Equipment and method for directly fabricating coal balls from pulverized coal

A technology of pulverized coal and equipment, which is applied in the field of equipment and production of briquettes made of fine coal pulverized coal, can solve the problems of waste coal and coke quality, high cost, etc., achieve high yield, save pellet making costs, and save coal resources Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

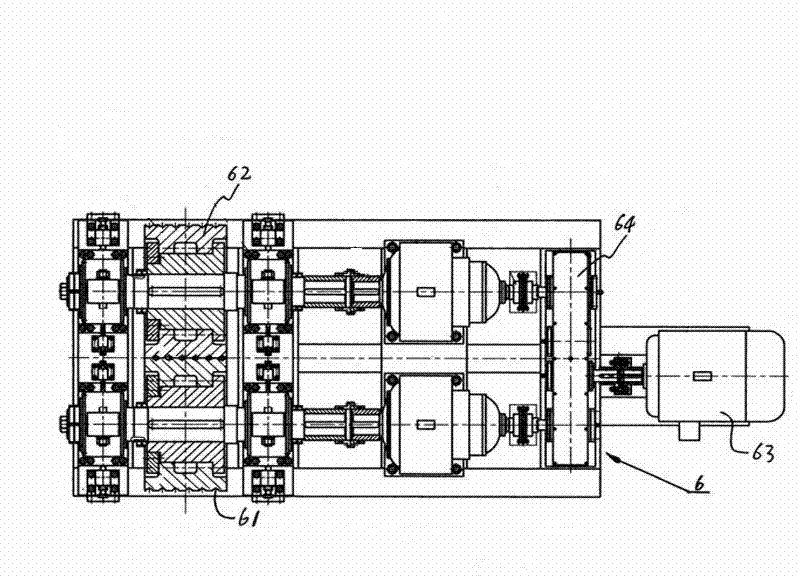

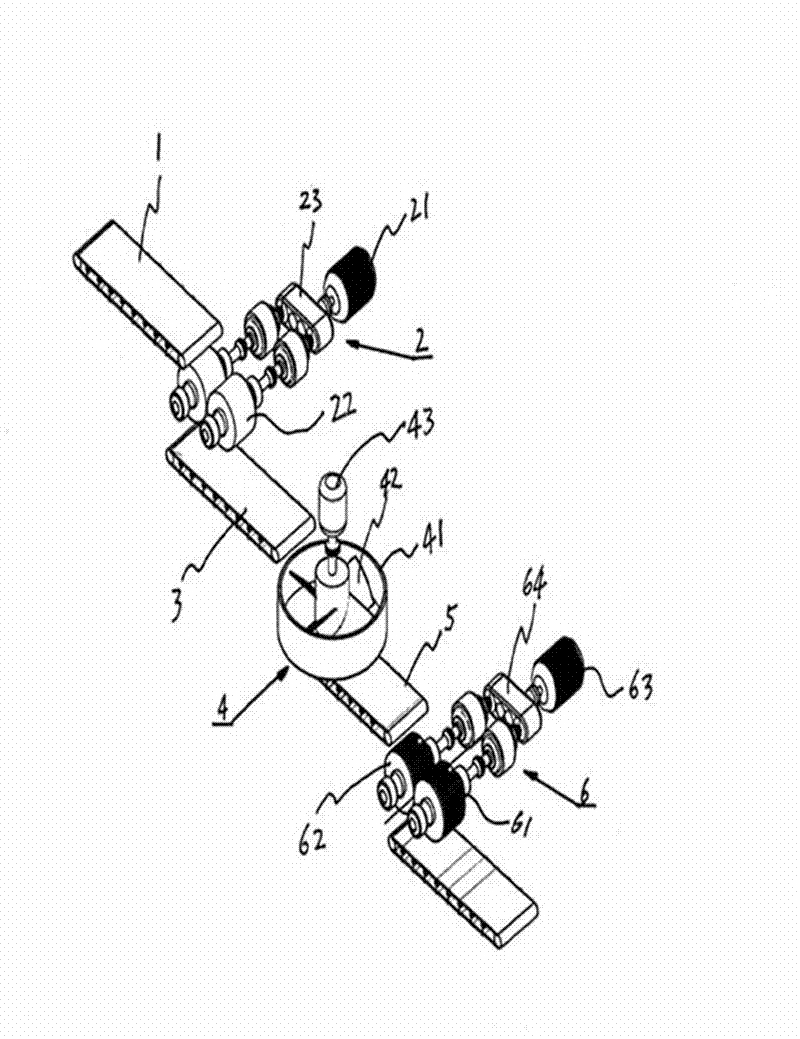

[0017] see figure 1 and figure 2 , which shows a schematic diagram of the appearance structure of an embodiment of the equipment for directly making pulverized coal into balls proposed by the present invention. The equipment includes a pulverized coal belt conveyor 1, a first pair of rollers 2, a sheet coal belt conveyor 3, a pulverizer 4, a coal particle belt conveyor 5 and a second pair of rollers 6.

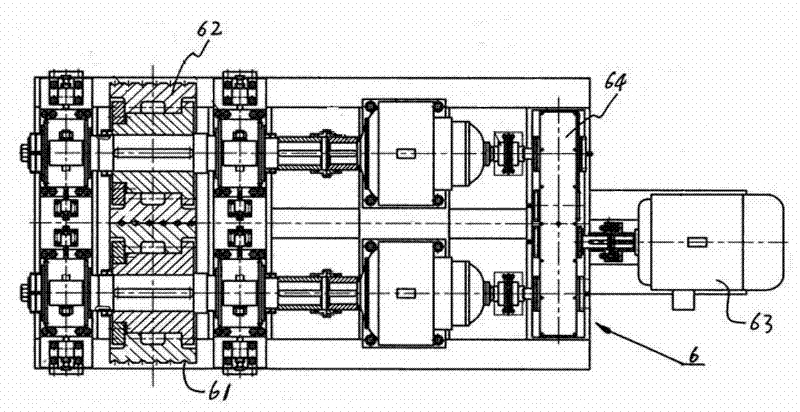

[0018] The first pair of rollers machine 2 is the equipment that is used to extrude pulverized coal to make it into sheet coal, and it comprises motor 21 and two cylindrical pair of rollers 22 with smooth surface, and is installed between motor 21 and two pair of rollers 22 Between the coupler 23, the motor 21 drives the coupler 23 to act, and the two output ends of the coupler 23 respectively drive the two pairs of rollers 22 to rotate in opposite directions (counter-rotation) to each other, so that the The pulverized coal forms flake briquettes. The second pair of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com