Patents

Literature

48 results about "Coal ball" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A coal ball is a type of concretion, varying in shape from an imperfect sphere to a flat-lying, irregular slab. Coal balls were formed in Carboniferous Period swamps and mires, when peat was prevented from being turned into coal by the high amount of calcite surrounding the peat; the calcite caused it to be turned into stone instead. As such, despite not actually being made of coal, the coal ball owes its name to its similar origins as well as its similar shape with actual coal.

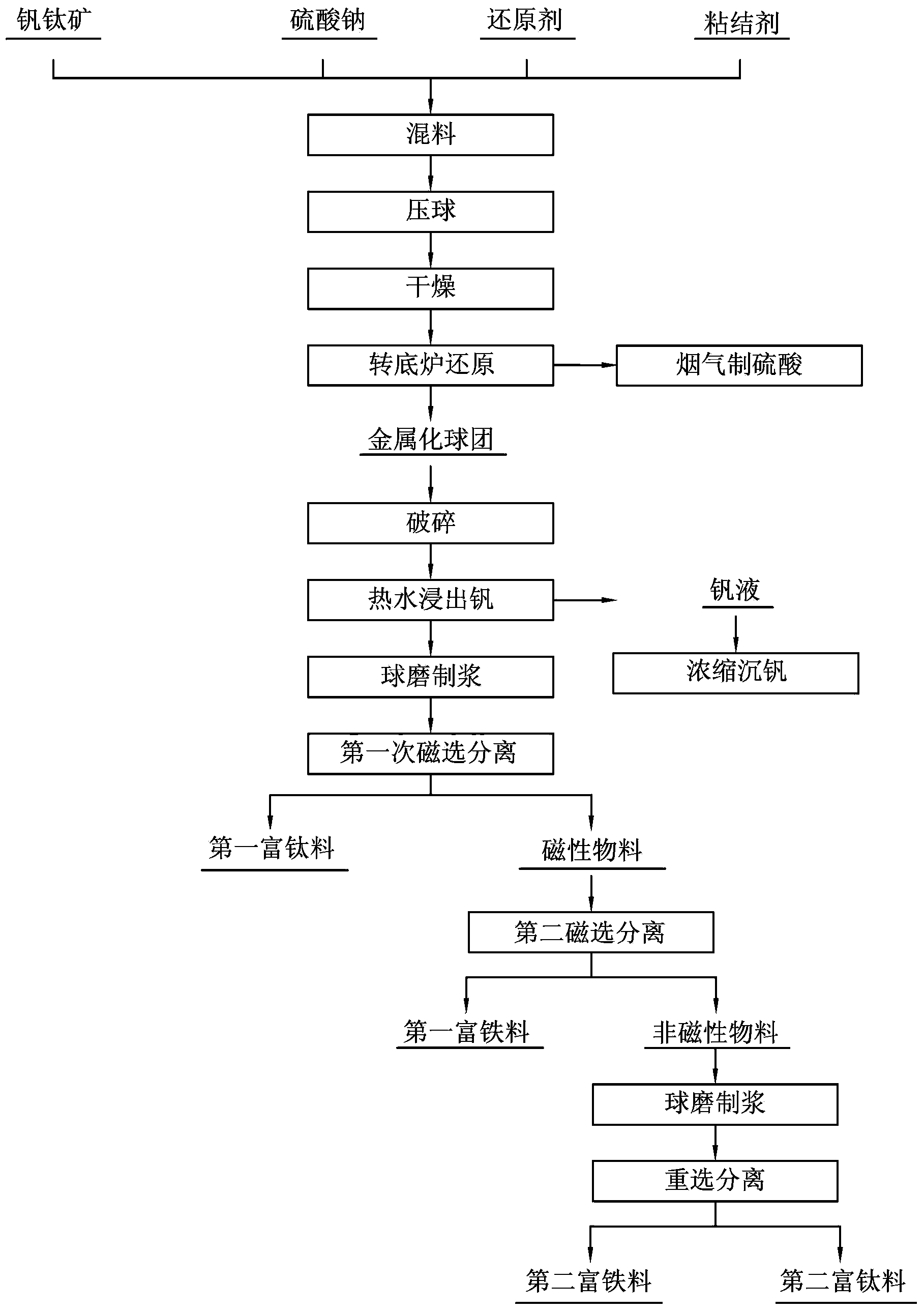

Method for separating iron, vanadium and titanium from schreyerite

ActiveCN103526051AEfficient separationAvoid high temperature reduction and meltingMagnetic separationAdhesiveMetal

