Patents

Literature

31results about How to "Easy to adjust particle size" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

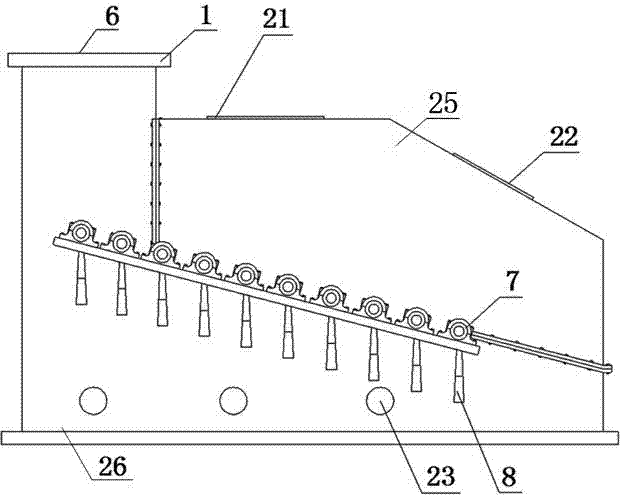

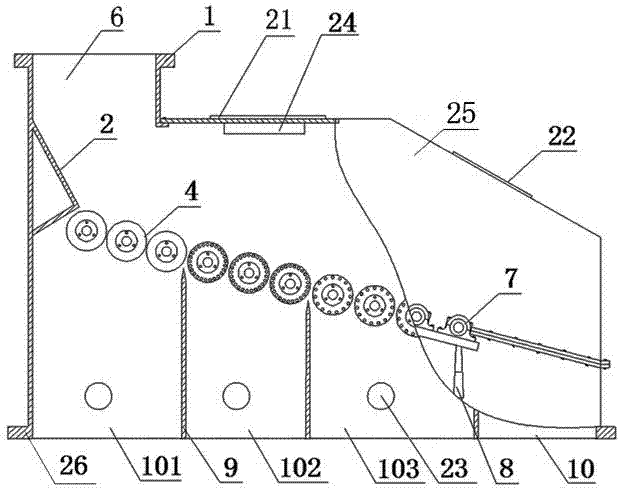

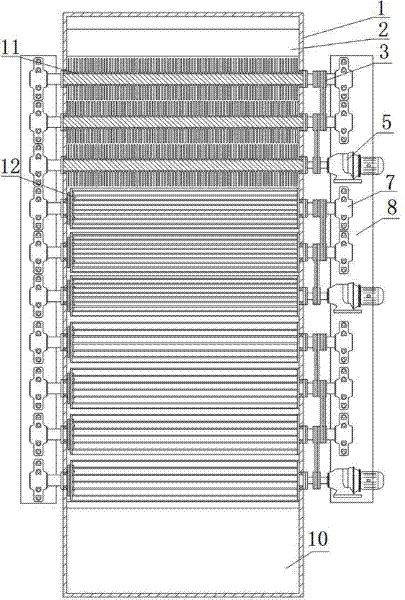

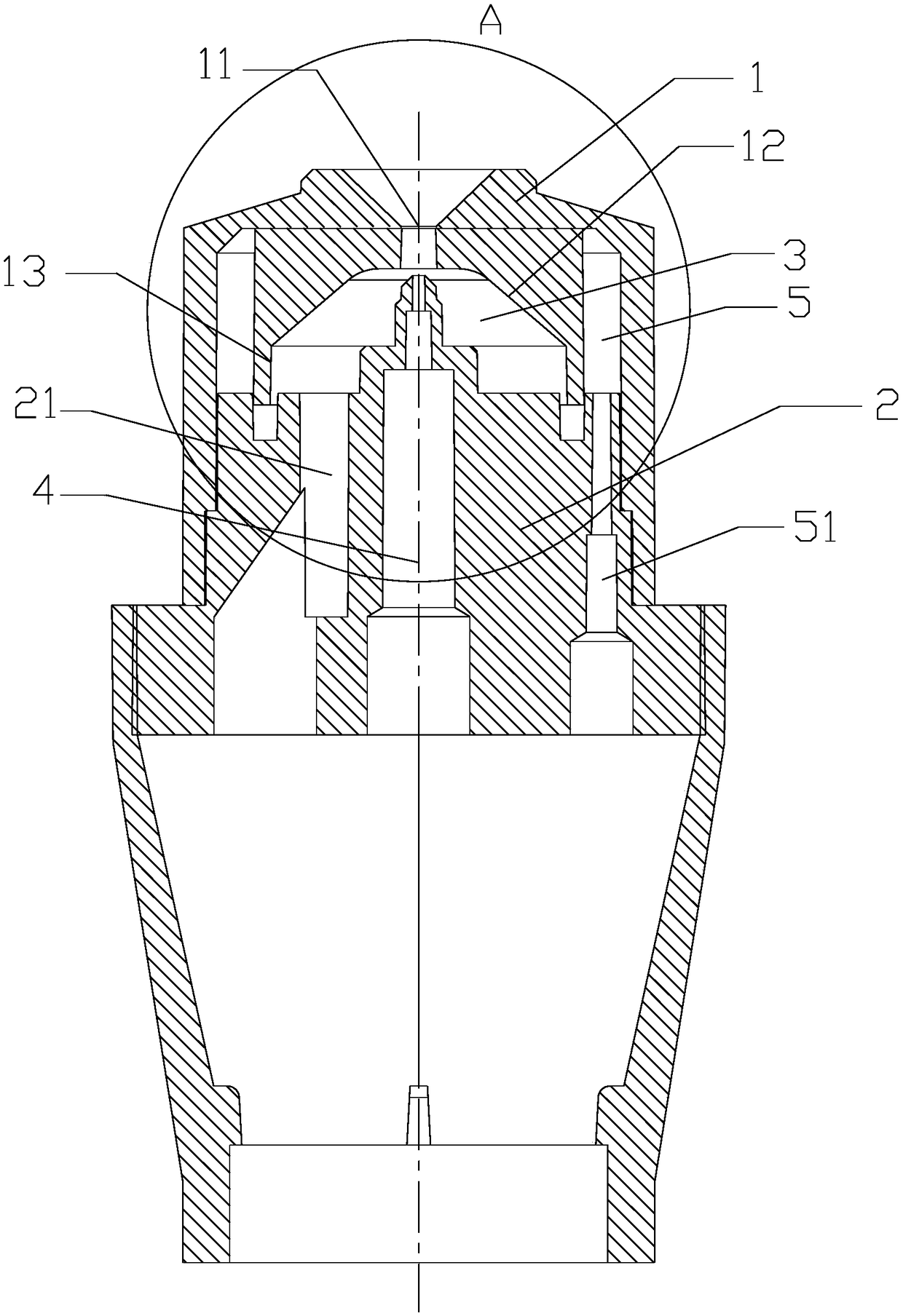

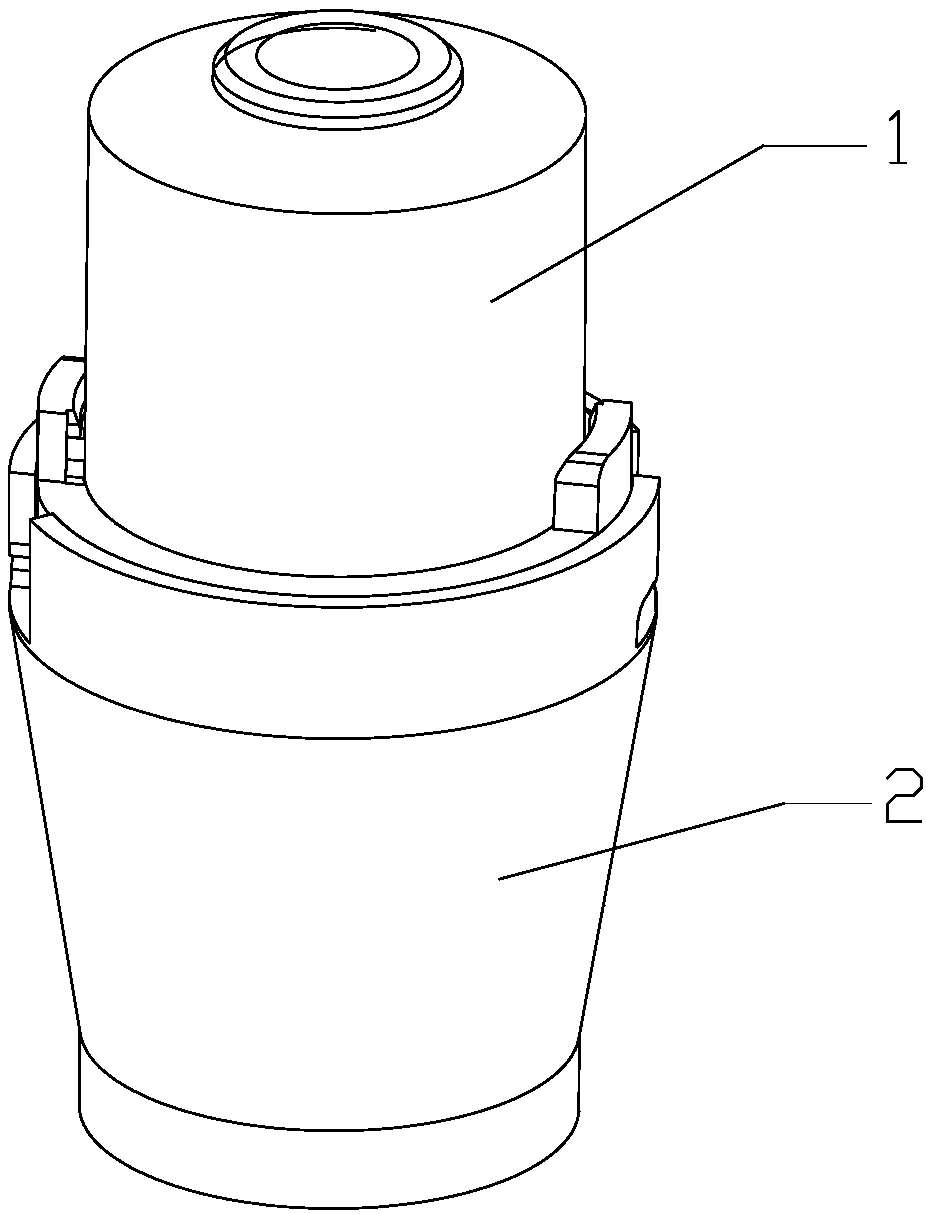

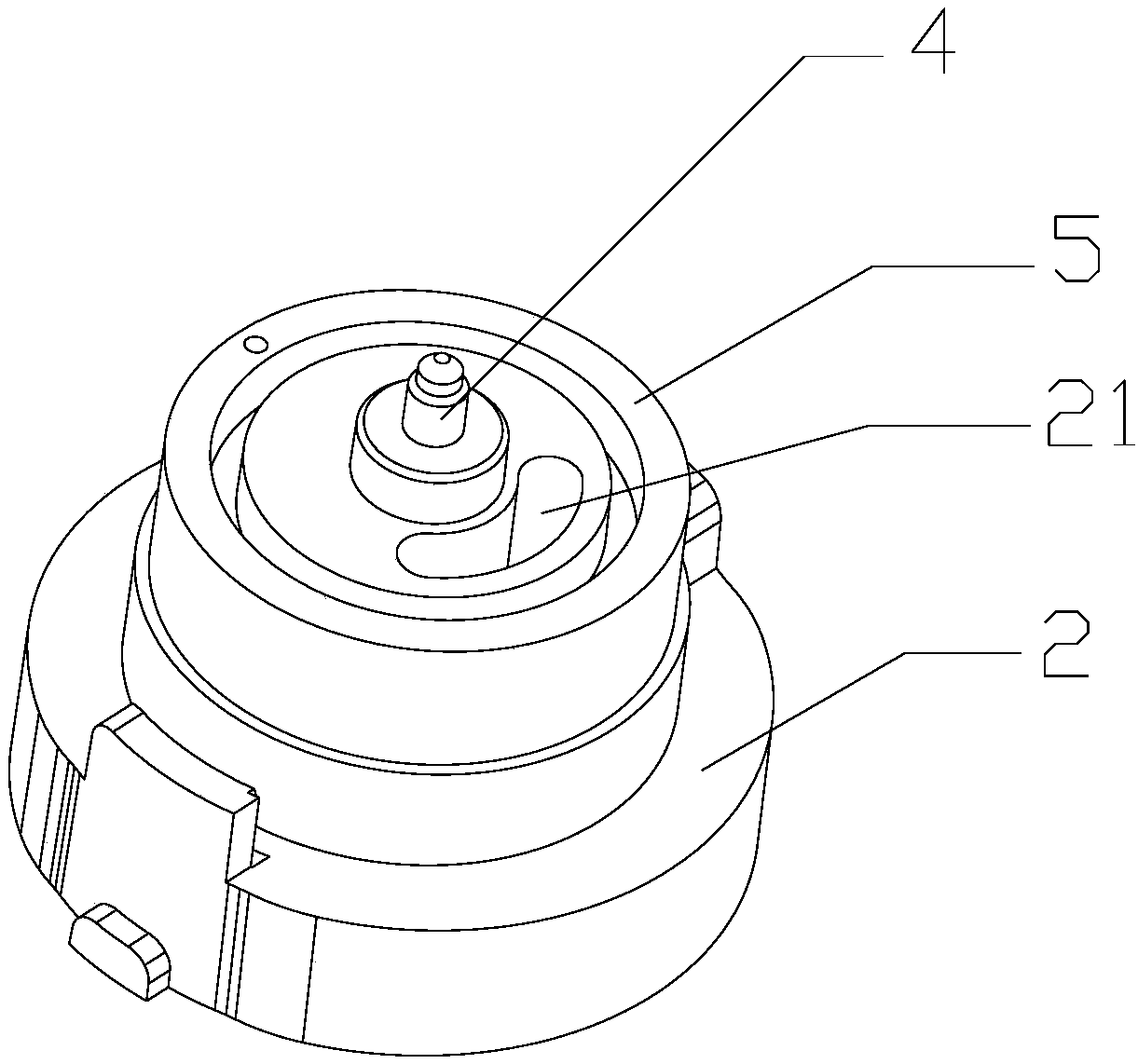

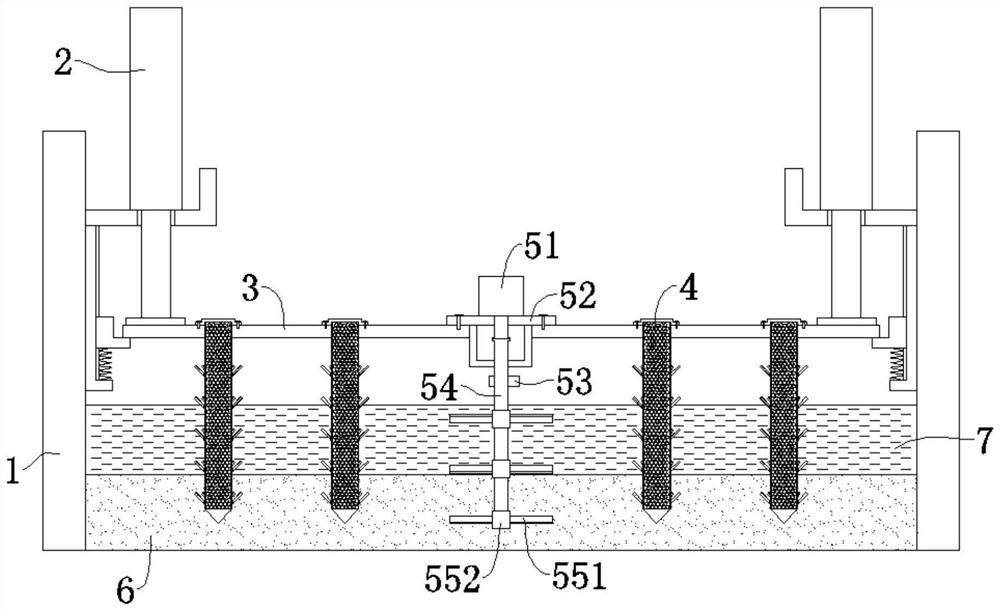

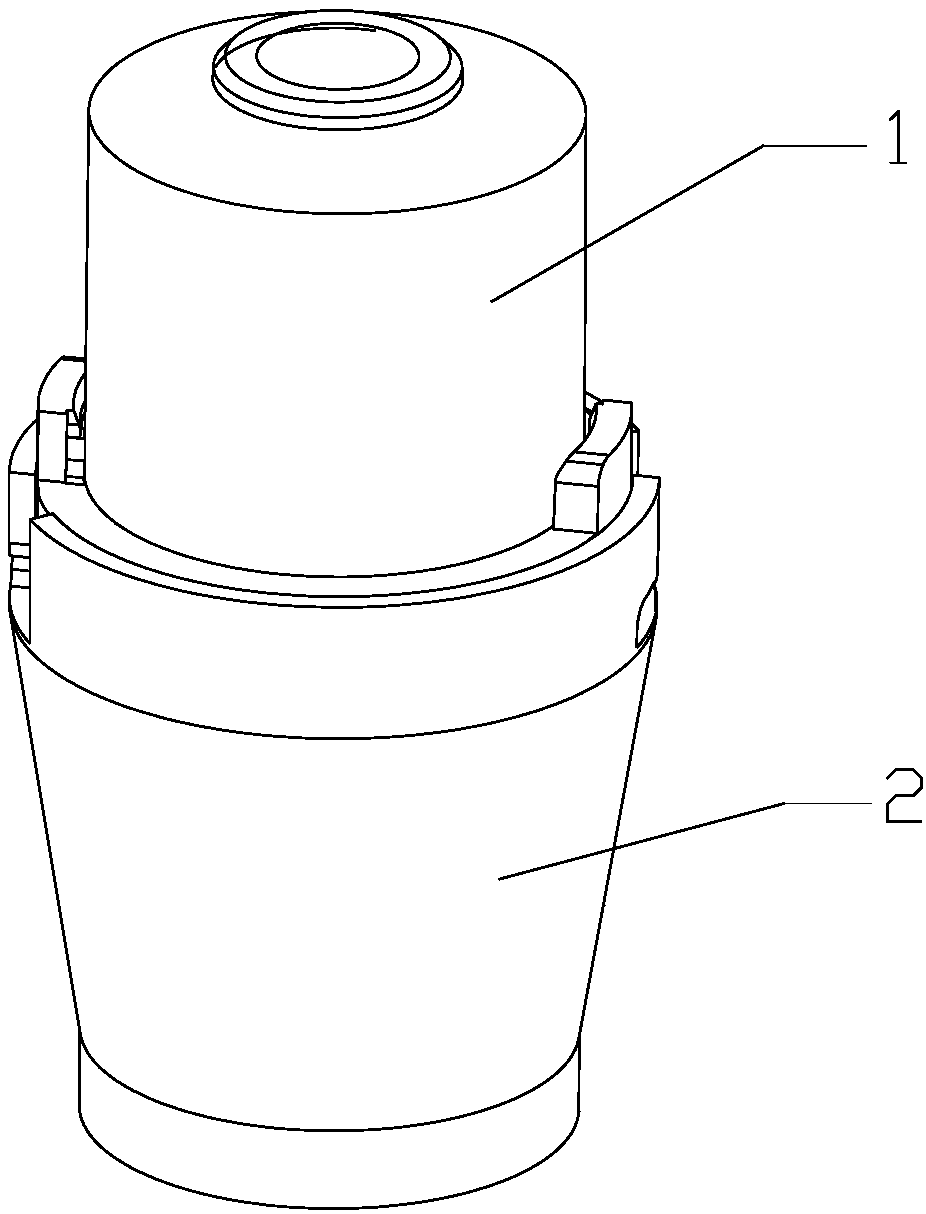

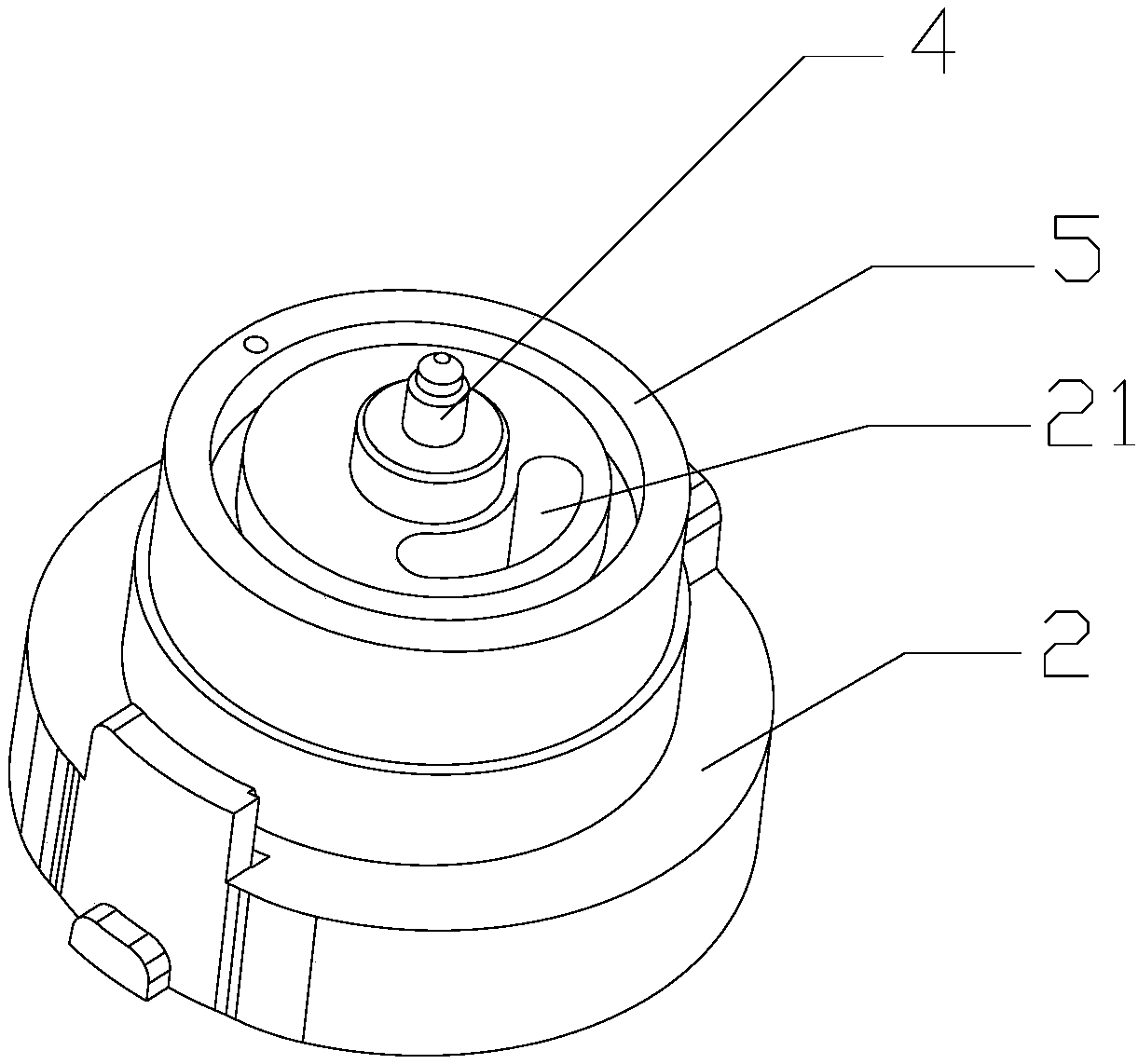

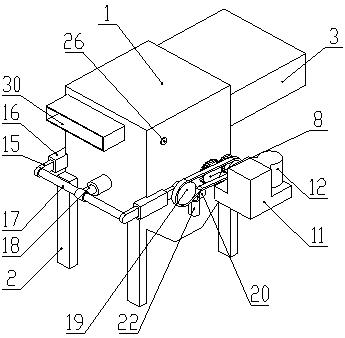

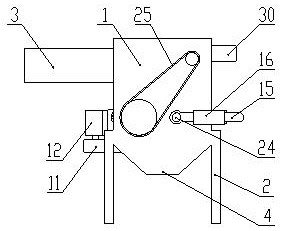

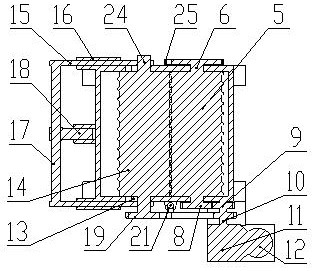

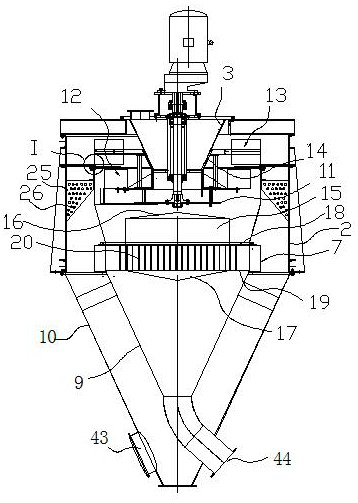

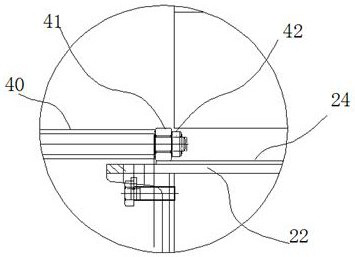

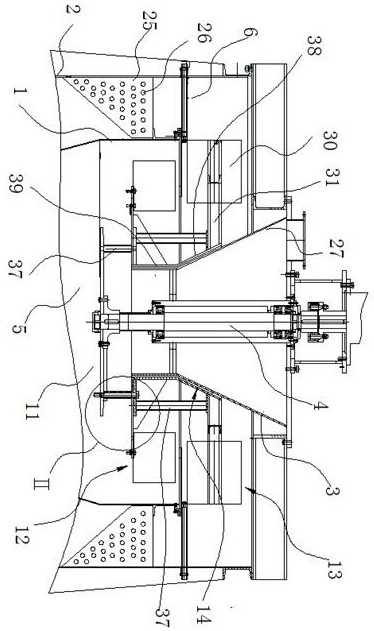

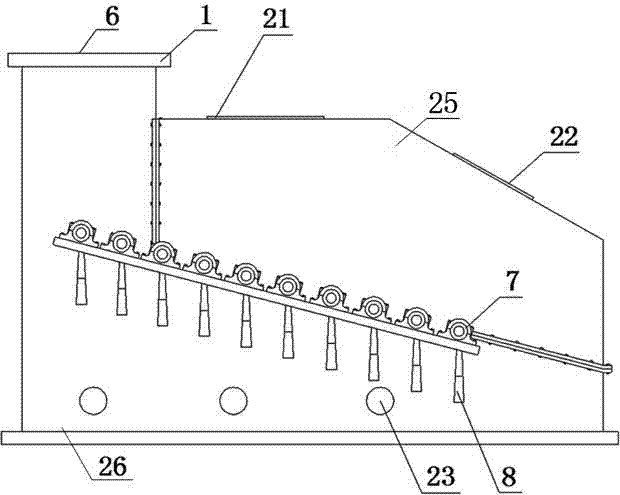

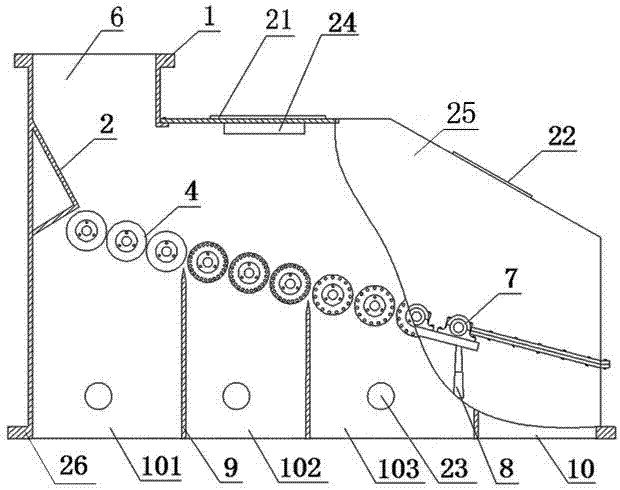

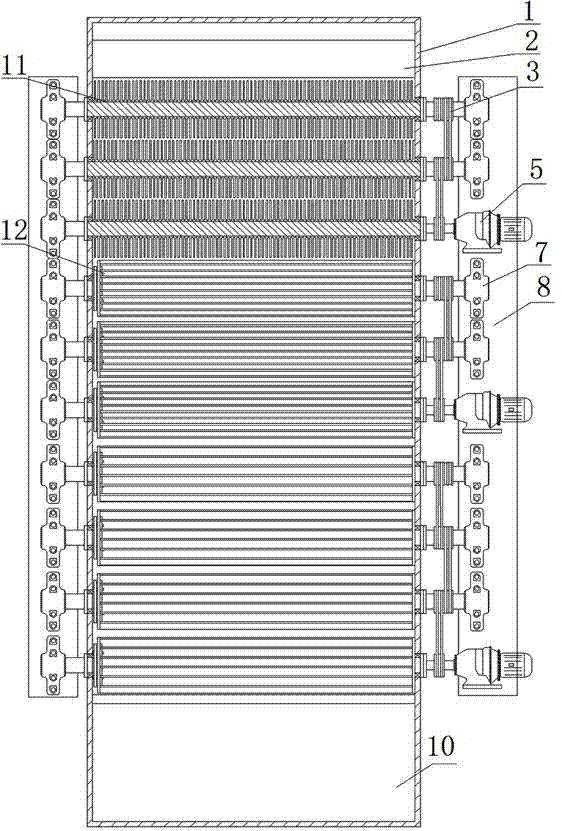

Material distributing screening machine

The invention discloses a material distributing screening machine, comprising a machine case (1), a forced fabric plate (2), a driving device (3), a filtering roller (4), a reducer motor (5) and an iron removing device (24), wherein the machine case (1) is provided with a feeding hole (6) and a plurality of discharging holes (10), the filtering roller (4) comprises a flange disk type roller (11) and a filtering rope type roller (12), the filtering roller (4) is provided with the driving device (3), the reducer motor (5) drives the filtering roller (4) to rotate by virtue of the driving device (3), and material enters from the feeding hole (6), is screened by the filtering roller (4) and is discharged by the discharging hole (10). The invention has the beneficial effects that: more than two materials in different grain sizes can be screened by setting different interstitial screen cuts, the working condition requirement for screening more than two materials can be met, screening efficiency is high, bulk material impact resistance is high, material is distributed more uniformly, no blockage is caused, and an iron piece contained in the material can be removed.

Owner:SICHUAN ZHONGMENG ELECTRIC POWER EQUIP MFG CO LTD

Method for ordered arrangement of nano particles on solid base surface

