Preparation method of foamed light soil, and foamed light soil

A foam lightweight soil quality technology, which is applied in the field of foam lightweight soil and foam lightweight soil preparation, can solve the problems of inability to play a protective role, proportion, and cockroach aggregation, so as to prevent insect aggregation and reduce water content , good stereotyped effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

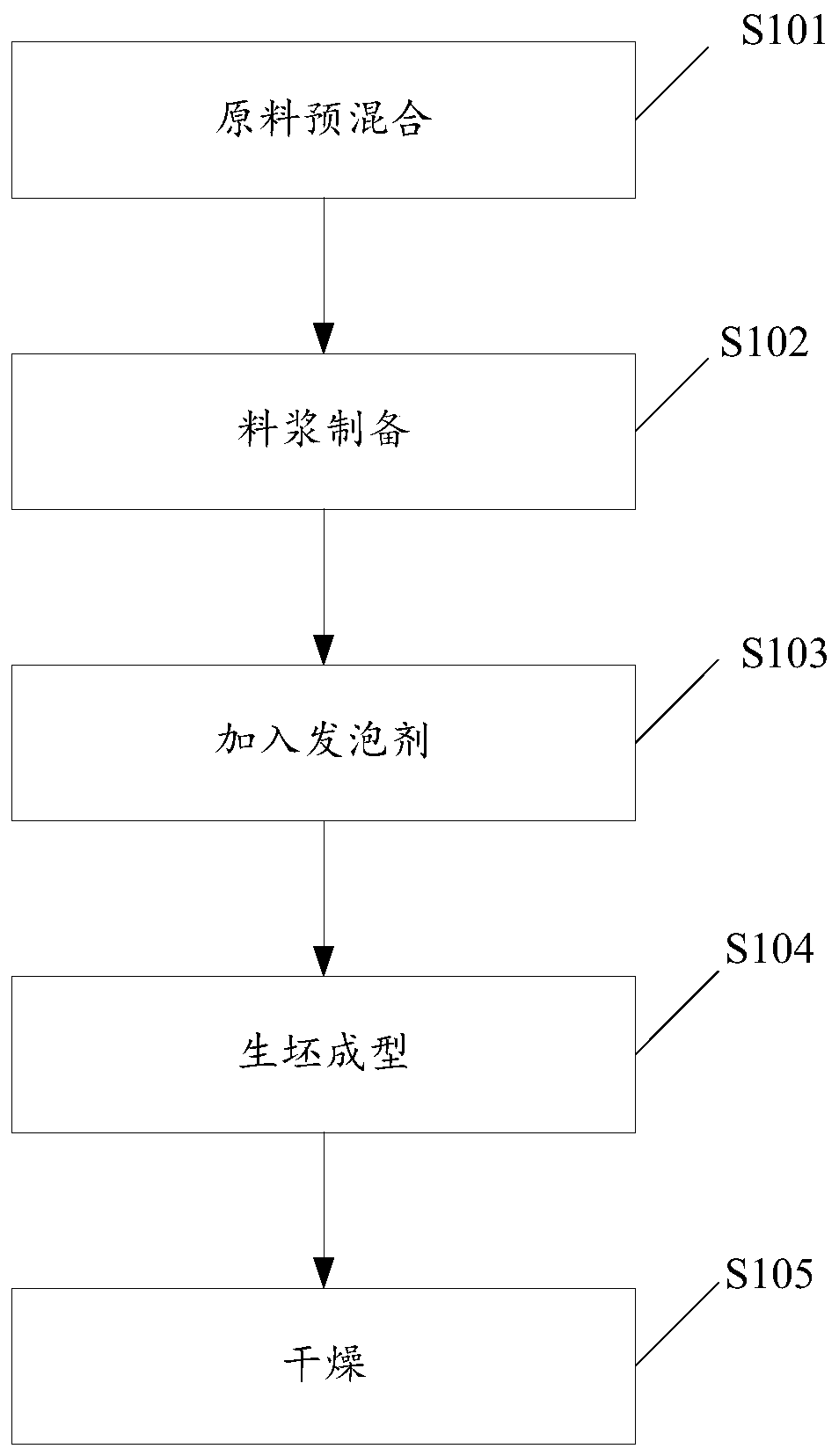

Method used

Image

Examples

specific Embodiment 1

[0043] The mass proportion of external admixture is about 30%, the mass proportion of cementing material is about 60%, the mass proportion of chemical auxiliary agent is about 8%, and the mass proportion of active silica-alumina material is about 2%. The mass proportion of ketone-2 powder is about 0.01%.

[0044] in:

[0045] The cementing material includes cement clinker, calcium oxide and bone glue powder, and the mass ratio of these three components in the cementing material is 2:3:1. The external admixture is a mixture of fly ash and wet ash. The active silica-alumina material is composed of fly ash and metakaolin, and the mass ratio of the fly ash to metakaolin is 1.8.

[0046] The chemical auxiliary agent includes sodium sulfate and sodium phenyldodecylsulfonate, the mass proportion of the sodium sulfate in the chemical auxiliary agent is about 60%, and the mass proportion of the sodium phenyldodecylsulfonate in the chemical auxiliary agent is 18% %. In this embodime...

specific Embodiment 2

[0049] The mass proportion of external admixture is about 33%, the mass proportion of cementing material is about 55%, the mass proportion of chemical auxiliary agent is about 9%, and the mass proportion of active silica-alumina material is about 3%. The mass proportion of ketone-2 powder is about 0.03%.

[0050] Among them: the cementing material includes cement clinker, calcium oxide and bone cement powder, and the mass ratio of these three components in the cementing material is 2:3:1. The active silica-alumina material is composed of fly ash and metakaolin, and the mass ratio of the fly ash and metakaolin is 2. The external admixture is formed by mixing fly ash and coal gangue after spontaneous combustion.

[0051] The chemical auxiliary agent includes sodium sulfate and sodium phenyldodecylsulfonate, the mass proportion of the sodium sulfate in the chemical auxiliary agent is about 65%, and the mass proportion of the sodium phenyldodecylsulfonate in the chemical auxiliar...

specific Embodiment 3

[0054] The mass proportion of external admixture is about 35%, the mass proportion of cementing material is about 50%, the mass proportion of chemical auxiliary agent is about 10%, and the mass proportion of active silica-alumina material is about 5%. The mass proportion of ketone-2 powder is about 0.04%.

[0055] Among them: the cementing material includes cement clinker, calcium oxide and bone cement powder, and the mass ratio of these three components in the cementing material is 2:3:1. The active silica-alumina material is composed of fly ash and metakaolin, and the mass ratio of the fly ash to metakaolin is 1.5. The external admixture is mixed with wet ash and coal gangue after spontaneous combustion.

[0056] The chemical auxiliary agent includes sodium sulfate and sodium phenyldodecylsulfonate, the mass ratio of the sodium sulfate in the chemical auxiliary agent is about 50%, and the mass ratio of the sodium phenyldodecylsulfonate in the chemical auxiliary agent is 10%...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Apparent density | aaaaa | aaaaa |

| Apparent density | aaaaa | aaaaa |

| Apparent density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com