The invention discloses a method for separating iron, vanadium and titanium from schreyerite, which comprises the following steps: mixing schreyerite, sodium sulfate, a reducer and an adhesive, pressing into mineral coal pellets, drying the mineral coal pellets, filling into a rotary hearth furnace, and roasting at 1000-1300 DEG C for 20-60 minutes to obtain metalized pellets, wherein a neutral or micro-oxygenation atmosphere is in the rotary hearth furnace; crushing the metalized pellets, leaching at 70-90 DEG C while controlling the pH value at 3-5, and filtering the leach solution to obtain a vanadium solution; slurrying the leaching leftovers by ball milling while controlling the particle size at 0.045mm, and carrying out primary magnetic separation under the magnetic field intensity of 0.3-0.5T to obtain a nonmagnetic material which is a first titanium-rich material; carrying out secondary magnetic separation on the magnetic material under the magnetic field intensity of 0.02-0.04T to obtain a magnetic material which is a first iron-rich material; and slurrying the nonmagnetic material from the secondary magnetic separation by ball milling, and reseparating to obtain a second iron-rich material and a second titanium-rich material.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

High-strength permeable brick and preparation method thereof

The invention discloses a high-strength permeable brick and a preparation method thereof. The high-strength permeable brick comprises the following raw materials (by weight): 60-80 parts of porous coarse aggregate, 30-40 parts of ceramsite, 20-30 parts of cement, 10-30 parts of calcined metakaolin powder, 10-20 parts of fly ash, 5-15 parts of coal gangue, 3-8 parts of coal ball micropowder, 2-8 parts of fiber, 1-5 parts of a pore-forming agent, 0.3-0.8 of a water reducing agent and 0.1-0.5 part of a sintering aid. The permeable brick of the invention has excellent water permeability and high strength; and the preparation method is simple, is easy to realize, and is suitable for large-scale production and application.

Owner:温州月煌科技有限公司

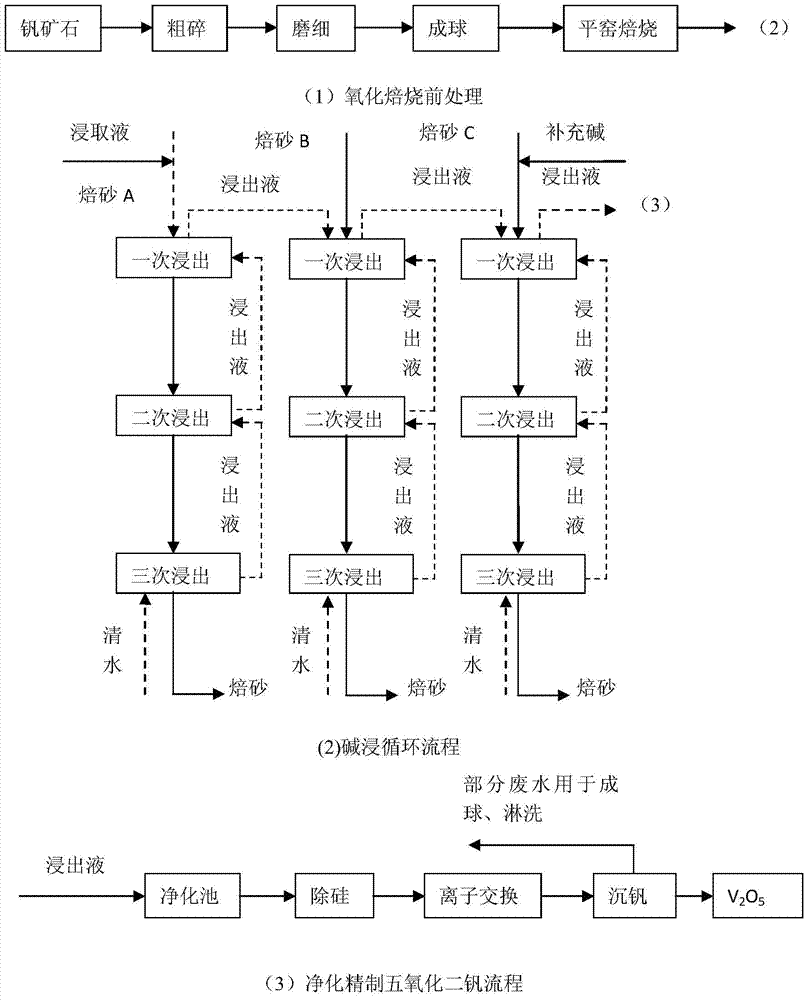

Process for extracting vanadium through alkaline leaching conducted after stone coal oxidizing roasting

