Preparation method of hollow glass beads

A technology of hollow glass microspheres and schemes, applied in glass manufacturing equipment, glass molding, manufacturing tools, etc., can solve the problems of high production cost, poor particle size controllability, complicated steps, etc., and achieve low cost and enhanced mechanical properties , The effect of simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Using the oil-in-water Pickering emulsion of hydrophilic nanocellulose emulsification as a template, the specific examples of preparing hollow glass microspheres are as follows:

[0033] The pH value of the water was adjusted to 2.0, and then the hydrophilic nanocellulose was dispersed in said pH 2.0 water, and sodium chloride was added as the aqueous phase A of the Pickering emulsion.

[0034] Mix toluene and methyl orthosilicate at a ratio of 1:1 by volume as the oil phase B of the Pickering emulsion.

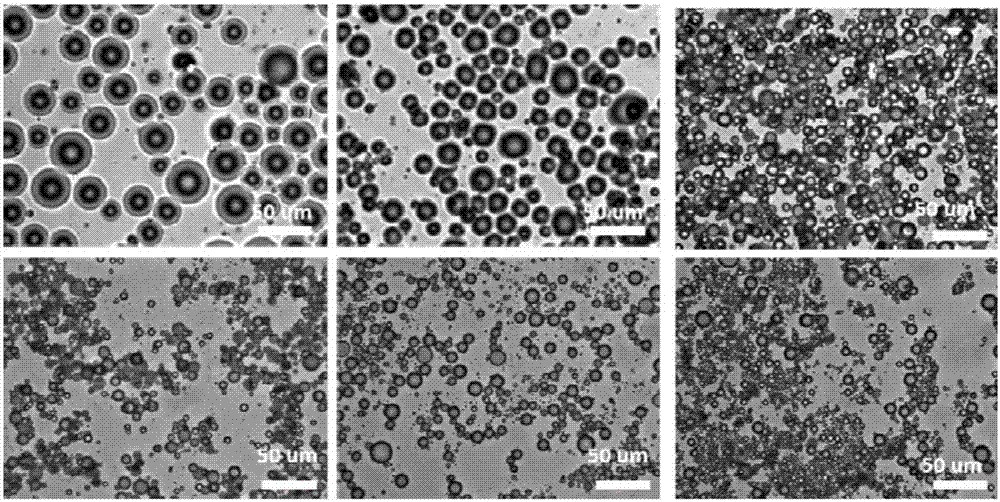

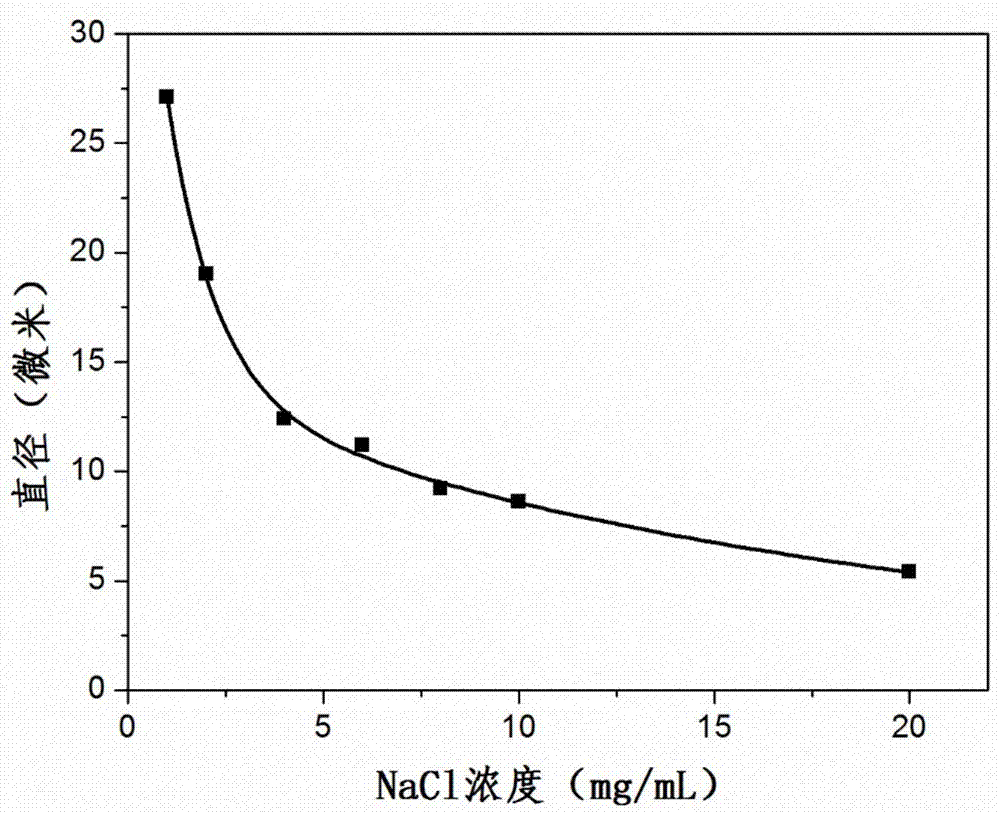

[0035] The above water phase A and oil phase B were mixed according to the volume ratio of 7:3, and then ultrasonicated for 2 minutes to obtain the Pickering emulsion. The aforementioned Pickering emulsion was allowed to stand at room temperature for 5 days, washed with acetone or ethanol and then dried to obtain hollow glass microspheres. The size of the hollow glass microspheres can be adjusted by the concentration of sodium chloride, the concentration of nanocellul...

Embodiment 2

[0043] This example studies the influence of different silica precursors, pH values and organic phase solvents on hollow glass microspheres.

[0044] The hydrophilic nanocellulose was dispersed in water with a certain pH value, and sodium chloride was added as the aqueous phase A of the Pickering emulsion.