The present invention relates to nano technology field. The process of arranging nano particles on the surface of solid base includes the specific steps of: dissolving chain organics molecule with hydrophilic or hydrophobic group into non-aqueous volatile solvent; dispersing nano particles in the said solution; spreading the non-aqueous solution on water as base liquid inside Langmuir tank and controlling the film pressure on the single-molecule film of the nano particles on the surface of water; transferring the film via vertical pulling process to treated surface of solid base to form Y-type LB film; and high temperature annealing or high-energy light beam irradiating the nano particle film to dissociate and evaporate organics molecule while leaving the nano particles on the base. The said process is simple, practical and effective and may be used widely.

Owner:SHANGHAI JIAO TONG UNIV

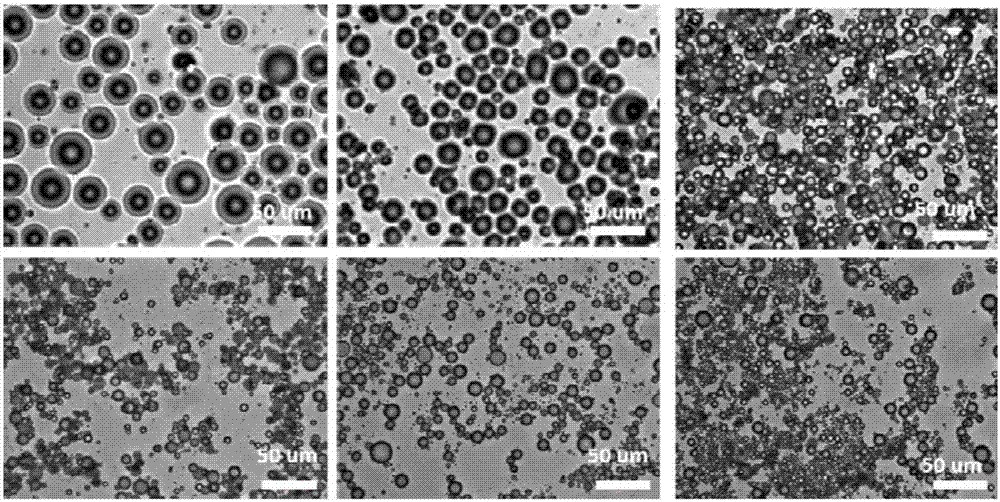

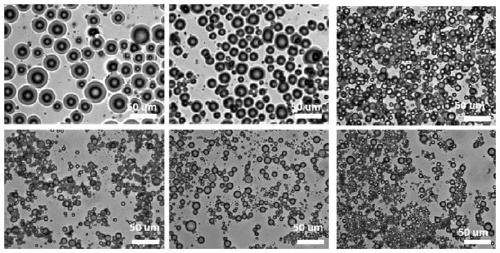

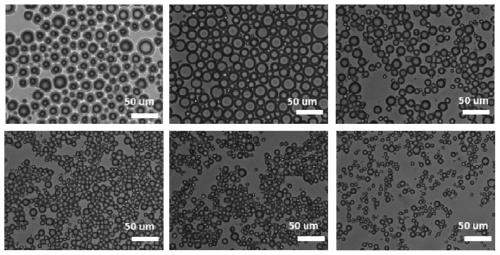

Preparation method of hollow glass beads

The invention relates to a preparation method of hollow glass beads. The preparation method comprises the following steps of: by taking nano cellulose as a Pickering emulsion, adding a precursor of silicon dioxide into an oil phase of the emulsion; and by taking the Pickering emulsion as a template, performing a sol-gel reaction on the precursor of silicon dioxide under an acidic or alkaline condition to prepare the hollow glass beads. The preparation method provided by the invention is simple and convenient, the particle sizes can be regulated, the preparation method can be performed at room temperature, and the cost of preparing the hollow glass beads is lowered.

Owner:张振

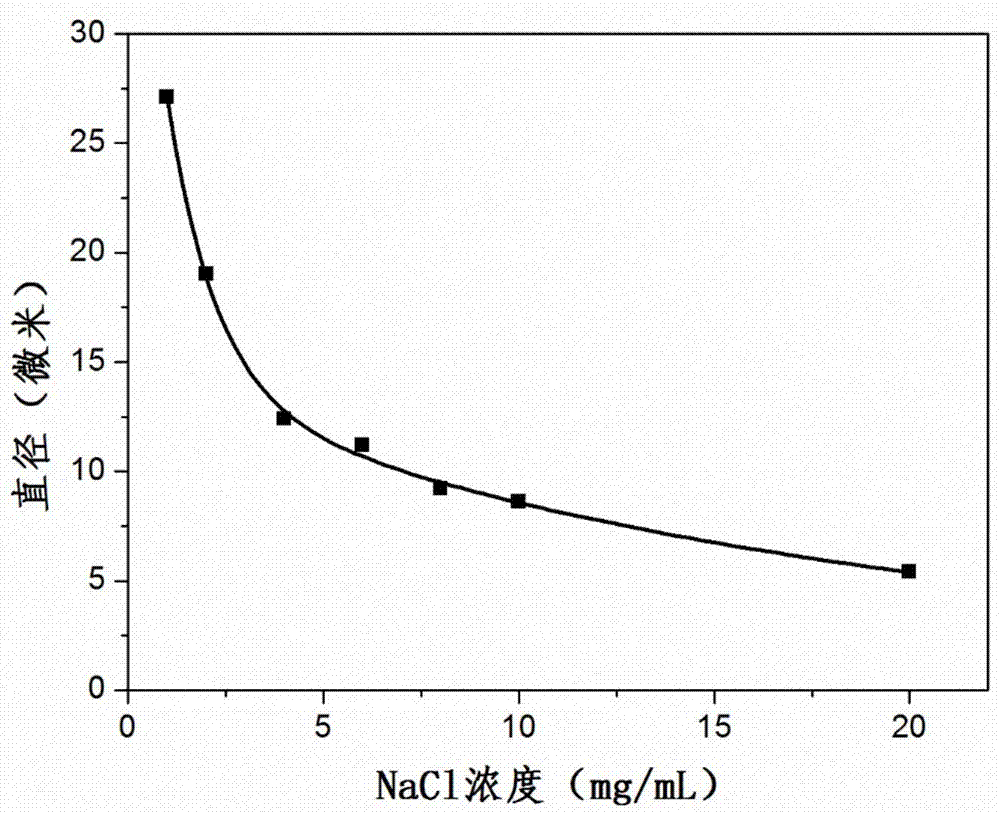

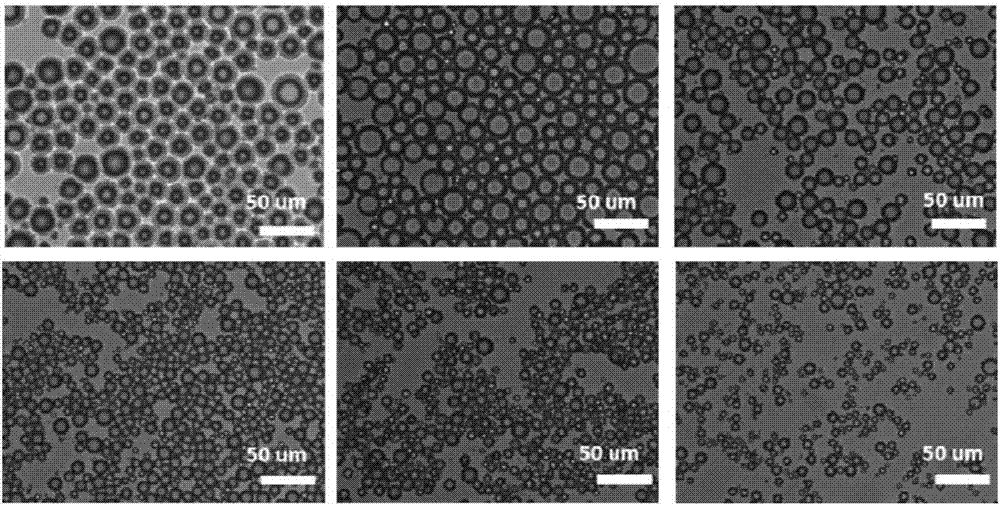

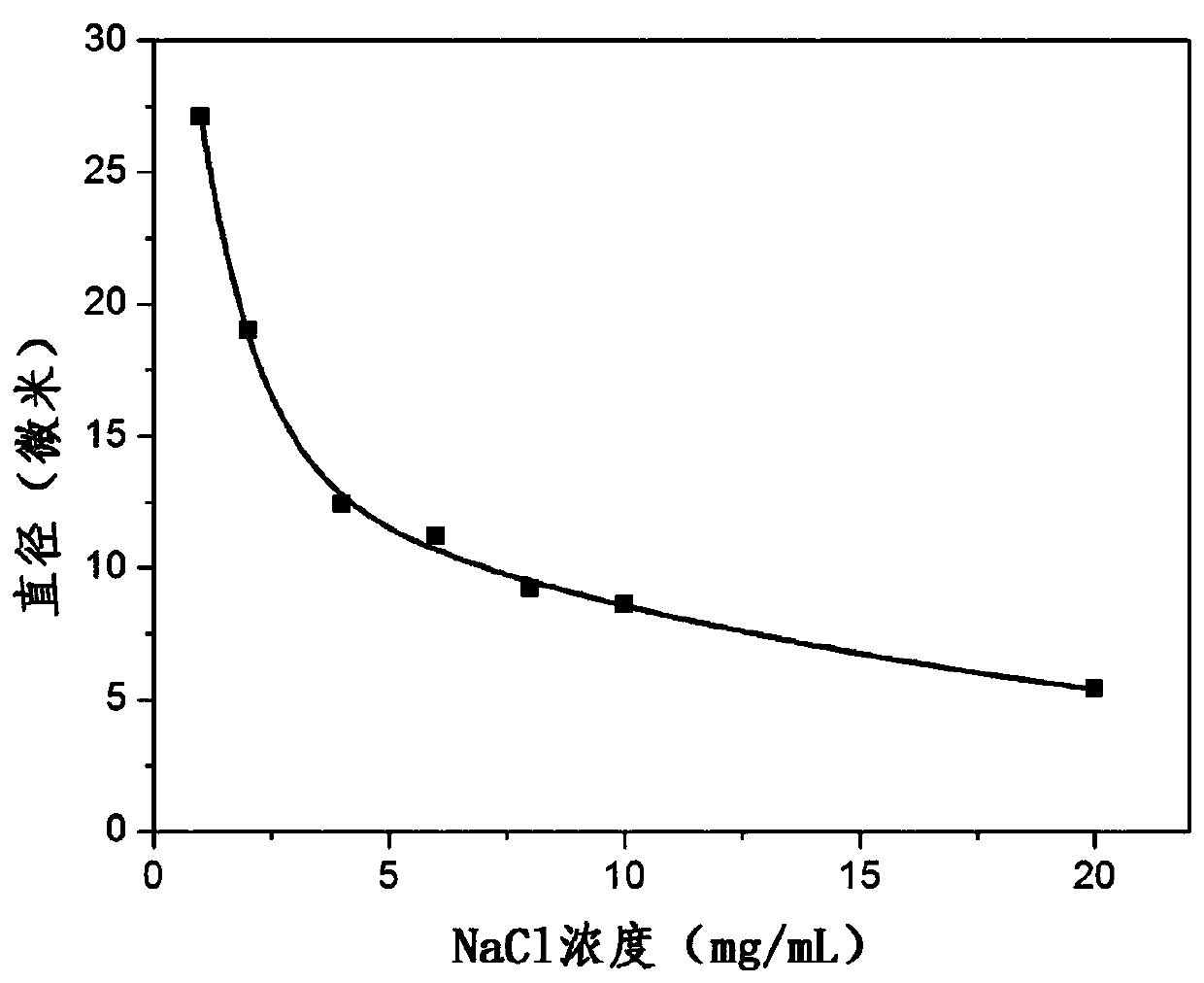

Oil-absorbing resin and preparation method

ActiveCN103333286AImprove hydrophobicityImprove adsorption capacityOther chemical processesPolymer scienceDistilled water

The invention relates to an oil-absorbing resin and a preparation method thereof. The oil-absorbing resin comprises an oil phase: 5-15 parts of glycol dimethacrylate, 15-30 parts of isobornyl methacrylate, 20-40 parts of p-diphenyl sulfone methacrylate, 10-15 parts of triethylene glycol methacrylate, 10-20 parts of divinylbenzene, 20-30 parts of styrene, 50-200 parts of porogen, 0.5-2 parts of AIBN; and a water phase: 500-1000 parts of distilled water, 5-15 parts of PVA, and 20-50 parts of NaCl. According to the preparation method provided by the invention, the isobornyl methacrylate and the p-diphenyl sulfone methacrylate are used as main synthesis materials, and meanwhile, the non-polar crosslinking agents divinylbenzene and glycol dimethacrylate are used as crosslinking agents, and the styrene with higher hydrophobicity is used as a comonomer to synthetically prepare the oil-absorbing resin which can effectively absorb oil.

