Multi-product mechanical wind power combined powder concentrator

A combined, multi-product technology, used in solid separation, sieves, grids, etc., can solve the problems of environmental, land and water pollution, inability to produce high-quality machine-made sand, environmental pollution of dry production lines, etc. The environment is good, the comprehensive utilization rate of resources is improved, and the adjustment is simple and easy to implement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

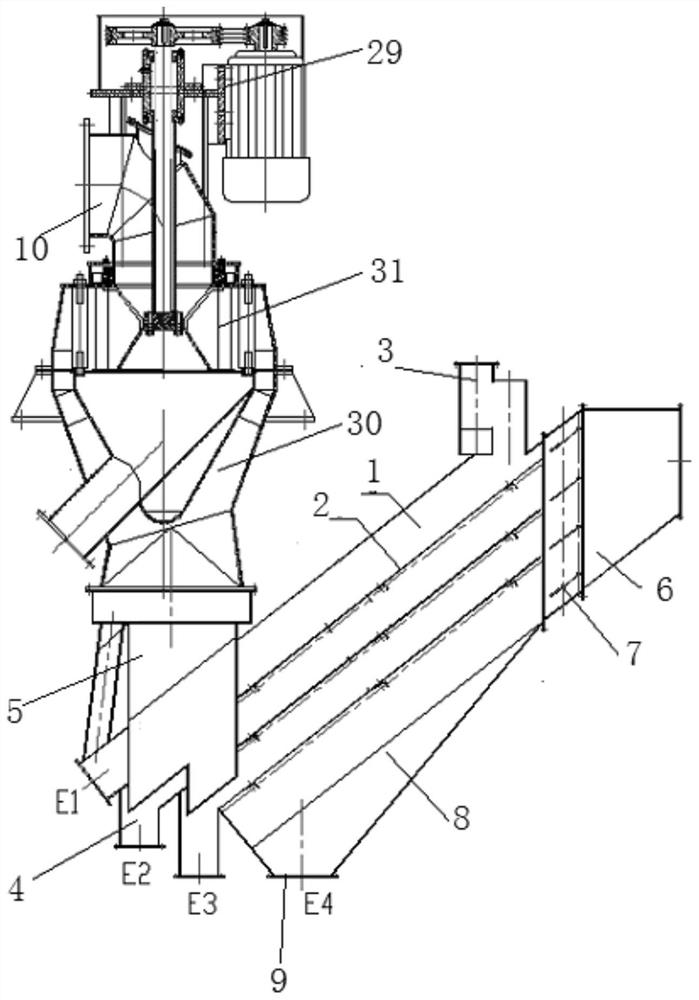

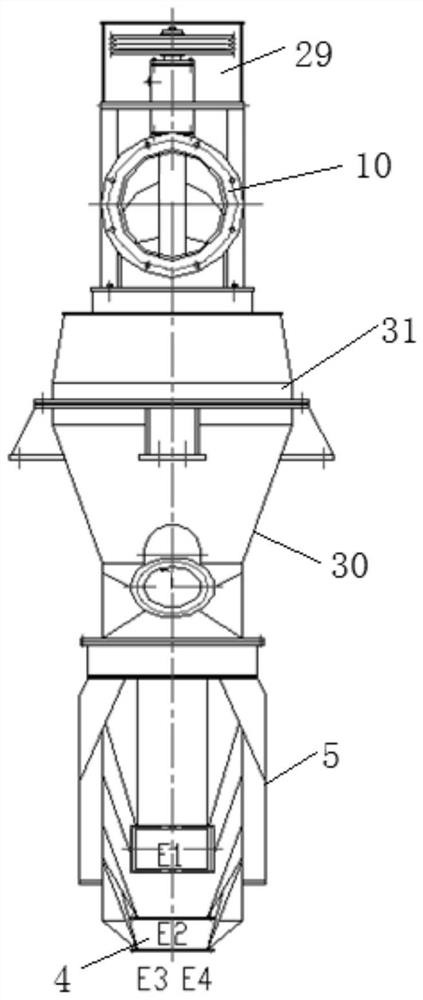

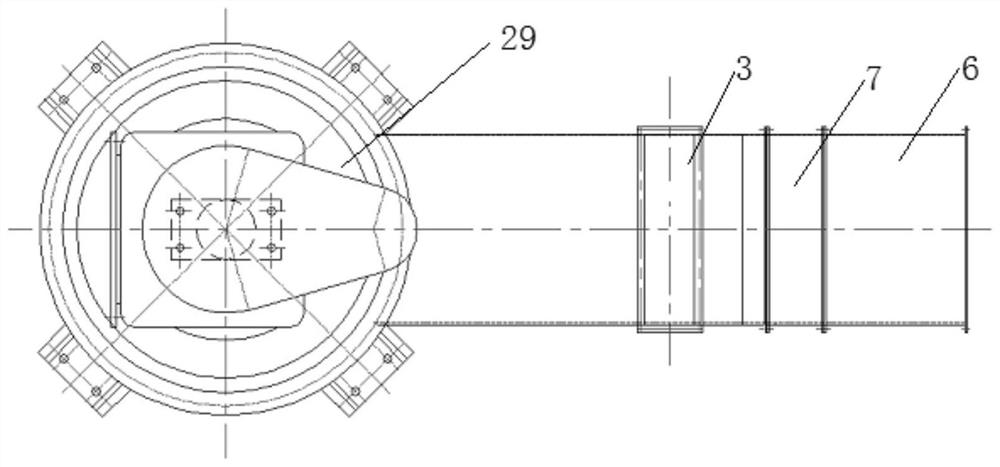

[0022] Such as figure 1 As shown, a multi-product mechanical wind combined powder separator includes a static grading unit and a dynamic grading unit;

[0023] The static grading unit includes a multi-layer screen grading cavity 1, and a screen 2 is installed at the bottom of each layer of sieve grading cavity 1, and the multi-layer sieve grading cavity 1 is connected up and down in sequence and parallel to each other. The grading cavity 1 is arranged obliquely, and the size of the sieve mesh decreases sequentially from top to bottom. A feed port 3 is provided on the upper side of the first layer of sieve grading cavity, and each layer of sieve grading cavity 1 The lower end is respectively provided with a material outlet 4, and also includes an air outlet 5, an air inlet 6, and an air volume adjustment module 7 connected to the air inlet 6. The air volume adjustment module 7 is connected to the upper end of a plurality of screen classification chambers 1 connected, the air o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com