[0045] The oil phase solvent and the silica precursor were mixed at a volume ratio of 1:1 as the oil phase B of the Pickering emulsion.

[0046] The above-mentioned water phase A and oil phase B were mixed according to the volume ratio of 7:3, and the Pickering emulsion was obtained after ultrasonication for 2 minutes. The aforementioned Pickering emulsion was allowed to stand at room temperature for 5 days, washed with acetone or ethanol and then dried to obtain hollow glass microspheres.

[0047] The summary of each test parameter and test result is as follows:

[0048]

[0049]

[0050]

[0051] The methyl orthosilicate in Example 1 can be replaced by other...

Embodiment 3

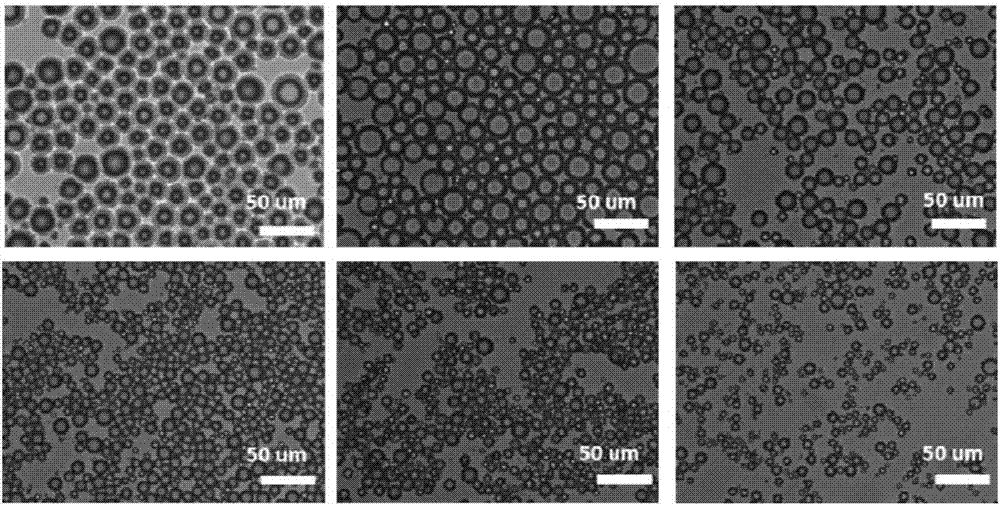

[0057] Using the water-in-oil Pickering emulsion emulsified by hydrophobic nanocellulose as a template, the specific examples of preparing hollow glass microspheres are as follows:

[0058] Firstly, the hydrophilic nanocellulose is hydrophobically modified, and the modified hydrophobic nanocellulose can be prepared by introducing a hydrophobic matrix onto the nanocellulose by means of small molecule reaction or polymer grafting. In this example, butyryl chloride was used to hydrophobically modify nanocellulose. Disperse 1 gram of nanocellulose into 100 milliliters of dimethylformamide, add 1 milliliter of triethylamine, 1 gram of 4-dimethylaminopyridine and 1 gram of butyryl chloride, and react at room temperature for 24 hours to obtain hydrophobic modification of nanocellulose.

[0059] The above-mentioned hydrophobically modified fiber nanocrystals were dispersed into an oily solvent, and the silica precursor methyl orthosilicate was added as the oil phase A of the Pickerin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Wall thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com