Owner:CHINA BLUESTAR CHENGRAND CO LTD

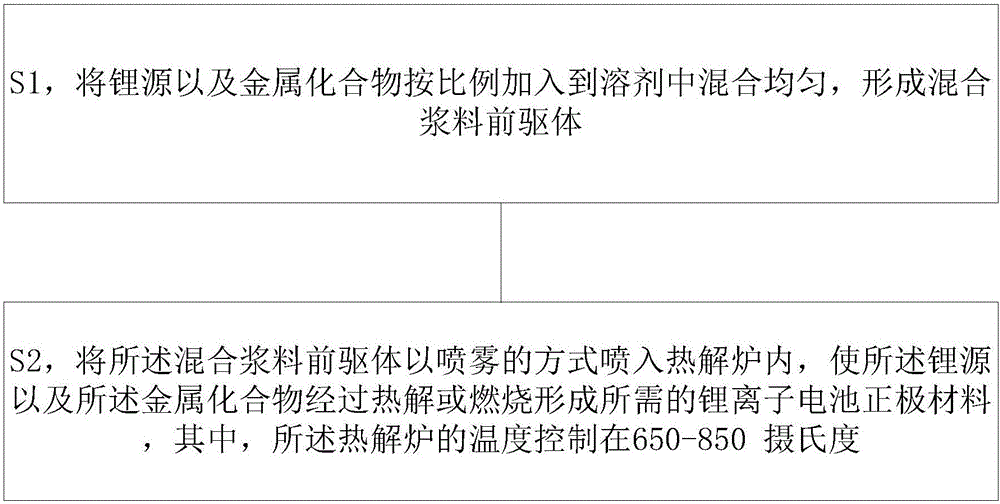

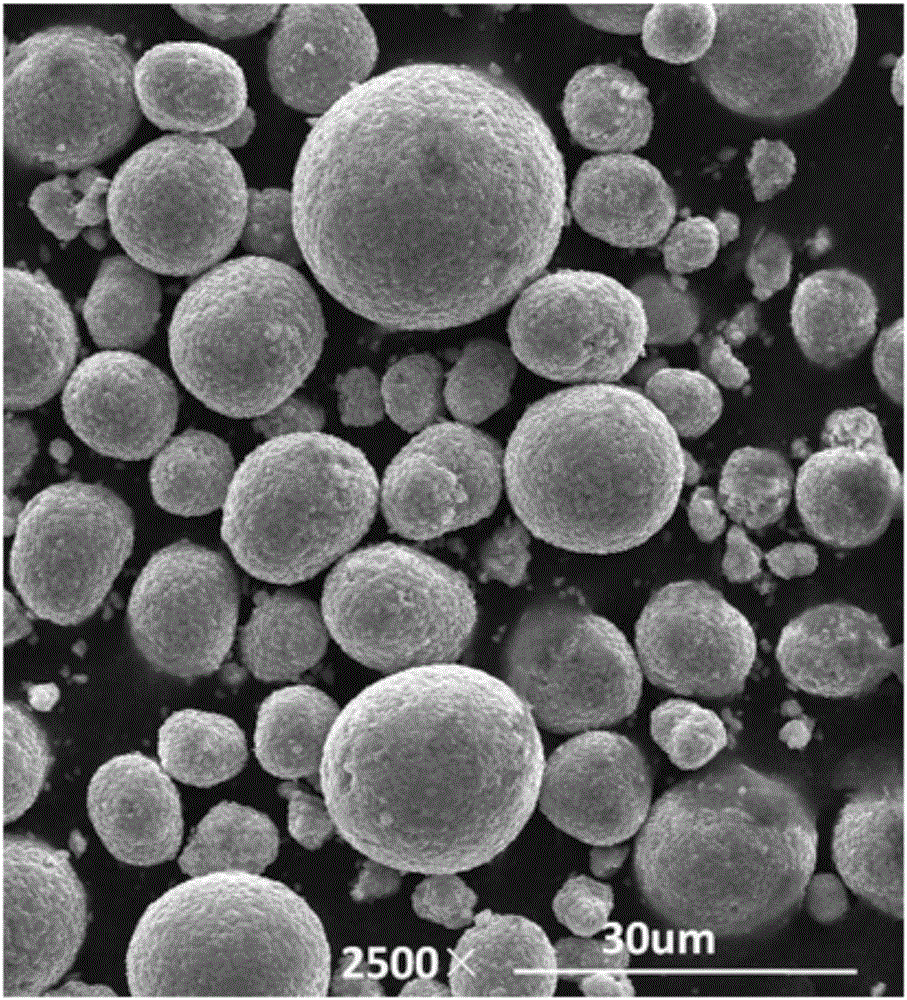

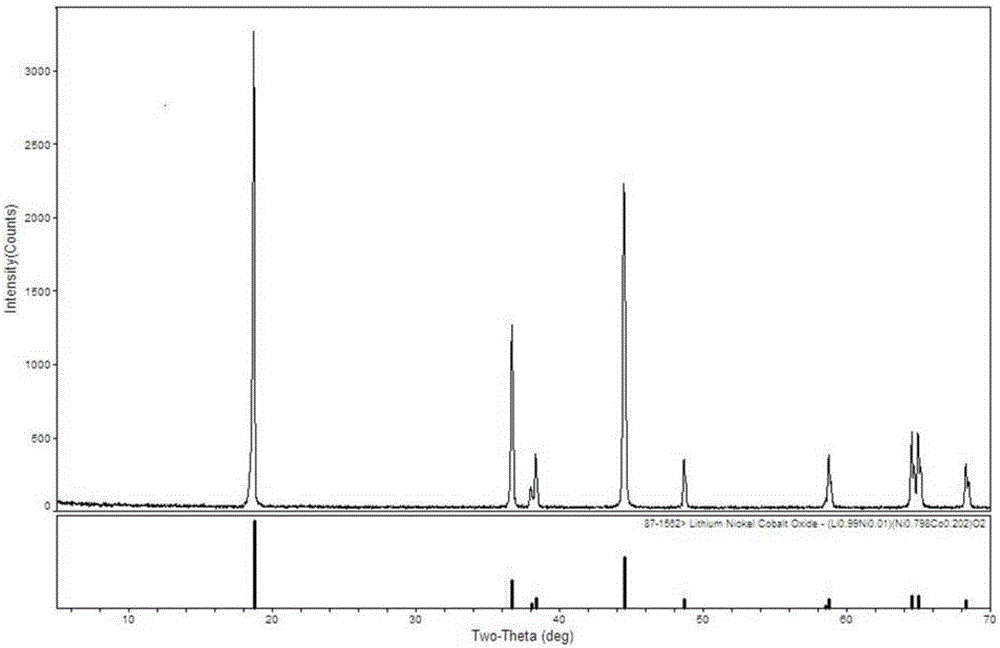

Method for preparing positive electrode material for lithium ion cell by spraying, combusting and pyrolyzing

ActiveCN105932269AShort synthesis cycleHigh purityCell electrodesSecondary cellsTemperature controlLithium

The invention provides a method for preparing a positive electrode material for a lithium ion cell by spraying, combustion and pyrolyzing. The method comprises the following steps of S1, proportionally adding a lithium source and a metal compound into a solvent and mixing them well, thus forming a mixed slurry precursor; and S2, spraying the mixed slurry precursor into a pyrolyzing furnace in a manner of spray, thus pyrolyzing or combusting the lithium source and the metal compound to form the required positive electrode material for the lithium ion cell, wherein the temperate of the pyrolyzing furnace is controlled to be 650-850 DEG C.