InactiveCN103498047AEasy to leachEasy to handleProcess efficiency improvementPregnant leach solutionChemical industry

The invention relates to a process for extracting vanadium through alkaline leaching conducted after stone coal oxidizing roasting, and belongs to the technical field of metallurgy and chemical industry. The process is characterized by including the steps of firstly, grinding stone coal ore till the 200-mesh particles accounts for about 80% of the total amount, adding water to form balls, and conducting high-temperature roasting in a flat kiln; secondly, using NaOH and sodium carbonate to conduct leaching together in the vanadium leaching process, and conducting leaching for three hours at the temperature lower than 95 DEG C, wherein the massic volume ratio of stone coal roasted product to leaching liquid is 1g / ml to 3g / ml, the additive amount of the NaOH is 40g / L, and the additive amount of the sodium carbonate is 13.5g / L; thirdly, enabling the stone coal to enter a purifying pool after primary leaching and washing are conducted so that the solid-liquid separation can be achieved, stacking and storing the stone coal balls, enabling lixivium to directly flow back to be used for leaching vanadium of newly added stone coal, adding leaching agents to the secondary lixivium according to the proportion of the NaOH to the leaching liquid, namely, 13.5g / L and the proportion of the sodium carbonate to the leaching liquid, namely, 4.5g / L, and enabling the product to flow back to be used for leaching vanadium of stone coal balls which are added for the third time. The process has the advantages of being small in pollution, high in vanadium extraction rate, few in heavy metal impurities produced in the leaching process, small in water consumption and the like, and has certain economic benefits under the present technical condition.

Owner:HUNAN UNIV

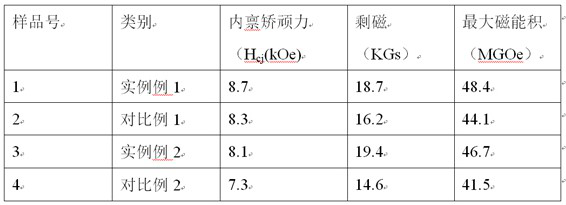

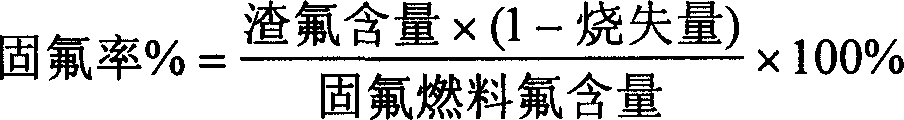

Preparation method of diffusion samarium-iron-nitrogen magnet with high coercivity and high magnetic energy product

ActiveCN112382498AIncreased anisotropyImprove magnetic propertiesInductances/transformers/magnets manufactureMagnetic materialsMetal particleMaterials science

The invention discloses a preparation method of a diffusion samarium-iron-nitrogen magnet with high coercivity and high magnetic energy product, which comprises the following steps: mixing heavy rareearth metal and transition element metal particles, carrying out high-energy ball milling on the mixed particles to form a nanoscale particle mixture, and mixing the mixture with an organic solvent toform a diffusion source mixed solution; perforating the surface of the samarium-iron-nitrogen magnet by using femtosecond to nano laser pulses to form a coal ball-shaped magnet; immersing the coal ball-shaped magnet into the diffusion source mixed solution, taking out the magnet, and presintering at low temperature under the protection of nitrogen to obtain a magnet with a diffusion source coating inside and on the surface of the magnet; and finally, carrying out heat treatment on the magnet under argon protection and a strong magnetic field, and obtaining the samarium-iron-nitrogen magnet with high performance. Under the condition that a main phase in the samarium-iron-nitrogen magnet is not damaged, the interior and the surface of the magnet are coated with the diffusion layers throughthe laser perforation processing technology, doping elements are introduced through three-dimensional diffusion, the anisotropy and the magnetic performance of the samarium-iron-nitrogen magnet are improved, and the process is simple, easy to operate and suitable for batch production.

