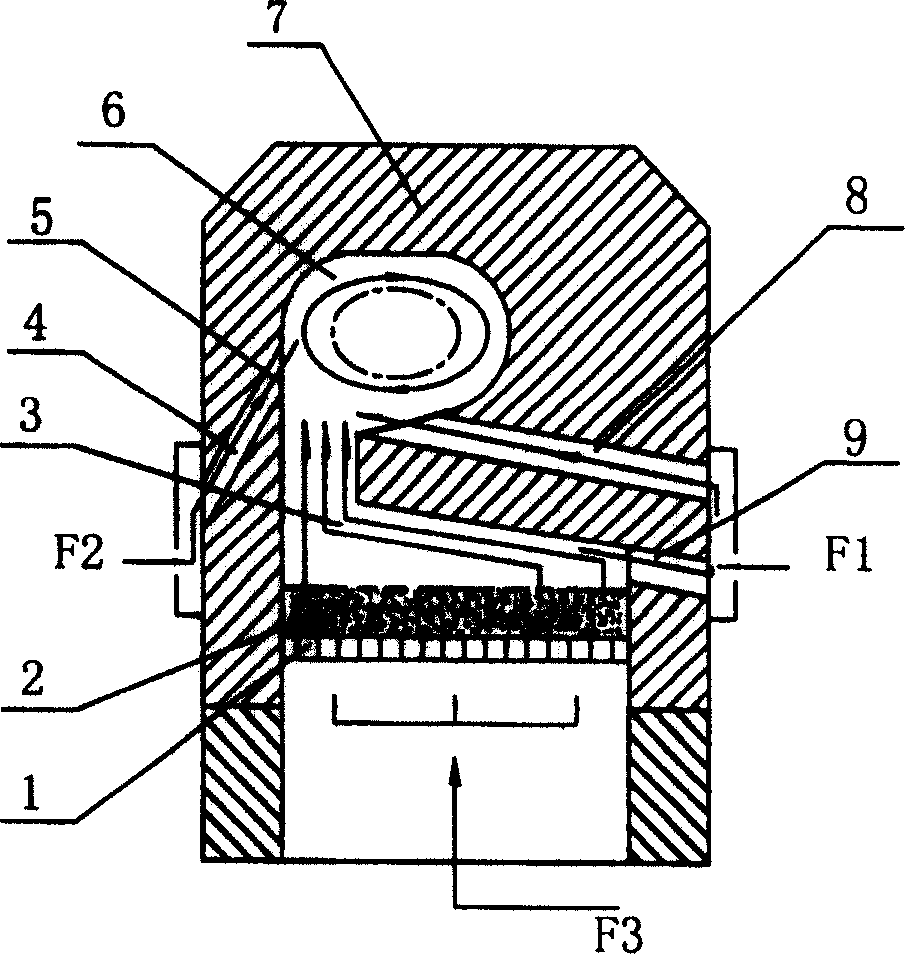

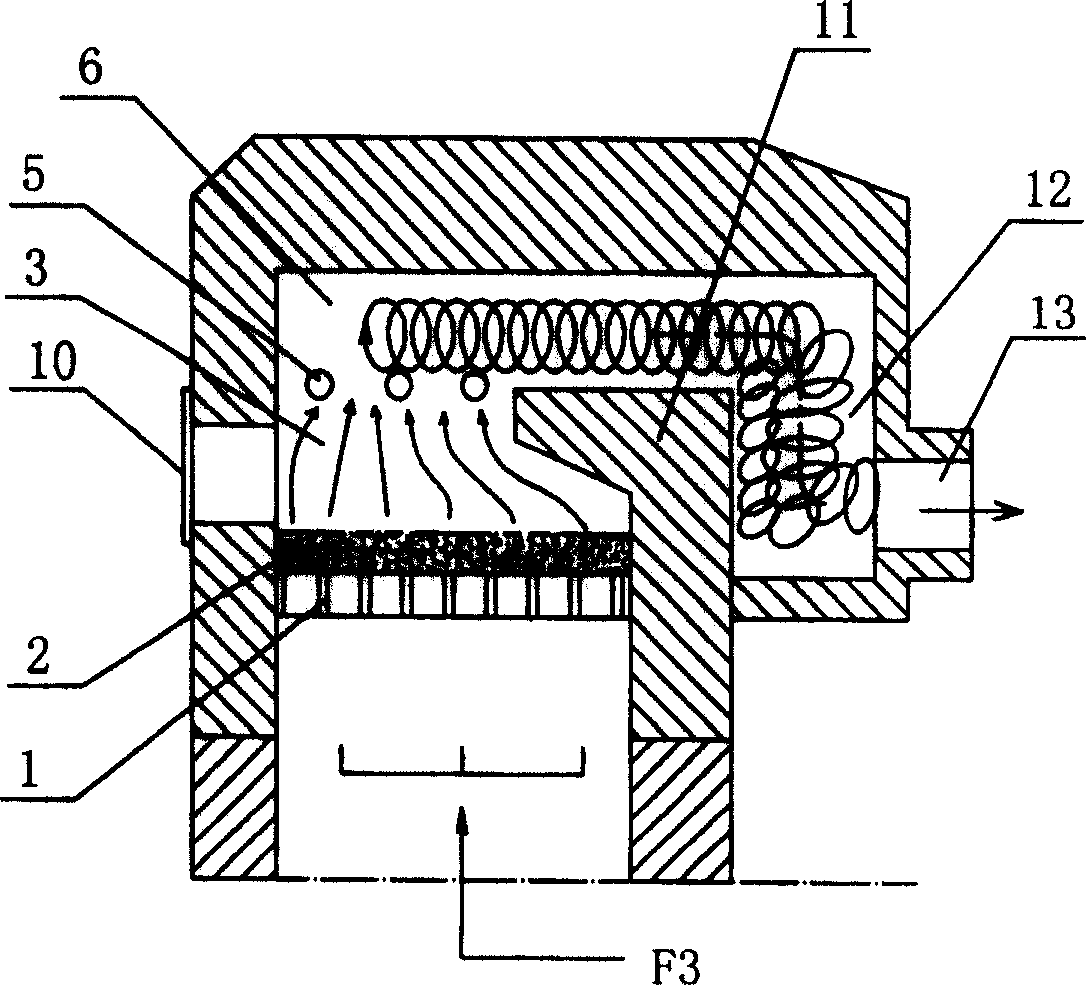

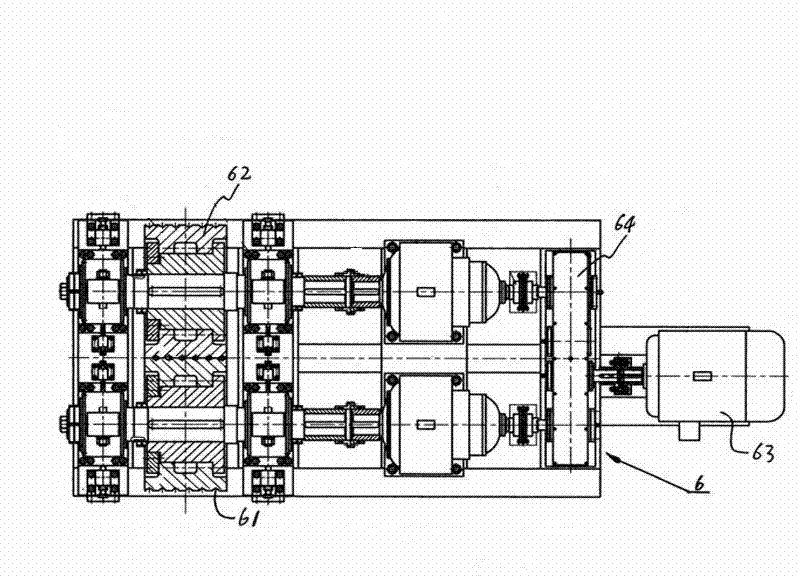

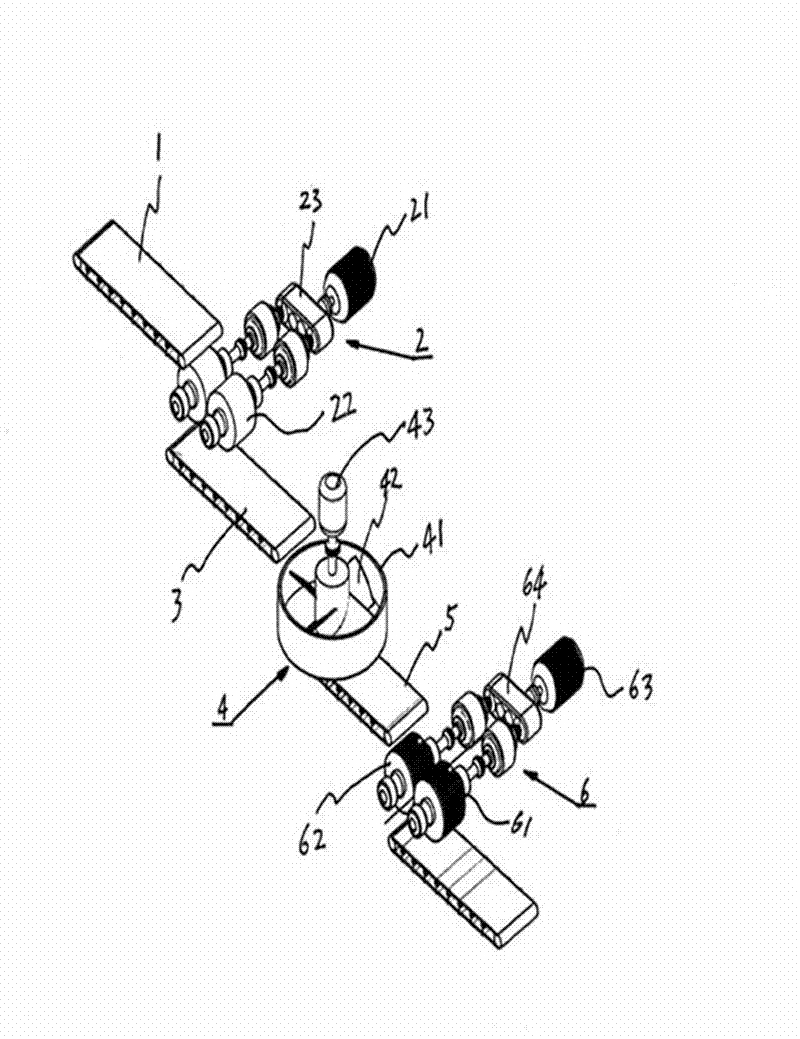

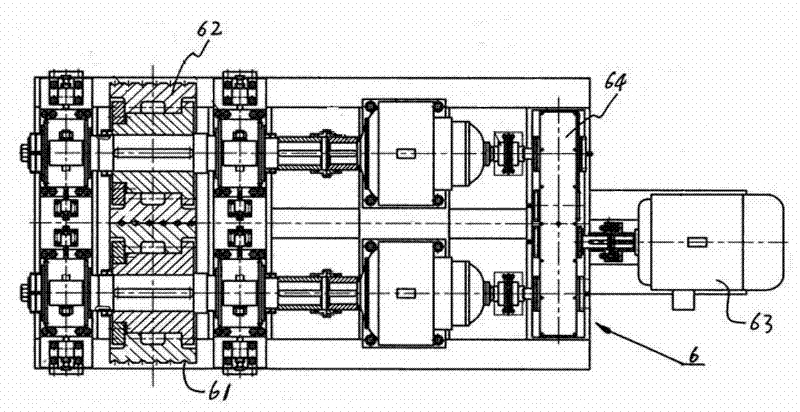

Material distributing screening machine

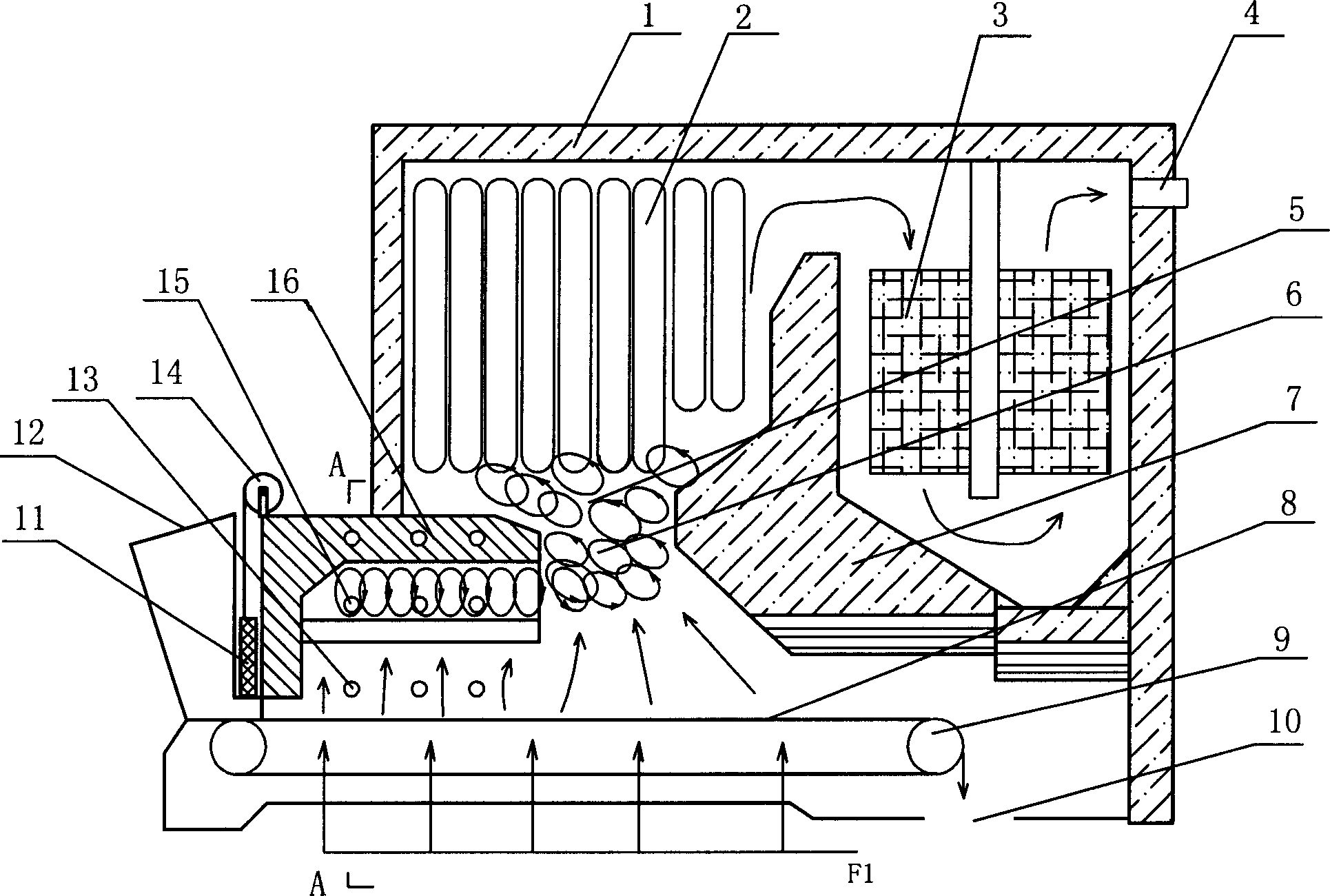

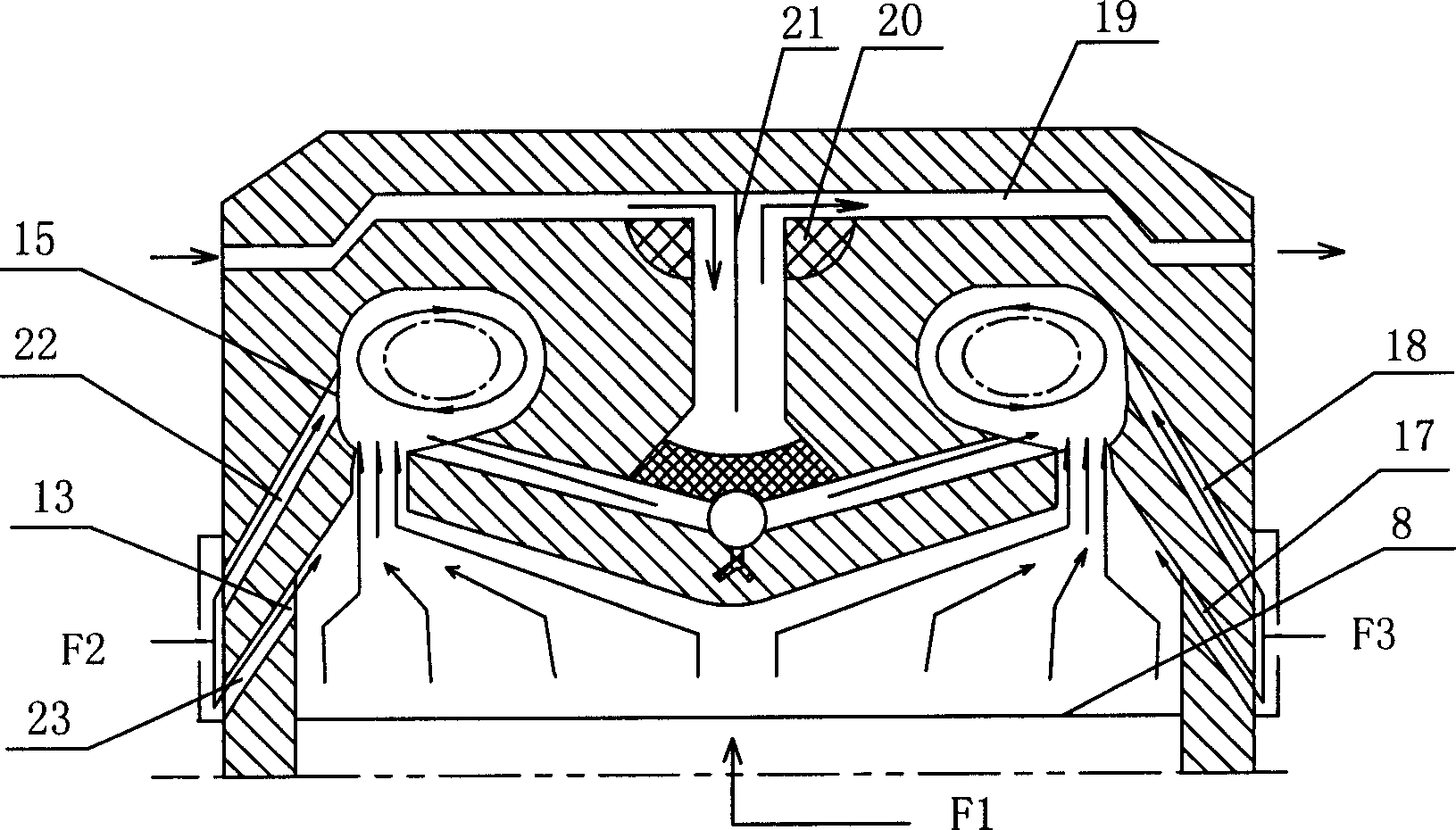

The invention discloses a material distributing screening machine, comprising a machine case (1), a forced fabric plate (2), a driving device (3), a filtering roller (4), a reducer motor (5) and an iron removing device (24), wherein the machine case (1) is provided with a feeding hole (6) and a plurality of discharging holes (10), the filtering roller (4) comprises a flange disk type roller (11) and a filtering rope type roller (12), the filtering roller (4) is provided with the driving device (3), the reducer motor (5) drives the filtering roller (4) to rotate by virtue of the driving device (3), and material enters from the feeding hole (6), is screened by the filtering roller (4) and is discharged by the discharging hole (10). The invention has the beneficial effects that: more than two materials in different grain sizes can be screened by setting different interstitial screen cuts, the working condition requirement for screening more than two materials can be met, screening efficiency is high, bulk material impact resistance is high, material is distributed more uniformly, no blockage is caused, and an iron piece contained in the material can be removed.

