Smokeless, coal saving type horizontal heat transfer oil stove with mechanical fire grate

A technology of mechanical grate and heat-conducting oil furnace, applied in lighting and heating equipment, solid fuel combustion, combustion equipment and other directions, can solve the problems of insufficient coal combustion, waste of energy, waste of coal resources, etc., and achieve economic benefits and Significant social benefits, saving coal resources and protecting the environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the accompanying drawings of the embodiments.

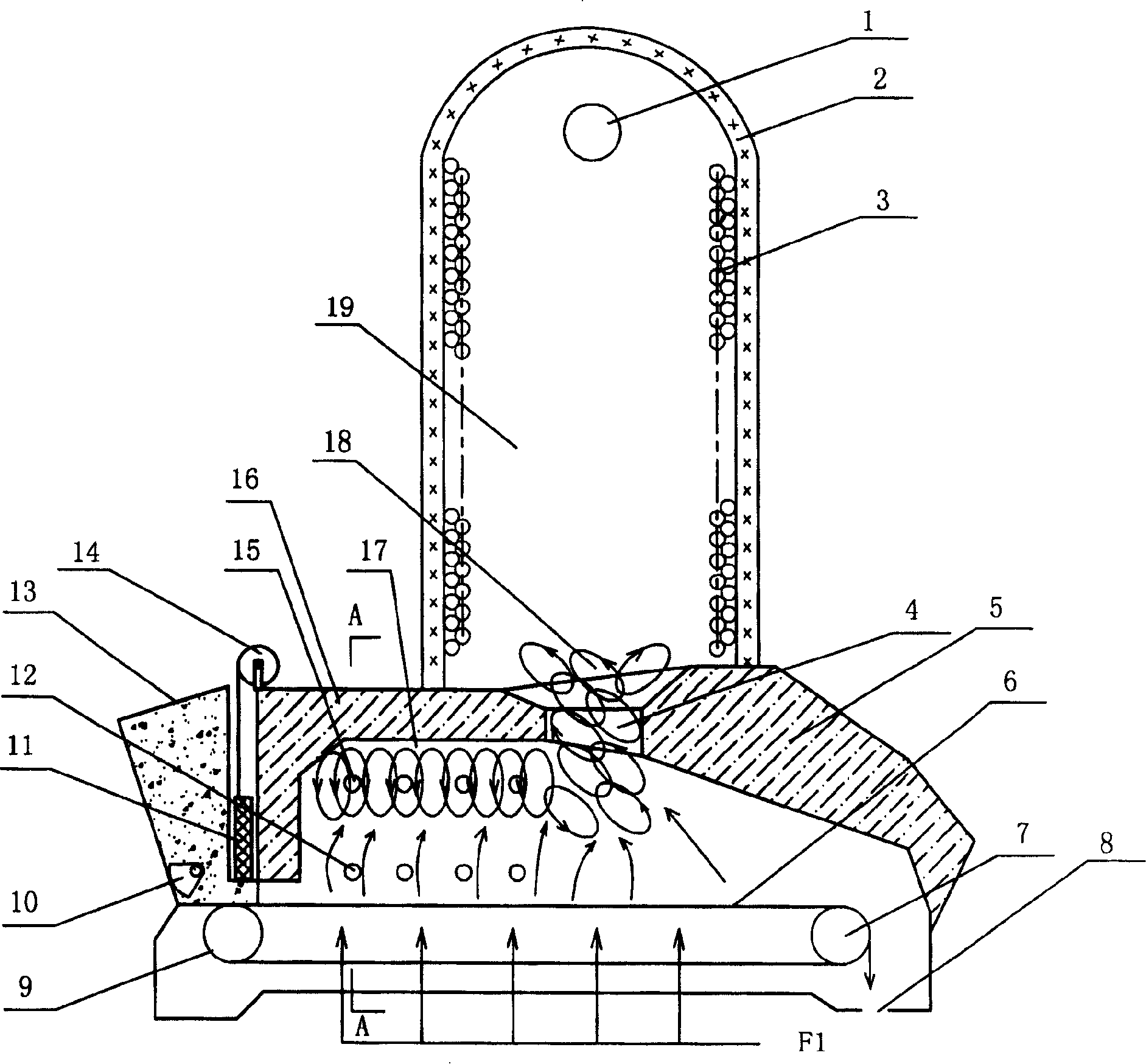

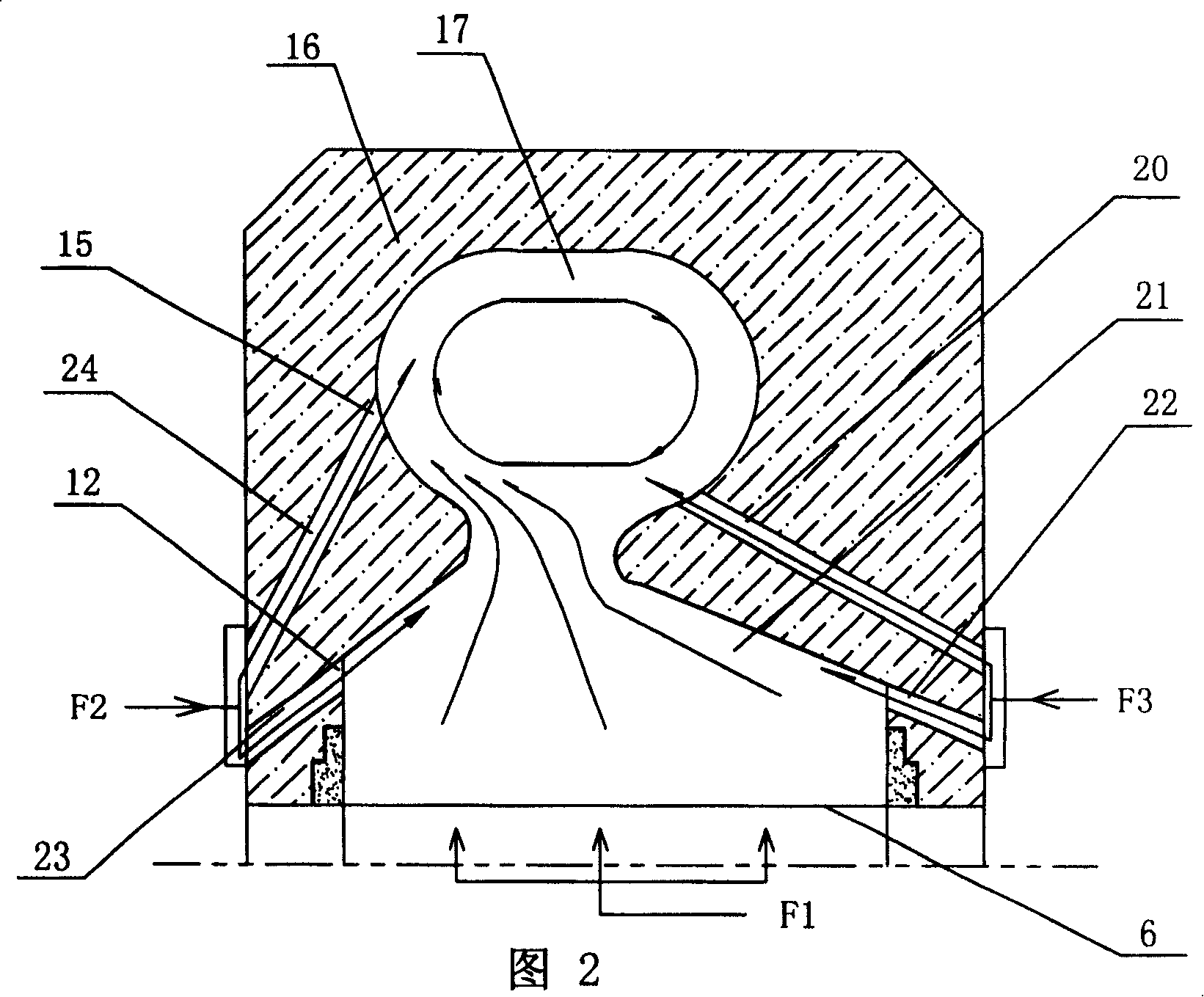

[0020] Such as figure 1 As shown in Fig. 2, the smokeless coal-saving type horizontal mechanical grate heat conduction oil furnace of the present invention, the top of the body of heater is the heating zone 19, the bottom of the body of heater is the hot gas supply zone, the body of heater 2 in the heating zone Equipped with a heat-conducting oil pipe 3, there is a hot gas inlet 18 at the bottom of the heating zone 19, and the top of the heating zone 19 is connected to the induced draft fan through the nozzle 1 of the induced draft fan; the hot gas supply zone has a coal burning device 16, and the coal burning device 16 has a combustion Furnace, chain grate 6, coal charging device and high-temperature gas outlet 4, coal charging device is composed of coal hopper 13, lower coal valve 10, lower coal ram 11 and lower coal ram lifting wheel 14, high-temp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com