Owner:CHINA JILIANG UNIV

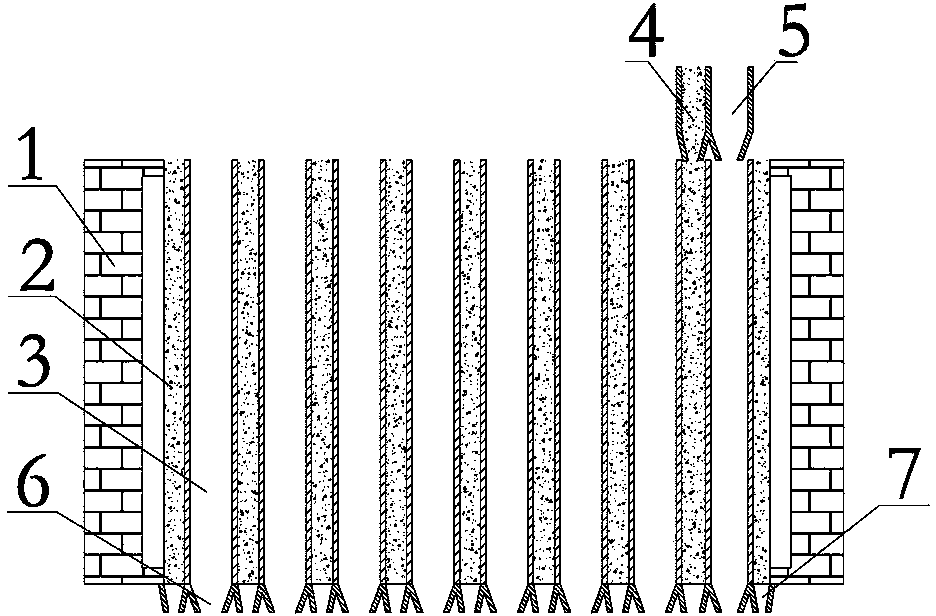

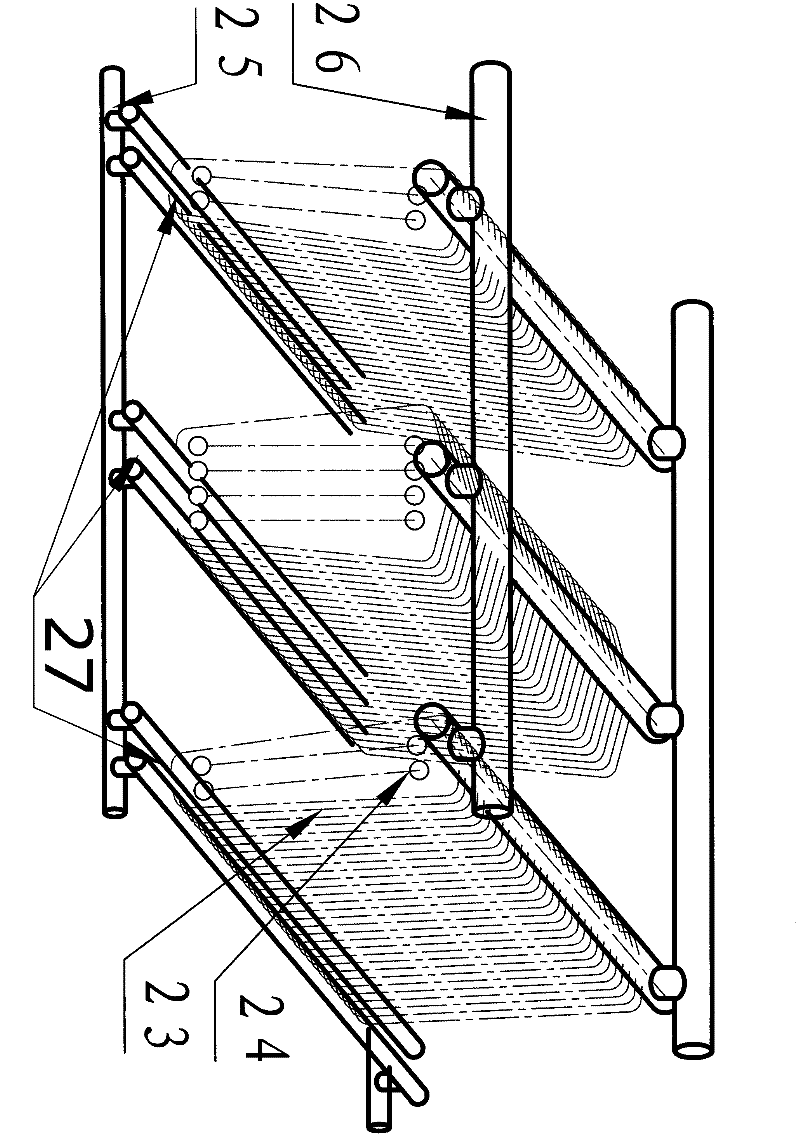

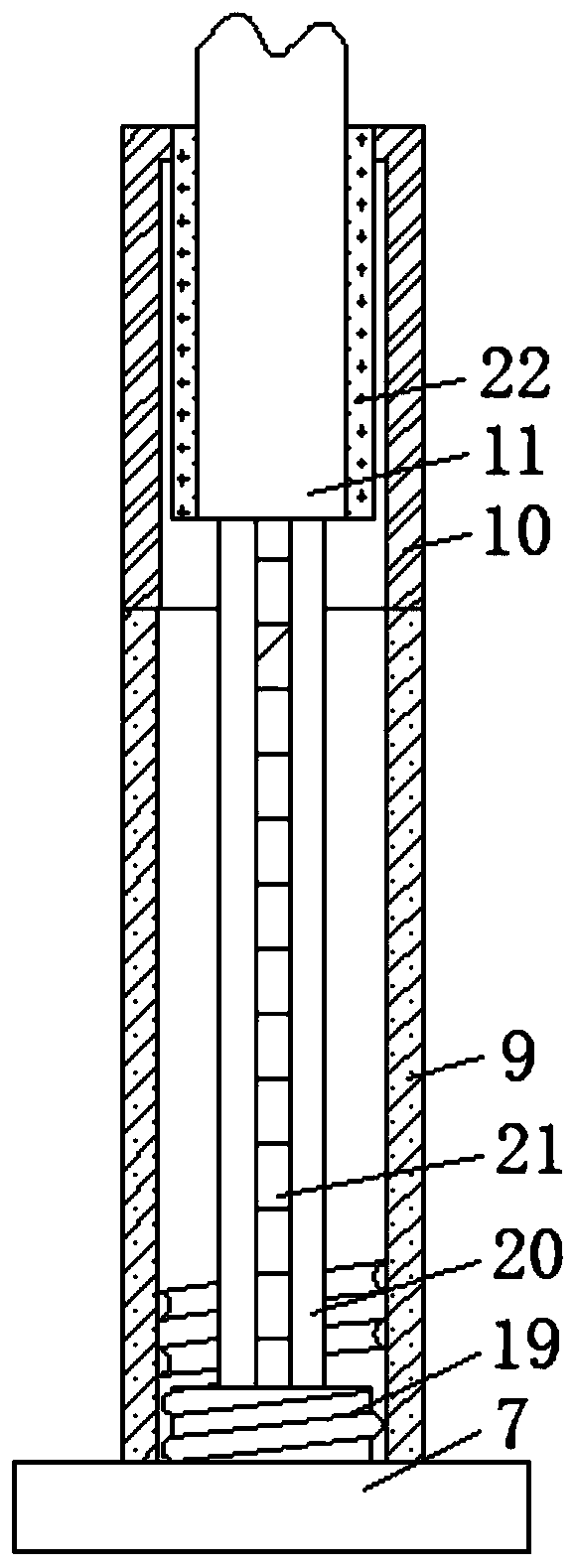