Owner:SICHUAN ZHONGMENG ELECTRIC POWER EQUIP MFG CO LTD

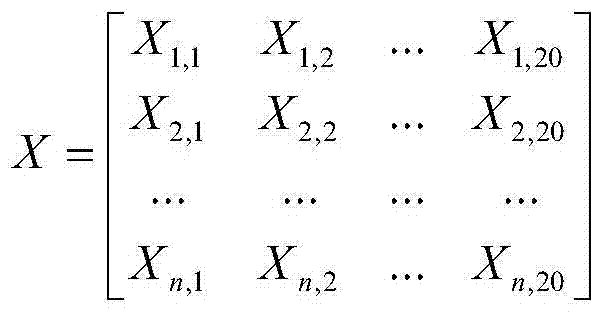

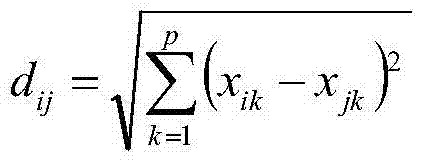

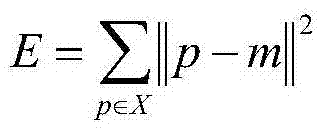

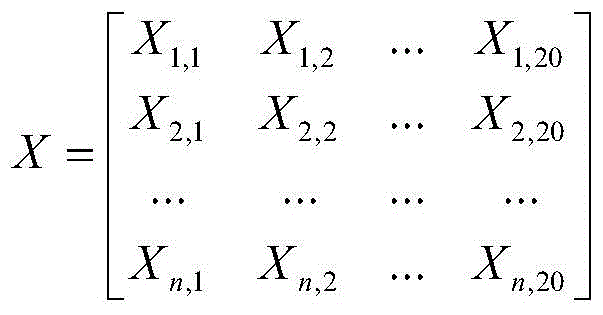

Energy consumption difference analysis method for load varying of ultra-supercritical generating unit of thermal power plant

ActiveCN103699786AReduce coal consumption for power generationSave coal resourcesTechnology managementSystems intergating technologiesCoalProcess engineering

The invention discloses an energy consumption difference analysis method for load varying of an ultra-supercritical generating unit of a thermal power plant. The method comprises the steps of selecting eighteen operation parameters having a greater influence on the economy of the unit as analysis objects; applying a clustering method to the eighteen operation parameters to obtain an operation optimum condition: taking the operation optimum condition as a stable operation standard working condition, and selecting eighteen actual working conditions from a load varying range; taking eighteen parameter influencing factors as independent variables: establishing eighteen equations by taking the energy consumption difference between a single influencing parameter change value and a stable operation standard value as a coefficient of the parameter influencing factor and taking the energy consumption difference between an actual working condition and the stable operation standard working condition as a dependent variable, and finally solving to obtain eighteen parameter influencing factors; finally sequencing the eighteen parameter influencing factors to obtain a parameter having the greatest influence on the coal consumption level in a load varying process. Guidance basis is provided for determination of load varying velocity, load varying amplitude and stable stage time in the load varying operation of million of units, so that the aim of reducing the coal consumption in electricity generation in the load varying operation of the power plant is achieved.