Owner:ZHEJIANG MEIDARUI NEW MATERIAL TECH CO LTD

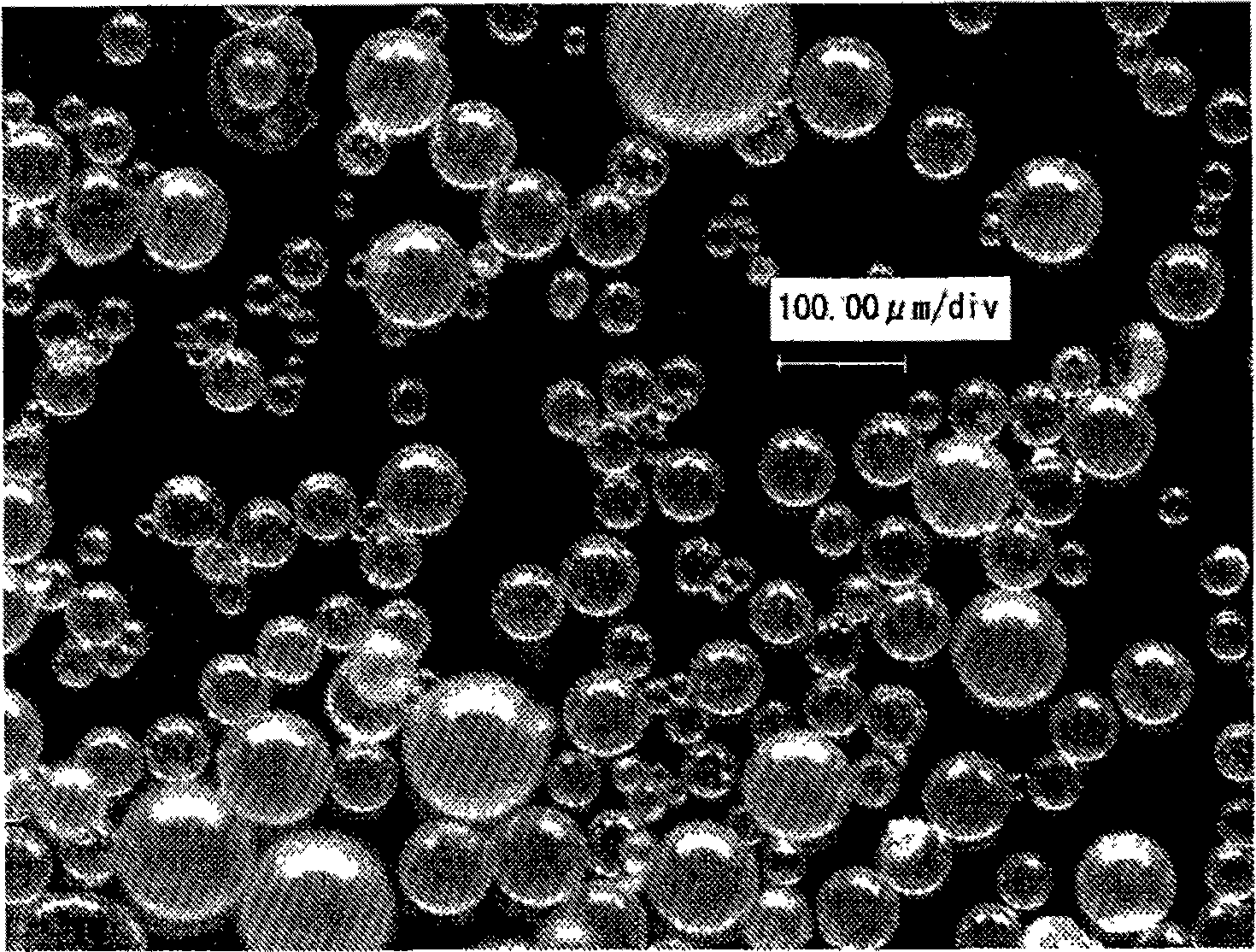

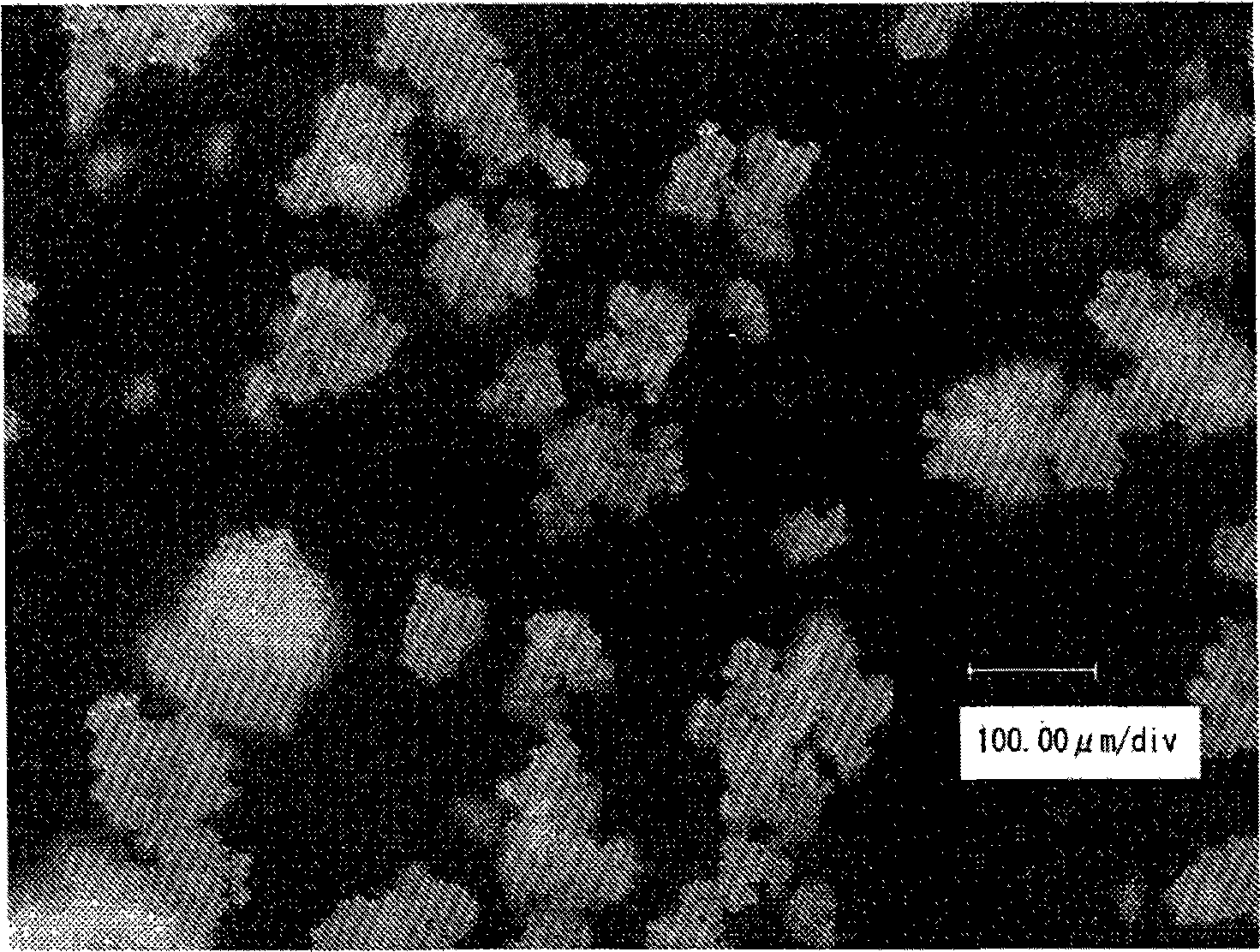

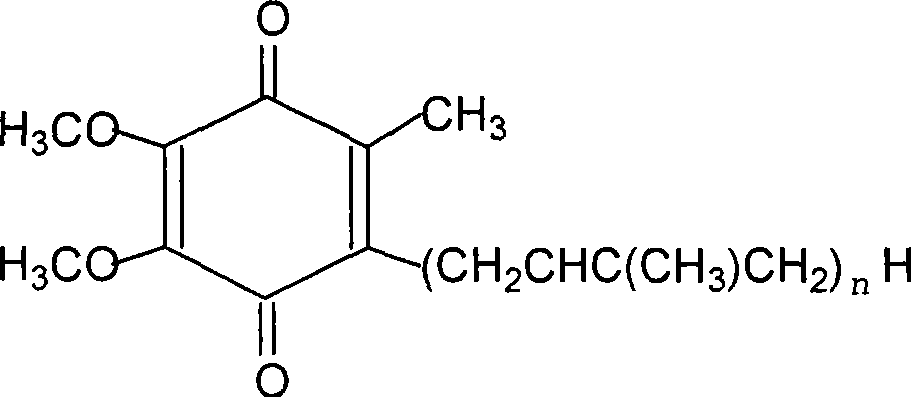

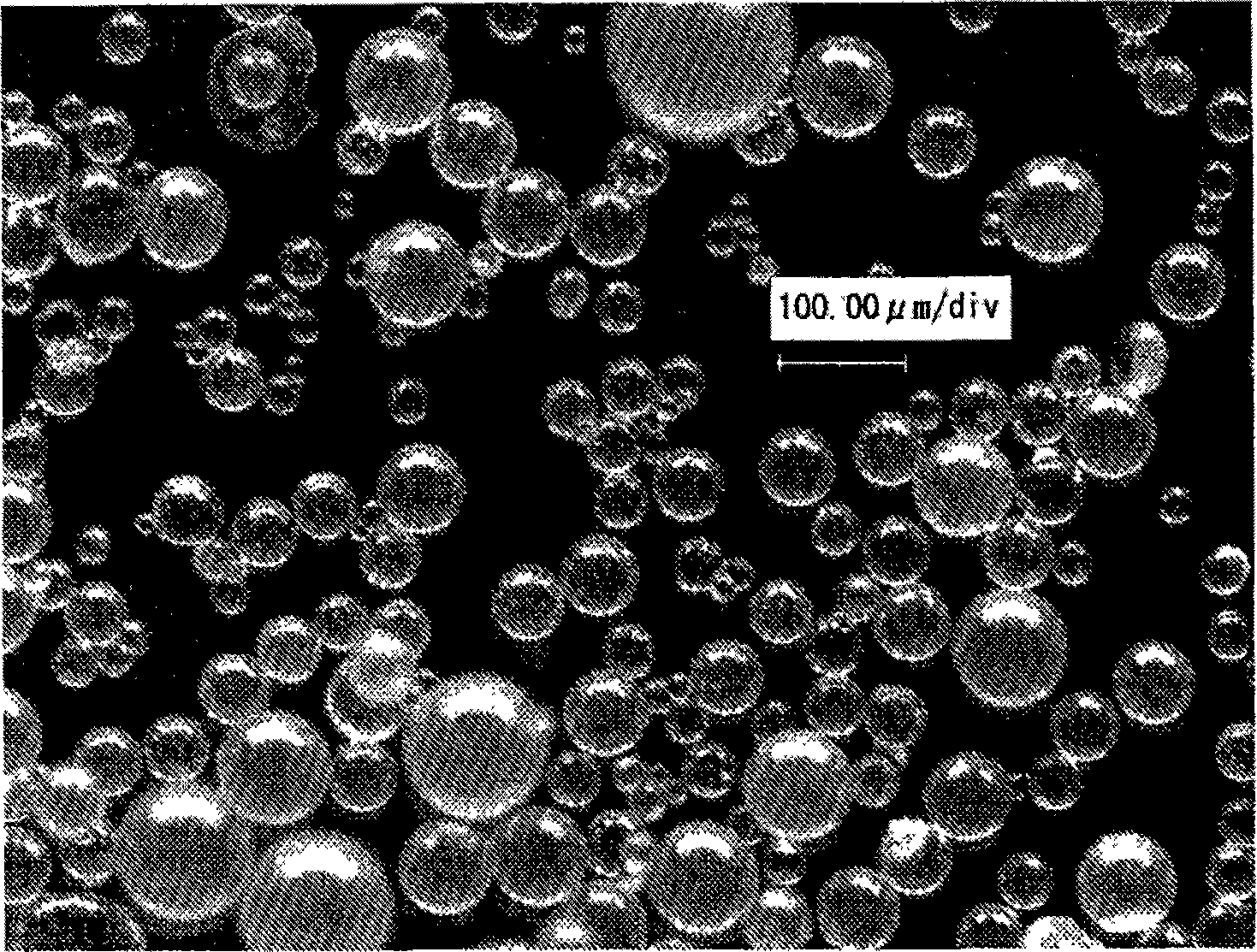

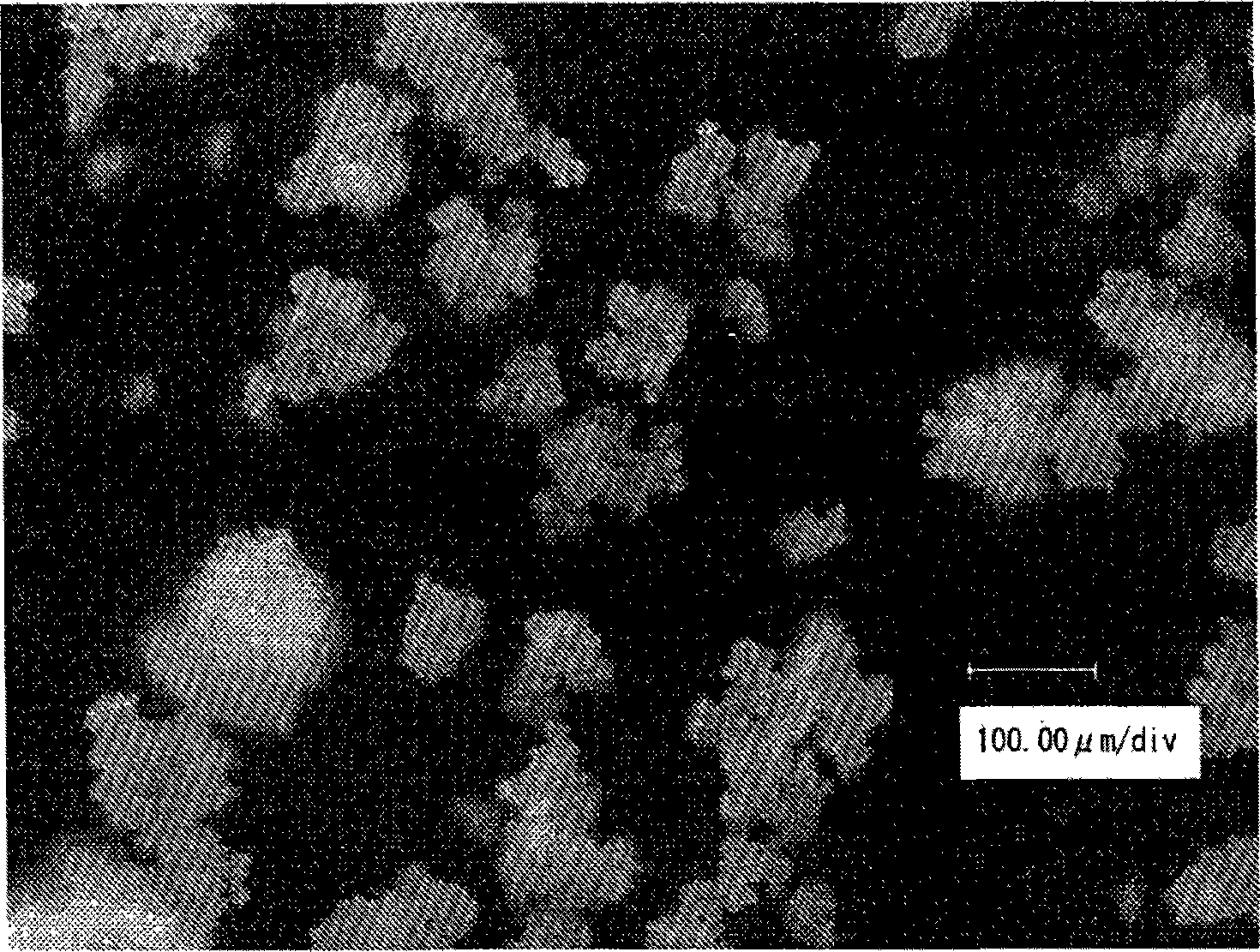

Physiologically active substance-containing granular composition and method of producing the same

InactiveCN101534796AGood water solubilityEasy to operatePowder deliveryHydroxy compound active ingredientsParticulatesSolubility

The present invention provides a particulate composition wherein an oil component (A) comprising a water-insoluble bioactive substance is poly-dispersed while forming a domain in a matrix comprising of a water-soluble excipient based on a water-soluble polymer, and wherein the sphericity of the particulate composition is not less than 0.9 and a method of producing the same. The particulate composition simultaneously has excellent water solubility, workability, tabletability and heat-resistance. It also provides a food, food with nutrient function claims, food for specified health uses, nutritional supplement, nutritional product, animal drug, drink, feed, pet food, cosmetic, pharmaceutical product, therapeutic drug, prophylactic drug and the like, which contain the particulate composition.

Owner:KANEKA CORP

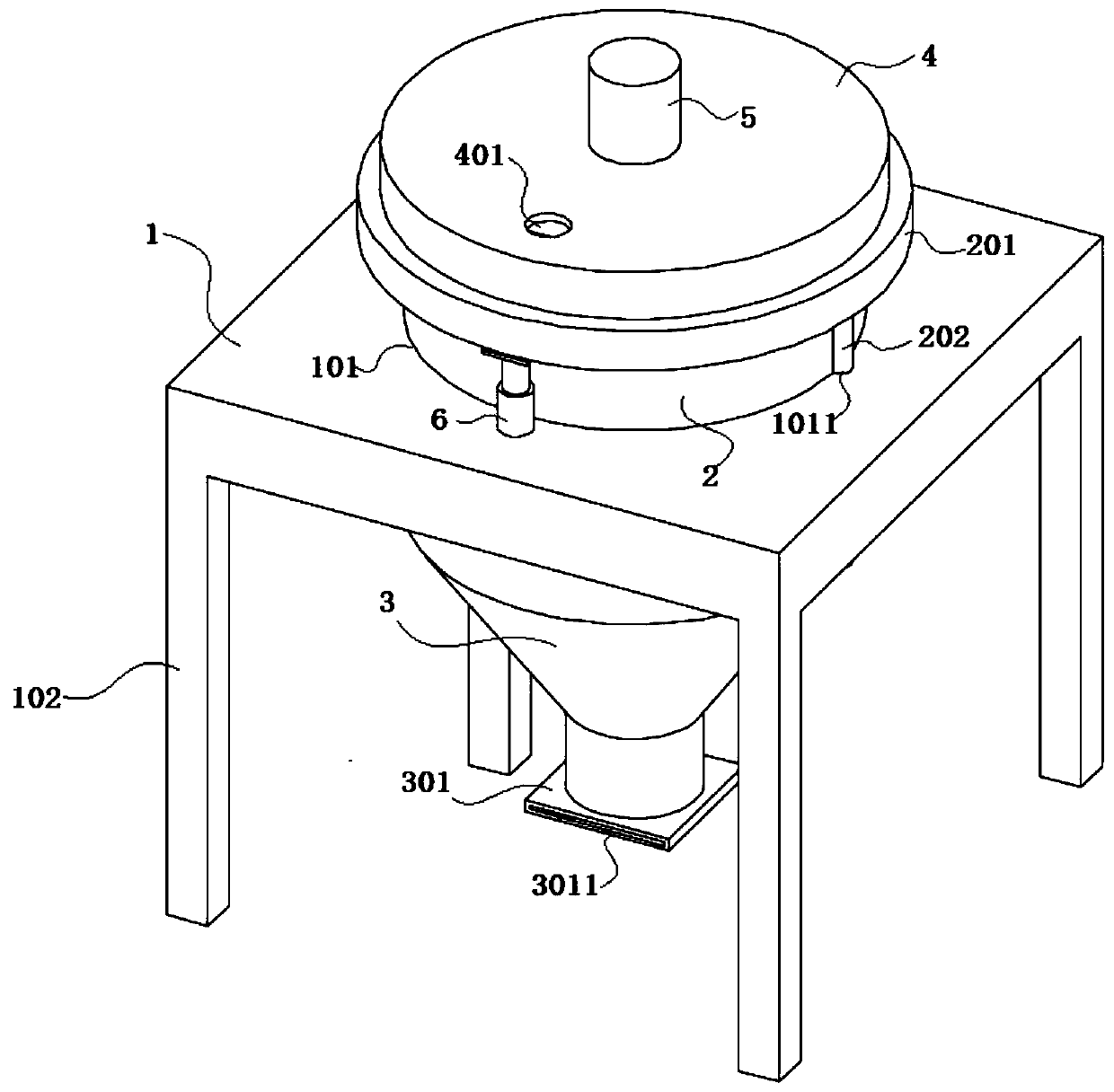

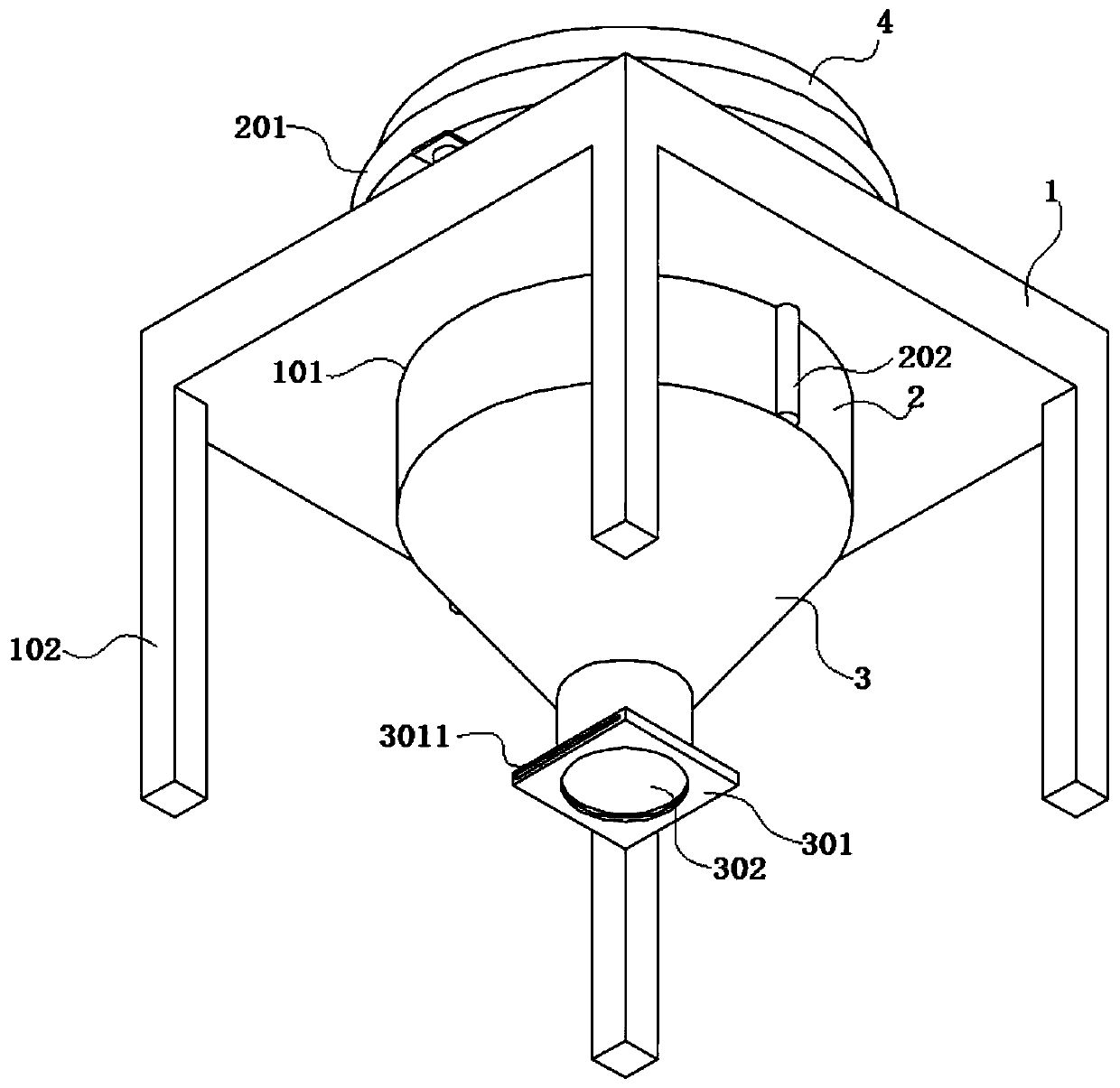

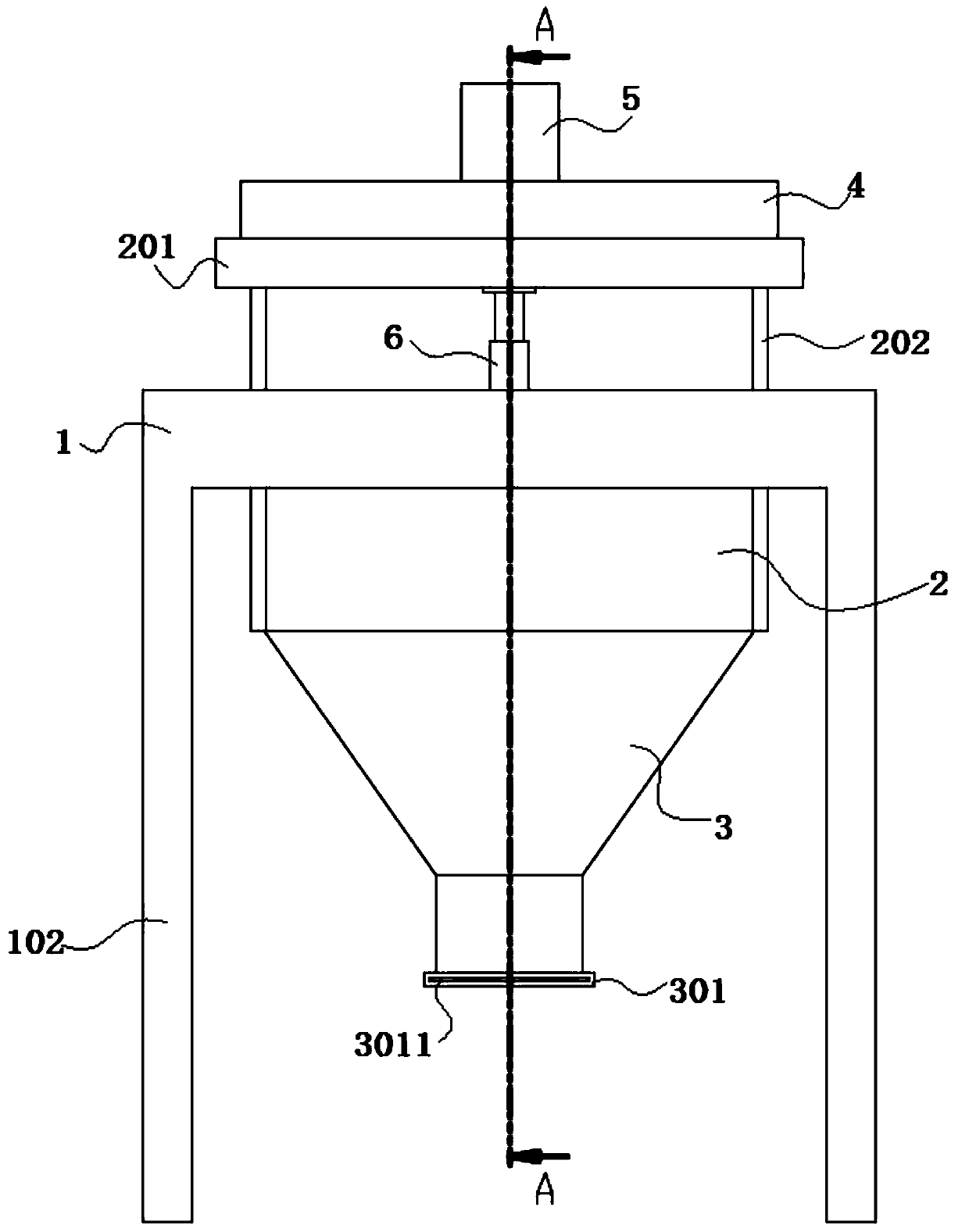

Discharge device for preparing electronic device alloy powder

InactiveCN110937258AUniform dischargeAvoid cloggingConveyorsLarge containersHydraulic cylinderElectric machine