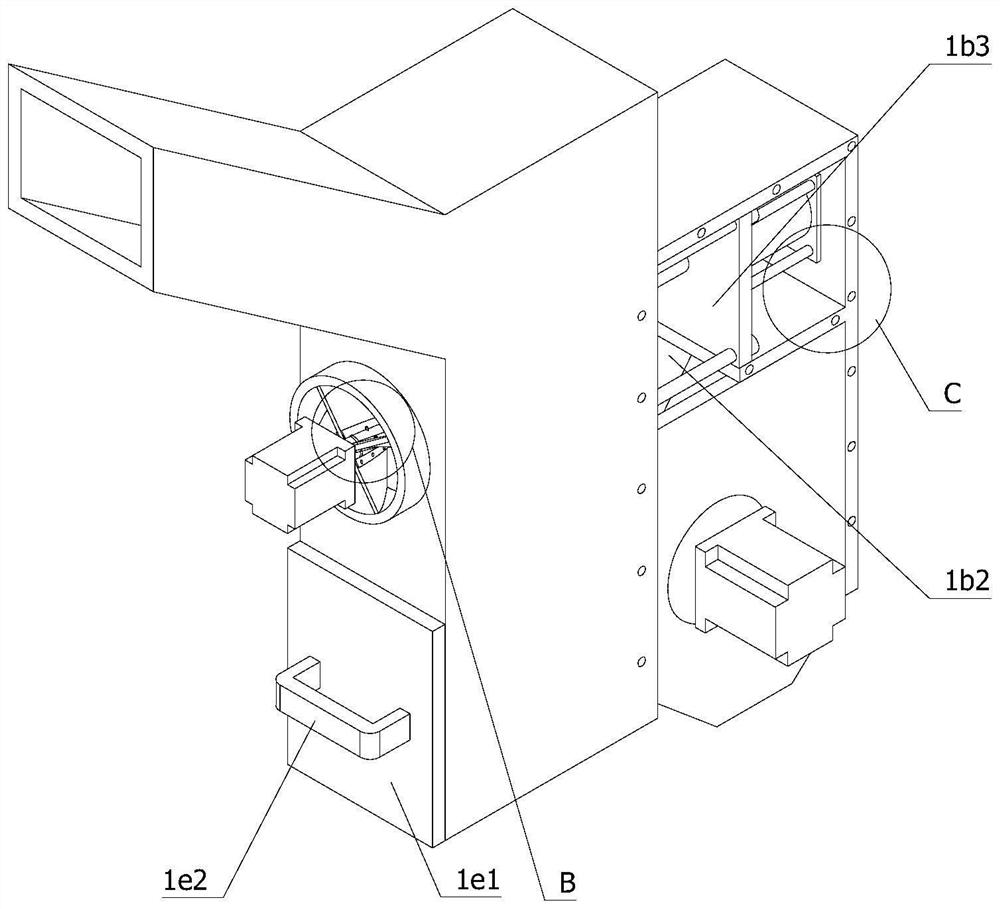

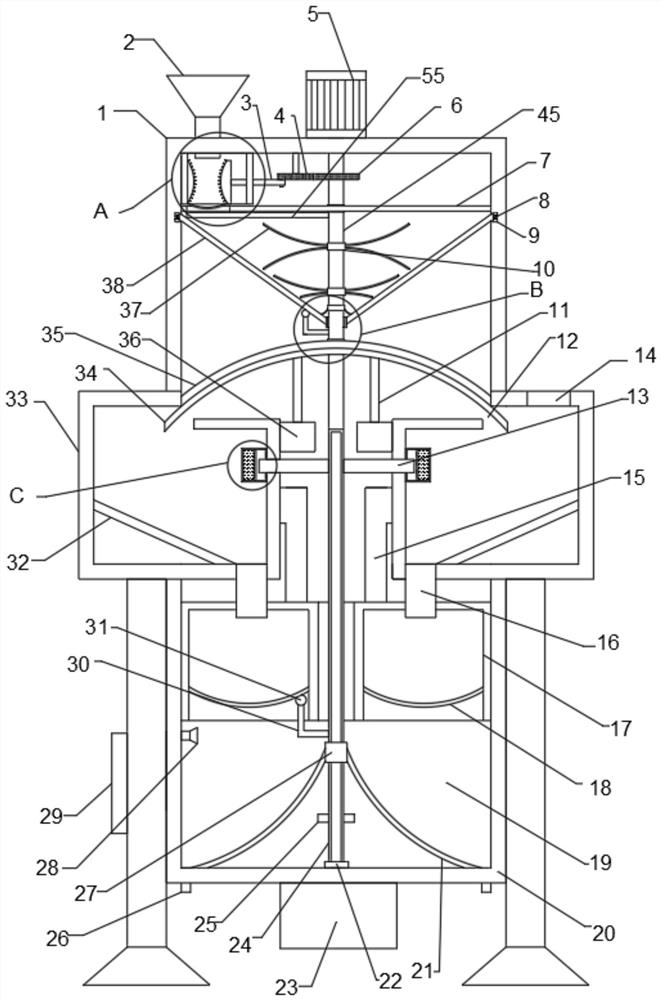

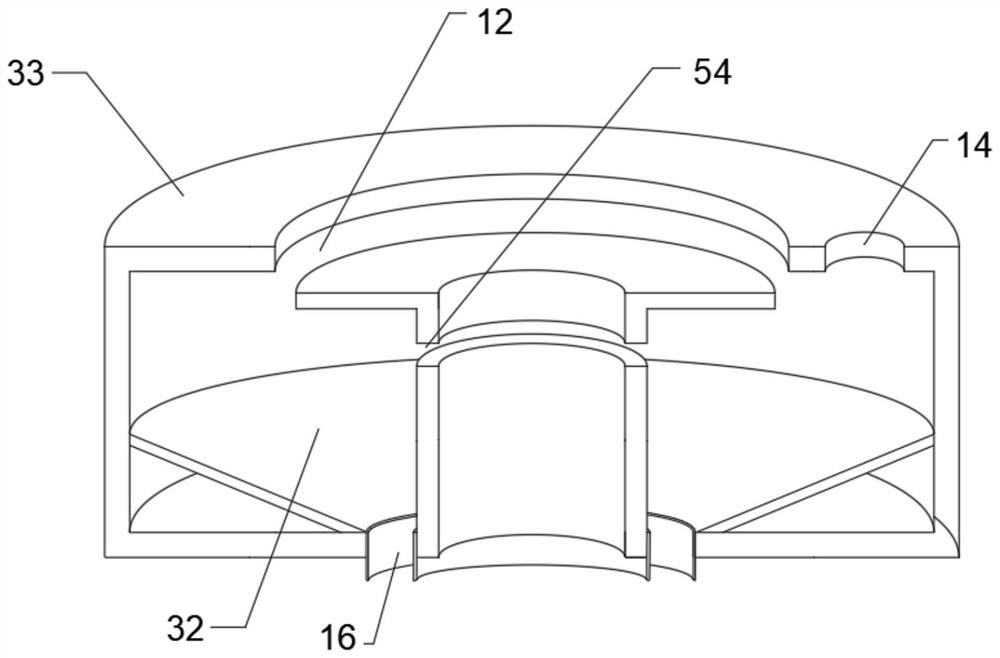