Owner:ELECTRIC POWER RES INST OF GUANGDONG POWER GRID +1

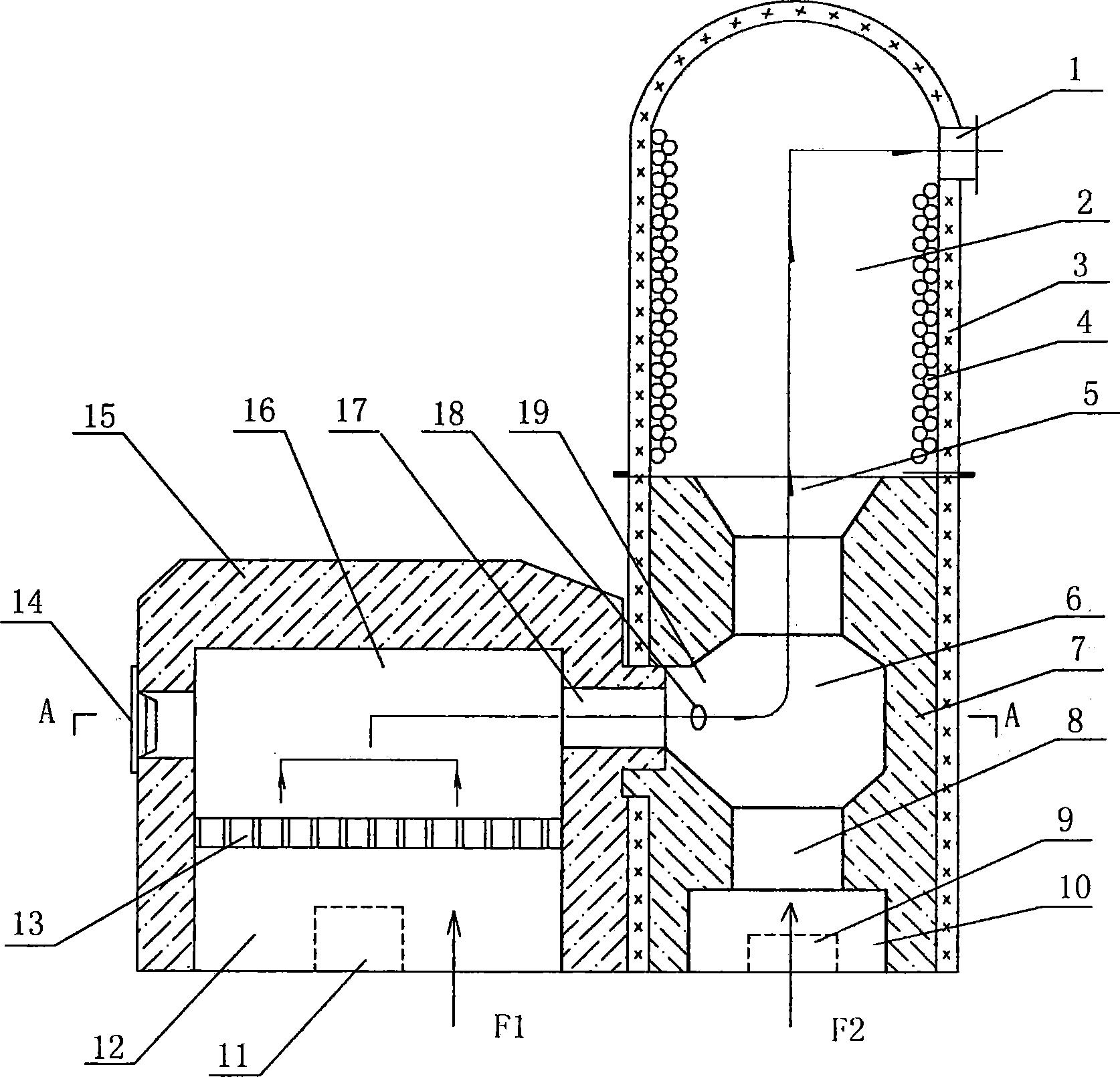

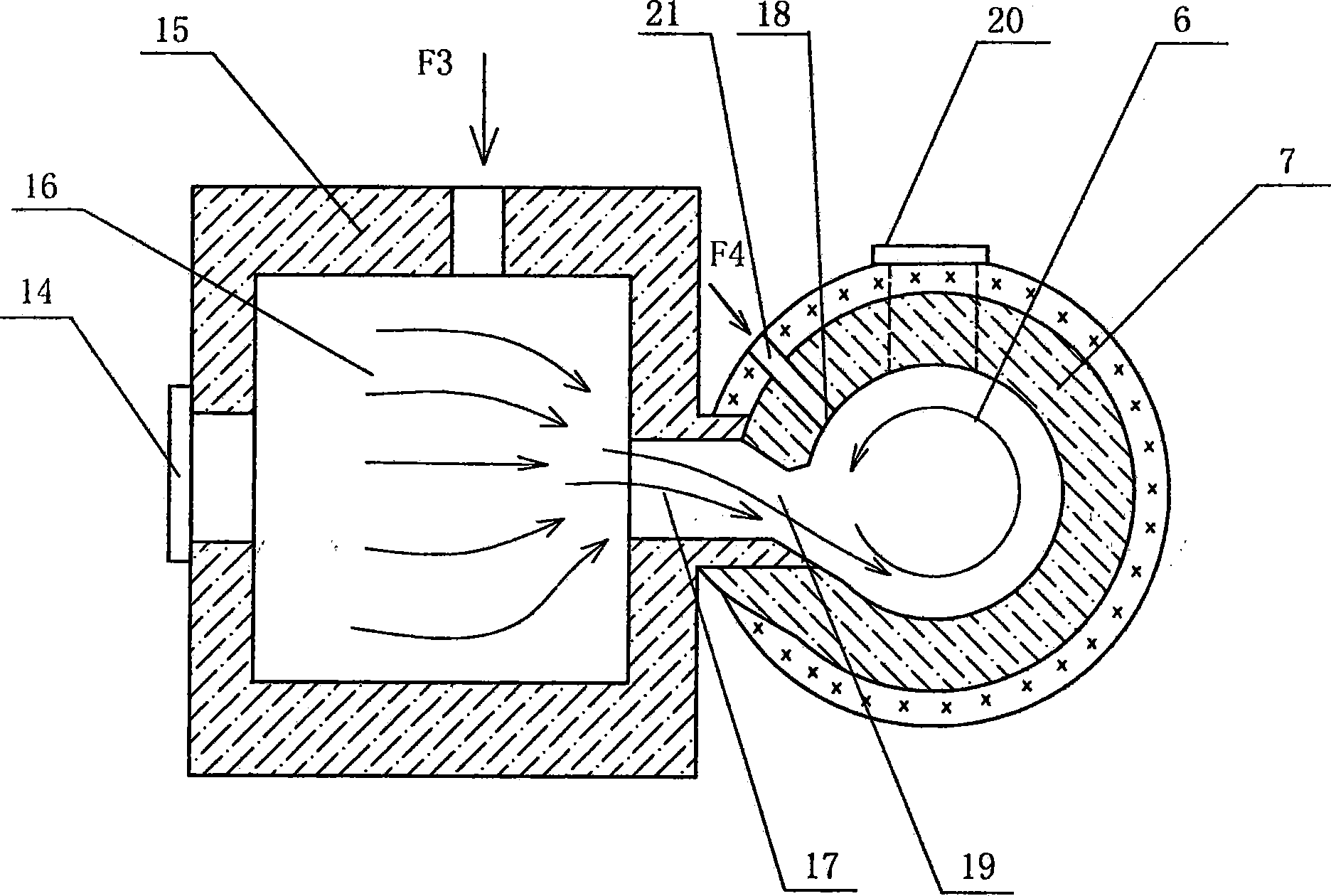

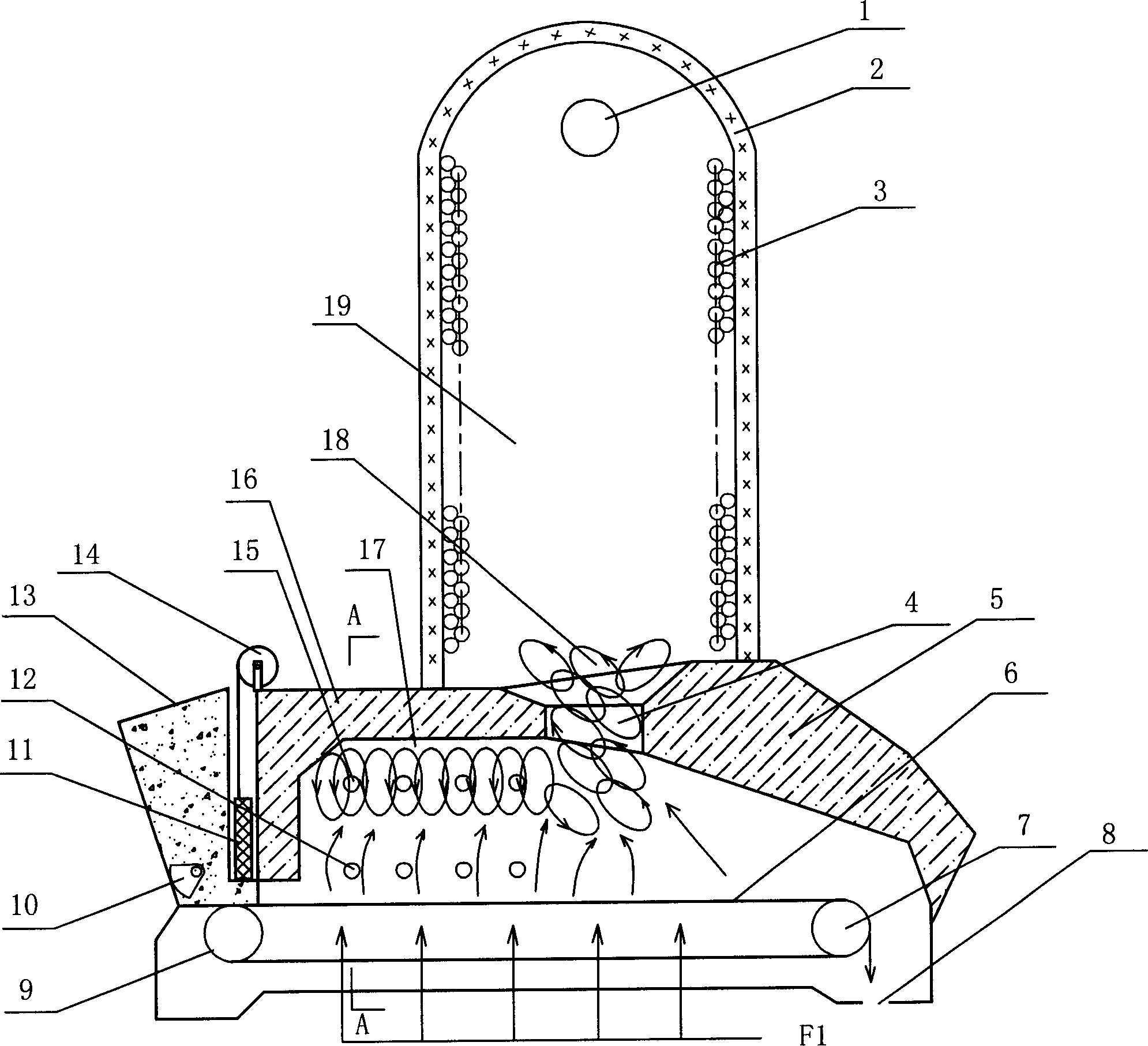

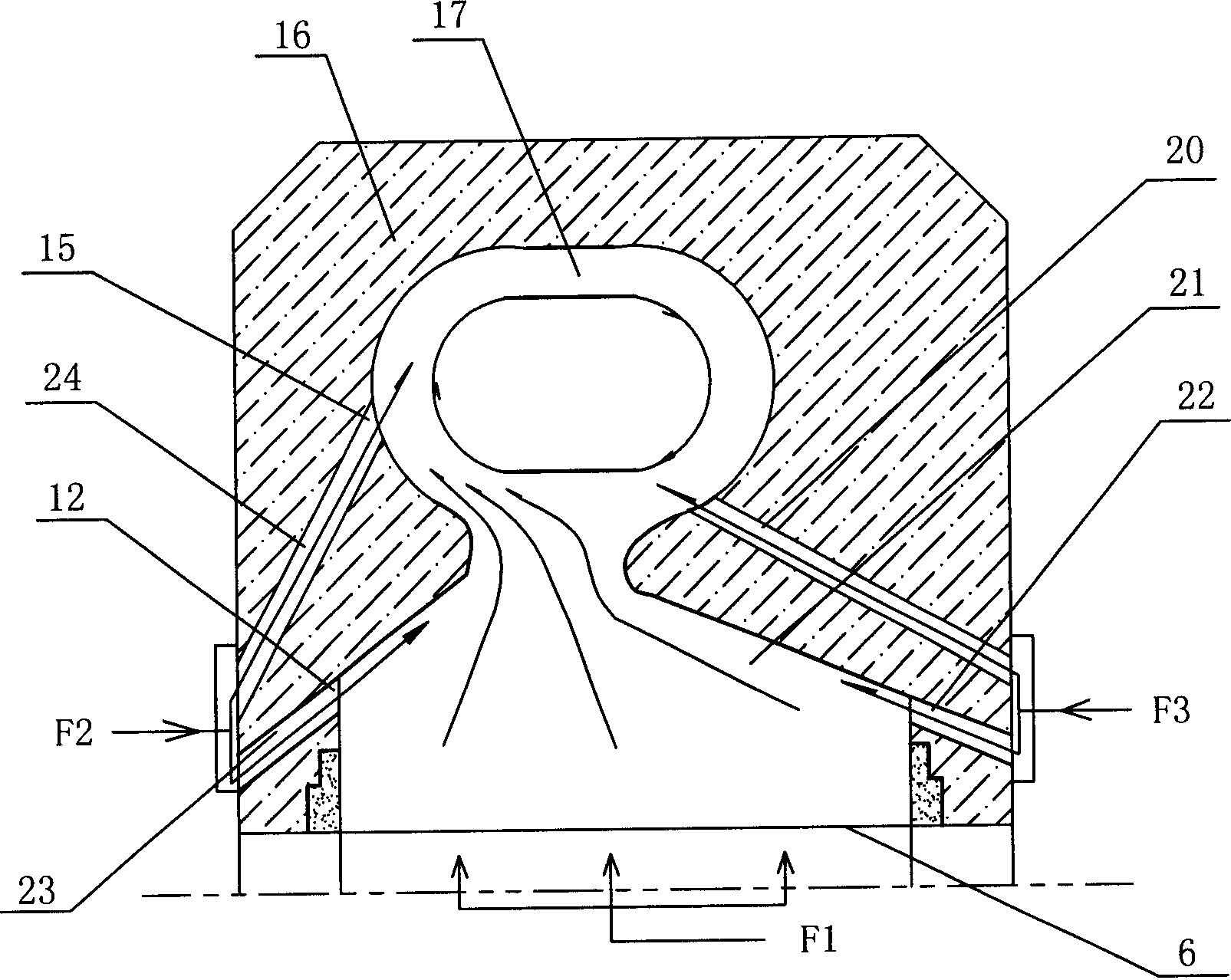

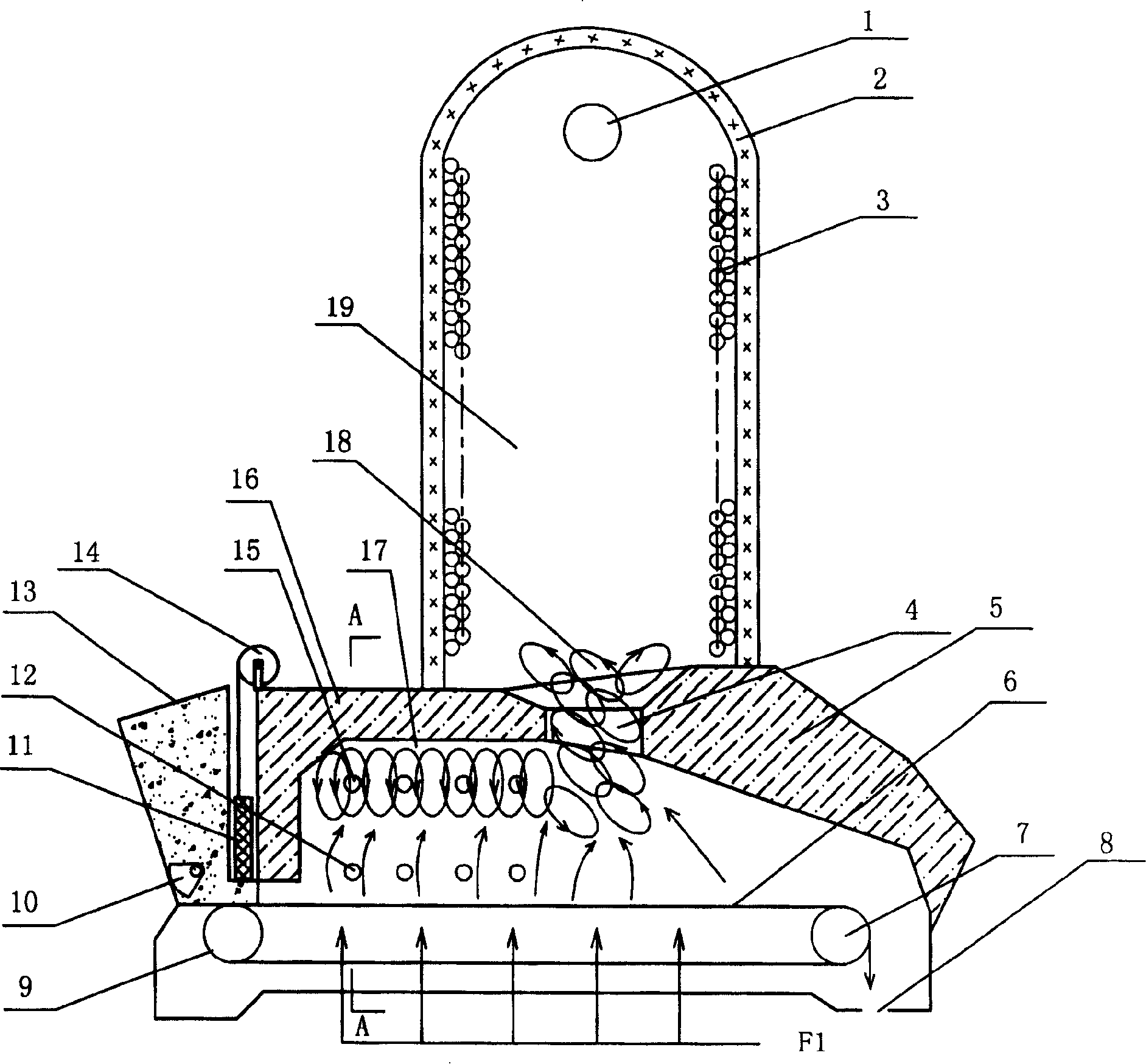

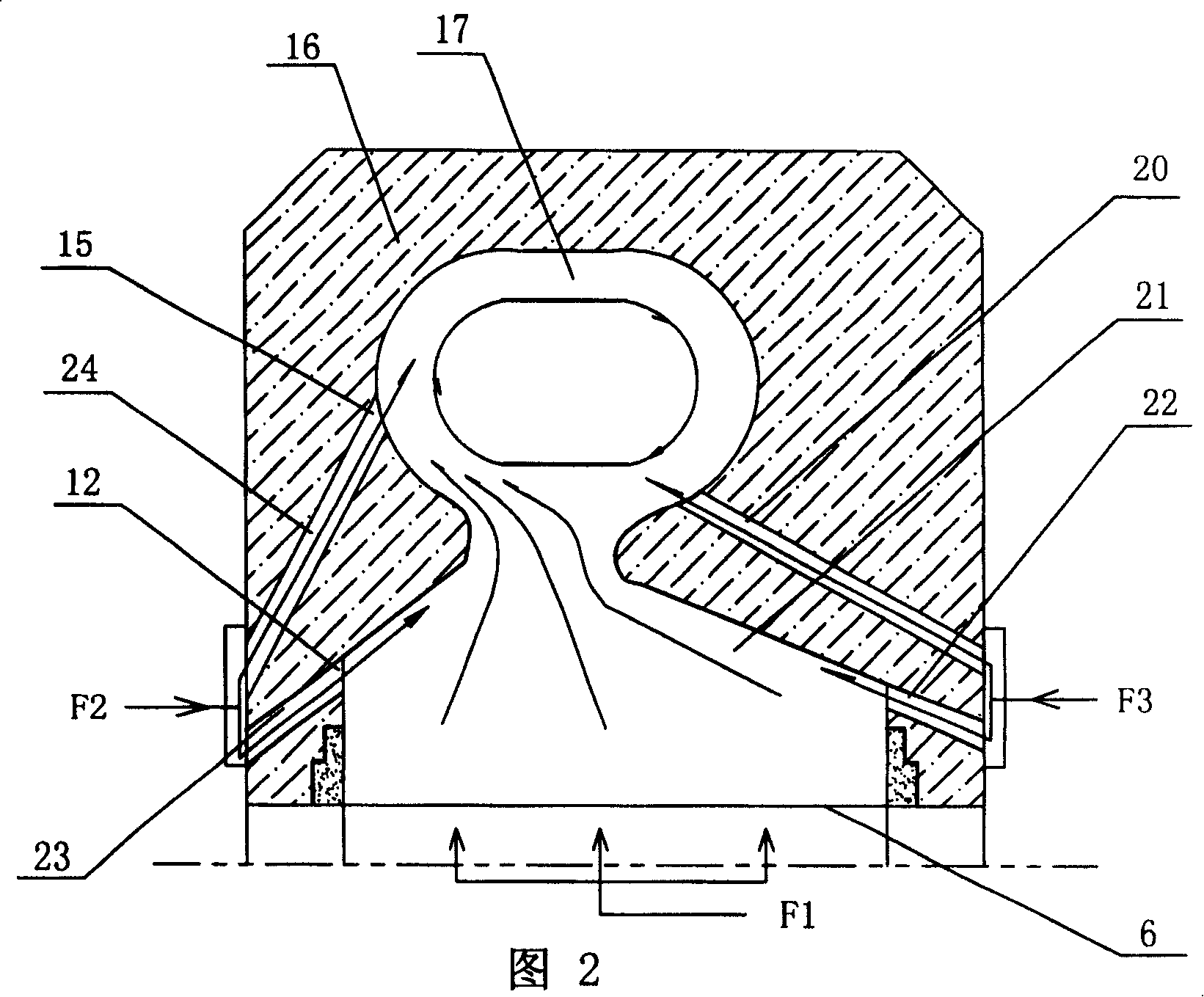

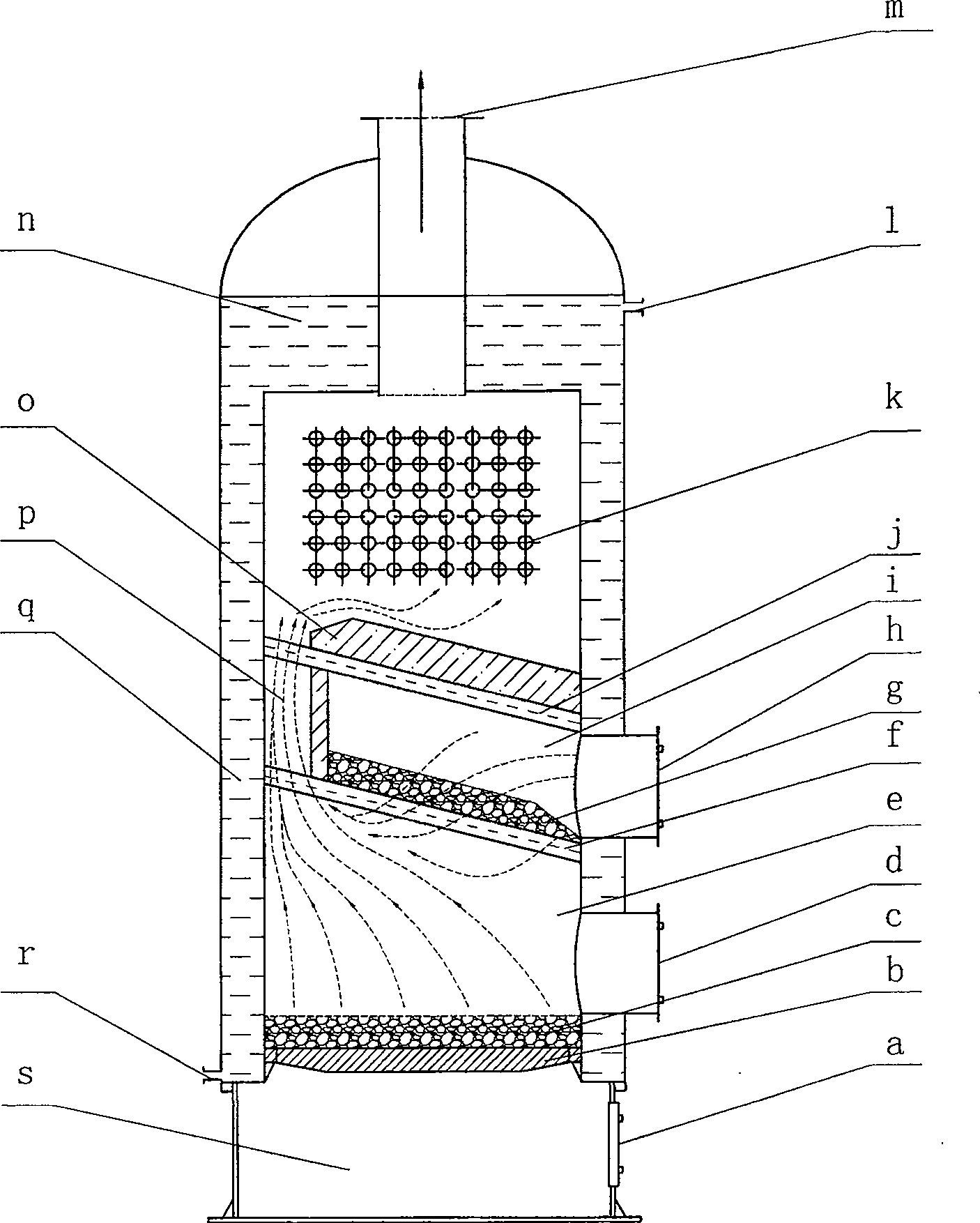

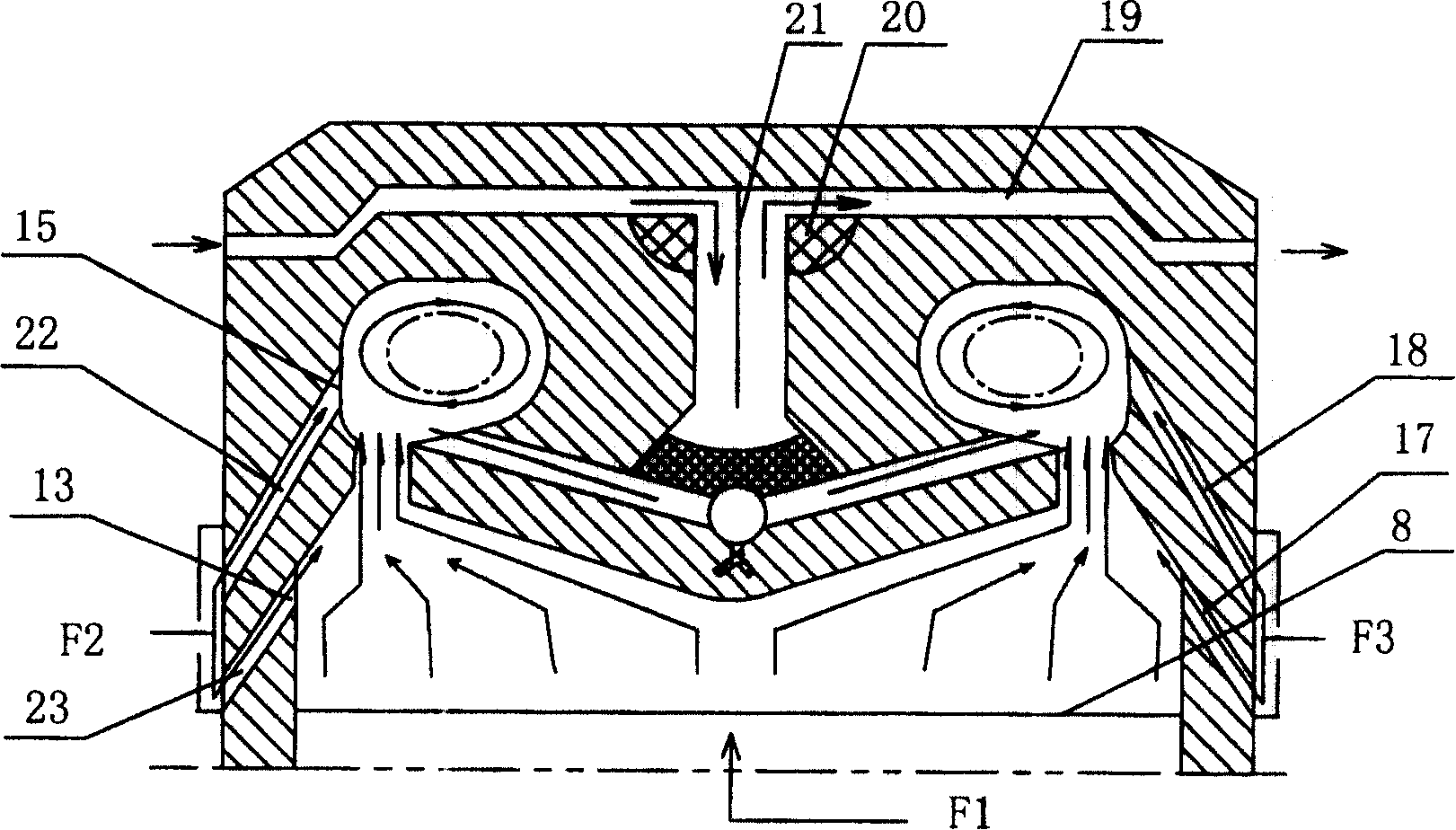

Pure smokeless, coal saving type heat transfer oil stove with external combustion and inner rotational flow

InactiveCN1873320AConvenient for centralized processingNo pollution in the processSolid fuel combustionCombustion apparatusCycloneCombustion

The present invention relates to a pure smokeless coal-saving type external-combustion internal-cyclone heat-conducting oil-fired boiler. It is characterized by that the upper portion of its furnace body is heating zone, the interior of furnace body of heating zone is equipped with heat-conducting oil pipe, the top portion of said heating zone is equipped with a draught fan, the lower portion of said furnace body is coal-burning zone, said coal-burning zone is equipped with a coal-burning device, its coal-burning device includes coal-burning combustion device outside of furnace body and cyclone combustion device in the furnace body, said coal-burning combustion device includes coal-adding mouth. Besides, said invention also provides the concrete structure of said cyclone combustion device. Said invention can completely solve the problem of discharging black smoke by burning coal, and can save coal resource and raise heat efficiency.

Owner:王树洲

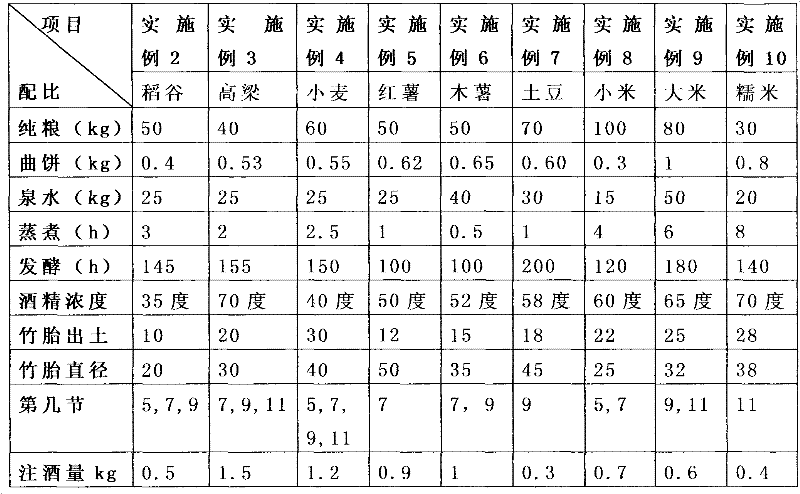

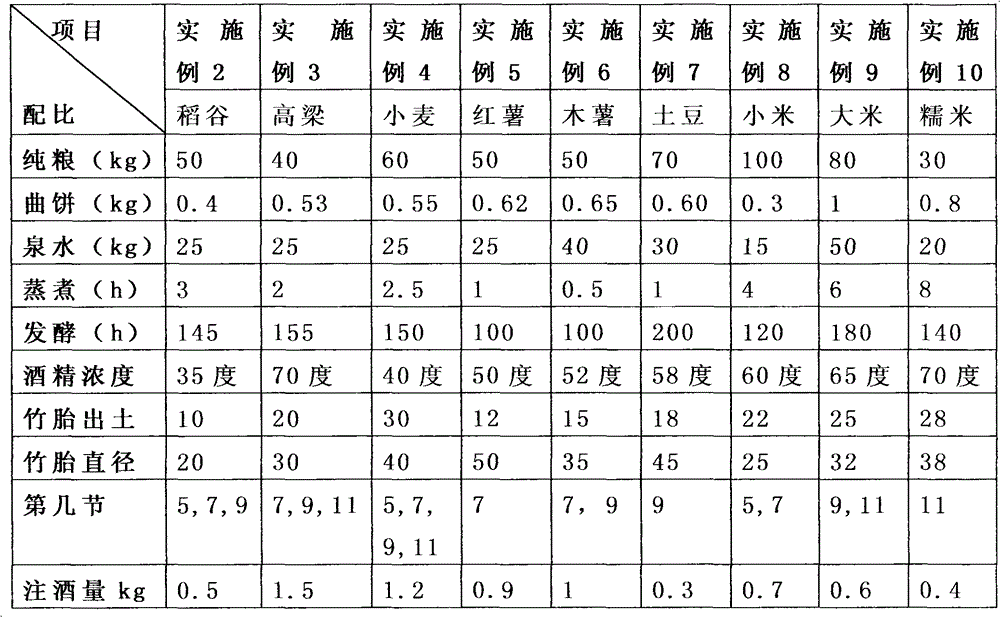

Bamboo embryo wine and preparation method thereof

InactiveCN102533488ABeautiful colorFull of nutritionAlcoholic beverage preparationChinese traditionalEmbryo

The invention relates to wines and preparation methods of wines, in particular to a bamboo embryo wine and a preparation method of the bamboo embryo wine. The invention solves the problems that the wine making technology in prior arts requires brewing, storage, a plurality of utensils and large energy cost; and the resource waste is serious. The existing bamboo-related wine making technology also has the same problems as the wine processing is performed after bamboos maturity. The bamboo embryo wine and the preparation method of the bamboo embryo wine provided by the invention have convenient operation, reliable conversion, and high product recovery, and can meet the requirement of industrial production. The preparation method comprises the following steps: injecting wine into a cavity of the bamboo embryo; and further fermenting with bamboo juice secreted by the bamboo during the growth of bamboo embryo. The method in the invention replaces the Chinese traditional glass containers and porcelain containers with bamboo embryo, and fundamentally saves a number of glass mineral resources and a number of coal resources used for calcining utensils, thereby greatly reducing the discharge of carbon dioxide gas. The bamboo embryo wine by the invention has sweet and luscious mouthfeel, and abundant vitamins, amino acids and trace elements, and is rich in nutrients, and is suitable for promotion and application.