Owner:芜湖应天光电科技有限责任公司

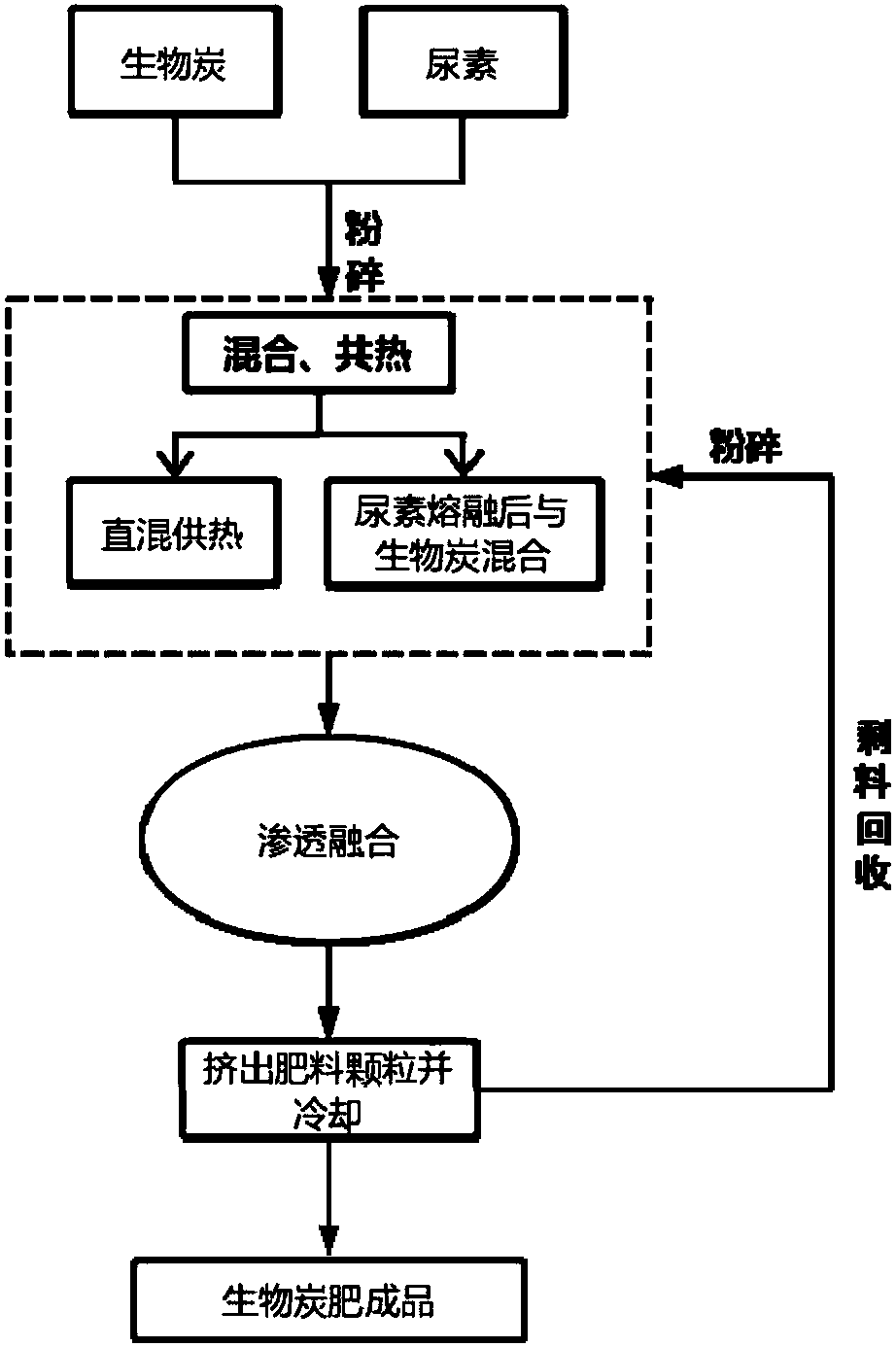

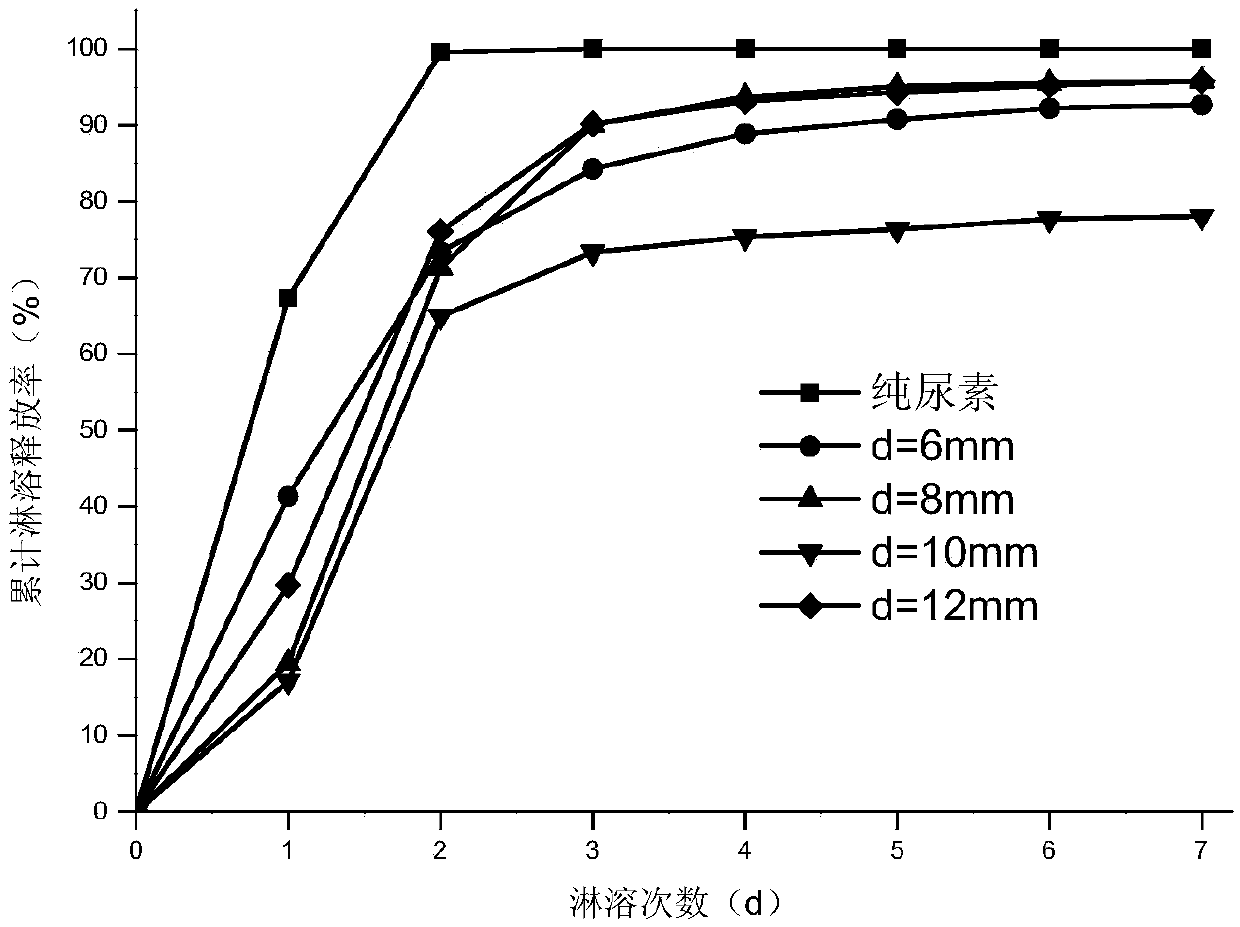

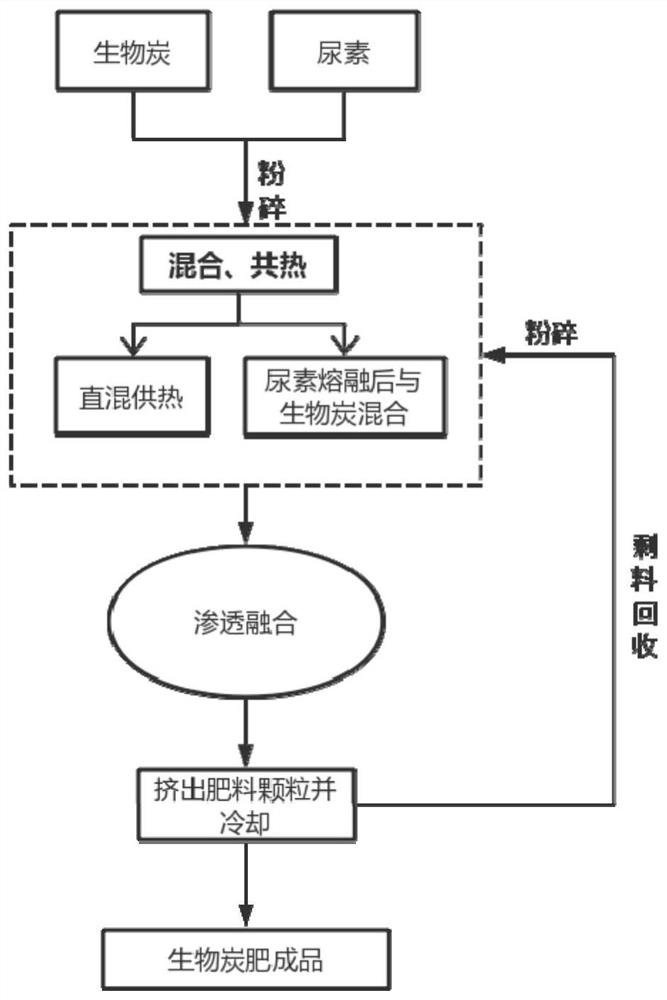

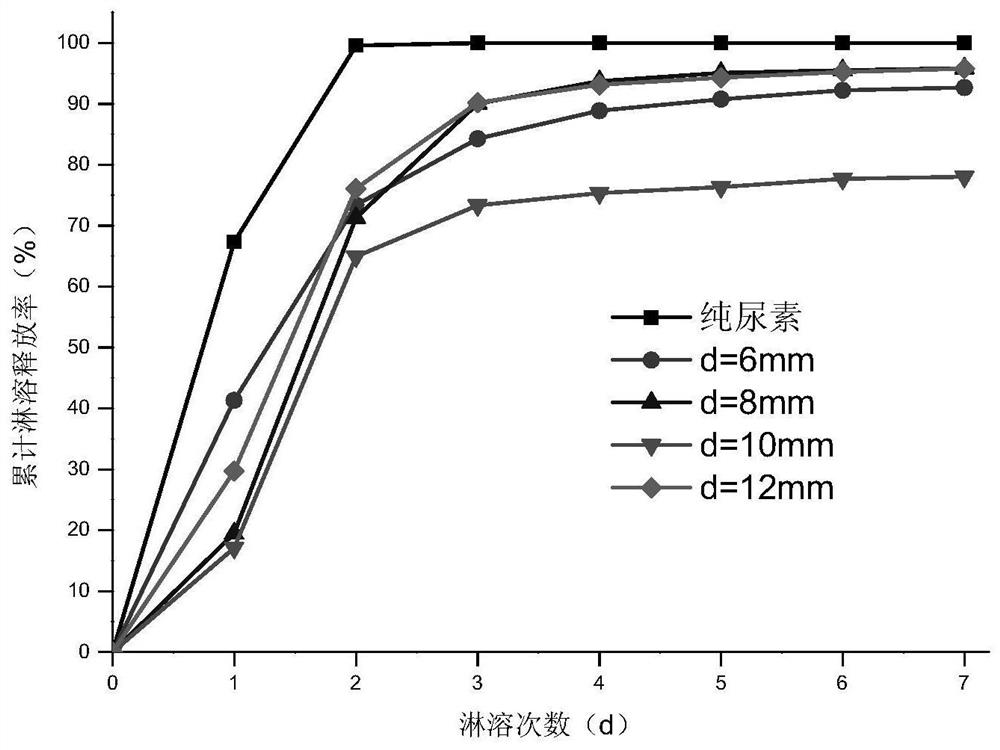

Permeation fusion method for preparing charcoal-based urea fertilizer

The invention discloses a permeation fusion method for preparing a charcoal-based urea fertilizer. The method comprises the following steps: raw material preparation; permeation fusion of charcoal andurea; and rapid cooling for forming the fertilizer. The main fertilizer preparation method is characterized by preheating urea powder and charcoal powder, the temperature of a system of the urea powder and charcoal powder is controlled to reach a urea melting temperature in order to realize the complete permeation fusion of the molten urea and the charcoal powder, and the charcoal-based urea fertilizer is finally obtained through cooling. The method has the advantages of adaption to different charcoal kinds, easiness in adjustment and control of the ratio, high charcoal fertilizer shaping rate, moderate mechanical strength, high stability, easiness in combination with an existing urea production technology to realize in situ shaping, certain promotion application industry foundation, andwide prospect. The method can be well combined with an existing urea shaping device in situ during the preparation, so the shaping time is short, the efficiency is high, the shaped product contains asmall amount of water, the particle size of the product is convenient to regulate and control, and the strength of the product is 50 N or more.

Owner:SOUTH CHINA AGRI UNIV

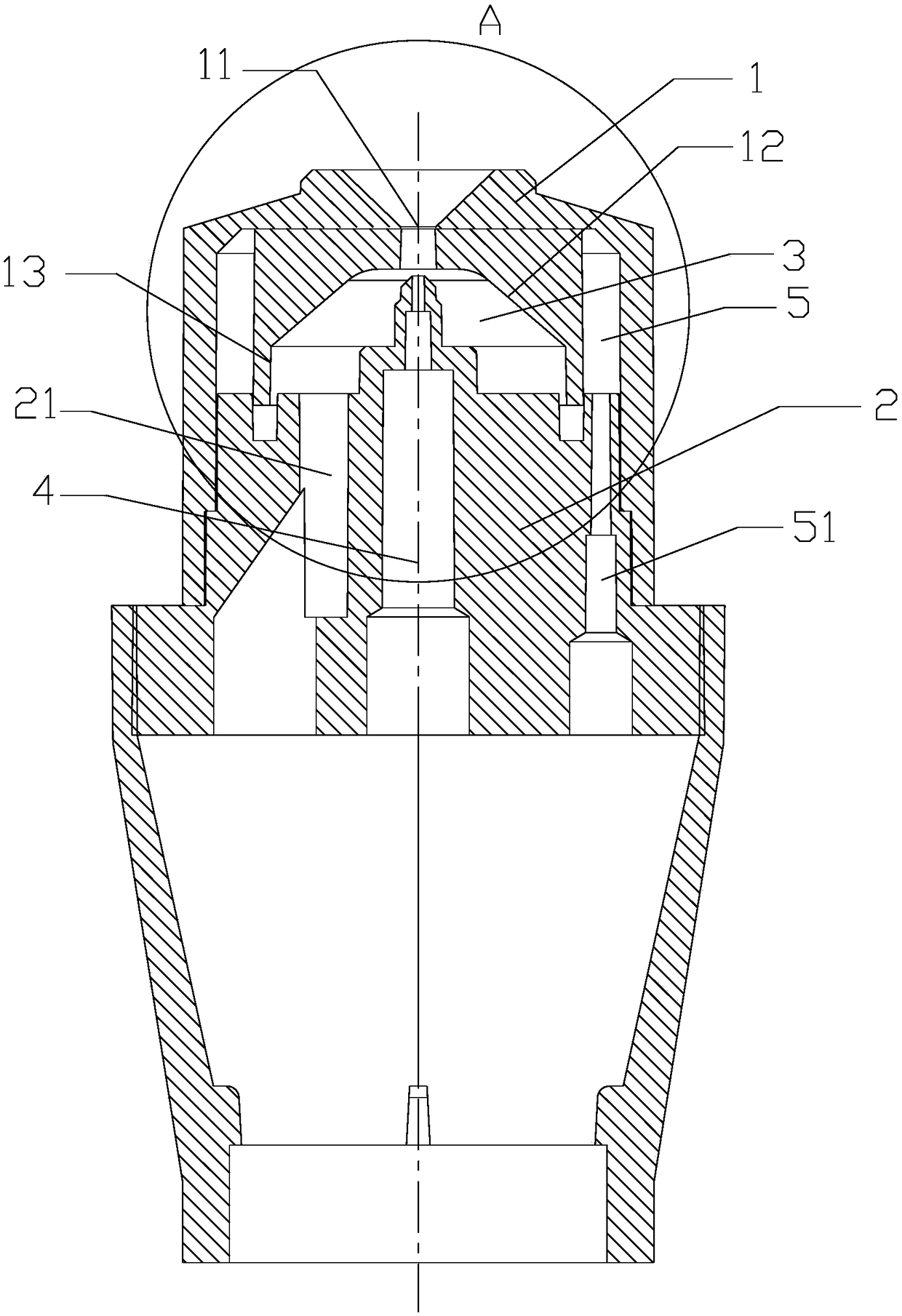

Pneumatic small-particle-size atomization spray head

PendingCN108325769AWith wind blowing effectImprove discretenessSpray discharge apparatusForming gasWorking pressure

The invention relates to an atomization spray head, and particularly relates to a pneumatic small-particle-size atomization spray head. The pneumatic small-particle-size atomization spray head comprises a spray head main body, a pneumatic knife assembly and an end cover installed on the spray head main body, wherein a liquid outlet pipeline used for spraying out liquid drops is arranged on the spray head main body; the end part of the liquid outlet pipeline is encircled by the end cover to form a gas chamber, and a nozzle corresponding to the end part of the liquid outlet pipeline in positionis formed in the end cover; the pneumatic knife assembly is used for forming gas flow sprayed to the space between the end part of the liquid outlet pipeline and the nozzle in the gas chamber; the nozzle is used for spraying out the liquid drops and gas; and the hole diameter of a liquid outlet port in the end part of the liquid outlet pipeline is r, the distance between the end part of the liquidoutlet pipeline and the nozzle is d, and the ratio of d to r is 1: 2 to 1.5: 1. The pneumatic small-particle-size atomization spray head disclosed by the invention does not need a high working pressure, and is capable of providing stable-particle-size mist drops, and low in system cost.

Owner:静快省(苏州)智能科技有限公司

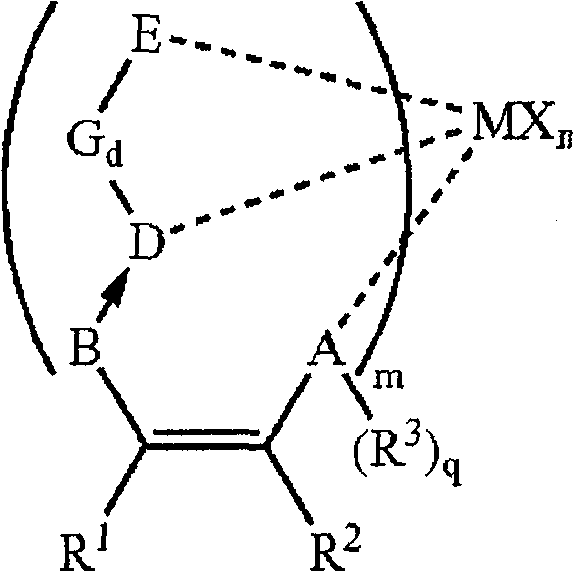

Supported nano Au catalyst and method for preparing the same

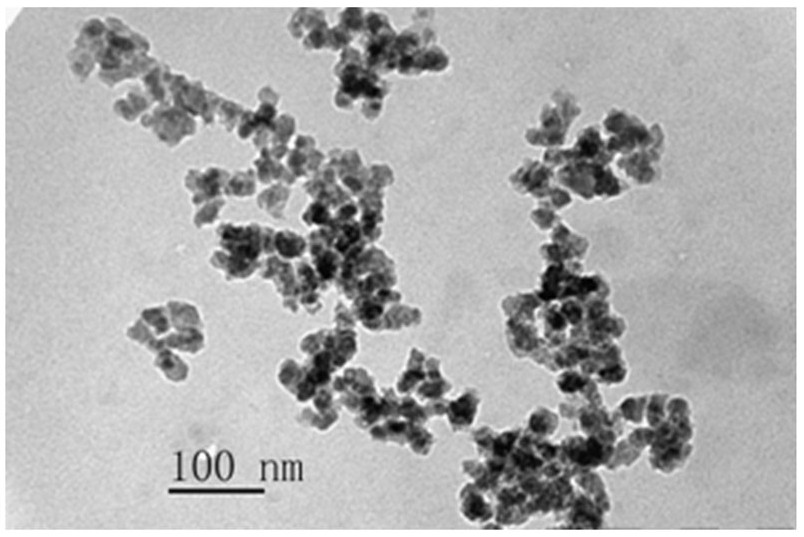

InactiveCN100364663CEvenly dispersedEasy to adjust particle sizeCatalyst carriersOxygen compounds preparation by hydrocarbon oxidationActive componentGold particles

The invention discloses a carrier nanometer gold catalyst gold catalyst and relative preparing method. Said invention is formed by Au, Al, and Ti / Si, Ag, Cu, Ce, Fe, or Zn. Wherein, Au is the main active component of catalyst, whose mass percentage is 0.1-4.0%; Al is the carrier of catalyst, whose mass percentage is larger than 90%; Ti or Si is the agent of catalyst carrier, whose mass percentage is 0.01-1.0%; Ag, Cu, Ce, Fe, or Zn is used as the auxiliary active component of catalyst, whose mass percentage is 0.1-5.0%. The invention has the advantages that: the gold is distributed uniformly, and the graininess of attained gold particle can be adjusted easily; the catalyst has high stability; and it can apply the oxide carrier for carrying gold whose isoelectric point pH is less than 6 and made by coprecipitation method. The invention has be used to apply the cyclohexane to prepare the nadone and cyclohexanol, with better activity and selectivity, less used amount and recycle support.

Owner:ZHEJIANG UNIV

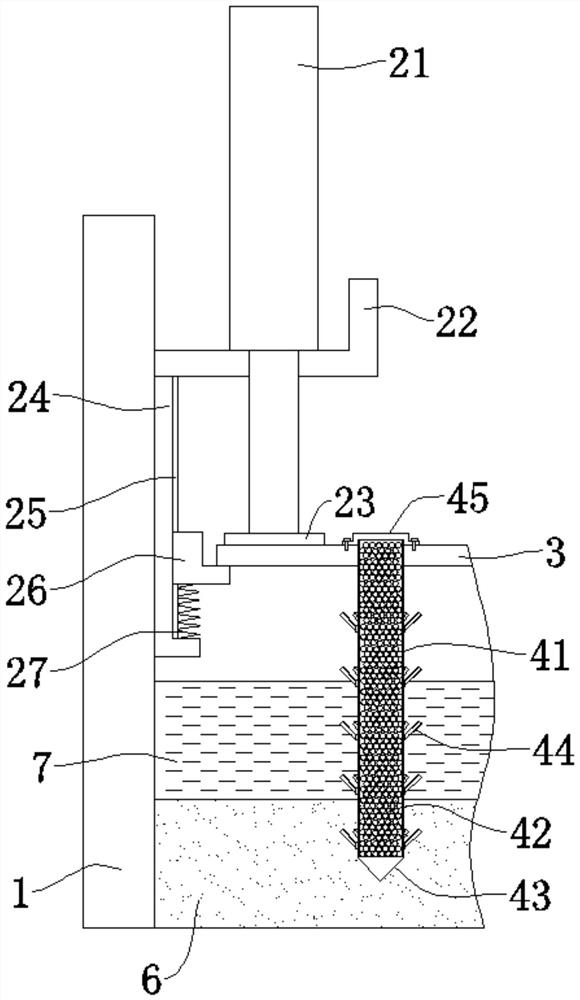

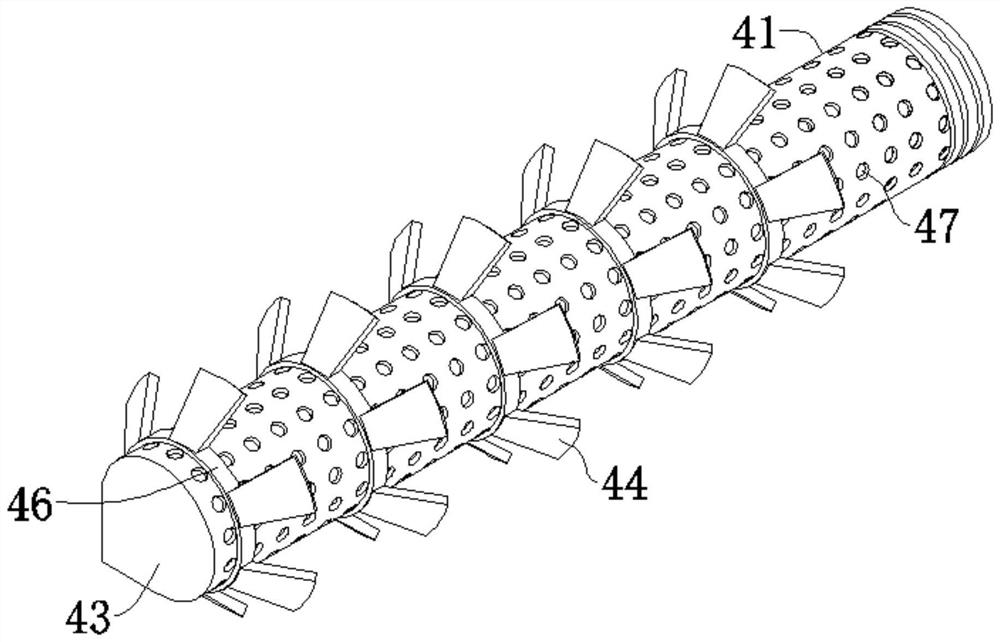

Riverway heavy metal treatment system

PendingCN112158938AHigh specific surface areaEfficient removalWater contaminantsWater/sewage treatment by magnetic/electric fieldsComposite materialTreatment system

The invention discloses a riverway heavy metal treatment system, which belongs to the technical field of riverway treatment and comprises a cofferdam, a lifting mechanism, a lifting platform, a heavymetal adsorption insertion column and a stirring mechanism, wherein the lifting mechanism is installed on the inner side of the cofferdam and used for driving the lifting table to move up and down, the heavy metal adsorption insertion column and the stirring mechanism are both detachably connected to the lifting table, and the lifting table is located in the cofferdam and located above a water layer; the lower end of the heavy metal adsorption insertion column is inserted into a mud layer, the upper end of the heavy metal adsorption insertion column penetrates through the water layer and thenis connected with the lifting table, the stirring mechanism is located in the middle of the cofferdam, and the stirring mechanism is used for stirring the mud layer and the water layer in the cofferdam and used for driving the lifting table to vibrate. Via the system, heavy metals in a water layer and a mud layer can be effectively removed, and the riverway heavy metal treatment effect is good.

