Coal firing equipment with single rotational flow

A coal-fired, turbulent technology, applied in the direction of burners, combustion chambers, combustion methods, etc., can solve the problems of energy waste, environmental pollution, etc., and achieve the effects of saving coal resources, protecting the environment, and simple and reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with the accompanying drawings of the embodiments.

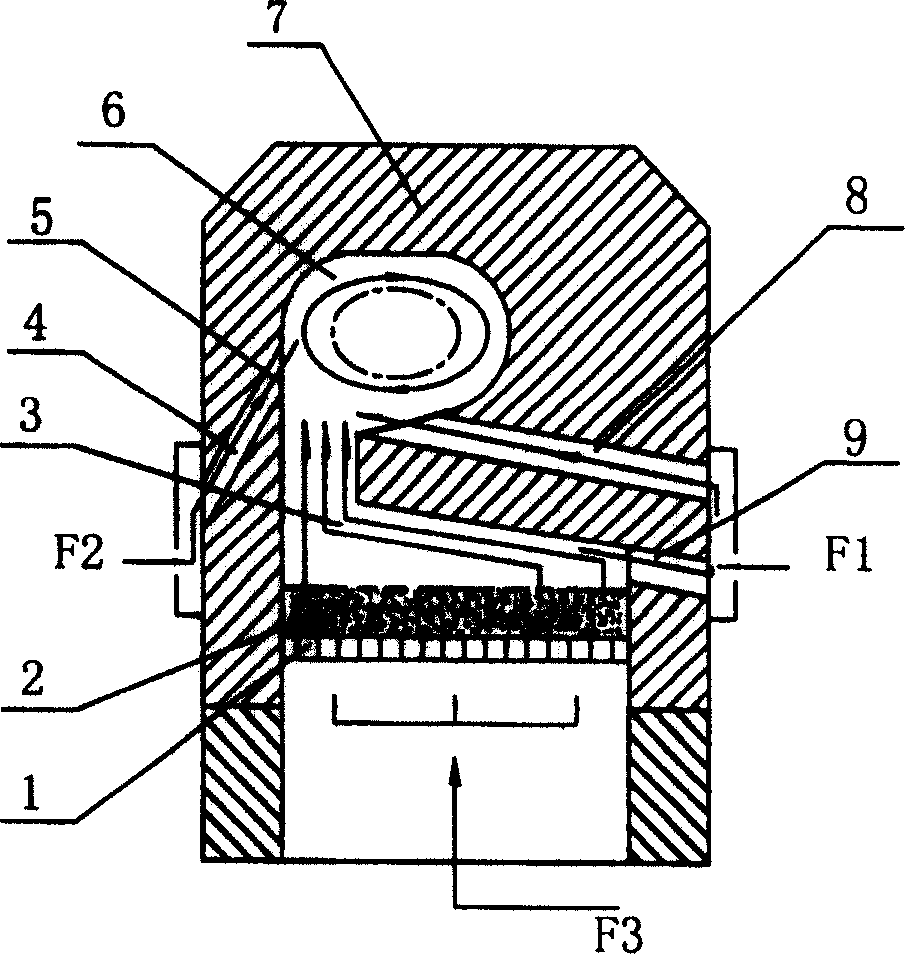

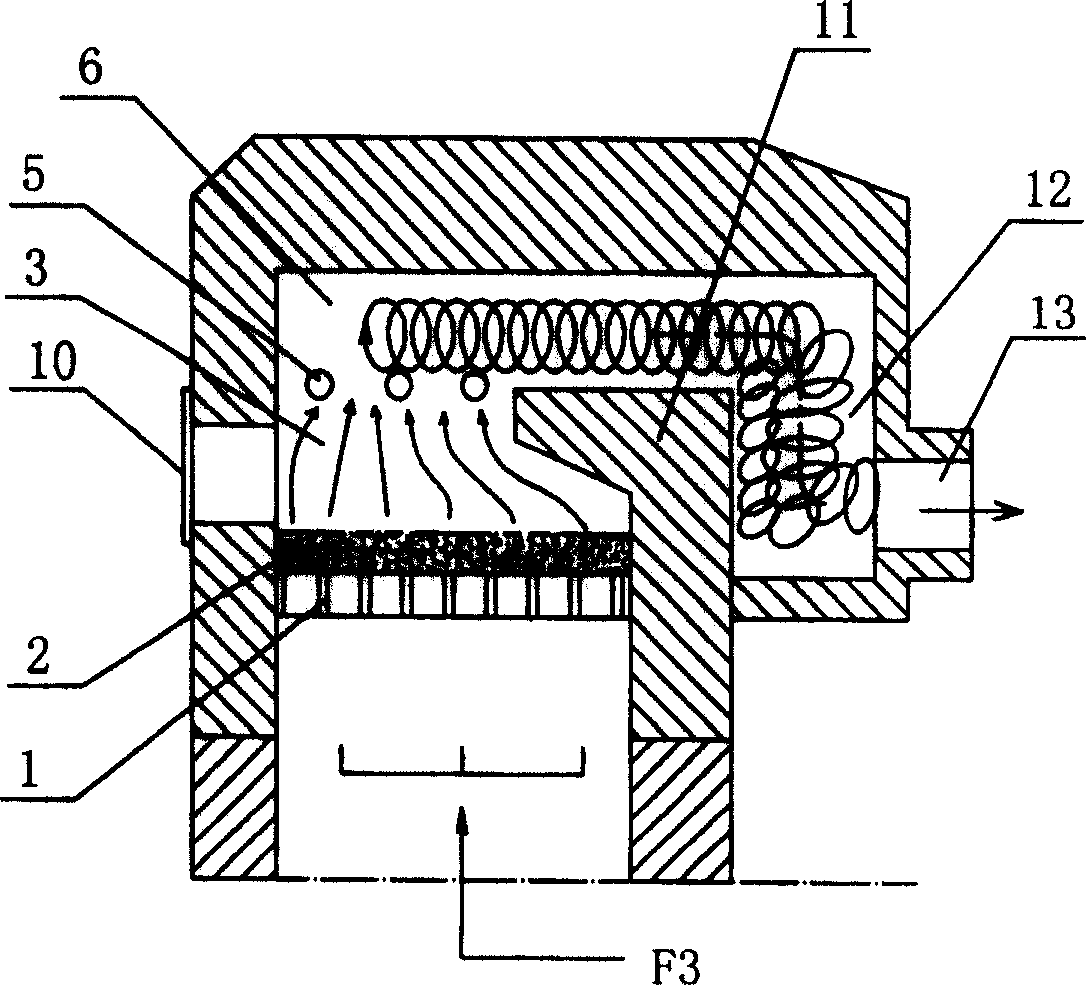

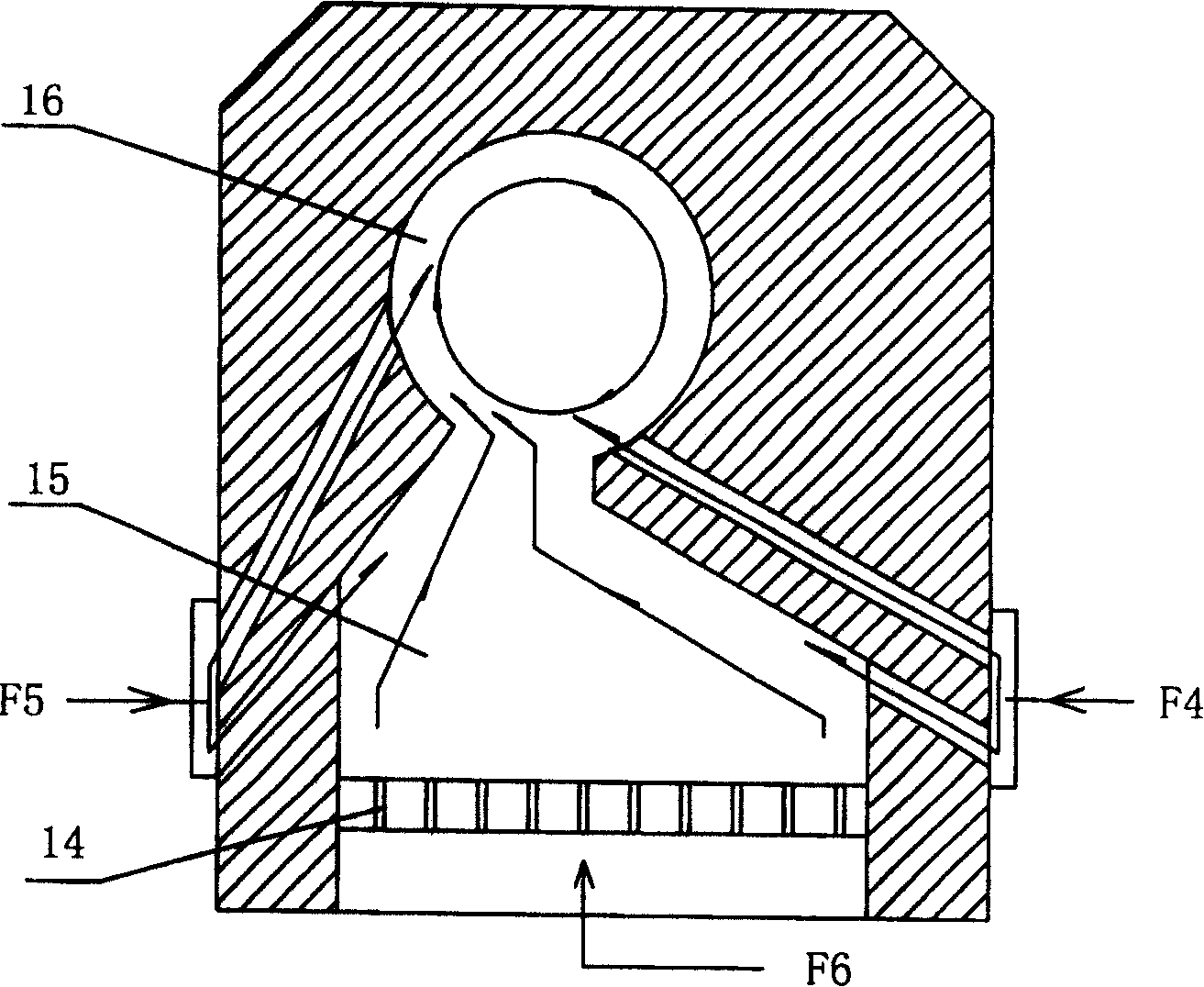

[0023] Such as figure 1 , figure 2 As shown, the single-swirl coal-fired device of the present invention includes a combustion furnace, a fire grate 1, a coal filling port 10 and a high-temperature gas outlet 13, and the top of the cross-section of the furnace is arched to form a swirl combustion, and the furnace The side wall is equipped with a combustion-supporting tuyere 5 leading to the furnace. The combustion-supporting tuyere 7 is tangent to the arch on the top of the furnace. The furnace is divided into two parts connected up and down. The cross section is R-shaped, including the lower furnace 3 and the upper furnace. It is a swirling flow furnace 6, the side wall of the furnace is provided with combustion-supporting air ducts 4 and 8 leading to the upper furnace respectively along the two R-shaped pins, and a combustion-supporting air duct ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com