Owner:曹建中 +1

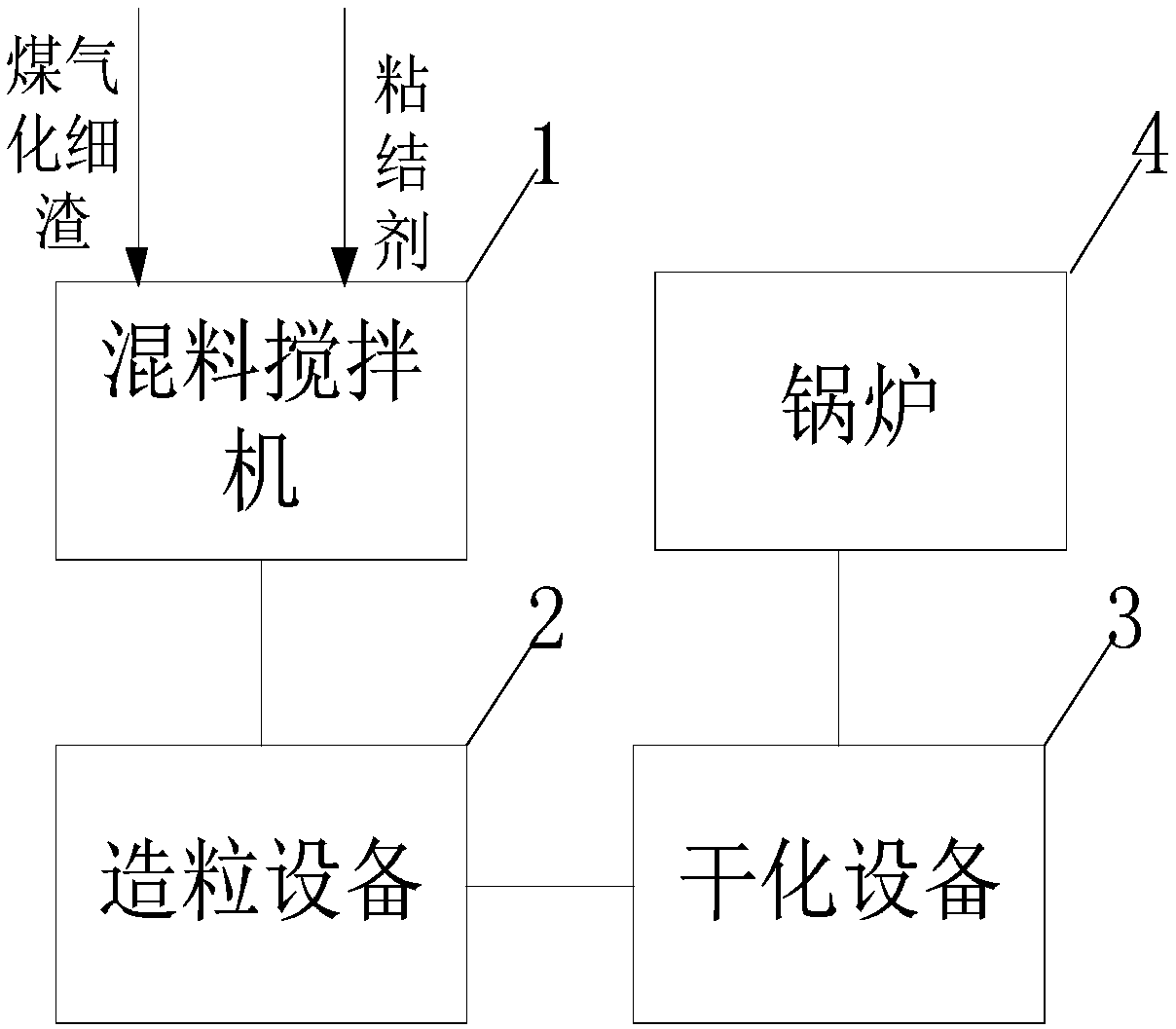

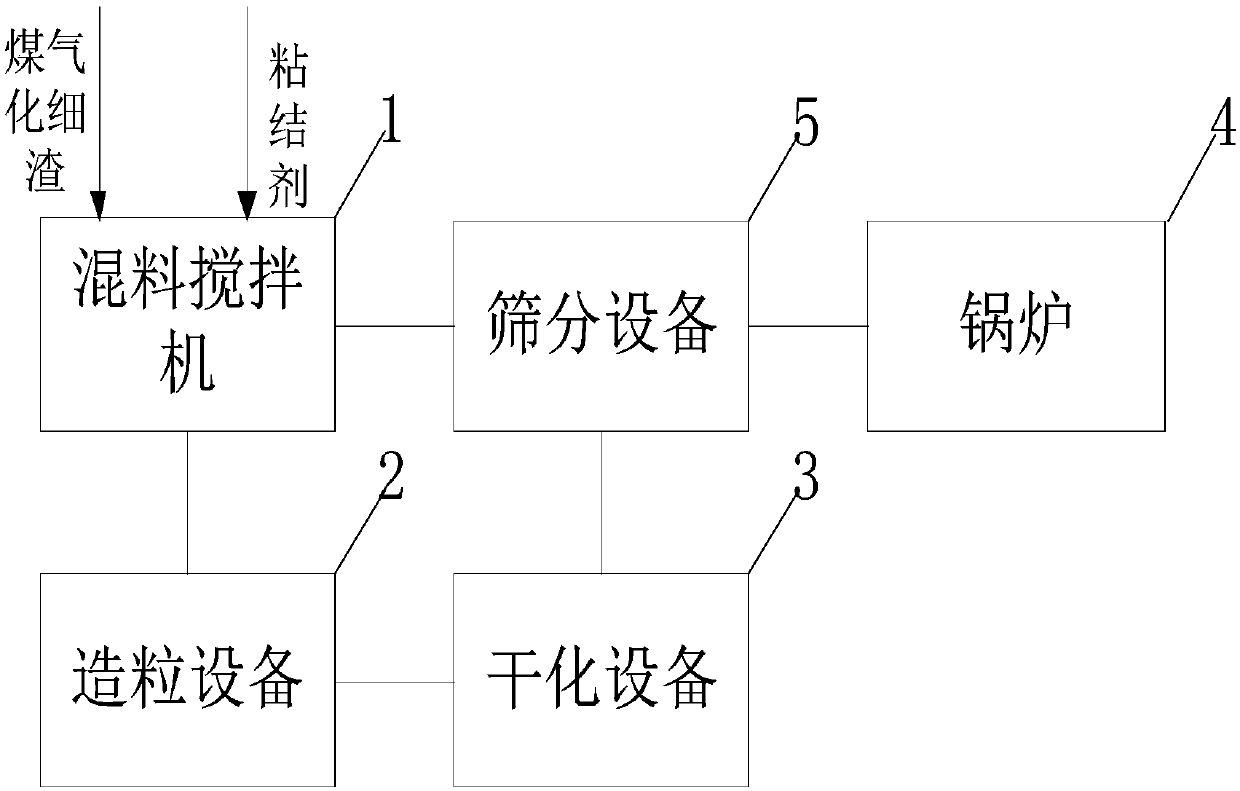

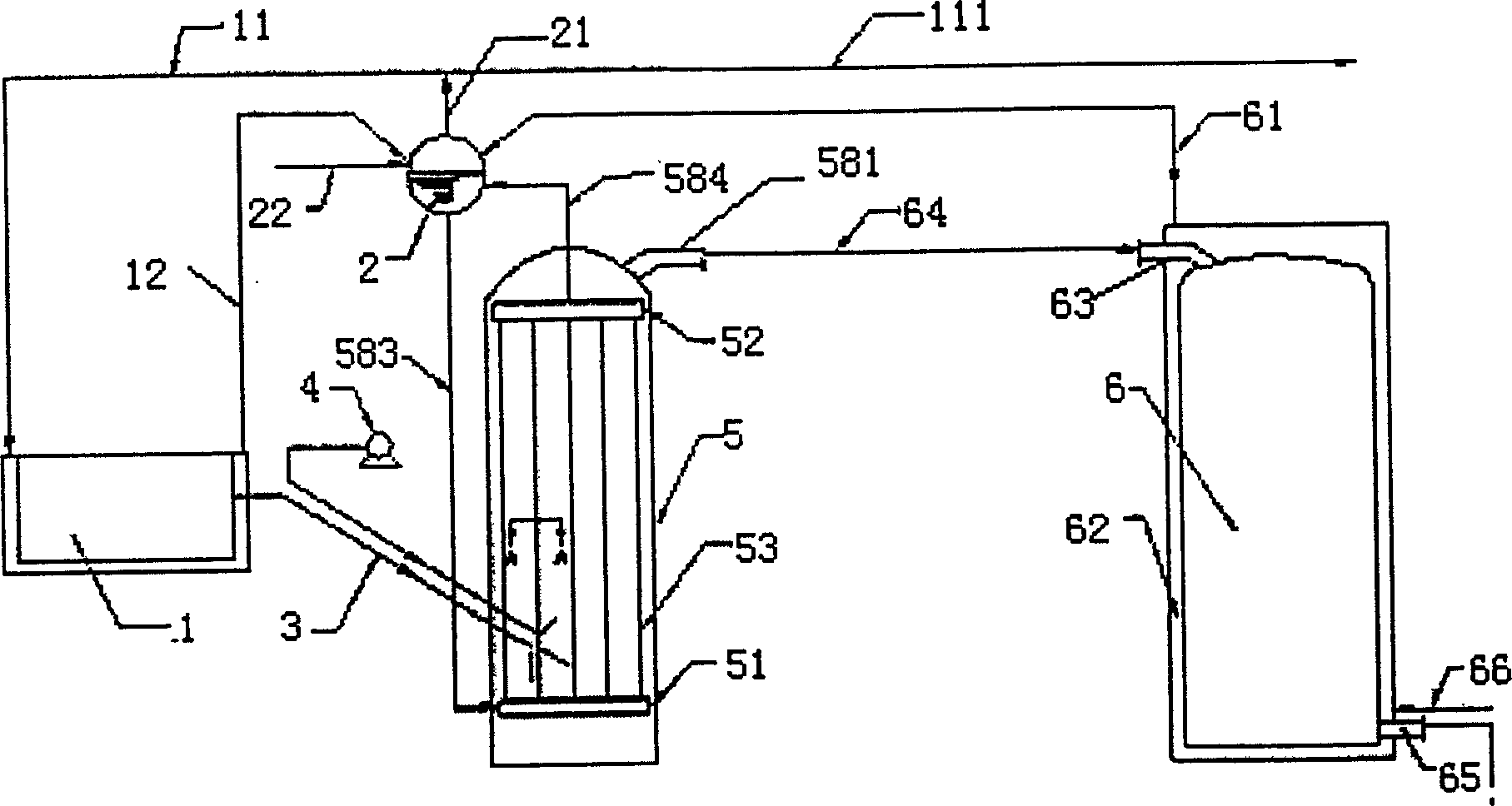

Coal gasification fine slag granulation and blending combustion system

InactiveCN109647279ARealize resource utilizationResource Utilization EliminationTransportation and packagingMixersParticulatesCombustion system

The invention provides a coal gasification fine slag granulation and blending combustion system. The system includes a mixing and stirring machine, granulation equipment and anhydration equipment. Themixing and stirring machine stirs and mixes coal gasification slag and a binder; the granulation equipment granulates the stirred and mixed coal gasification slag and binder to form particles; and the anhydration equipment dries the particles and transports the dried particles to a boiler for blending combustion, wherein the binder includes starch, amide and bentonite. According to the invention,when the blending combustion is carried out on the coal gasification fine slag granulation, the coal gasification fine slag granulation particles can be fully burned in the boiler by stirring and mixing the coal gasification fine slag granulation and binder and then granulating. The stability of the combustion of the coal gasification fine slag granulation particles can be ensured by angydratingthe particles formed by the granulation. the coal gasification fine slag can be ensured to form the clean particles with sufficient strength and the blending combustion cost can be ensured to be lessthan the combustion economic value by selecting the components of the binder, which facilitates the promotion of the blending combustion system.

Owner:光大清洁技术股份有限公司

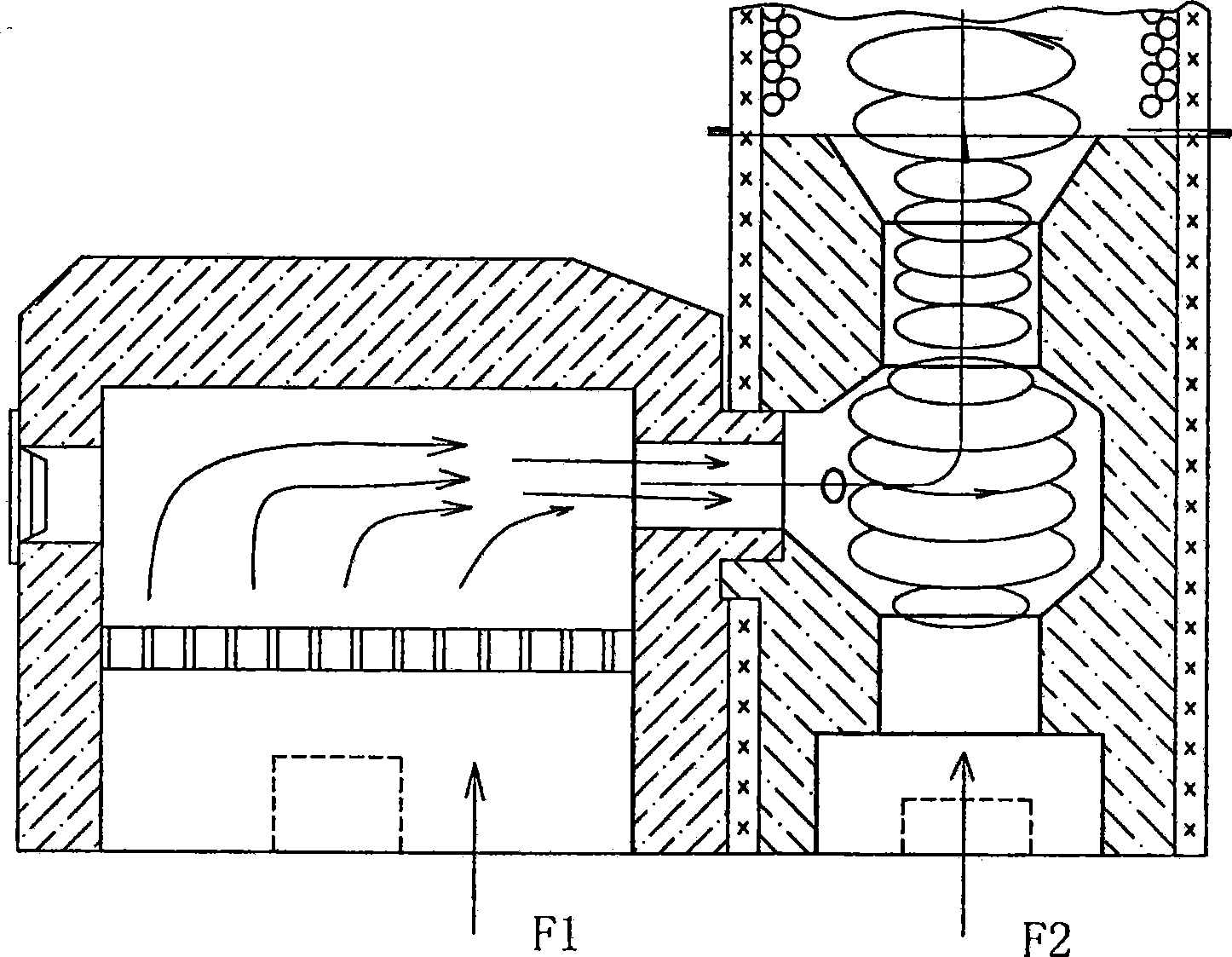

Multi-fire head continuous balanced combustion method and long-tube rotary stove derived therefrom

InactiveCN102183044ASave coal resourcesEasy fireStove/ranges for heating waterWater heatersCombustion chamberPower equipment

The invention discloses a multi-fire head continuous balanced combustion method and a long-tube rotary stove derived therefrom, and belongs to coal combustion methods and coal stove utensils. The long-tube rotary stove can produce a dozen of fire heads, large fire and extremely strong firepower under the action of a fire combustion chamber. Compared with the conventional coal stove, the long-tuberotary stove has the advantages that: coal resources can be saved to the greatest extent; coal gas can be used to the greatest extent; combustion strength of the coal gas can be increased to the greatest extent; heat energy is utilized to the greatest extent; environmental pollution is greatly improved; the stove body of the new stove can combust the coal gas in a reverse direction after being turned 180 degrees; the long-tube rotary stove consists of components such as a stove plate, a middle fire cover, a coal support, a stove body, a fire combustion chamber, a lower fire cover and the like; the components are arranged on the stove body in sequence; the long-tube rotary stove is used for heating, cooking meals, sweeping snow and cutting ice; and an external combustion vehicle and a generator are driven by using the long-tube rotary stove, so that a generating power equipment system is greatly simplified.

Owner:张启凤

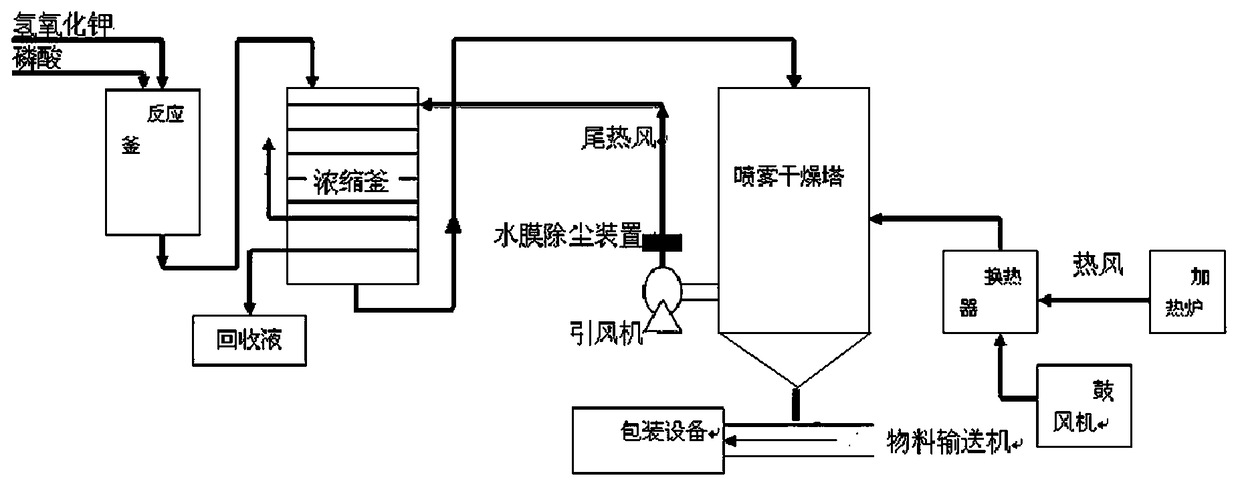

Technology for preparing dipotassium phosphate through spray-drying method

InactiveCN108557790AEfficient ConcentrationReduce pollutionChemical industryPhosphorus compoundsPotassium hydroxidePhosphoric acid

The invention provides a technology for preparing dipotassium phosphate through a spray-drying method. The technology comprises the following steps: (1) carrying out neutralization reaction on potassium hydroxide and phosphoric acid in a reaction kettle; controlling the pH (Potential of Hydrogen) value of a finishing point of the reaction; (2) after concentrating a reaction solution obtained by step (1), conveying the reaction solution into a drying tower and carrying out spray-drying; (3) conveying clean air into a heat exchanger through an air blower, and carrying out heat exchange with hotair of a heating furnace; (4) conveying hot air of the drying tower and enabling the hot air to be in sufficient contact with a spraying material, so as to evaporate water instantly; enabling a solidproduct to fall down to a tower bottom in a powder form, and conveying through a conveying machine and packaging; (5) discharging and conveying the hot air in a spray-drying tower to a concentration kettle by an induced draft fan through a tail hot air outlet, and heating a concentrated material through tail air; conveying the concentrated material into the spray-drying tower; recycling residual liquid and emptying tail gas to realize energy recycling. The technology provided by the invention has the beneficial effects that the hot air exhausted by the drying tower is introduced into the concentration kettle to heat a concentrated reaction solution, so that 1 / 3 of coal resources are saved, the heat utilization rate is improved and the environment pollution is reduced.