Owner:湖南诚至环保科技有限公司

Material grading method

InactiveCN103285995AImprove classification efficiencyHandle a large amount of materialVortex flow apparatusGrain treatmentsParticulatesProcess engineering

The invention provides a material grading method. The method comprises the following steps that: (1) materials enter a grinding machine for grinding; (2) the ground materials are fed to a powder sorting machine, primary air, secondary air and tertiary air are fed into the powder sorting machine so as to generate rotary airflow, and the materials are subjected to sorting in the rotary airflow; (3) after sorting, large granular materials return to the grinding machine for grinding, gas enters a cyclone for being subjected to sorting again, and dust is collected by a dust collecting point; (4) gas sorted from the cyclone passes through a blower, part of the gas returns to the powder selecting machine, the other part of the gas enters a bag dust collector for continuous sorting, and sorted material products are collected; and (5) waste gas sorted from the bag dust collector is exhausted through a blower, and the sorted material products are collected. The method has the advantages that the grading efficiency is high, the material processing capacity is high, the graded size range of product particles is narrow, the operation is simple, and the particle diameter is convenient to adjust.

Owner:NANTONG SANXIN HEAVY IND

Pneumatic atomizing sprayer

PendingCN108284007AWith wind blowing effectLarge particle sizeSpray discharge apparatusWorking pressureSprayer

The invention relates to an atomizing sprayer and particularly relates to a pneumatic atomizing sprayer. The pneumatic atomizing sprayer comprises a sprayer main body and an air knife unit, wherein aliquid outlet pipeline used for spraying liquid drops is arranged on the sprayer main body; the air knife unit comprises an end cover which is mounted on the sprayer main body and an air knife assembly, an air chamber is formed between the sprayer main body and the end cover, and the air knife assembly is used for spraying gas to the end part of the liquid outlet pipeline so as to cut the sprayedliquid drops; and a nozzle used for guiding the spraying of the liquid drops and the gas is arranged at a position corresponding to the liquid outlet pipeline on the end cover. The pneumatic atomizingsprayer which does not need high working pressure can provide mists with stable particle sizes, and the system cost is low.

Owner:静快省(苏州)智能科技有限公司

Fishing reef production raw material crushing device for crushing oyster shells and steel slag

ActiveCN114192223ASimple and efficient centralized processingAffect healthDirt cleaningGrain treatmentsGear wheelSlag

The raw material crushing device comprises a machine body, supporting legs are fixedly installed at the four corners of the lower end of the machine body, a feeding channel is formed in the right side of the upper end of the machine body, a discharging opening is formed in the lower end of the machine body, a main roller shaft is arranged in the middle of the inner side of the machine body, and a feeding channel is formed in the lower end of the machine body; short connecting shafts are fixedly connected to the front end and the rear end of the main roller shaft, the short connecting shafts at the front end and the rear end of the main roller shaft and the front side wall and the rear side wall of the machine body form bearing connecting structures correspondingly, the short connecting shaft at the front end of the main roller shaft is in key connection with a large gear, and the right side of the large gear is meshed with the left side of a small gear. According to the fishing reef production raw material crushing device for crushing the oyster shells and the steel slag, the size of crushed particles can be conveniently adjusted, dust generated in the crushing process can be simply and efficiently treated in a centralized mode, and the dust is prevented from affecting the body health of workers.

Owner:山东多旭新材料科技有限公司

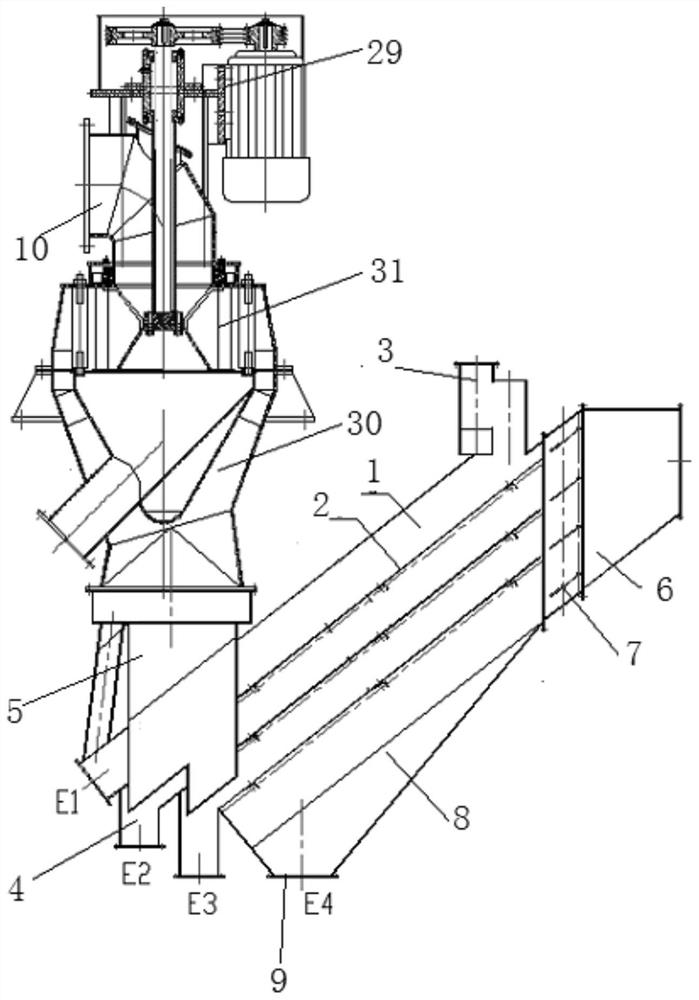

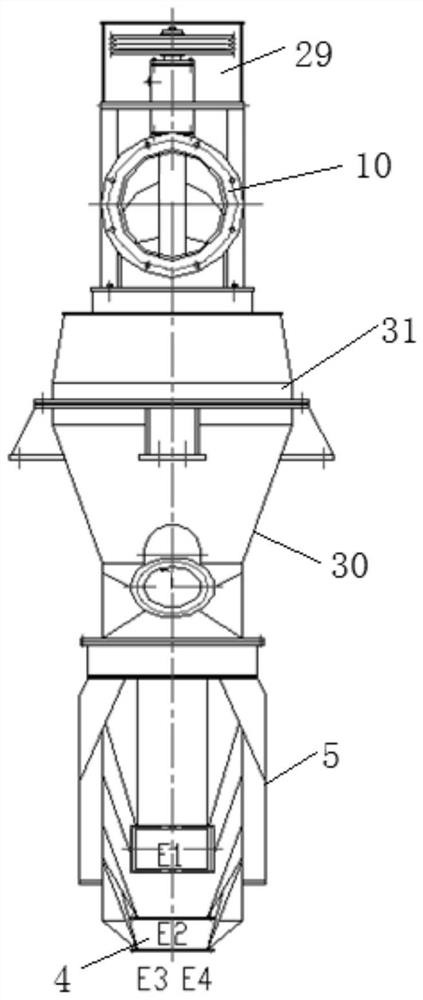

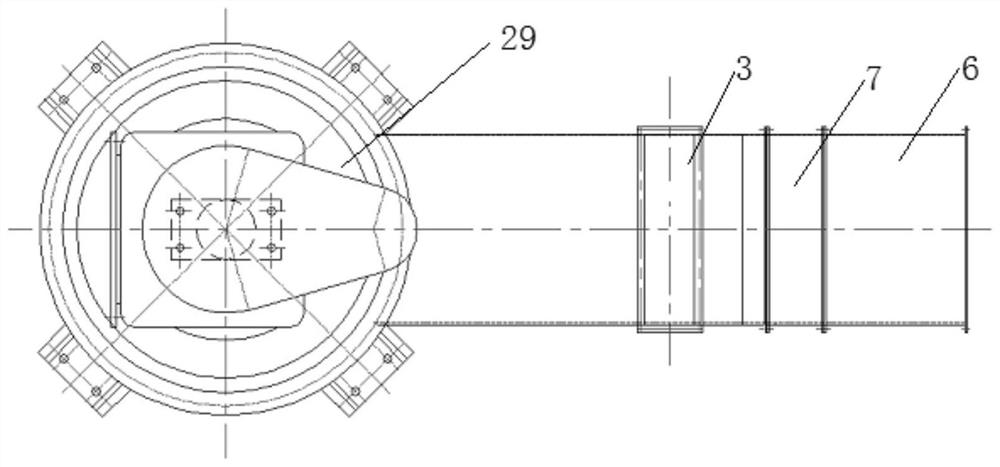

Multi-product mechanical wind power combined powder concentrator

PendingCN113171982AThe content is easy to controlIncrease profitSievingGas current separationFrequency conversionModular design

The invention discloses a multi-product mechanical wind power combined powder concentrator. The multi-product mechanical wind power combined powder concentrator combines mechanical separation and pneumatic separation as well as static separation and dynamic efficient separation, so that various finished products can be produced by one equipment. According to the pneumatic dry separation equipment, the sand making separation process is optimized, system equipment configuration is reduced, classification is accurate, efficiency is high, the cleaning effect is good, and the product quality can be improved; a power unit adopts a frequency conversion control technology, so that energy consumption is reduced, product granularity adjustment is simple and easy, the content of finished product particles in tail discharged dust can be conveniently controlled, and the comprehensive utilization rate of resources is improved; each layer of screen mesh can realize standardized and modular design, and is convenient to select, assemble, disassemble and replace; and the equipment works under negative pressure, does not need water resources and sewage treatment facilities during operation, is small in occupied area, environment-friendly, free of dust raising points, free of dust pollution and good in production environment, and can effectively reduce environmental, water and land pollution caused by existing production equipment.

Owner:HEFEI CEMENT RES DESIGN INST +1

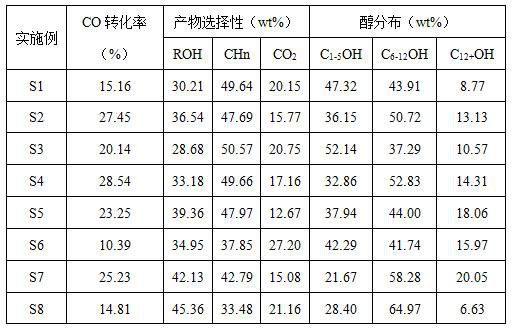

Catalyst for preparing plasticizer alcohol from synthesis gas as well as preparation method and application of catalyst

ActiveCN114225939AThe composition is convenient to controlEasy to adjust particle sizeOrganic compound preparationHydroxy compound preparationPlasticizerMaterials science

The invention relates to the field of preparation of high-carbon alcohol from synthesis gas, in particular to a catalyst for preparation of plasticizer alcohol from synthesis gas as well as a preparation method and application of the catalyst. The invention relates to a catalyst for preparing plasticizer alcohol from synthesis gas, the catalyst is a Cu2M2S confined Cu1M1 structure with an outer layer Cu2M2S and an inner layer Cu1M1, Cu1 and Cu2 represent Cu elements from different Cu precursors, M1 is one or more of Co, Fe and Mn, M2 is one or more of Co, Fe, Mn, Zn and Ni, and S is one or more of Si, Al, Ga, Zr, Ti, Ce and La; the molar ratio of M < 1 > to Cu < 1 > is (0.5-50): 1, and the molar ratio of S / M < 2 > to Cu < 2 > is (0.01-50): (0.01-30): 1; and the Cu1M1 accounts for 5-95% of the total amount of the catalyst in percentage by mass, and the particle size of the Cu1M1 is 1-50 nm. The invention also relates to a preparation method and application of the catalyst.

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

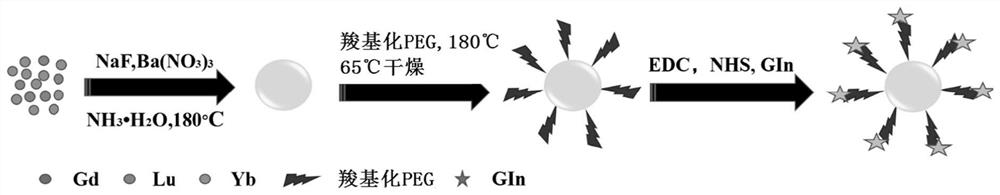

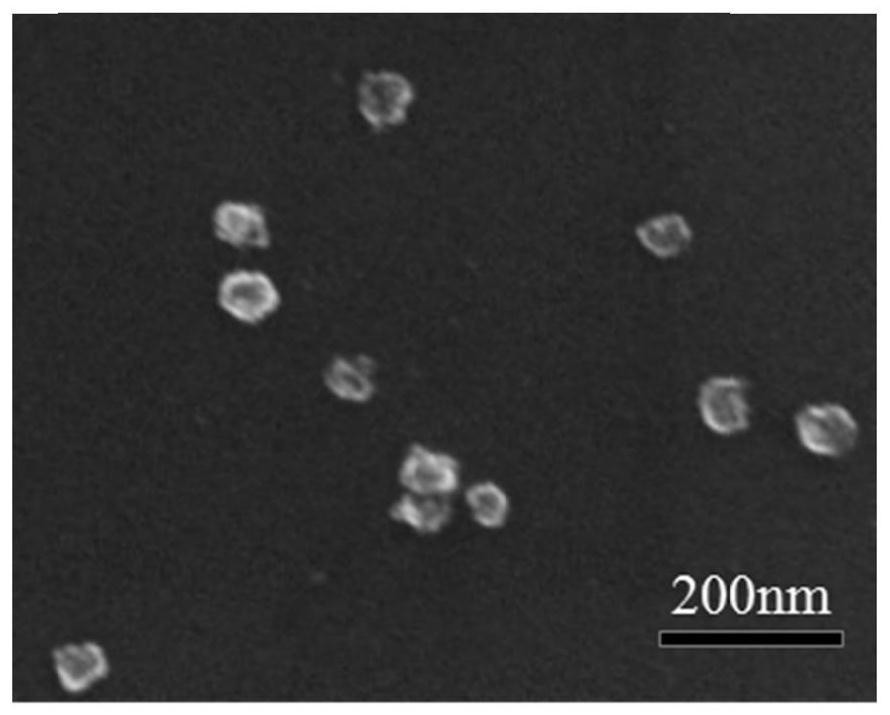

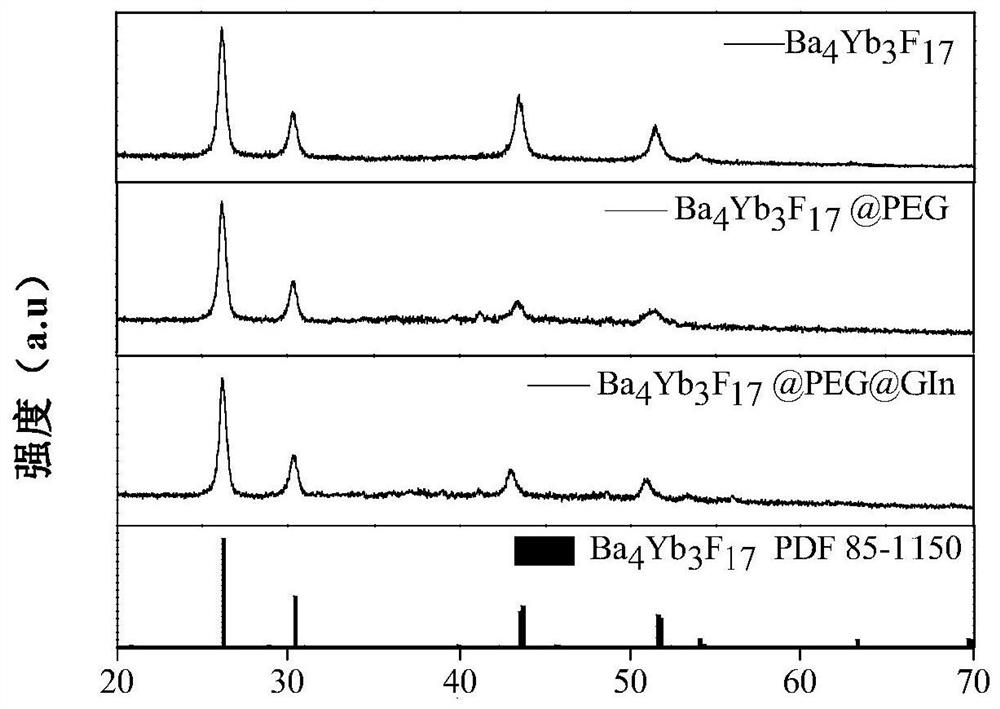

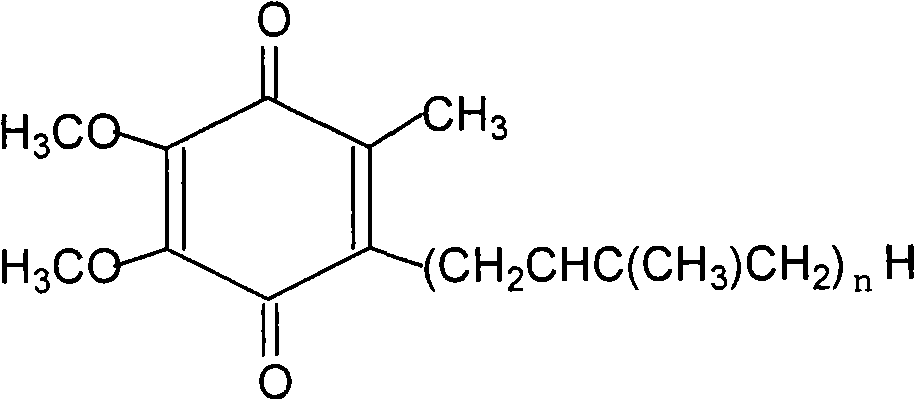

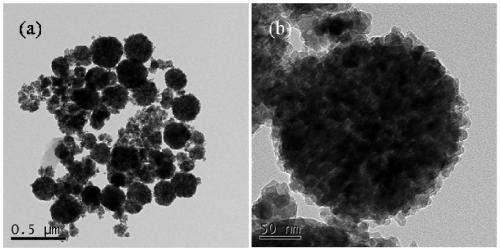

Nanoparticle with core-shell structure, preparation method and application

ActiveCN108452326BPotential for applicationGood contrast effectPowder deliveryGeneral/multifunctional contrast agentsNanoparticlePolyethylene glycol

The invention provides a nanoparticle with a core-shell structure. The nanoparticle comprises a core layer made of Gd / Lu nanoparticles doped with BaxYbyF(2x+3y), a first shell layer made of polyethylene glycol and a second shell layer made of amino acid. The invention also provides a preparation method and application of the nanoparticle with the core-shell structure. The nanoparticle with the core-shell structure can be applied to multiple imaging techniques such as CT, MRI and fluorescence imaging and the like, is capable of prolonging circulation time of the nanoparticle in the blood, has the advantages of the nanomaterial, is simple and convenient in preparation method, and is used as a multi-modality contrast medium with a great application potential.

Owner:INST OF HIGH ENERGY PHYSICS CHINESE ACAD OF SCI

Physiologically active substance-containing granular composition and method of producing the same

InactiveCN101534796BGood water solubilityEasy to operatePowder deliveryHydroxy compound active ingredientsAdditive ingredientExcipient

The present invention provides a granular composition with good water solubility, operability, sheetability, and heat resistance and a preparation method thereof. The granular composition has the following characteristics: an oily component (A ) are polydispersed in a matrix and form domains, the matrix is composed of a water-soluble excipient containing a water-soluble polymer as the main component, and the granular composition has a sphericity of 0.9 or more. In addition, food, nutritional functional food, food for specific health use, nutritional supplement, nutrition, animal medicine, beverage, feed, pet food, cosmetics, medicine, therapeutic medicine, preventive medicine, etc. containing the granular composition are also provided.

