Method for preparing positive electrode material for lithium ion cell by spraying, combusting and pyrolyzing

A technology for lithium ion batteries and cathode materials, which is applied in the field of preparation of lithium ion cathode materials, can solve the problems of insignificant improvement of the electrochemical properties of cathode materials, difficulty in large-scale continuous industrial production, and difficulty in controlling the morphology of cathode materials. Achieve the effects of excellent processability and electrochemical performance, improved purity, and easy large-scale continuous industrial production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

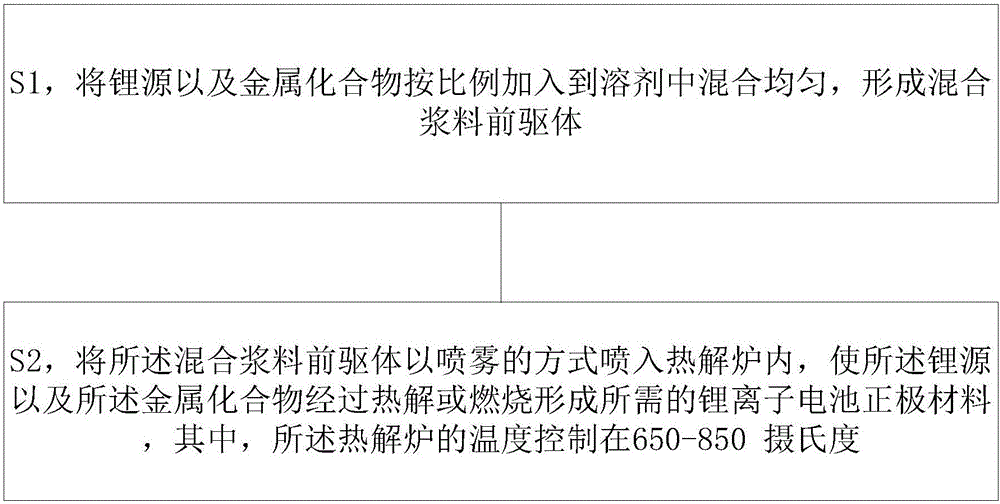

[0038] Further, the preparation method may further comprise the steps:

[0039] S3, recover the tail gas produced by the pyrolysis furnace.

[0040] Specifically, the tail gas can be absorbed and purified by the tail gas absorption device to produce by-products such as nitric acid, sulfuric acid and hydrochloric acid, which can effectively control the pollution discharge and improve the profit at the same time.