Owner:闫超良

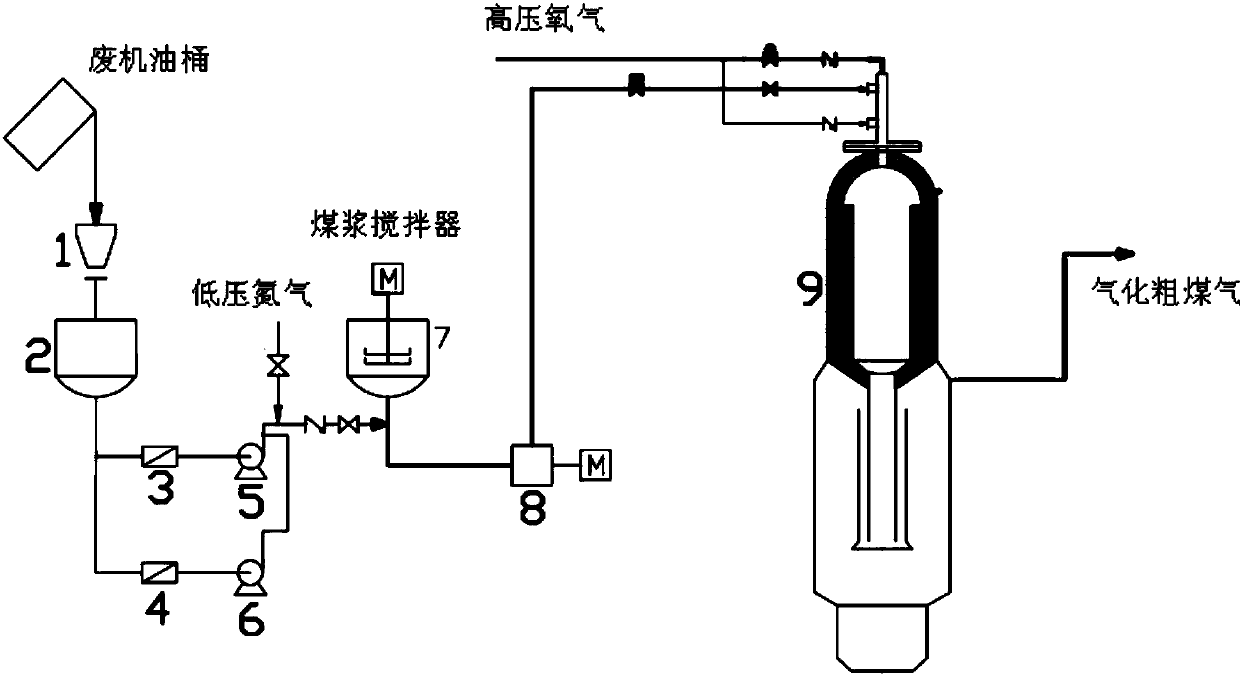

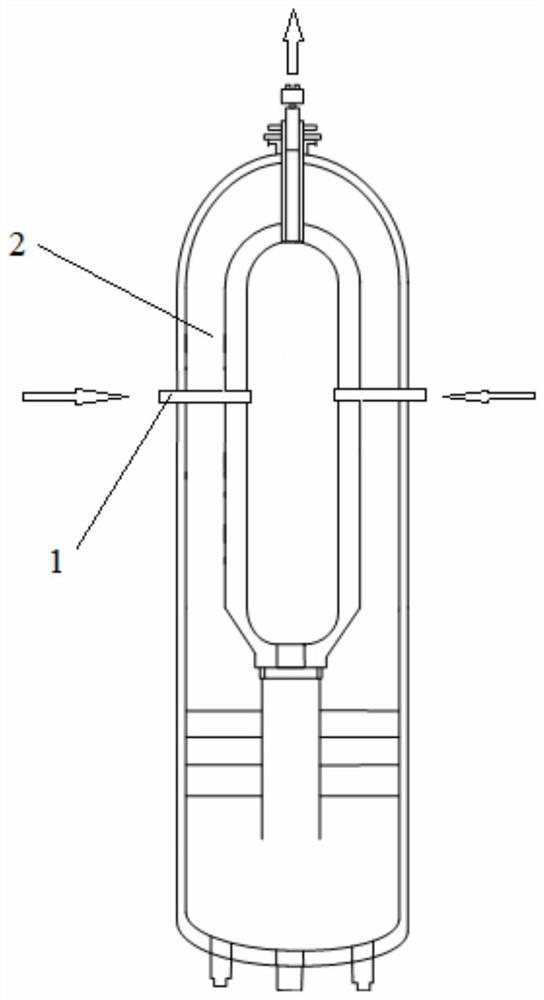

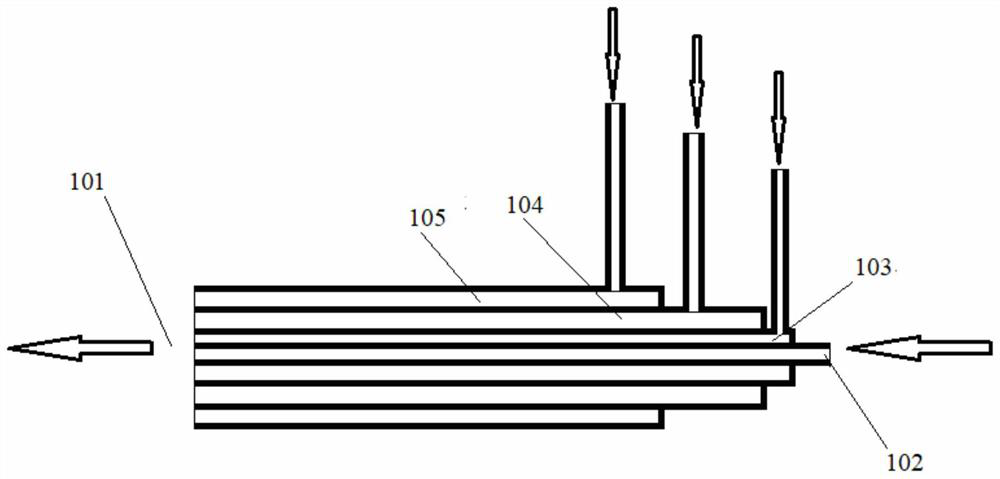

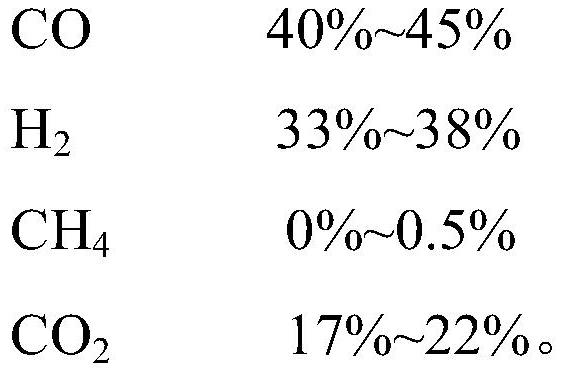

Device and method for treating waste engine oil by using blending combustion through coal gasification furnace

InactiveCN107559845ARealize harmless treatmentSimple and reliable technical systemIncinerator apparatusCombustionHigh pressure

The invention discloses a device and use method for treating waste engine oil by using blending combustion through a coal gasification furnace. The device comprises an oil filtering funnel, wherein awaste engine oil storage tank is arranged right below the oil filtering funnel; two pipelines are connected with a liquid outlet of the waste engine oil storage tank in parallel; one pipeline is provided with a first filter and a first screw metering pump, and the other pipeline is provided with a second filter and a second screw metering pump; waste engine oil subjected to two-stage filtering isconnected to an inlet pipeline of a high-pressure coal slurry pump; and then the waste engine oil is conveyed into the gasification furnace through the high-pressure coal slurry pump. The collected waste engine oil is filtered through the oil filtering funnel, and then is added into the middle waste engine oil storage tank for storage; after being further filtered through the pipeline filters andmetered by the screw metering pumps, the waste engine oil is sent to the inlet pipeline of the high-pressure coal slurry pump in a small flow; and the waste engine oil is mixed with a large amount ofcoal slurry, and then is sent into the gasification furnace to be incinerated through the high-pressure coal slurry pump. The device and use method for treating the waste engine oil by using blendingcombustion through the coal gasification furnace has the characteristics of saving coal resources and turning waste into wealth.

Owner:SHAANXI CARBONIFICATION ENERGY CO LTD

Method for preparing synthesis gas by co-gasifying livestock and poultry waste hydrothermal carbon and pulverized coal

InactiveCN111718761ARaw material processing scale is largeHigh reaction conversion rateChemical industryGasification processes detailsCoal waterEnergy recovery

The invention discloses a method for preparing synthesis gas by co-gasifying livestock and poultry waste hydrothermal carbon and pulverized coal. The method comprises the following steps: (1) airing livestock and poultry waste; (2) performing hydrothermal carbonization to obtain hydrothermal carbon; (3) adding water into the hydrothermal carbon, and pulping to obtain hydrothermal carbon slurry; and (4) respectively feeding the hydrothermal carbon slurry, the coal water slurry, the hydrothermal carbon slurry oxidant and the coal water slurry oxidant in the step (3) into a gasification furnace through respective runners of a multi-channel nozzle to obtain the synthesis gas. According to the method, pathogenic bacteria can be killed, organic matter in the waste is subjected to energy recoveryand cyclic utilization, the raw material treatment scale is large, the reaction conversion rate is high, environmental friendliness is achieved, and the technical possibility is provided for large-scale livestock and poultry waste treatment. According to the method, the poultry waste is subjected to resourceful treatment from the source so that a big problem of environmental governance is solved,coal resources are saved, and clean breeding of livestock and poultry and resourceful and clean utilization of the poultry waste are promoted.

Owner:NINGXIA UNIVERSITY

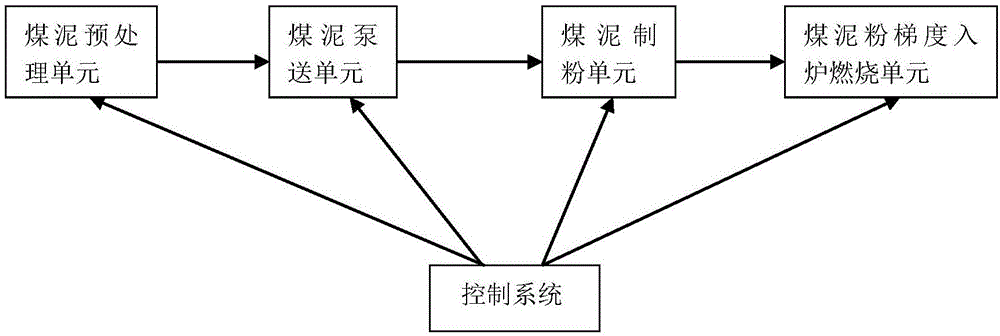

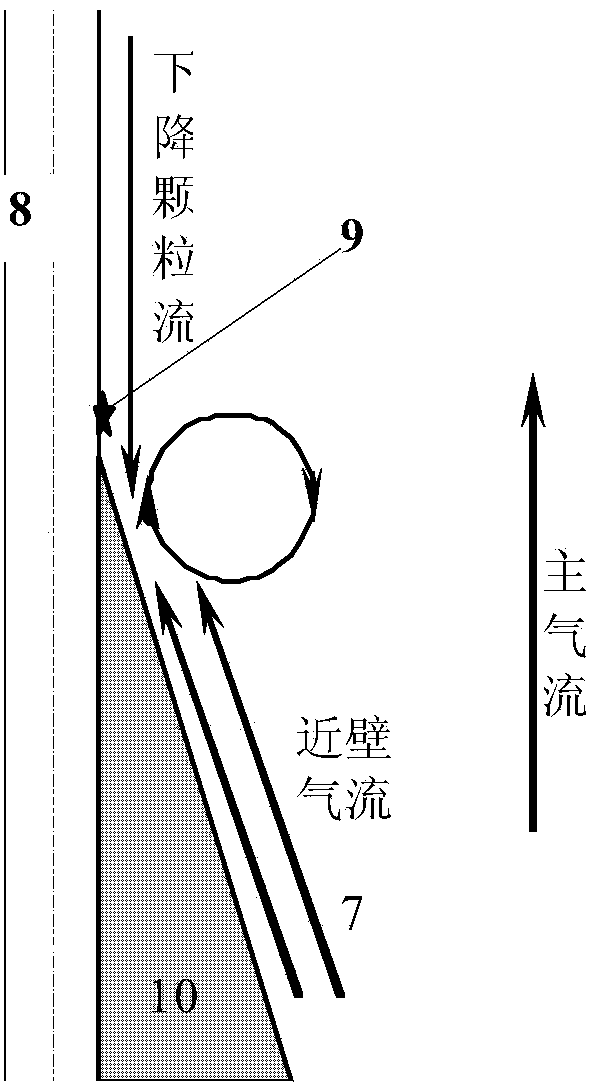

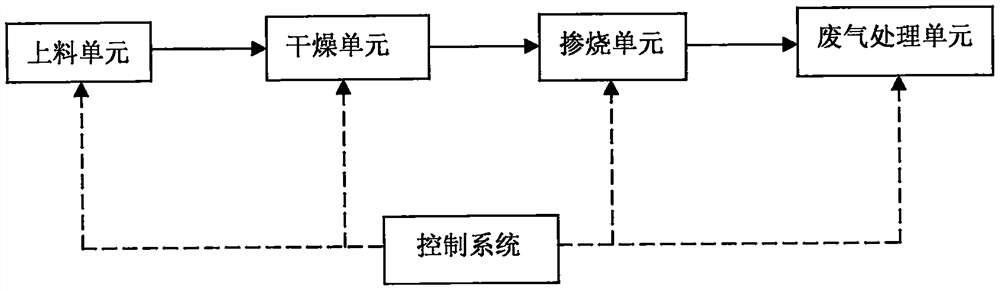

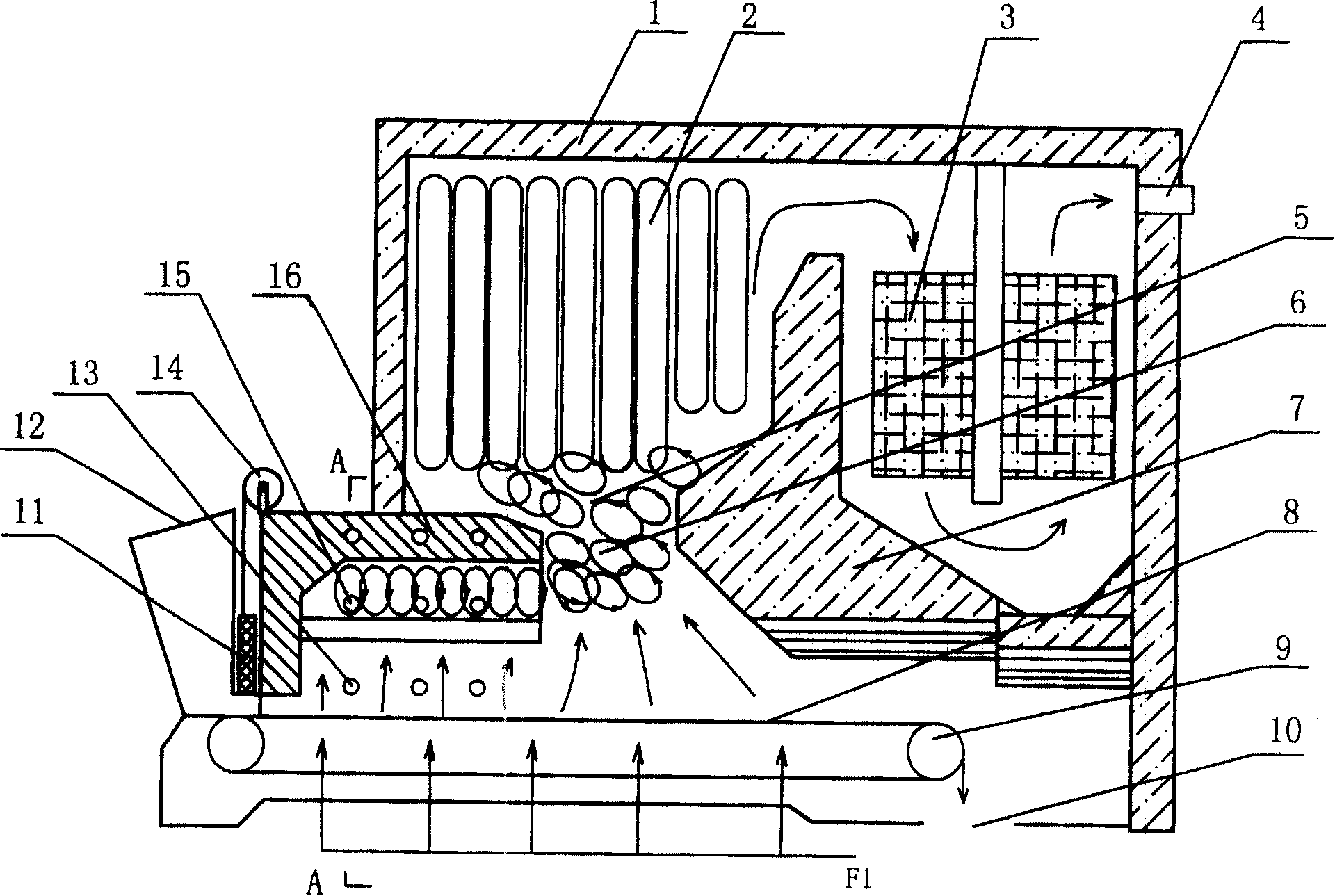

Process and system for mixed burning of coal slime in big proportion in coal-powder boiler

ActiveCN106642185ARealize a large proportion of blended combustionAchieve stratified combustionSolid fuel pretreatmentLump/pulverulent fuel feeder/distributionThermodynamicsAir volume

The invention provides a process and a system for mixed burning of coal slime in big proportion in a coal-powder boiler. The process comprises the following steps that coal slime is pre-treated, that is, the coal slime is subjected to impurity removal, crushing and paste manufacturing, so that the coal slime is suitable for pumping; the coal slime is pumped, that is, coal slime paste is hermetically transported in a coal slime powdering unit through a pipeline; the coal slime is powdered, that is, the air inlet temperature of a coal mill is increased and the air volume is increased by adopting a fuel gas heating or high-temperature steam heat exchanging method, and coal slime powder meeting the burning requirement is obtained; and the coal slime powder is fed in the coal-powder boiler in a gradient manner for burning, that is, the coal slime powder is fed in the coal-powder boiler in a gradient and layered manner for burning. The process and the system realize mixed burning of coal slime in big proportion, the operation stability and reliability of the system are improved, the fire coal resources in the boiler are saved, the effects of energy conservation and emission reduction are remarkable, and the pollution of wastes on the environment is eliminated.