Owner:KANEKA CORP

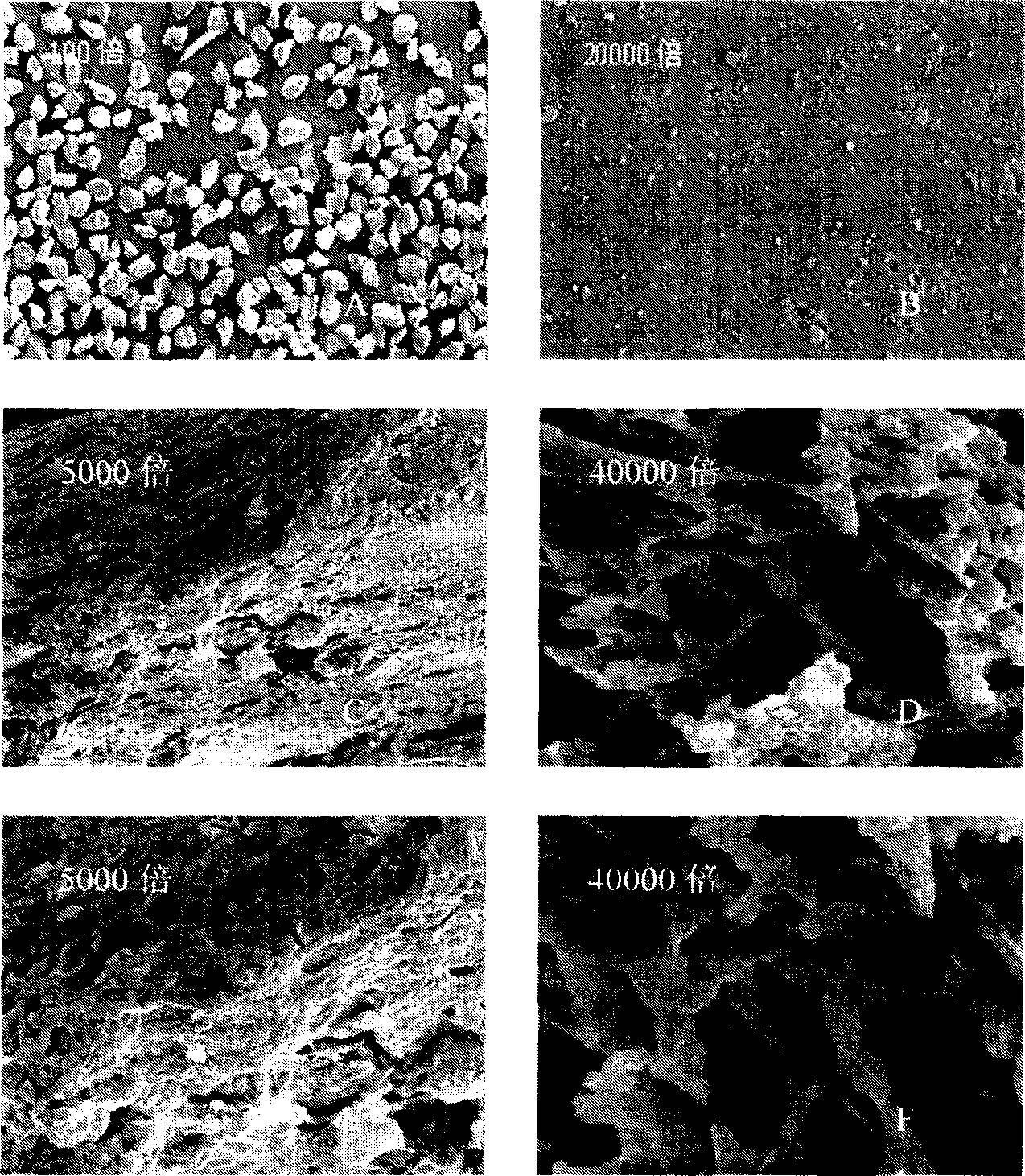

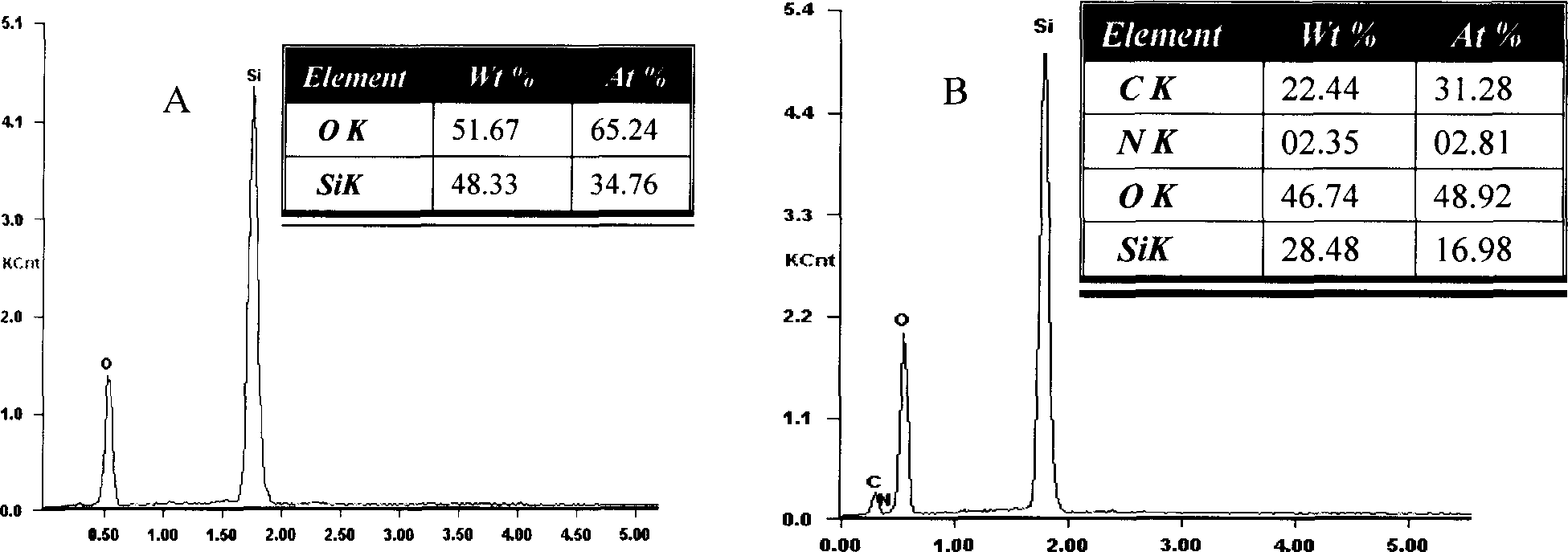

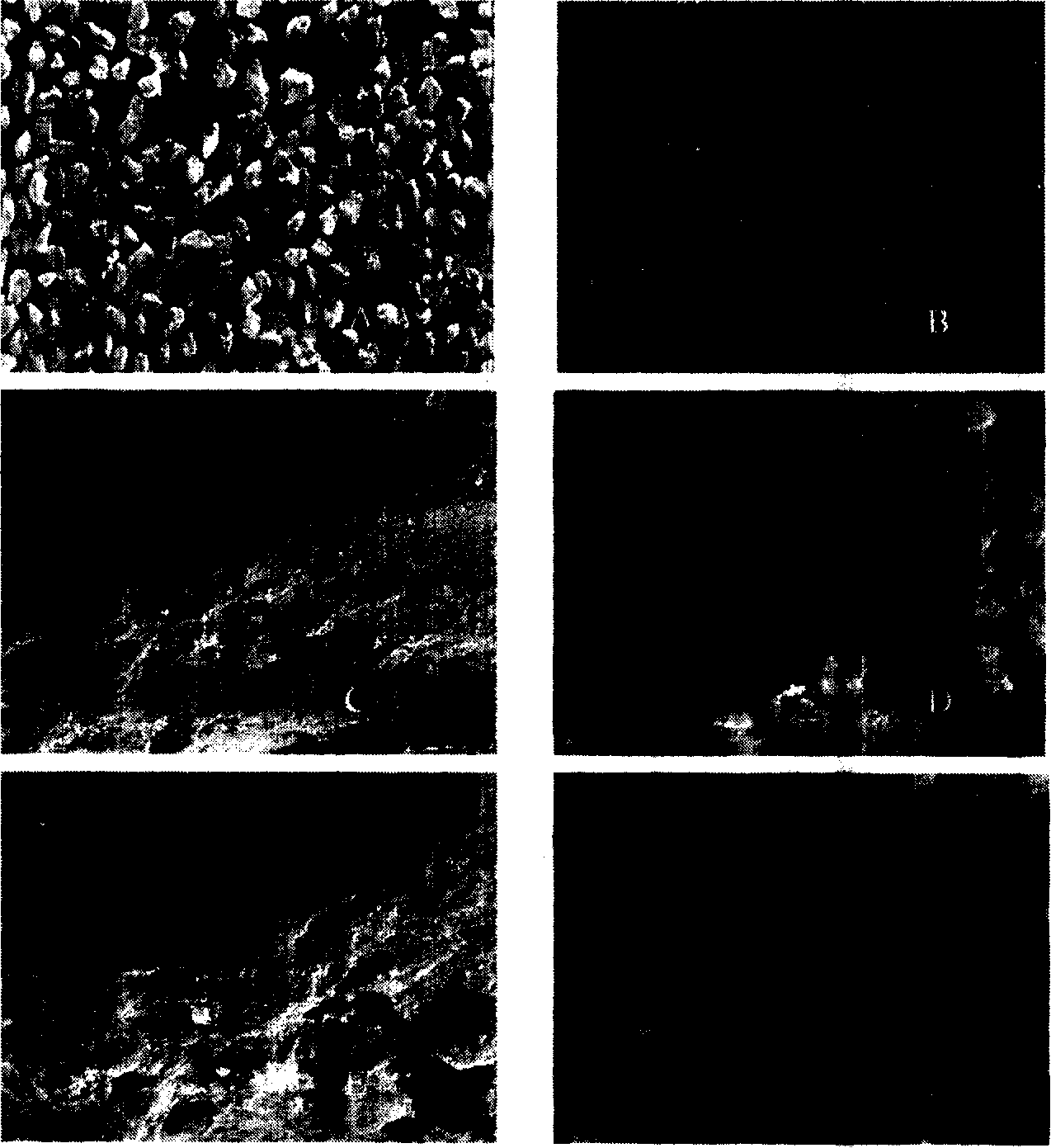

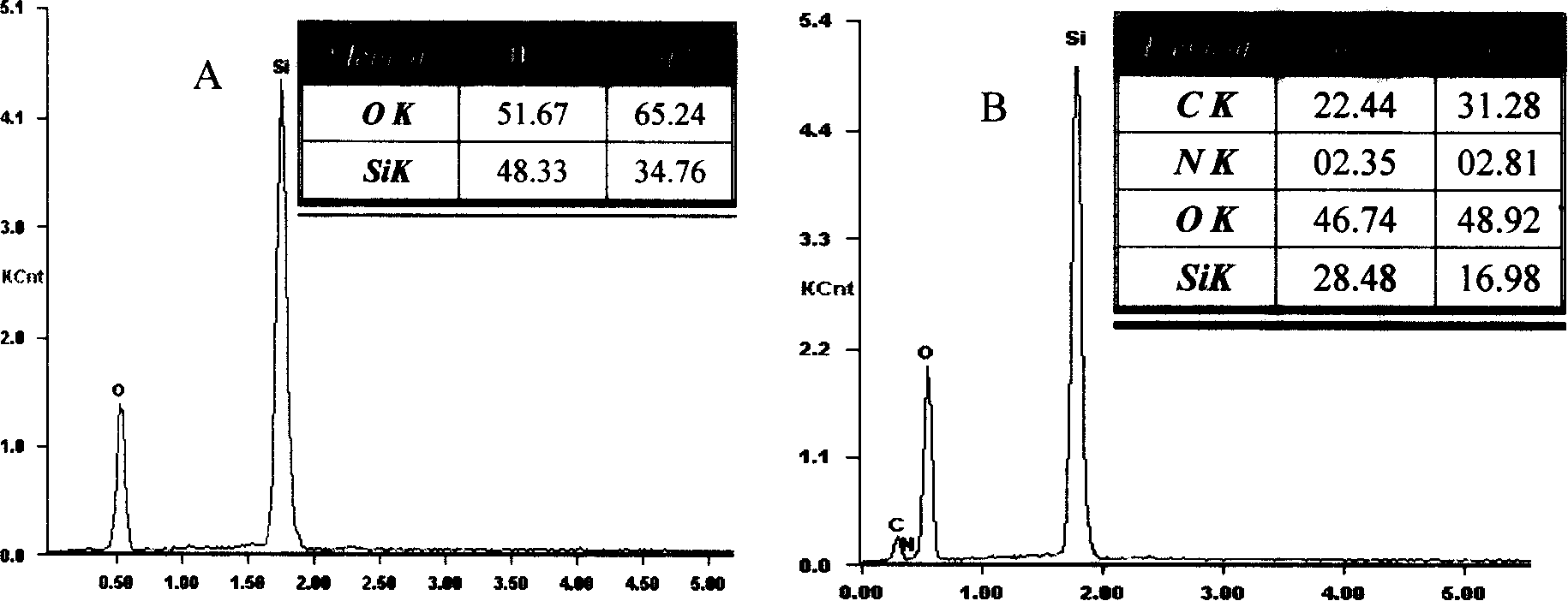

Silica-gel-carrier surface macroporous chitin substrate for lysozyme affinity chromatography

InactiveCN1818060ALarge specific surface areaHigh mechanical strengthEnzymesPolyethylene glycolCross linker

The invention opened a new macro porous silica gel loading surface Chitin base for the lysozym affinity chromatography. The invention is to load the chitosan in the silica gel firstly, the cross linker is the gamma-epoxypropyl trimethoxy silane with the epoxy groups and the silane. After acetylating, the product would be get. The grain size of the base can be adjusted by adjusting the size of the silica gel carrier. The polyethylene glycol 20000 is to make the hole to fit for the protein. The nonspecific base is small because of the free amino group is removed by the hydrocarbonylation. The product can be used for the purifying of the lysozym in the egg white.

Owner:QINGDAO UNIV OF SCI & TECH

Powder grading method

InactiveCN103285994AImprove classification efficiencyHandle a large amount of materialGas current separationGrain treatmentsParticulatesProcess engineering

The invention provides a powder grading method. The powder grading method comprises the following steps that: (1) materials enter a grinder for grinding; (2) the ground materials are fed into a powder concentrator, primary air, secondary air and tertiary air are fed into the powder concentrator so as to generate rotary air flow, and the materials are sorted in the rotary air flow; (3) after sorting, large-particle materials return and enter the grinder for grinding, gas enters a high-efficiency bag-type dust collector for re-sorting, and the dust is collected by dust-collecting points; (4) waste gas sorted out from the high-efficiency bag-type dust collector is exhausted by a fan, and the sorted-out finished materials are collected. The powder grading method provided by the invention can grade powder and is applicable to grading powdery materials in the cement industry or grading equivalent materials in other industries; compared with a traditional air powder-grading method, the powder grading method provided by the invention has the advantages that the grading efficiency is high, the material treating amount is large, the particle grading size range of a product is narrow, the operation is simple, and the adjustment of the particle diameter is convenient.

Owner:NANTONG SANXIN HEAVY IND

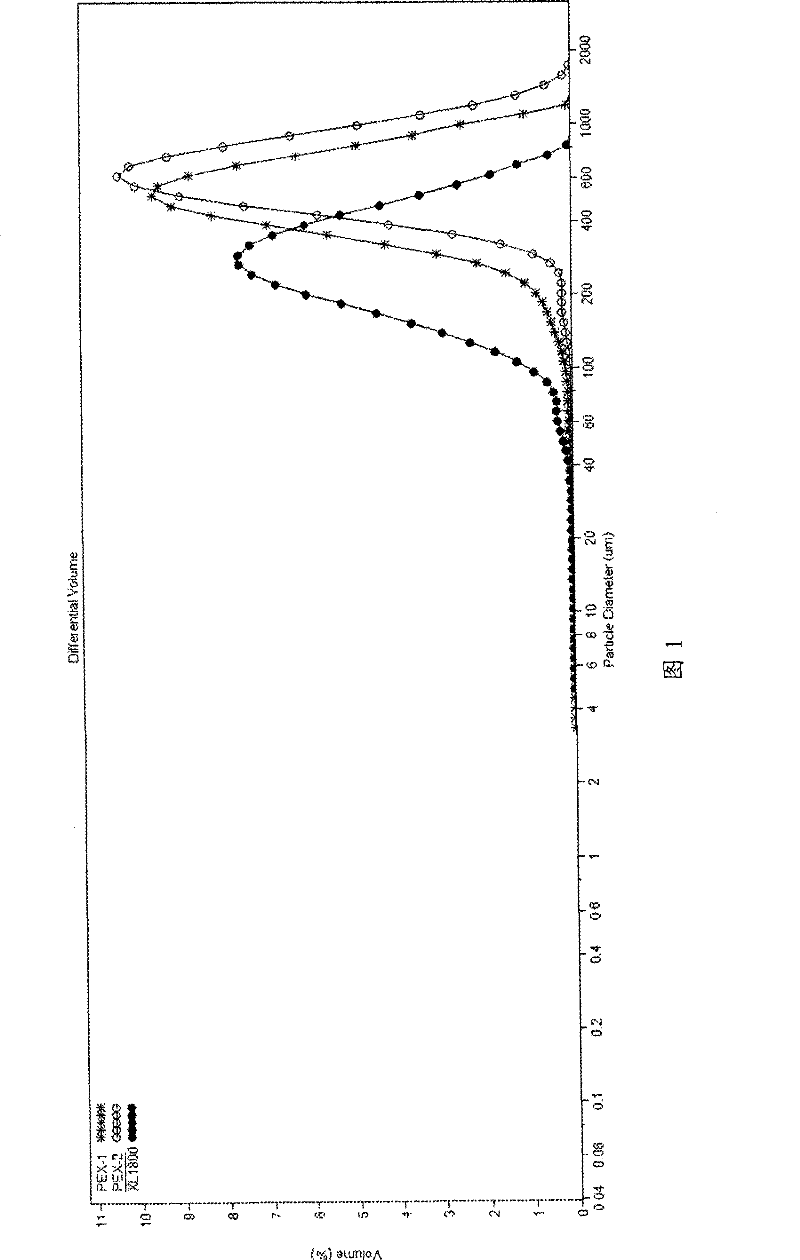

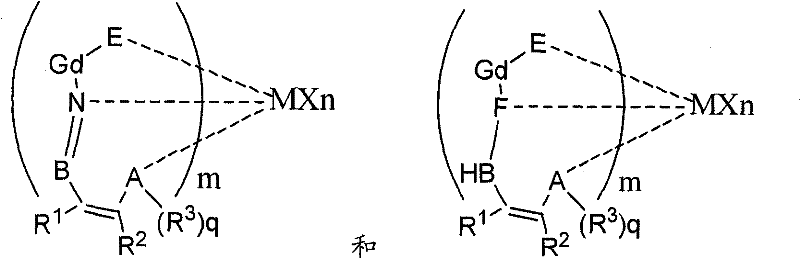

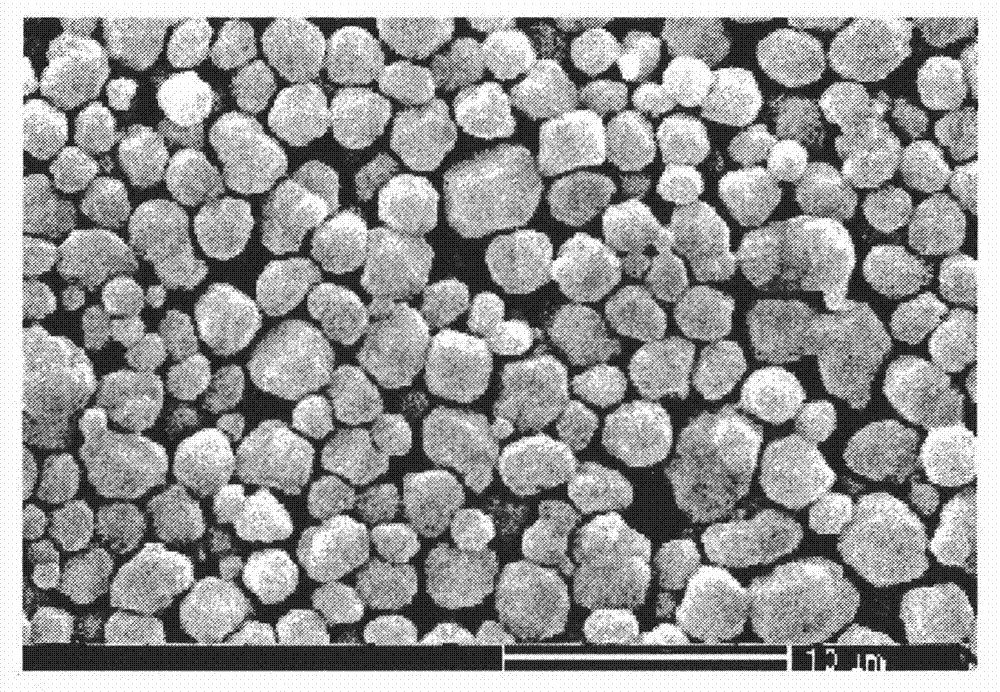

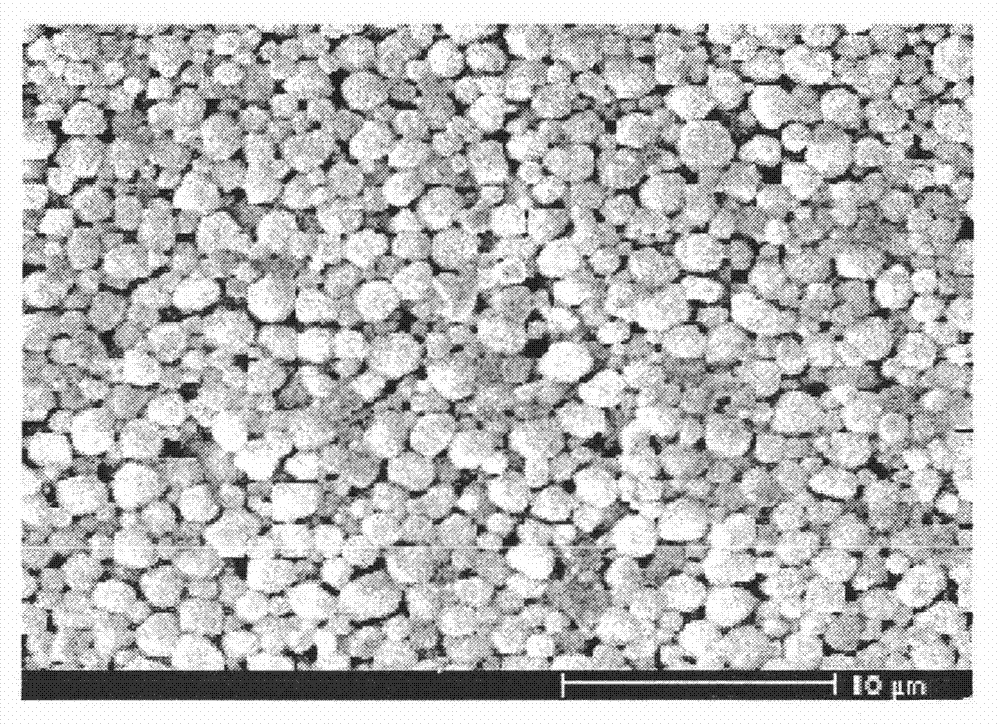

Ethane copolymer and preparation method and application thereof

ActiveCN101654494BHigh bulk densityNarrow particle size distributionRigid pipesTubular articlesDust explosionCopolymer

The invention relates to an ethane copolymer prepared by utilizing a specific supported non-metallocene catalyst, and a preparation method thereof. Besides, the invention also relates to a method for preparing a peroxide-crosslinked PE pipe from the ethane copolymer and the peroxide-crosslinked PE pipe prepared by the method. The method for preparing the peroxide-crosslinked PE pipe is suitable for industrial large-scale implementation, and can effectively avoid the problem of dust flying and the risk of dust explosion in the manufacturing process; and the prepared peroxide-crosslinked PE pipe has longer oxidation induction time.