Embodiment 1

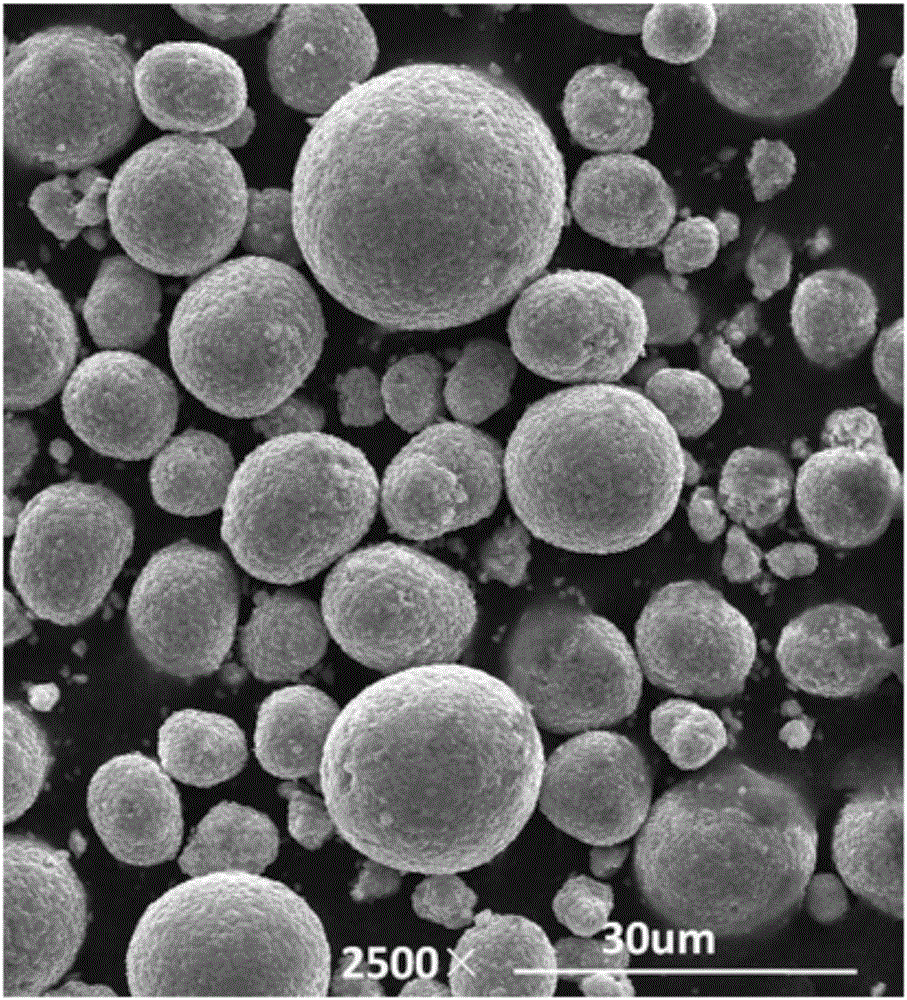

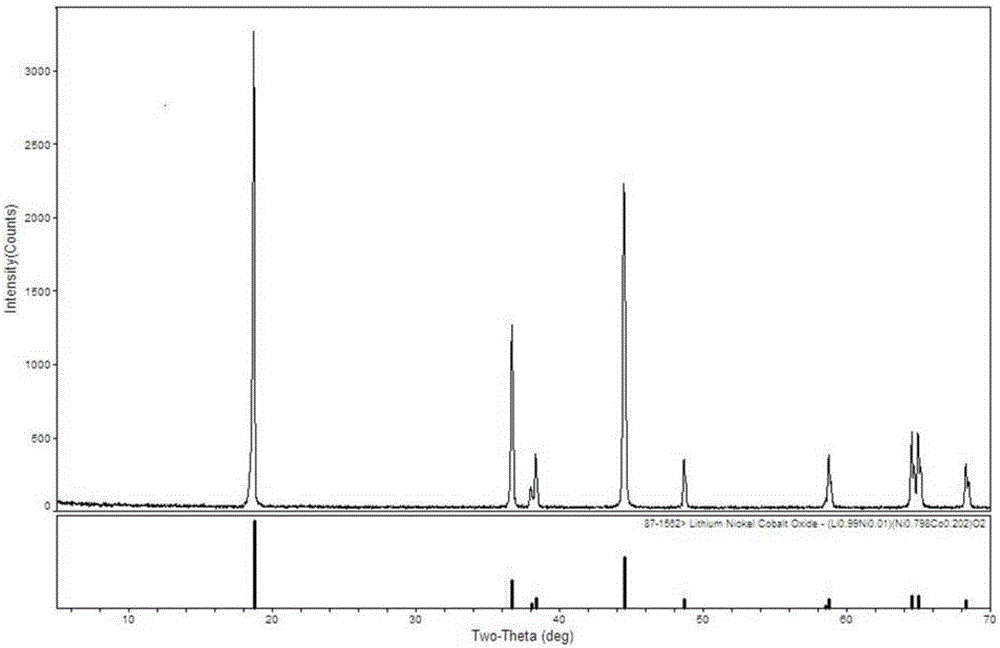

[0042] Lithium nitrate, nickel nitrate, cobalt nitrate and aluminum nitrate were dissolved in absolute ethanol in the ratio of Li:Ni:Co:Al=1.1-1.2:0.85:0.1:0.05 for high-speed stirring for 30 minutes, and then sonicated for 10 minutes. High-speed agitation and ultrasonic circulation for 3 times in turn to form a mixed slurry precursor, wherein the total concentration of metal ions is 7mol / L; the above-mentioned slurry is sprayed vertically from the upper part of the pyrolysis furnace at a speed of 500kg / h. Pyrolysis or combustion in the pyrolysis furnace, and at the same time, oxygen is injected horizontally at the bottom of the pyrolysis furnace along the tangential direction of the furnace wall, so that the lithium source and the metal compound are pyrolyzed or burned to form LiNi 0.85 Co 0.1 Al 0.05 O 2 , wherein the temperature of the pyrolysis furnace is controlled at 700°C.

[0043] Please refer to Figure 2-3 , the electrochemical performance test of the obtained po...

Embodiment 2

[0045] Lithium nitrate and cobalt nitrate are dissolved in water according to the ratio of Li:Co=1.1-1.2:1, stirred at high speed for 30 minutes, then ultrasonicated for 10 minutes, followed by high-speed stirring and ultrasonic cycles for 3 times to form a mixed slurry precursor, wherein The total concentration of metal ions is 5mol / L; the above-mentioned slurry is sprayed vertically into the pyrolysis furnace at a speed of 450kg / h from the upper part of the pyrolysis furnace for pyrolysis or combustion, and at the same time, along the bottom edge of the pyrolysis furnace. Oxygen is injected horizontally in the tangential direction of the furnace wall, so that the lithium source and the metal compound undergo pyrolysis or combustion to form LiCoO 2 , wherein the temperature of the pyrolysis furnace is controlled at 750°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com