Smokeless, coal saving type heat transfer oil stove with large mechanical fire grate

A heat-conducting oil furnace and large-scale machinery technology, applied in the field of improved smokeless coal-saving large-scale mechanical grate heat-conducting oil furnace, can solve the problems of insufficient coal combustion, energy waste, large coal consumption, etc., and achieve economic benefits and Significant social benefits, saving coal resources, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings of the embodiments.

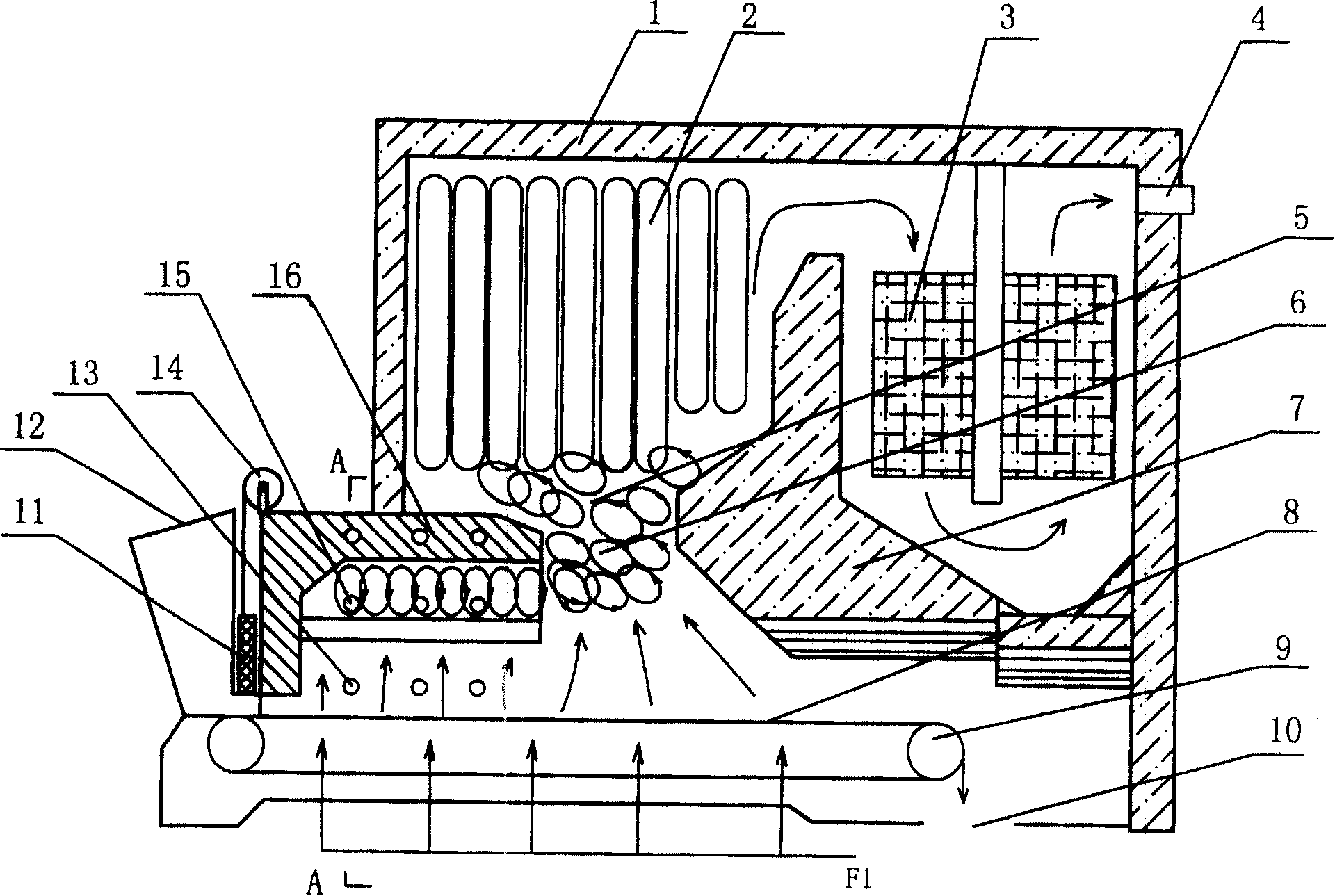

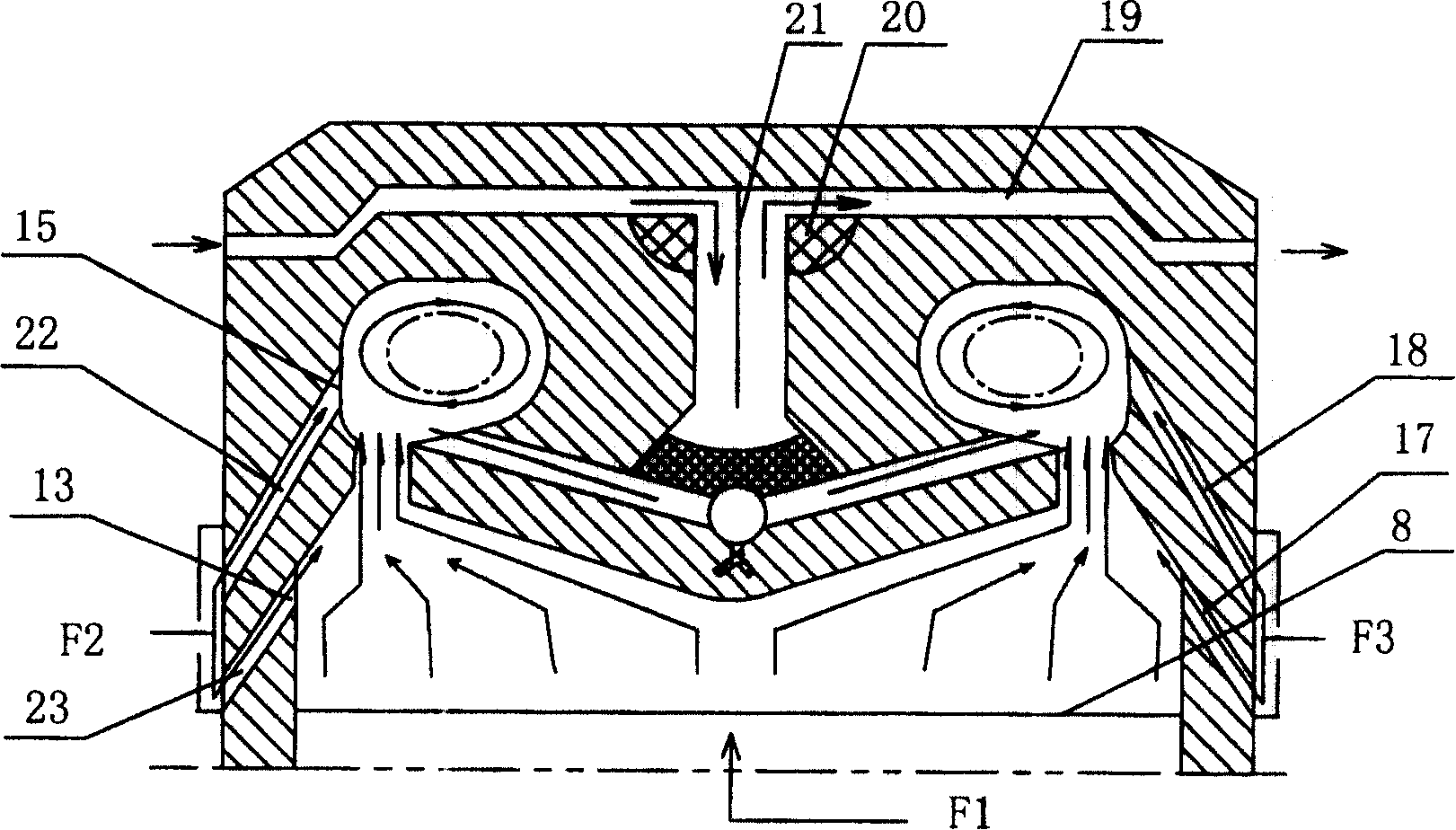

[0022] Such as figure 1 with figure 2 As shown, the smokeless coal-saving large-scale mechanical grate heat-conducting oil furnace of the present invention has a heating zone and a hot gas supply zone. Gas inlet 5, the top of the heating zone is connected to the nozzle 4 by the induced draft fan and equipped with an induced draft fan; the hot gas supply area has a coal burning device, and the coal burning device has a combustion furnace, a chain grate 8, a coal charging device and a high temperature gas outlet 6 , the high-temperature gas outlet 6 is located in front of the back furnace arch 7, and the high-temperature gas outlet 6 is set correspondingly to the hot gas inlet 5 of the heating zone. The furnace is divided into an upper furnace and a lower furnace. The upper and lower furnaces are connected. The cross section of the furnace is two sy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com