Owner:光大清洁技术股份有限公司

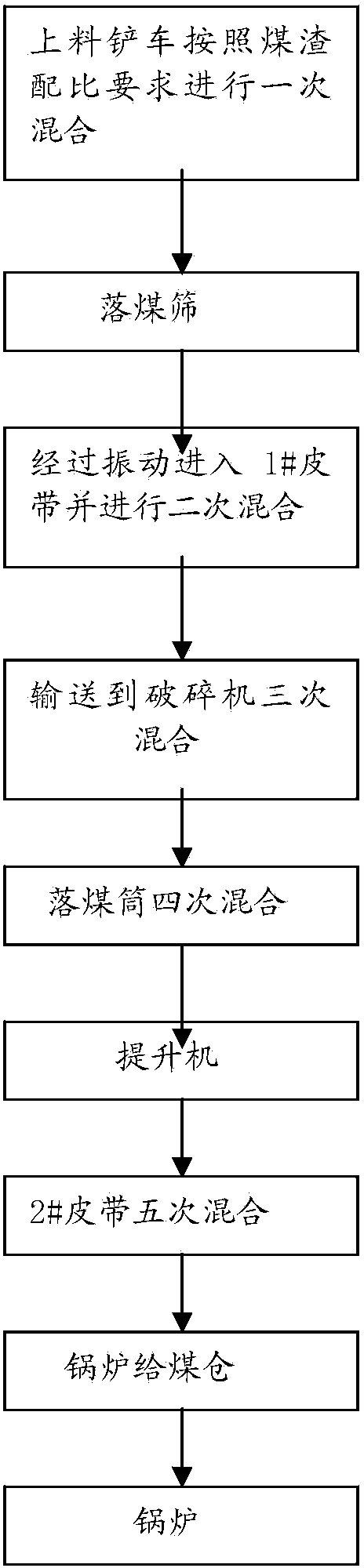

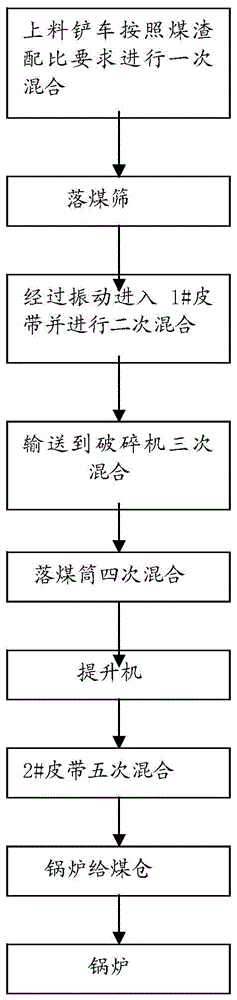

Recycling process for waste furnace slag in fluidized bed boiler combustion system

ActiveCN103411212AReduce pollutionReduce wasteFluidized bed combustionApparatus for fluidised bed combustionCombustion systemSlag

The invention relates to a process method and equipment for recycling waste furnace slag in a fluidized bed boiler combustion system. The process method comprises the following steps of (1) analyzing the low caloric value of the waste furnace slag, and judging the combustibility of the waste furnace slag; (2) uniformly proportioning and mixing coal and the combustible waste furnace slag as required, and loading materials to a circulating fluidized bed loading system; (3) setting parameters such as primary air openness, current, induced air openness, the air pressure of an air chamber, primary air amount, primary air pressure and the smoke pressure of an induced air inlet according to the different thicknesses of backing materials; and (4) combusting a coal slag mixture in a circulating fluidized bed boiler according to the parameters which are set in the step (3). By the adoption of the process method for recycling the waste furnace slag in the fluidized bed boiler combustion system and the fluidized bed boiler system corresponding to the process, a great number of coal resources can be saved, the environmental pollution is alleviated, the resource wasting is reduced, the benefit is improved, waste materials are changed into profitable materials, and energy conservation and emission reduction are realized.

Owner:太原钢铁(集团)有限公司

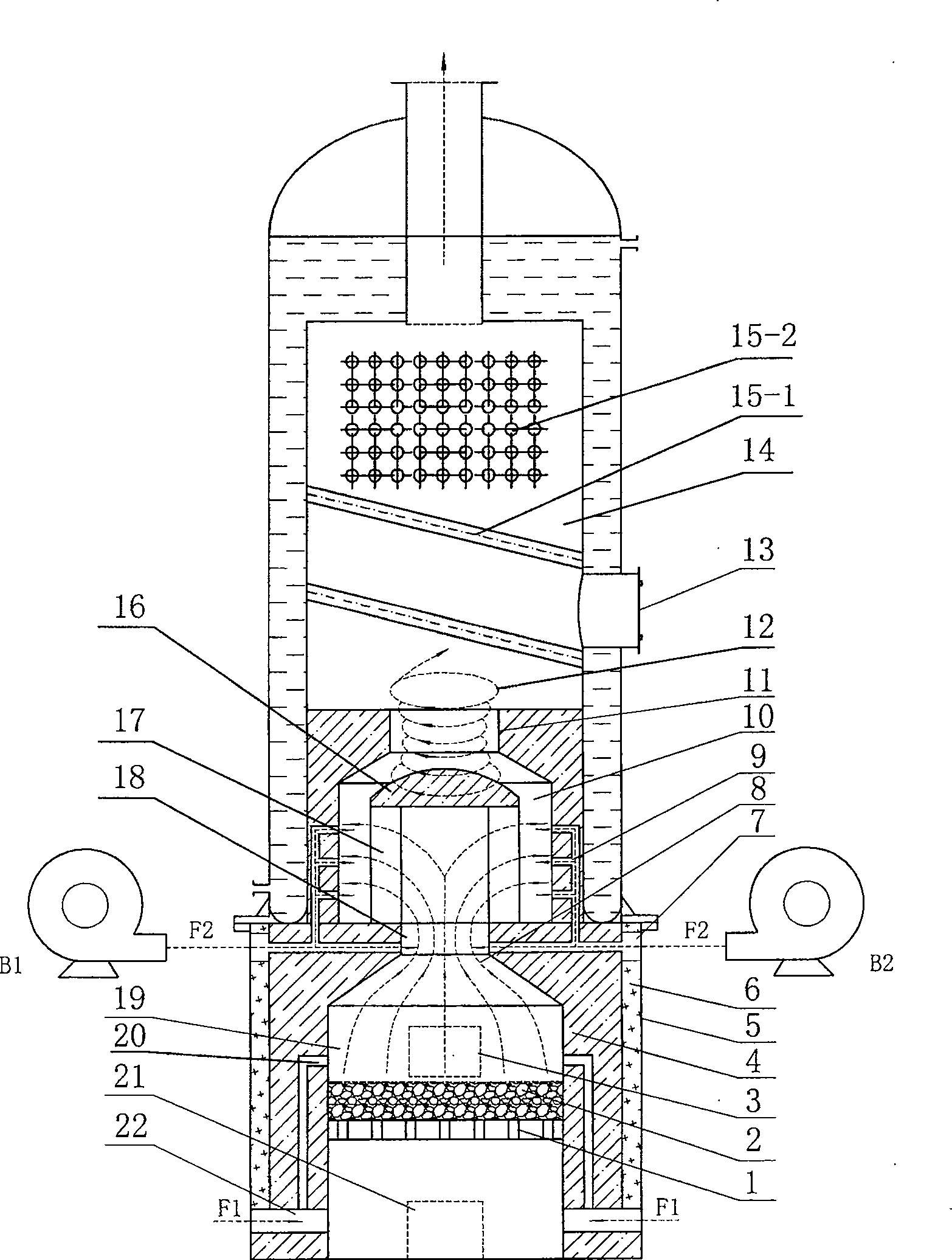

Smokeless, coal saving type heat transfer oil stove with large mechanical fire grate

InactiveCN1873322ANo implementationNo pollution in the processSolid fuel combustionCombustion apparatusCombustionHeat conducting

The present invention relates to a smokeless coal-saving large-size mechanical fire grate heat-conducting oil-burning boiler. It is characterized by that said furnace body has heating zone and hot gas supply zone, the interior of furnace body of heating zone is equipped with heat-absorbing tube bank, the bottom portion of heating zone is equipped with a hot gas inlet, and the top portion of said heating zone is equipped with a draught fan; the hot gas supply zone possesses a coal-burning device, said coal-burning device has a combustion furnace cavity, meachinical fire grate, coal-adding device and high-temperature gas outlet. Said invention also provides the concrete structure of said furnace cavity. Said invention is simple in structure and can completely solve the problem of discharging black smoke by burning coal.

Owner:王树洲

Equipment for recovering and utilizing heat energy generated by phosphor combustion and system for preparing phosphor acid by hot method

InactiveCN1131171CReduce dosageSave energyPhosphorus oxidesChemical industryO-Phosphoric AcidSprayer

An equipment for recovering and utilizing the heat energy generated by burning yellow phosphorus and a system for preparing phosphoric acid by the hot method are disclosed. It is composed of steam manifold and burning tower with heat energy recovering function. The burning tower consists of ring-shaped membrane heat exchanger with fins, heat-insulaitng enclosed casing, P2O5 gas outlet tube, connecting tube of phosphorus sprayer, etc.. Its advantages include low consumption of coal, water and energy, low cost and reduced environmental pollution.

Owner:TSINGHUA UNIV +1

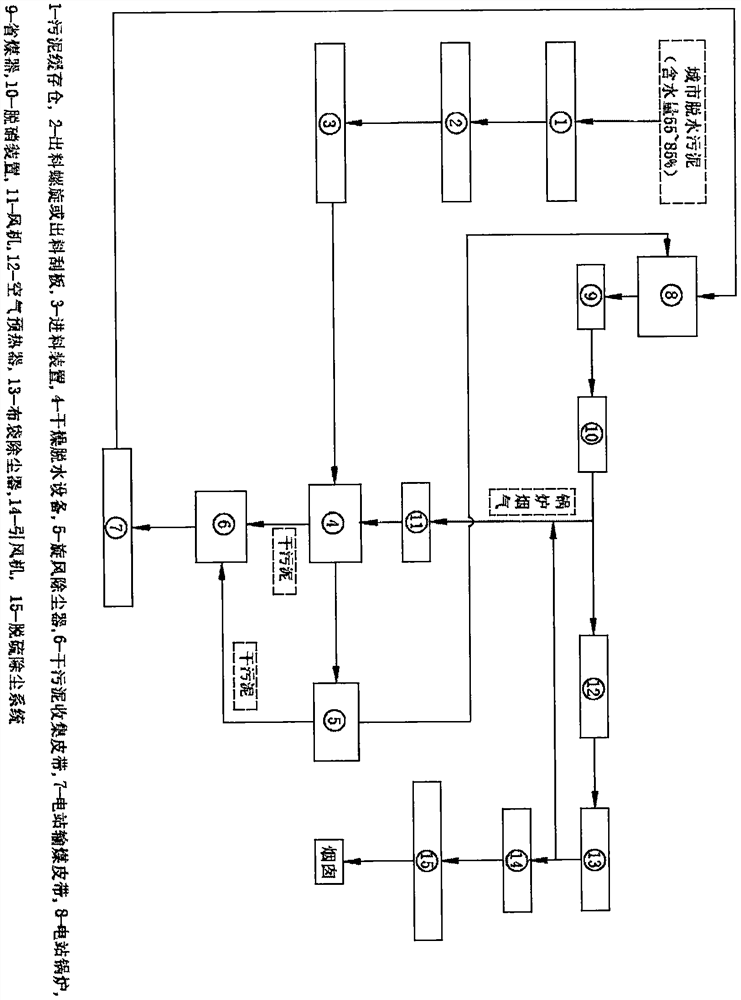

Process and system for treating sludge by utilizing waste heat of boiler

PendingCN113803730APrevent leakageSignificant environmental benefitsSludge treatment by de-watering/drying/thickeningCombustion technology mitigationPollutionCombustion system

The invention relates to a process and system for treating coal slime or sludge by using waste heat of a power station boiler. The process comprises the steps of feeding, wherein coal slime or sludge is purified, crushed and then conveyed into a drying machine to have the characteristic of being suitable for drying; drying, wherein hot flue gas of the boiler is introduced into the drying machine to serve as a heat source and makes direct contact with the coal slime or sludge for heat exchange so that the coal slime or sludge can be dewatered and dried; blending combustion, wherein the dried coal slime or sludge is conveyed into the boiler for blending combustion to realize final treatment of the coal slime or sludge; and drying waste gas treatment, wherein evaporated moisture in the drying machine is introduced into the boiler for combustion to prevent odor generated by sludge drying from leaking. According to the process, the coal slime or sludge is treated by utilizing the waste heat of the boiler in an environment-friendly manner, no odor leaks, the operation stability and reliability of a blending combustion system of the boiler are improved, the bunker coal resources of the boiler are saved, the energy conservation and emission reduction effects are obvious, and the pollution of the waste to the environment is eliminated.

Owner:光大清洁技术股份有限公司

Coal-saving combustion improver improving coal combustion efficiency

The invention discloses a coal-saving combustion improver improving the coal combustion efficiency. The coal-saving combustion improver is prepared from an oxygen producer, a curing agent, a catalystand a main raw material. The coal-saving combustion improver is prepared from the components in percentage by weight: the oxygen producer: 10% of sodium chloride, the curing agent: 10% of epoxy resin,the catalyst: 5% of calcium carbonate, the main raw material: 60% of mineral powder, a synergist: 5% of a fuel gas synergist, and an enhancer: 10% of stearic acid. The raw materials are placed into amixer to be mixed and stirred, and the mixed material which is blended uniformly is ground to be powdery by using a grinder. The coal-saving combustion improver is formed through matching of variouskinds of raw materials, the raw materials are mixed at different ratios, 10% of coal can be saved by adding 1% of coal-saving combustion improver, the economic cost is reduced, the coal sources are saved, and the utilization efficiency of the coal is improved. The raw materials are mixed more sufficiently through forward and reverse rotation of stirring blades and design of multiple grinding procedures, the homogenization and the pulverization of the mixed material are ensured, and accordingly the good combustion effect is achieved.

Owner:山东润生节能科技股份有限公司

Smokeless, coal saving type horizontal heat transfer oil stove with mechanical fire grate

InactiveCN1873323ANo implementationNo pollution in the processSolid fuel combustionCombustion apparatusCombustionHeat conducting

The present invention relates to a smokeless coal-saving horizontal mechanical fire grate heat-conducting oil-burning boiler. It is characterized by that the upper portion of said furnace body is heating zone, the lower portion of said furnace body is hot gas supply zone, the interior of furnace body of heating zone is equipped with a heat-conducting oil pipe, the bottom portion of heating zone has a hot gas inlet, the top portion of heating zone is equipped with a draught fan; the hot gas supply zone has a coal-burning device, said coal-burning device possesses combustion furnace cavity, mechanical fire grate, coal-adding device and high-temperature gas outlet. Besides, said invention also provides the concrete structure of said combustion furnace cavity. Said invention is simple in structure, and can completely solve the problem of discharging black smoke by burning coal.

Owner:王树洲

Smokeless, coal saving type horizontal heat transfer oil stove with mechanical fire grate

InactiveCN100402923CNo implementationNo pollution in the processSolid fuel combustionCombustion apparatusCombustionHeat conducting

The present invention relates to a smokeless coal-saving horizontal mechanical fire grate heat-conducting oil-burning boiler. It is characterized by that the upper portion of said furnace body is heating zone, the lower portion of said furnace body is hot gas supply zone, the interior of furnace body of heating zone is equipped with a heat-conducting oil pipe, the bottom portion of heating zone has a hot gas inlet, the top portion of heating zone is equipped with a draught fan; the hot gas supply zone has a coal-burning device, said coal-burning device possesses combustion furnace cavity, mechanical fire grate, coal-adding device and high-temperature gas outlet. Besides, said invention also provides the concrete structure of said combustion furnace cavity. Said invention is simple in structure, and can completely solve the problem of discharging black smoke by burning coal.

Owner:王树洲

A method for analyzing the differential consumption of ultra-supercritical generating units with variable loads in thermal power plants

ActiveCN103699786BReduce coal consumption for power generationSave coal resourcesTechnology managementResourcesProcess engineeringAnalysis method

The invention discloses an energy consumption difference analysis method for load varying of an ultra-supercritical generating unit of a thermal power plant. The method comprises the steps of selecting eighteen operation parameters having a greater influence on the economy of the unit as analysis objects; applying a clustering method to the eighteen operation parameters to obtain an operation optimum condition: taking the operation optimum condition as a stable operation standard working condition, and selecting eighteen actual working conditions from a load varying range; taking eighteen parameter influencing factors as independent variables: establishing eighteen equations by taking the energy consumption difference between a single influencing parameter change value and a stable operation standard value as a coefficient of the parameter influencing factor and taking the energy consumption difference between an actual working condition and the stable operation standard working condition as a dependent variable, and finally solving to obtain eighteen parameter influencing factors; finally sequencing the eighteen parameter influencing factors to obtain a parameter having the greatest influence on the coal consumption level in a load varying process. Guidance basis is provided for determination of load varying velocity, load varying amplitude and stable stage time in the load varying operation of million of units, so that the aim of reducing the coal consumption in electricity generation in the load varying operation of the power plant is achieved.

Owner:ELECTRIC POWER RES INST OF GUANGDONG POWER GRID +1

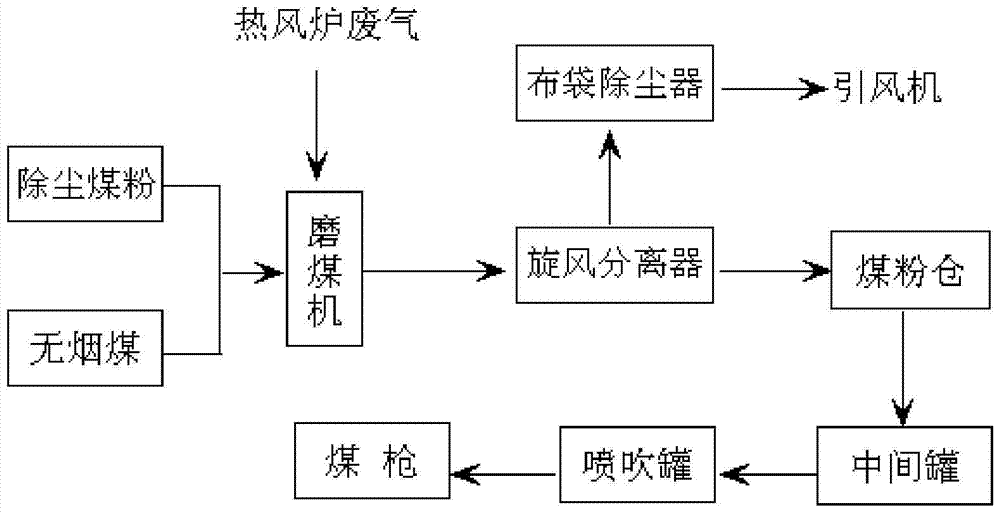

A method of utilizing corex melting to reduce dedusting coal powder

ActiveCN105018666BMeet coal injection requirementsDoes not affect normal productionRecycling and recovery technologiesCost savingsMaterials science

Owner:BAOSHAN IRON & STEEL CO LTD

A kind of bamboo tire wine and preparation method thereof

InactiveCN102533488BBeautiful colorFull of nutritionAlcoholic beverage preparationChinese traditionalEngineering

The invention relates to wines and preparation methods of wines, in particular to a bamboo embryo wine and a preparation method of the bamboo embryo wine. The invention solves the problems that the wine making technology in prior arts requires brewing, storage, a plurality of utensils and large energy cost; and the resource waste is serious. The existing bamboo-related wine making technology also has the same problems as the wine processing is performed after bamboos maturity. The bamboo embryo wine and the preparation method of the bamboo embryo wine provided by the invention have convenient operation, reliable conversion, and high product recovery, and can meet the requirement of industrial production. The preparation method comprises the following steps: injecting wine into a cavity of the bamboo embryo; and further fermenting with bamboo juice secreted by the bamboo during the growth of bamboo embryo. The method in the invention replaces the Chinese traditional glass containers and porcelain containers with bamboo embryo, and fundamentally saves a number of glass mineral resources and a number of coal resources used for calcining utensils, thereby greatly reducing the discharge of carbon dioxide gas. The bamboo embryo wine by the invention has sweet and luscious mouthfeel, and abundant vitamins, amino acids and trace elements, and is rich in nutrients, and is suitable for promotion and application.