Owner:SINOPEC YANGZI PETROCHEM

Silica-gel-carrier surface macroporous chitin substrate for lysozyme affinity chromatography

InactiveCN100387711CEasy to adjust particle sizeMild conditions for the crosslinking processEnzymesPolyethylene glycolCross linker

The invention opened a new macro porous silica gel loading surface Chitin base for the lysozym affinity chromatography. The invention is to load the chitosan in the silica gel firstly, the cross linker is the gamma-epoxypropyl trimethoxy silane with the epoxy groups and the silane. After acetylating, the product would be get. The grain size of the base can be adjusted by adjusting the size of the silica gel carrier. The polyethylene glycol 20000 is to make the hole to fit for the protein. The nonspecific base is small because of the free amino group is removed by the hydrocarbonylation. The product can be used for the purifying of the lysozym in the egg white.

Owner:QINGDAO UNIV OF SCI & TECH

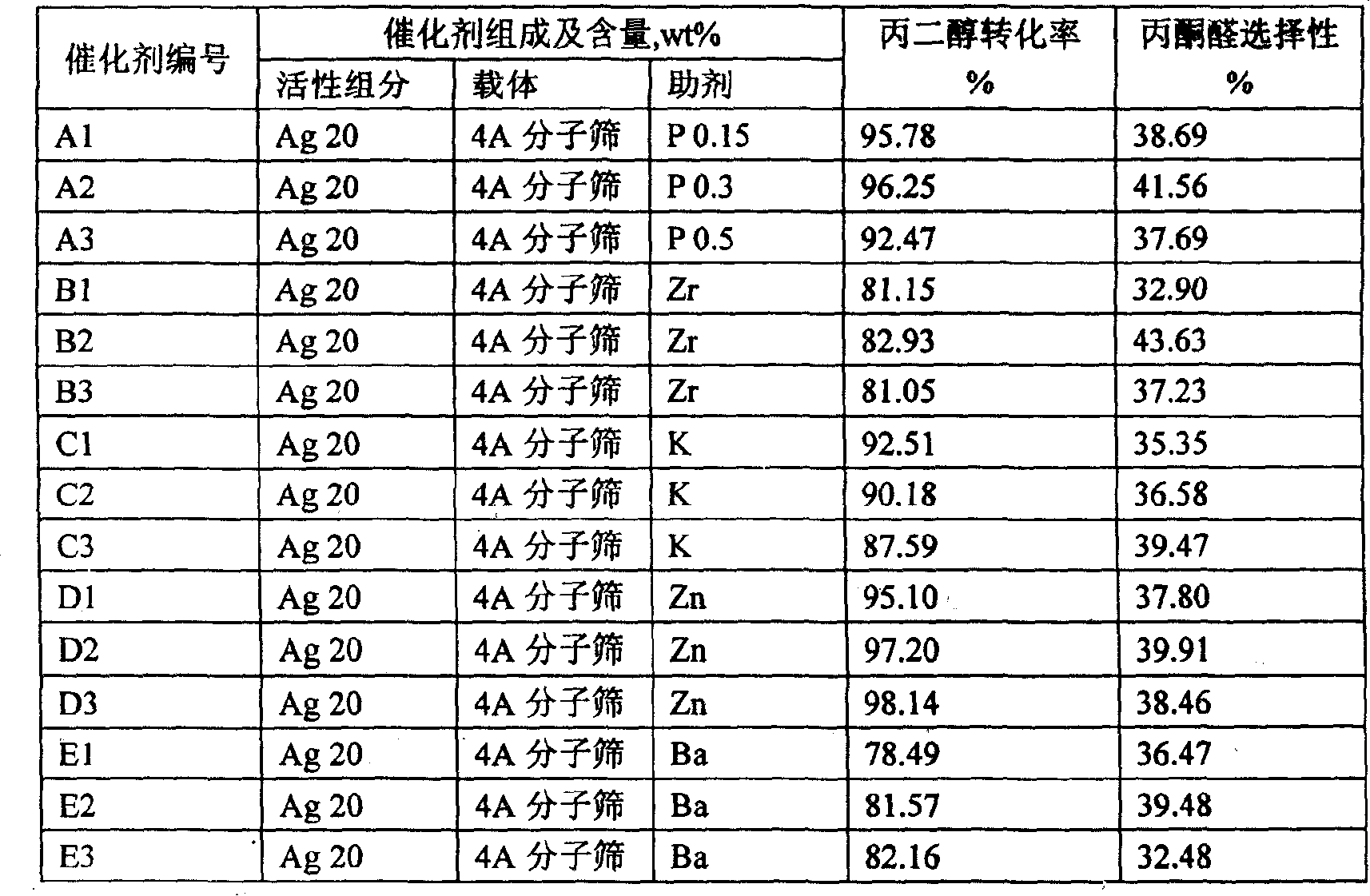

Catalyst for synthesizing pyruvic aldehyde and its preparing method

InactiveCN100398207CEvenly dispersedEasy to adjust particle sizeMolecular sieve catalystsOrganic compound preparationActive componentPotassium

The present invention discloses catalyst for synthesizing pyruvic aldehyde and its preparation process. The catalyst contains Ag as the main active component and accounting for 1-20 wt%; P, Bioavailability, Zr, K and Zn as auxiliary active components and accounting for 0.01-10 wt%; and catalyst carrier not less than 70 wt%. The catalyst of the present invention has the advantages of: homogeneous dispersion and easy granulation regulation of Ag, high stability, mild pyruvic aldehyde preparing reaction condition, high activity, high selectivity, small use quality and easy circulating use.

Owner:ZHEJIANG UNIV

Coarse powder grader

The invention relates to a coarse powder grader which comprises a cylinder body. The cylinder body comprises an inner cylinder and an outer cylinder. The inner cylinder is fixedly installed in the outer cylinder. The upper end of the outer cylinder is closed and is provided with a feeding hole. A feeding cylinder located in the inner cylinder is fixedly installed at the feeding hole. A material dispersing device located below the discharging end of the feeding cylinder is installed in the cylinder body in a rotating manner. A grading mechanism located between the inner cylinder and the feedingcylinder is further installed in the cylinder body in a rotating manner. A fan for generating airflow moving upwards between the inner cylinder and the feeding cylinder is further arranged in the cylinder body. A fine material passing gap is formed between the upper end of the inner cylinder and the outer cylinder. A ventilating device located below the material dispersing device is arranged between the inner cylinder and the outer cylinder. Coarse powder crashes on the wall of the inner cylinder under the effect of centrifugal force, and slides down to deposit on the lower portion of an inner discharging cylinder. Fine powder rapidly changes the motion direction through a grading mechanism and centrifugal force of the fan to be separated from airflow. The grader has the advantages of small occupied area, little fly dust pollution and large treatment amount.

Owner:山东惟远新材料装备有限公司

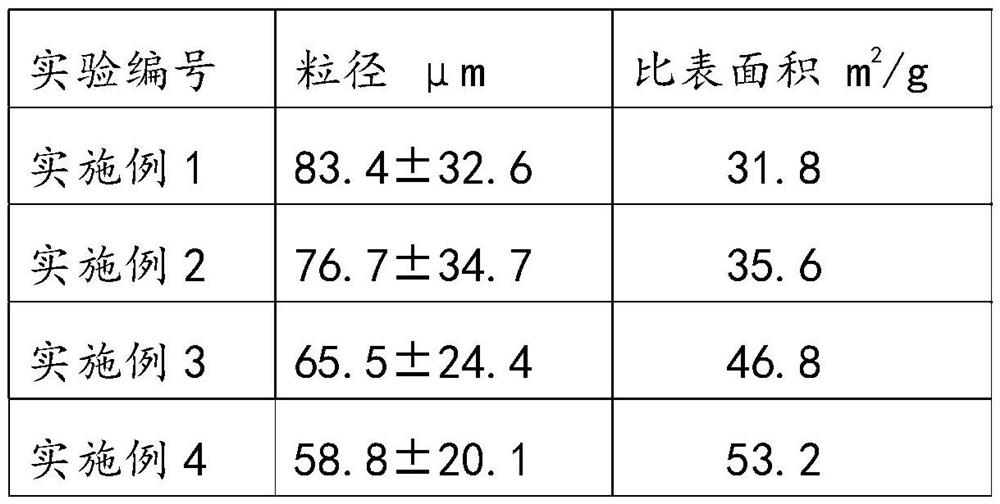

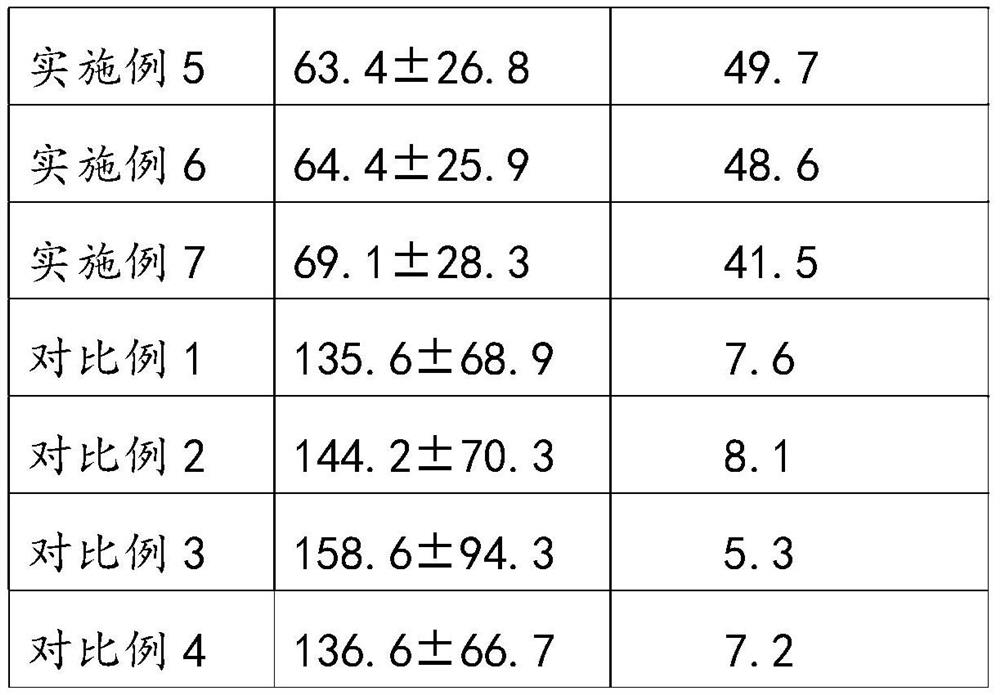

A kind of adsorbent for removing cobalt ion in sewage and preparation method thereof

ActiveCN108176376BImprove adsorption capacitySimple preparation processOther chemical processesWater contaminantsMicrosphereSorbent

The invention discloses an adsorbent used for efficiently removing cobalt ions in sewage and a preparation method thereof. The method comprises the following steps: preparing MgFe2O4 nanospheres, preparing a starch-grafted endellite nanotube composite material, and finally compositing the MgFe2O4 nanospheres and the starch-grafted endellite nanotube composite material to obtain the MgFe2O4-HNT-coated Starch composite material as the adsorbent. The preparation technology has the advantages of simple process, low cost, and strong operationality, the adsorbent can rapidly absorb and remove the cobalt ions in the sewage, separation is easy, the adsorbent can remove the cobalt ions in the sewage, and can degrade an organic matter in the sewage as a photocatalyst and removes SO2 in atmosphere.

Owner:HEFEI UNIV OF TECH

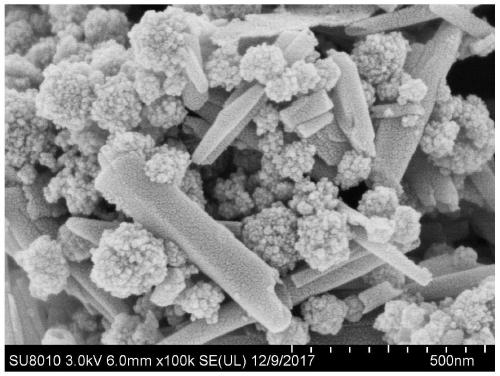

A kind of heteropolyacid salt catalyst with high specific surface area and preparation method thereof

ActiveCN110975903BLarge specific surface areaSimplify the morphology control processOrganic compound preparationCatalyst activation/preparationPtru catalystHeteropoly acid

Owner:YANTAI UNIV

A kind of biochar-based urea fertilizer osmotic fusion fertilizer method

ActiveCN107586220BGuarantee carbonization qualityIncrease pyrolysis rateFertilizer mixturesEnvironmental engineeringBiochar

The invention discloses a method for fertilizing biochar-based urea fertilizer by infiltration and fusion. The method includes the following steps: raw material preparation; biochar and urea melting and infiltration; rapid cooling to fertilize; the main fertilization process is to preheat the urea powder and the biochar powder, and control the temperature of the two systems to reach the melting temperature of urea to realize the melting of urea Complete infiltration and fusion of biochar powder, and finally cooling to obtain biochar-based urea fertilizer. This method can adapt to different types of biochar, easy to adjust and control the ratio, high carbon fertilizer molding rate, moderate mechanical strength, high stability, easy to combine with the existing urea production process to achieve in-situ molding, and has a certain industrial basis for popularization and application ,bright future. The present invention can be well combined with the existing urea molding device in situ during the preparation process, the molding time is short, the efficiency is high, the moisture content of the product obtained after molding is small, the particle size of the obtained product can be easily adjusted, and the product strength is high. All above 50N.

Owner:SOUTH CHINA AGRI UNIV

A kind of preparation method of hollow glass microsphere

ActiveCN107352549BWide variety of sourcesReduce usageSilicaGlass shaping apparatusPickering emulsionOil phase

The invention relates to a preparation method of hollow glass beads. The preparation method comprises the following steps of: by taking nano cellulose as a Pickering emulsion, adding a precursor of silicon dioxide into an oil phase of the emulsion; and by taking the Pickering emulsion as a template, performing a sol-gel reaction on the precursor of silicon dioxide under an acidic or alkaline condition to prepare the hollow glass beads. The preparation method provided by the invention is simple and convenient, the particle sizes can be regulated, the preparation method can be performed at room temperature, and the cost of preparing the hollow glass beads is lowered.

Owner:张振

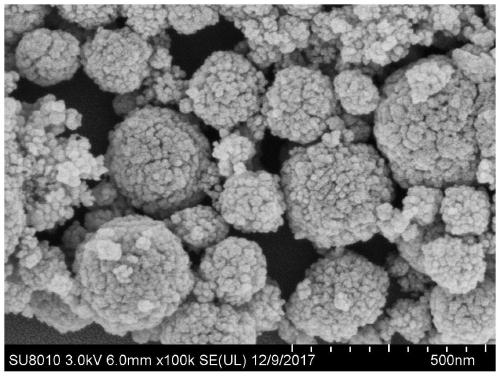

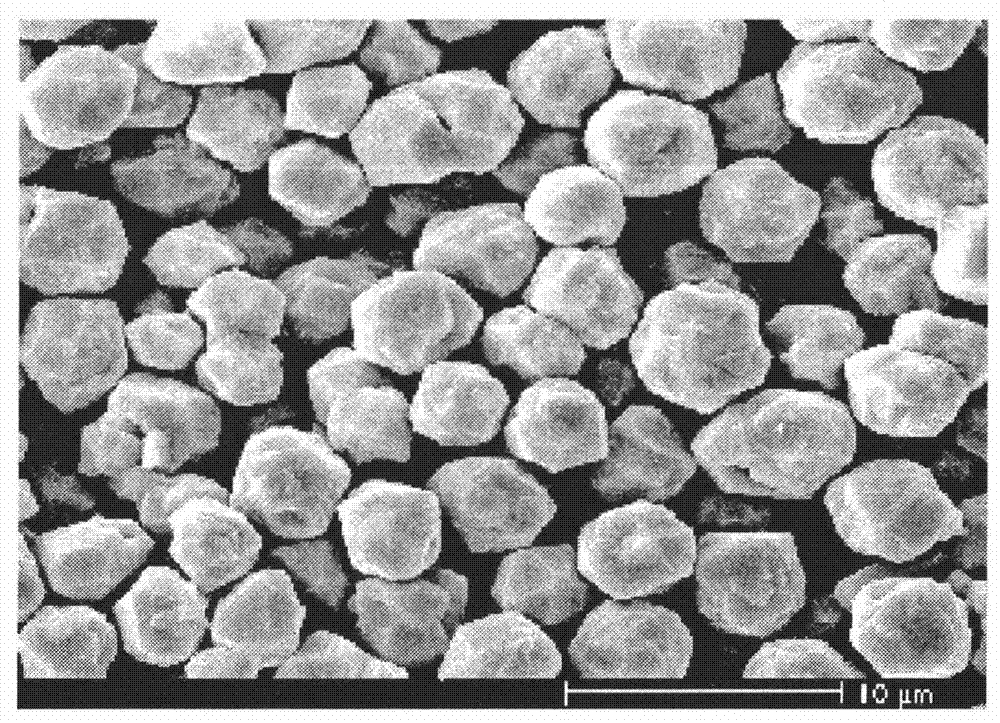

Preparation method of high dispersibility superfine silver powder with adjustable grain diameter

ActiveCN101733410BHigh tap densityEasy to adjust particle sizeVolumetric Mass DensitySURFACTANT BLEND

The invention relates to a preparation method of high dispersibility superfine silver powder with adjustable grain diameter, comprising the following steps: 1. dissolving silver nitrate and surfactant in water to prepare silver solution A; 2. dissolving ascorbic acid, PH regulator and surfactant in water to prepare reducing liquid B; 3. preparing alkaline aqueous solution C by alkaline PH regulator; dropwise adding alkaline aqueous solution C and silver solution A to reducing liquid B at the set time. PH value of the reducing liquid B and flow velocity of alkaline aqueous solution C are adjusted, so that silver power particle size can be easily adjusted and the silver power particles can grow up uniformly. The silver powder obtained by the method of the invention has the characteristics of polyhedral microcosmic appearance, good dispersibility, narrow size distribution, high tap density and good sintering character.

Owner:GUANGDONG FENGHUA ADVANCED TECH HLDG

Material distributing screening machine

ActiveCN102247945BImprove screening efficiencyIncrease the screening areaSievingScreeningReducerFlange

The invention discloses a material distributing screening machine, comprising a machine case (1), a forced fabric plate (2), a driving device (3), a filtering roller (4), a reducer motor (5) and an iron removing device (24), wherein the machine case (1) is provided with a feeding hole (6) and a plurality of discharging holes (10), the filtering roller (4) comprises a flange disk type roller (11) and a filtering rope type roller (12), the filtering roller (4) is provided with the driving device (3), the reducer motor (5) drives the filtering roller (4) to rotate by virtue of the driving device(3), and material enters from the feeding hole (6), is screened by the filtering roller (4) and is discharged by the discharging hole (10). The invention has the beneficial effects that: more than two materials in different grain sizes can be screened by setting different interstitial screen cuts, the working condition requirement for screening more than two materials can be met, screening efficiency is high, bulk material impact resistance is high, material is distributed more uniformly, no blockage is caused, and an iron piece contained in the material can be removed.

Owner:SICHUAN ZHONGMENG ELECTRIC POWER EQUIP MFG CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com