Coarse powder grader

A classifier and coarse powder technology, which is applied in the direction of solid separation, separation of solids from solids by air flow, chemical instruments and methods, etc., can solve the problems of low processing capacity, dust, large workshop area, etc., and achieve the goal of processing The effect of large amount, low energy consumption and small dust pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

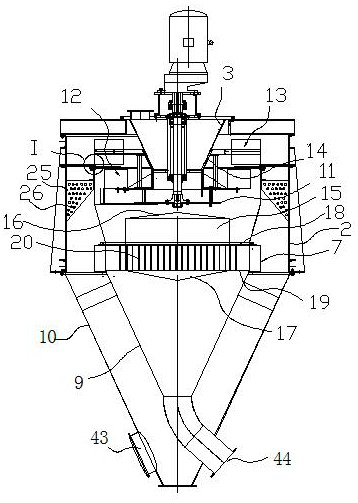

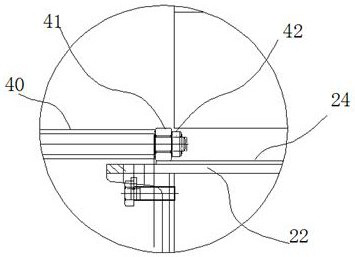

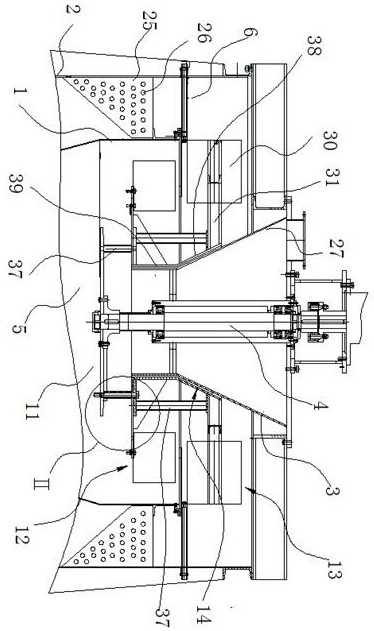

[0023] Such as Figure 1 to Figure 7 As shown, a coarse powder classifier includes a cylinder body, the cylinder body includes an inner cylinder 1 and an outer cylinder 2, the inner cylinder 1 is fixedly installed inside the outer cylinder 2, and the upper end of the outer cylinder 2 is closed And be provided with feed hole, described feed hole is fixedly installed with the feed cylinder 3 that is positioned at described inner cylinder, and the material dispersing device that is positioned at the below of the discharge end of described feed cylinder 3 is installed in described cylinder, A grading mechanism located between the inner cylinder 2 and the feeding cylinder 3 is also installed in the cylinder, and an upward pressure generated between the inner cylinder 2 and the feeding cylinder 3 is also provided in the cylinder. The fan of the moving air flow, the fine material passing gap 6 is provided between the upper end of the inner cylinder 1 and the outer cylinder 2, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com