Owner:曹建中 +1

A recycling process of waste slag in the combustion system of fluidized bed boiler

ActiveCN103411212BReduce pollutionReduce wasteFluidized bed combustionApparatus for fluidised bed combustionAir volumeSlag

The invention relates to a process method and equipment for recycling waste furnace slag in a fluidized bed boiler combustion system. The process method comprises the following steps of (1) analyzing the low caloric value of the waste furnace slag, and judging the combustibility of the waste furnace slag; (2) uniformly proportioning and mixing coal and the combustible waste furnace slag as required, and loading materials to a circulating fluidized bed loading system; (3) setting parameters such as primary air openness, current, induced air openness, the air pressure of an air chamber, primary air amount, primary air pressure and the smoke pressure of an induced air inlet according to the different thicknesses of backing materials; and (4) combusting a coal slag mixture in a circulating fluidized bed boiler according to the parameters which are set in the step (3). By the adoption of the process method for recycling the waste furnace slag in the fluidized bed boiler combustion system and the fluidized bed boiler system corresponding to the process, a great number of coal resources can be saved, the environmental pollution is alleviated, the resource wasting is reduced, the benefit is improved, waste materials are changed into profitable materials, and energy conservation and emission reduction are realized.

Owner:太原钢铁(集团)有限公司

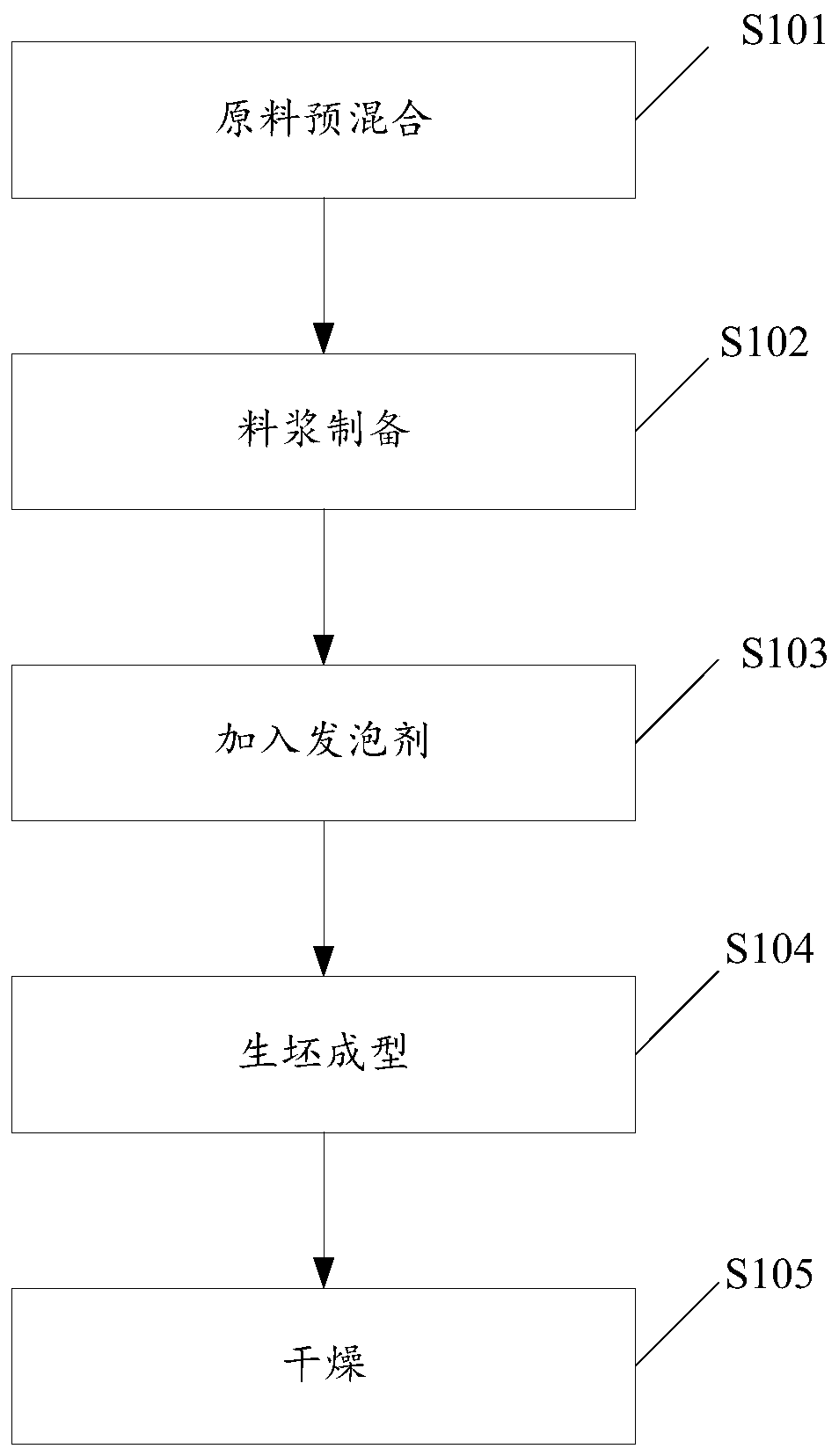

Preparation method of foamed light soil, and foamed light soil

The invention discloses a preparation method of foamed light soil, and the foamed light soil. The foamed light soil comprises, by mass, 25-40% of an admixture, 40-65% of a cementing material, 3-21% ofa chemical auxiliary agent, 1-5% of an active silica-alumina substance material and camphanone-2 powder; and the cementing material comprises cement clinker, calcium oxide and bone glue powder, and the mass ratio of the three components in the cementing material is 2: 3: 1. The invention also discloses a preparation method of the foamed light soil. The preparation method comprises the following steps: premixing the raw materials; preparing a slurry; adding a foaming agent; forming a green body; and drying. The energy utilization shortage is effectively relieved, and the foamed light soil is high in strength, less in moisture, quick to dry, good in bonding and shaping and convenient to use.

Owner:GUANGZHOU UNIVERSITY

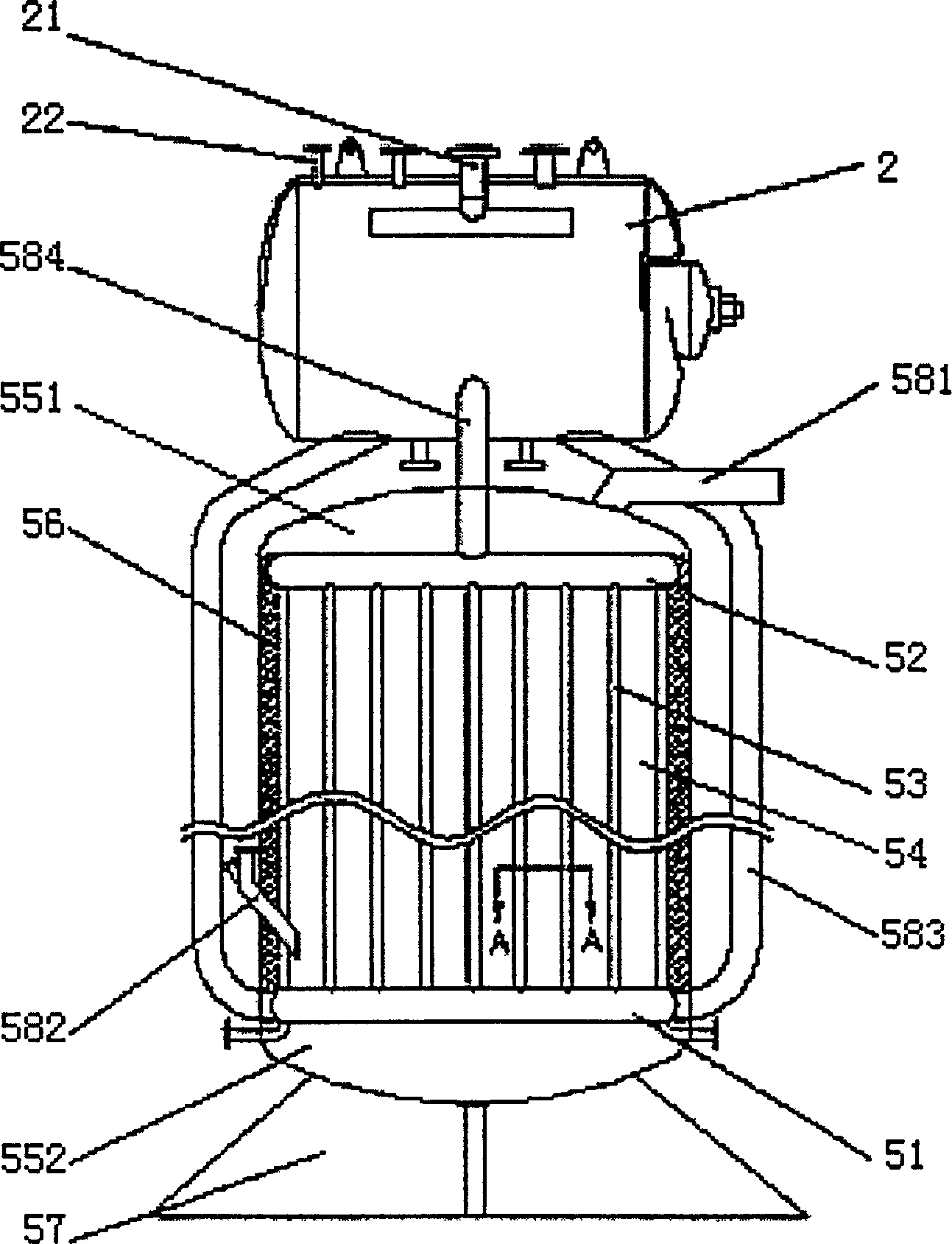

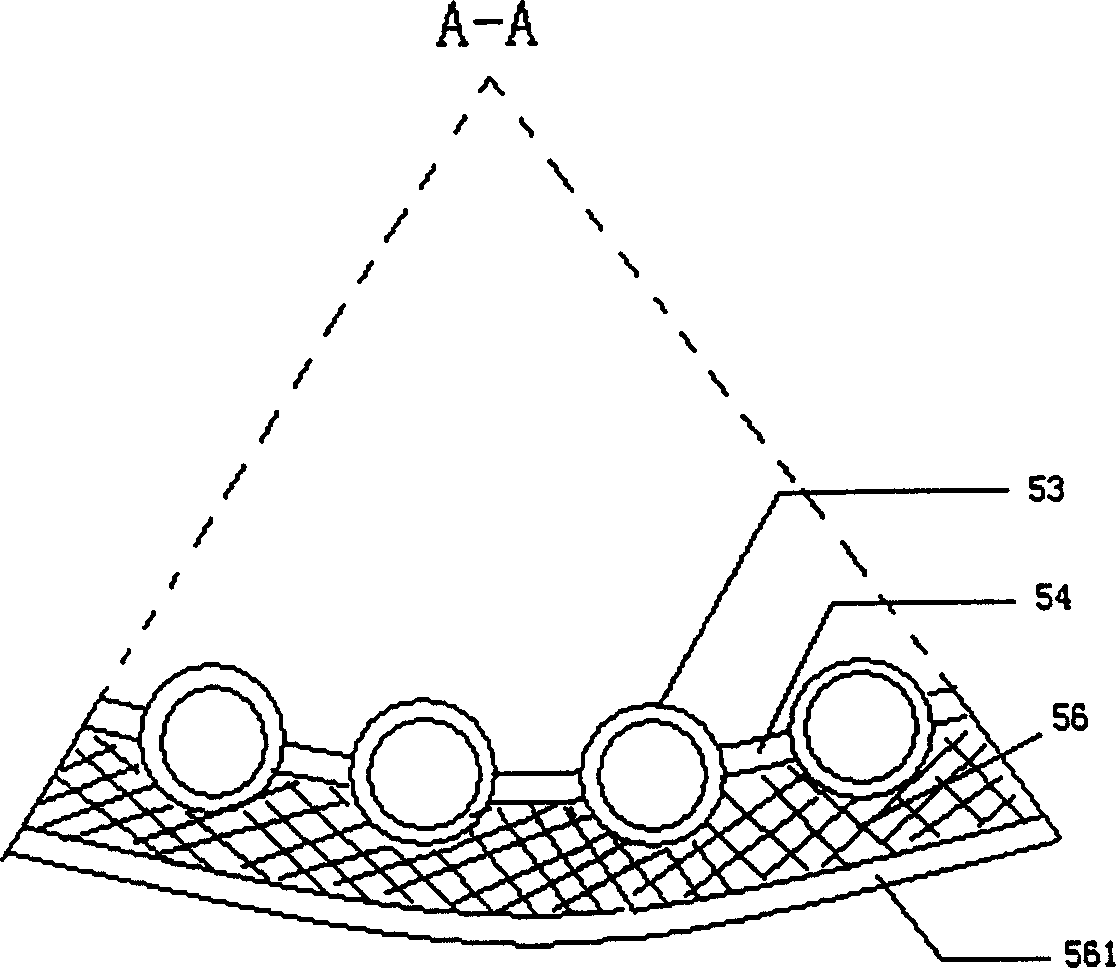

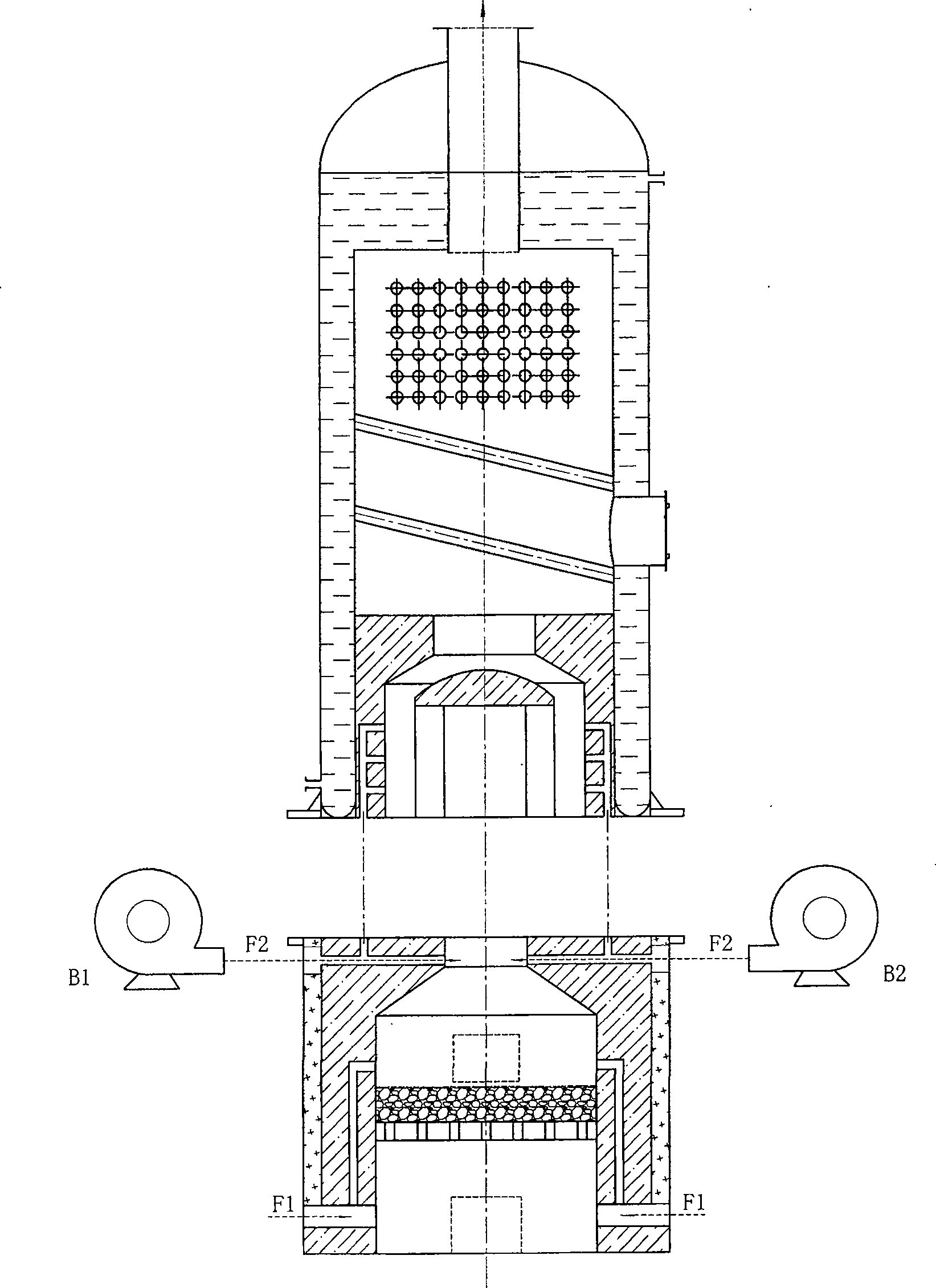

Flow guiding tapering shape pure smokeless vertical type water heater boiler

InactiveCN100520216CTo achieve the effectSolve the emission problemSolid fuel combustionWater heatersCombustionEngineering

The invention discloses a flow guiding awl type pure smokeless vertical hot water boiler, which is characterized by the following: comprising container, boiler pipe group and burning device; arranging condensed high temperature smoke outlet at the top of the burning furnace bed; arranging twice burning furnace bed at the upper of the high smoke outlet; displaying round for the lateral section of the twice burning furnace bed; corresponding to high temperature gas outlet; arranging guiding awl in the twice burning furnace bed; constructing the guiding awl with high temperature smoke guiding flow plate and top lid of the guiding flow plate; arranging twice combustion tuyere on the twice burning furnace bed; corresponding to tangent direction of the twice burning furnace bed of the round lateral section; consisting with the gas flow guiding direction of the high temperature smoke guiding flow plate; arranging high temperature gas outlet on the top of the twice burning furnace bed; communicating the outlet of the high temperature gas to hog gas cavity. This invention possesses reasonable structure and high hot efficiency, which can protect environment.

