Pneumatic atomizing sprayer

An atomizing nozzle and pneumatic technology, applied in the direction of spray discharge device, etc., can solve the problems of large particle size fluctuation range, increased system cost, and easy blockage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

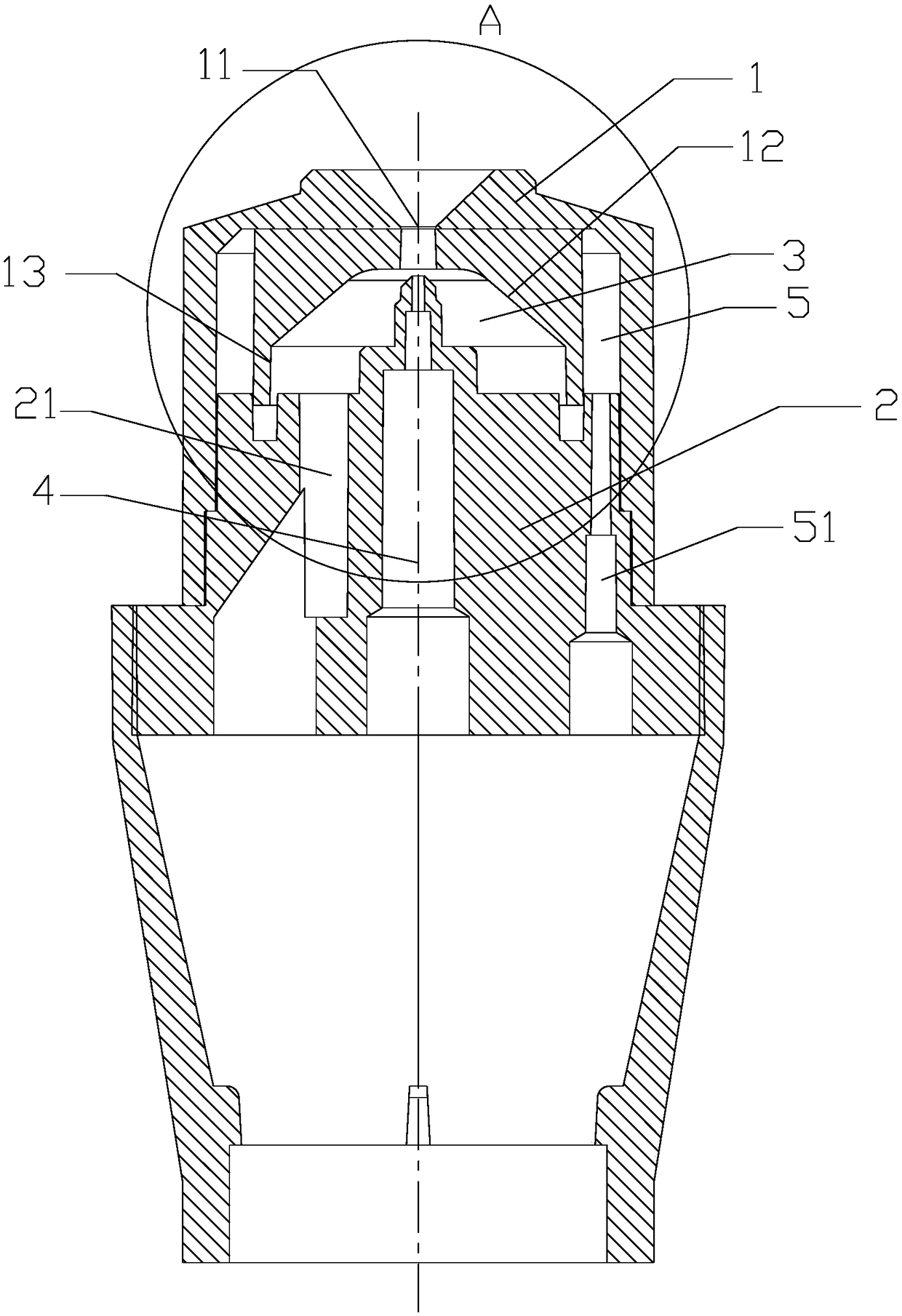

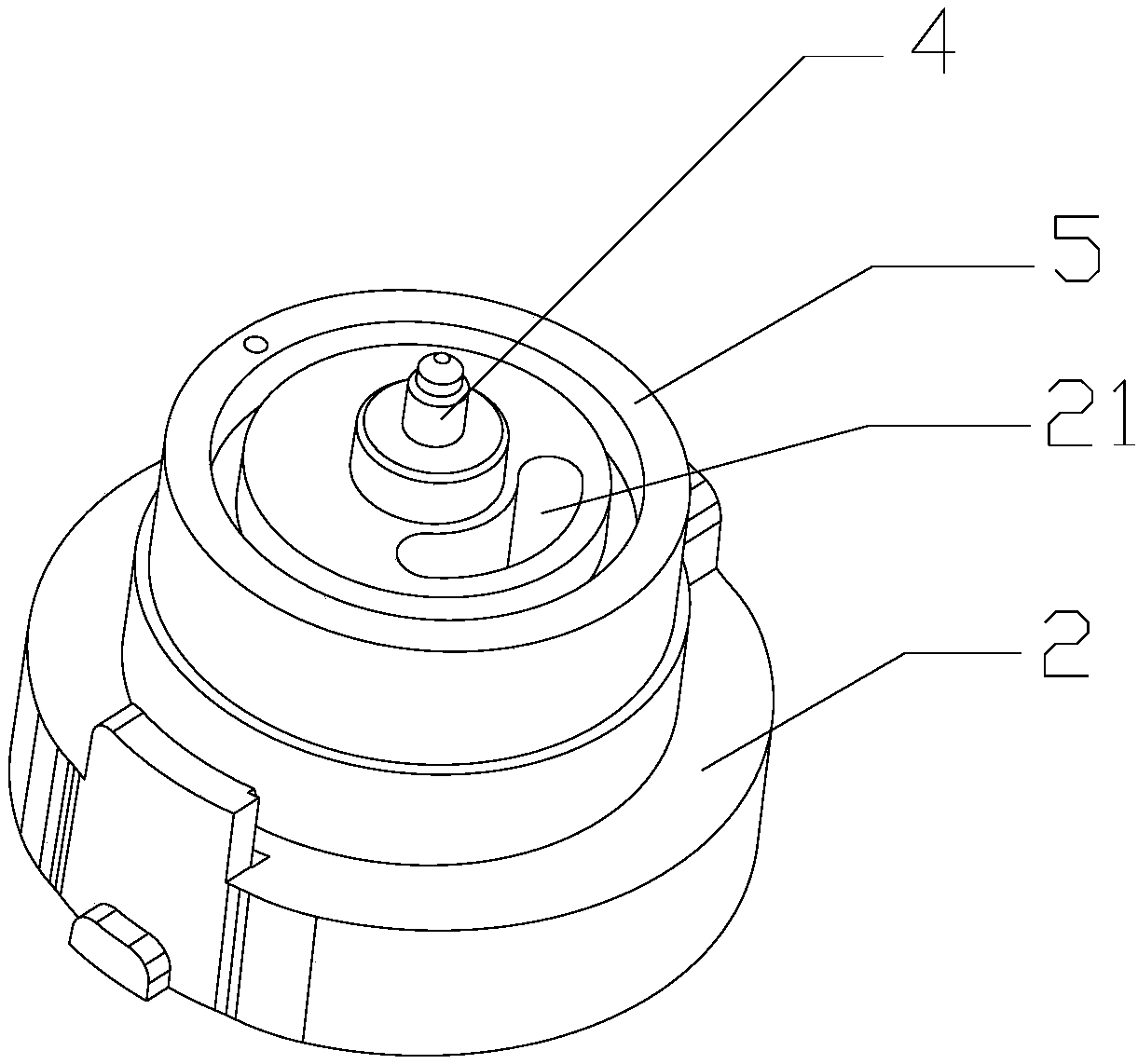

[0026] Such as Figure 1 to Figure 4 As shown, a preferred embodiment of the present invention provides a pneumatic atomizing nozzle, including a nozzle body 2, and an air knife unit. The nozzle body 2 is provided with a liquid outlet pipeline 4 for spraying liquid droplets, and the air knife unit It includes an end cover 1 installed on the main body of the spray head 2 and forming an air chamber 3 with the main body 2 of the spray head, and an air knife assembly for spraying gas to the end of the liquid outlet pipeline 4 to cut the sprayed liquid droplets. The position corresponding to the liquid outlet pipeline 4 on the cover 1 is provided with a nozzle 11 for guiding liquid droplets and ejecting gas; The gas channel 13 for guiding the gas flow and the inclined surface 12 arranged inside the end cover and used to refract the gas from the gas tank to the end of the liquid outlet pipeline.

[0027] The main body of the nozzle is provided with a gas pipeline connector connecte...

Embodiment 2

[0039] In order to detect the distance d between the end of the liquid outlet pipeline and the nozzle, and the cutting effect of the airflow on the sprayed liquid droplets, this embodiment provides a pneumatic atomizing nozzle whose main parameters are: The inner diameter is 1mm, the inner diameter inside the nozzle is 2mm, the output pressure of the liquid outlet pipeline is 1.2Mpa, the output pressure of high-pressure air is 2.5Mpa, and the slope angle α is 50°.

[0040] Adjust the distance d between the end of the liquid outlet pipeline and the nozzle, and the results are shown in Table 2. It can be seen that when the distance d between the end of the liquid outlet pipeline and the nozzle becomes smaller, due to the insufficient contact between the air knife and the sprayed droplets, although it can Increasing the cutting intensity makes part of the droplet size smaller, but the proportion of non-atomized droplets will increase accordingly. Considering the actual applicatio...

Embodiment 3

[0044] This embodiment provides a pneumatic atomizing spray head that further improves the spraying effect compared with the second embodiment. The inner side of the end cover 1 is located between the inclined surface 12 and the nozzle 11 and is further provided with an arc surface 14 . The curved surface 14 allows the swirling airflow to slide smoothly along the inner wall to form a gas envelope, which protects the atomized liquid from being pushed toward the nozzle, and makes the inner cavity dry, so as to prevent the accumulation of liquid from interfering with the airflow or causing short circuit of the electrodes. If there is no arc surface, the gas will form multi-layer convection in the gas chamber, causing the liquid part to deposit on the inner wall of the gas chamber, shortening the spraying distance of the atomized liquid droplets.

[0045] In order to detect the cutting effect and spraying effect of sprayed liquid droplets on different arc surfaces, this embodiment ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com