Owner:王树洲

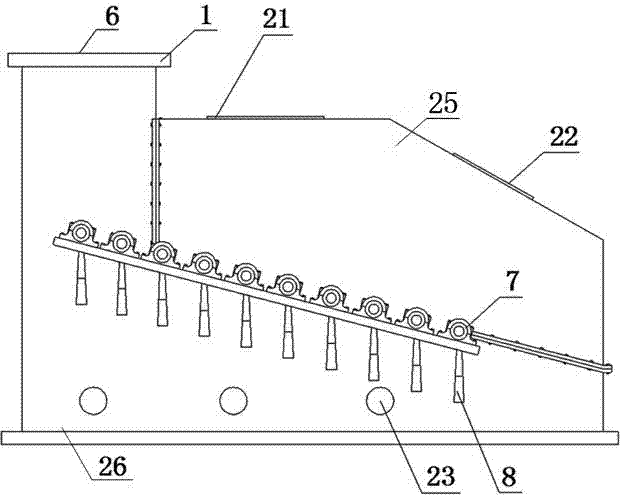

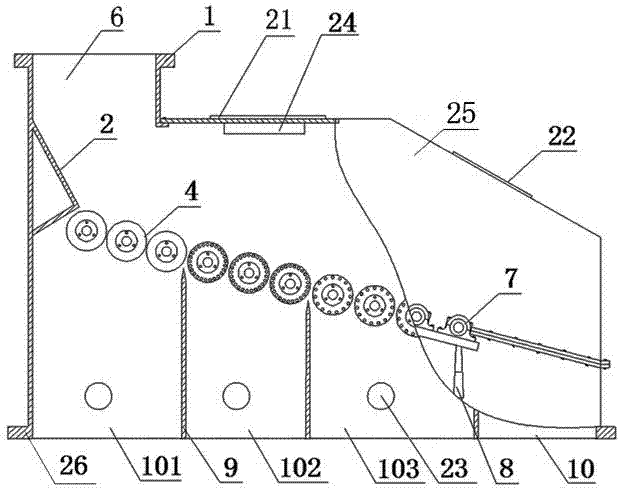

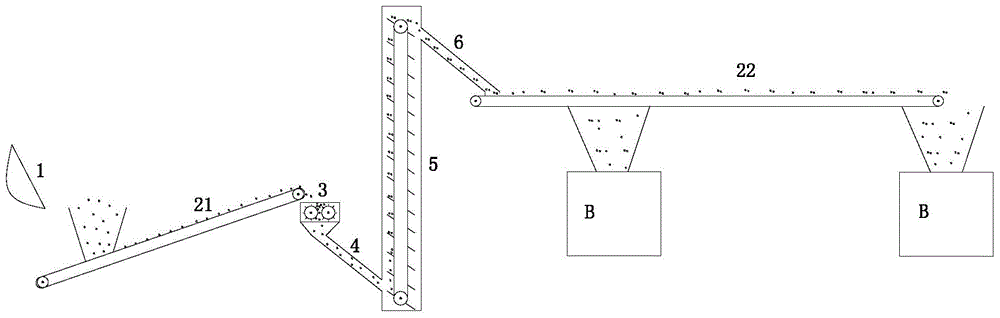

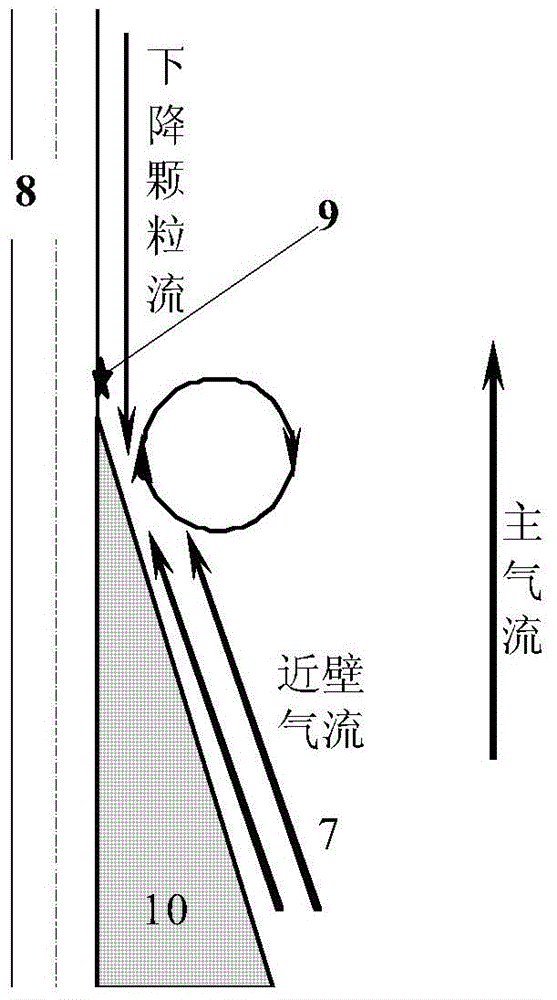

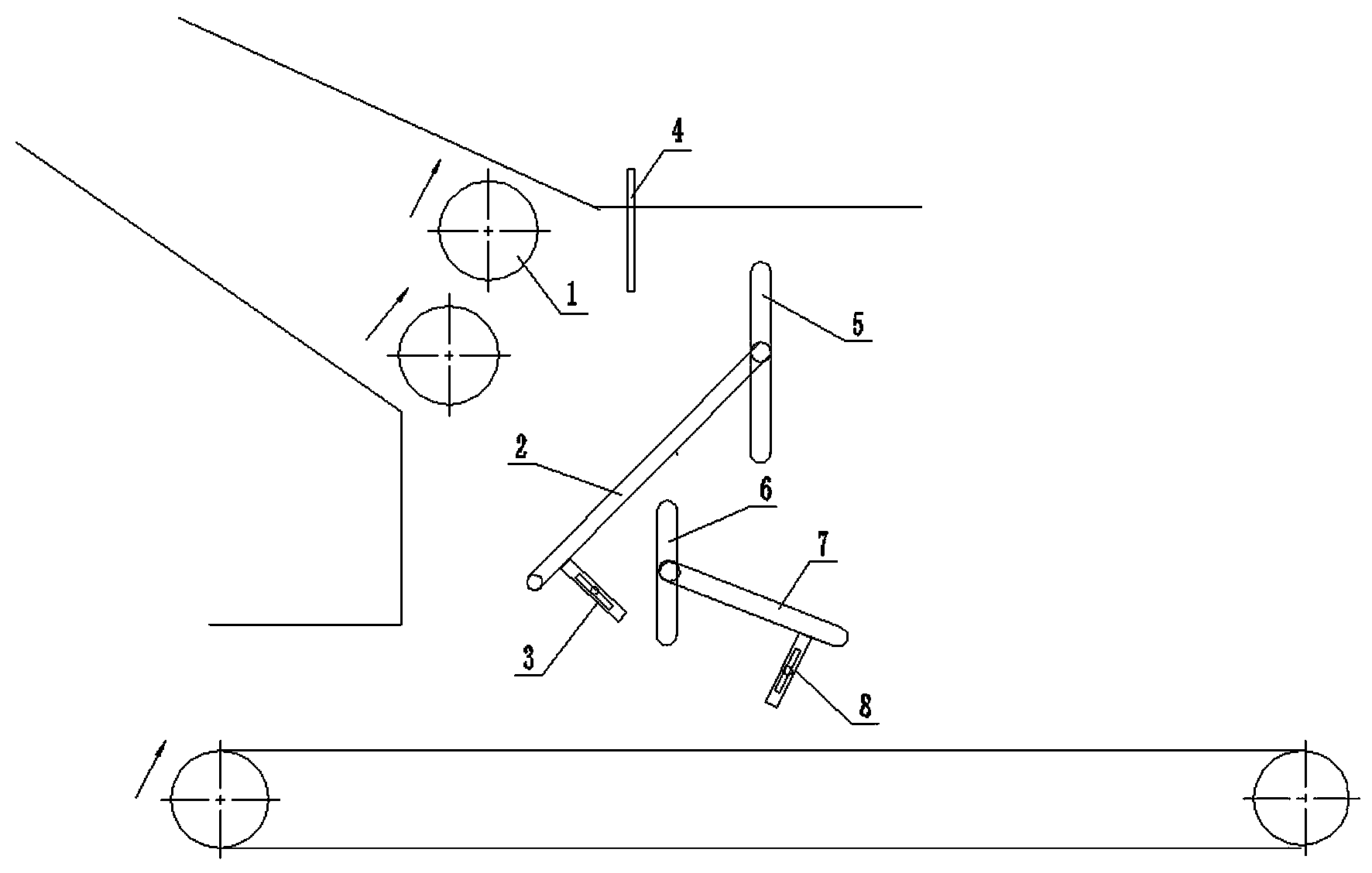

Unpowered layered and lined coal feeding device of chain grate boiler

ActiveCN102563683BImprove adaptabilityImprove securityLump/pulverulent fuel feeder/distributionGratingGranularity

The invention discloses an unpowered layered and lined coal feeding device of a chain grate boiler. The unpowered layered and lined coal feeding device comprises a layered grating, lined baffles and fixing and adjusting mechanisms thereof, wherein the layered grating is divided into a dense rod area, a sparse rod area and a rodless area from top to bottom; the lined baffles are arranged under the dense rod area of the layered grating; the layered grating is obliquely arranged and has a low front part and a high rear part; the lined baffles are obliquely arranged and has a high front part and a low rear part; the layered grating and the lined baffles are respectively provided with the adjusting mechanism with an adjustable oblique angle; and the layered grating and the lined baffles are arranged between the front end of a grate of the boiler and an outlet of a coal bin, and are respectively provided with a fixing mechanism with an adjustable installing height. The unpowered layered and lined coal feeding device has the advantages that external power and a transmission mechanism are not needed, the structure is simple, the operation and the adjustment are simple and convenient, the fault rate and the maintenance cost are low, the adaptability of the boiler to the quality, the water content and the granularity of coal are improved, the burning efficiency is high, the energy consumption is low, the safety of the coal bin of the boiler is improved and the coal resource is greatly saved.

Owner:CHINA TOBACCO HENAN IND

Heating plate with solar heating function

InactiveCN104676733ASave coal resourcesNo pollution to the environmentSolar heat devicesSpace heating and ventilation detailsWater pipeCoal

The invention relates to a heating plate, and specifically relates to a heating plate with the solar heating function. The heating plate comprises a solar absorbing device and water pipes; the water pipes are spirally arranged in the heating plate; the solar absorbing device is arranged on the outer surface of the heating plate; heat transfer pipes connected with the solar absorbing device are arranged on the water pipes. The heating plate with the solar heating function has the advantages that the coating material for absorbing solar energy is arranged, the absorbed solar energy is transmitted to the spiral water pipes in the heating plate through the heat transfer pipes, and then the water pipes circle to radiate heat into a room, so as to achieve the indoor heating effect; therefore, the coal carbon resources can be effectively saved, and no pollution is generated to the environment.

Owner:段辉

Coal firing equipment with single rotational flow

InactiveCN100394105CSimple structureLow costPulverulent fuel combustion burnersCasings/liningsCombustionEngineering

The present invention relates to a single-cyclone coal-burning equipment. It includes combustion furnace cavity, fire grate, coal-adding device and high-temperature gas outlet. It is characterized by that the top portion of its furnace cavity cross-section is made into the arched form capable of forming cyclone combustion, the side wall of said furnace cavity is equipped with a combustion-supporting air inlet communicated with the furnace cavity, said combustion-supporting air inlet is tangential to said arched form of top portion of furnace cavity, the rear portion of said furnace cavity, is connected with high-temperature gas outlet. Said invention is simple in structure, and can completely solve the problem of discharging black smoke by burning coal, and can save fuel coal.

Owner:王树洲

Smokeless, coal saving type heat transfer oil stove with large mechanical fire grate

InactiveCN100394103CNo implementationNo pollution in the processSolid fuel combustionCombustion apparatusCombustionHeat conducting

The present invention relates to a smokeless coal-saving large-size mechanical fire grate heat-conducting oil-burning boiler. It is characterized by that said furnace body has heating zone and hot gas supply zone, the interior of furnace body of heating zone is equipped with heat-absorbing tube bank, the bottom portion of heating zone is equipped with a hot gas inlet, and the top portion of said heating zone is equipped with a draught fan; the hot gas supply zone possesses a coal-burning device, said coal-burning device has a combustion furnace cavity, meachinical fire grate, coal-adding device and high-temperature gas outlet. Said invention also provides the concrete structure of said furnace cavity. Said invention is simple in structure and can completely solve the problem of discharging black smoke by burning coal.

Owner:王树洲

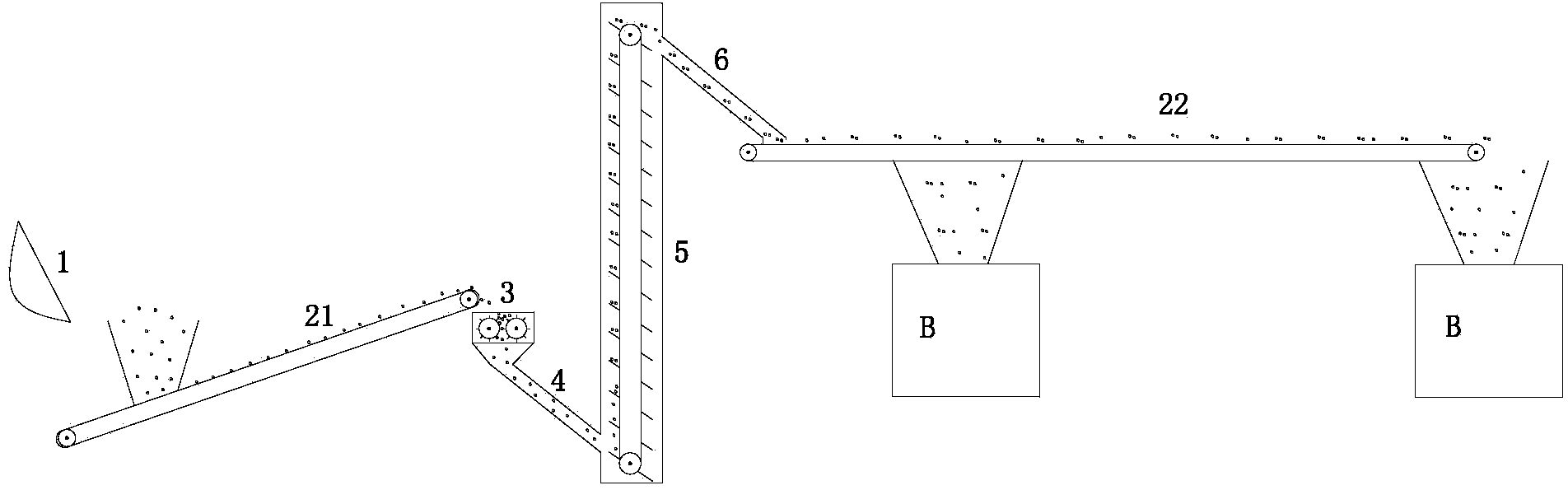

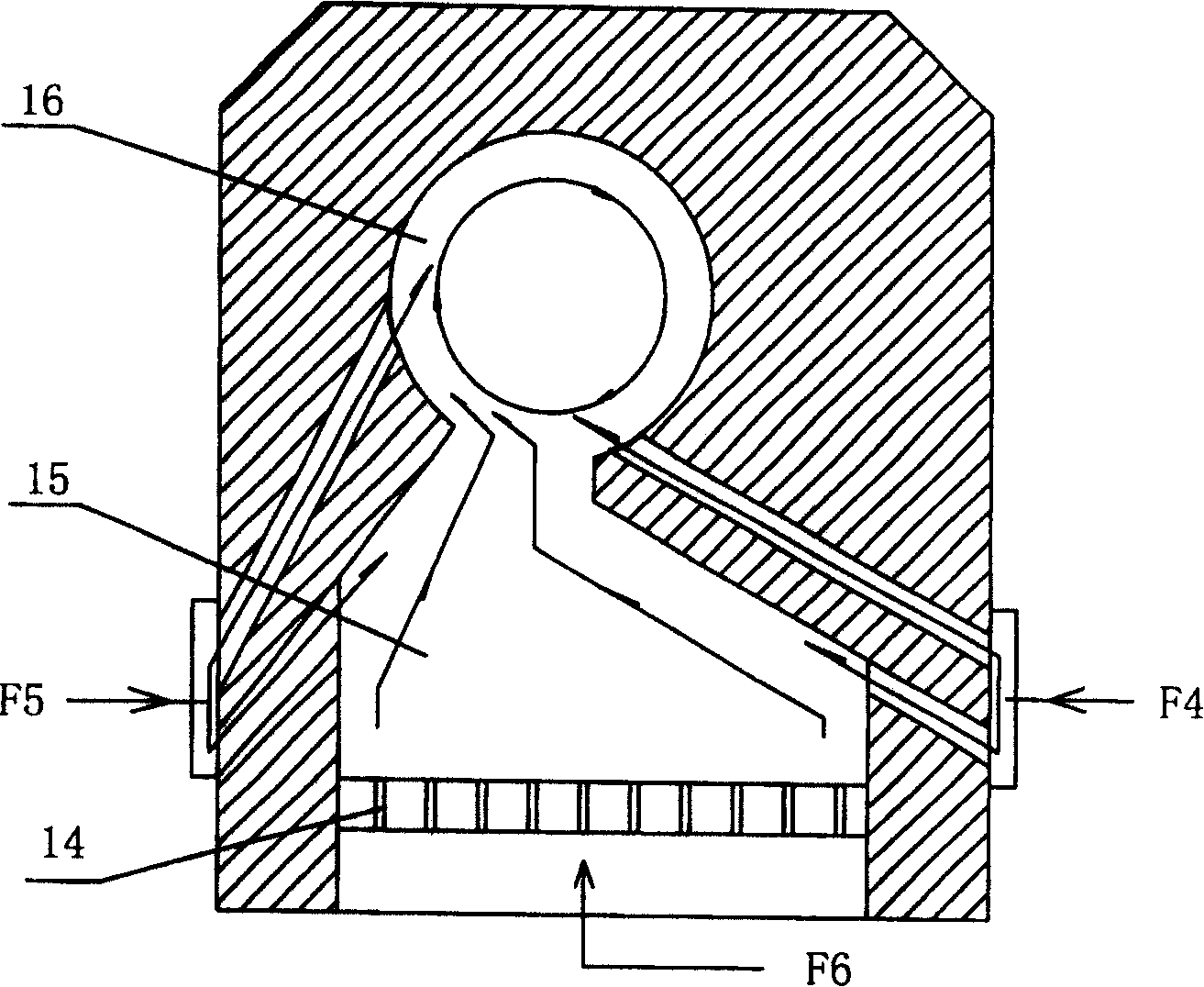

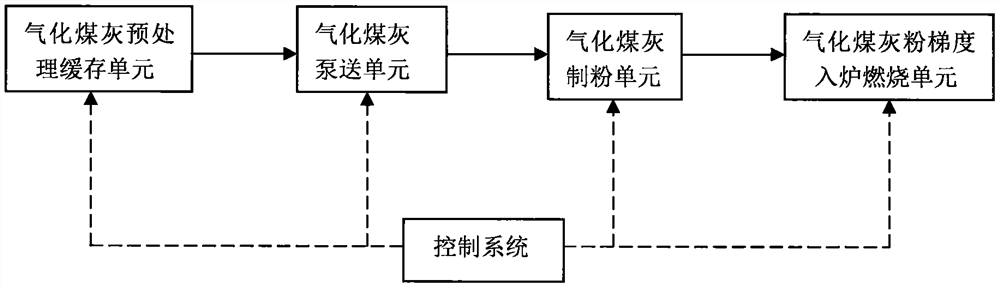

Coal ash blending combustion and gasification process and system for pulverized coal furnace

PendingCN113464969AReliable blendingEliminate system cloggingFuel supply regulationLump/pulverulent fuel feeder/distributionProcess engineeringEnvironmental geology

The invention relates to a coal ash blending combustion and gasification process and system for a pulverized coal furnace. The process comprises the steps of 1, pretreatment and temporary storage of gasified coal ash, 2, pumping of the gasified coal ash, 3, preparation of gasified coal ash powder, and 4, gradient charging combustion of the gasified coal ash powder. In the step 1, impurity removal, separation prevention and temporary storage are carried out on the gasified coal ash, so that the gasified coal ash has characteristics suitable for pumping; in the step 2, the gasified coal ash is conveyed into a gasified coal ash pulverizing unit in a sealed manner through a conveying pump and a pipeline; in the step 3, by adopting a fuel gas heating or high-temperature steam heat exchange method, the outlet temperature of a coal mill and the inlet air volume are improved, and the gasified coal ash powder meeting the combustion requirement is obtained; and in the step 4, the gasified coal ash powder is fed into the pulverized coal furnace according to different proportions and fed into the pulverized coal furnace for mixed combustion in a layered and gradient manner. According to the coal ash blending combustion and gasification process and system for the pulverized coal furnace, blending combustion power generation of the gasified coal ash pulverized coal furnace is achieved, the operation stability and reliability of a blending combustion system are improved, the boiler coal-fired resources are saved, the energy-saving and emission-reducing effects are obvious, and pollution of waste to the environment is eliminated.

Owner:光大清洁技术股份有限公司

Equipment and method for directly fabricating coal balls from pulverized coal

The invention relates to equipment for directly fabricating coal balls from pulverized coal, which comprises a first roller machine, a grinder and a second roller machine, wherein the first roller machine is used for directly compressing pulverized coal into sheet type coal, the grinder is used for receiving the sheet type coal and fabricating the sheet type coal into block-shaped coal, and the second roller machine is used for receiving the block-shaped coal and compressing the block-shaped coal into coal balls, a plurality of concave parts are arranged on the outer periphery of each roller in the second roller machine, and the concave parts on each two rollers are opposite. According to the equipment, pulverized coal with low water content is directly fabricated into coal balls, binding agent is not needed for addition, on one hand, the cost on fabricating coal balls can be saved, and on the other hand, plenty of coal resources can be saved by using the coal balls for coking.

Owner:本溪鹤腾高科技研发(中心)有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com