Reducing furnace, and technology for directly reducing coal-containing pellets through preheating outside coal base

InactiveCN103352097AAvoid the fatal flaw of small restoration capacityEvenly heatedFluidised-bed furnacesSteelmakingThermodynamics

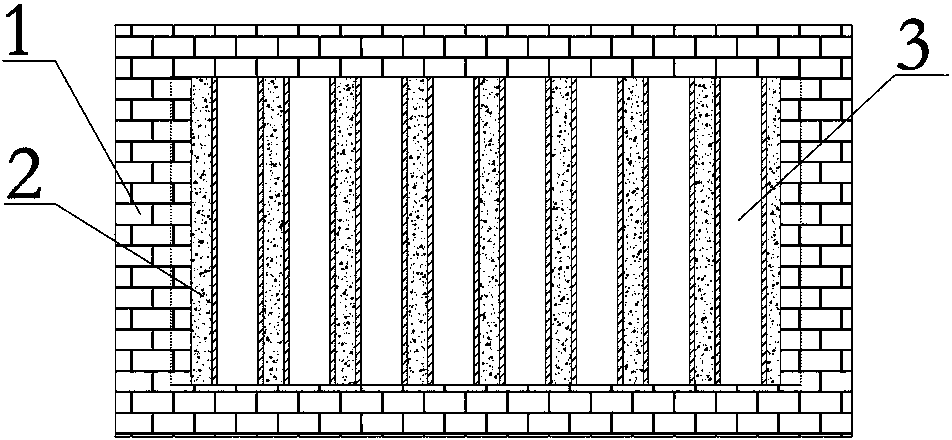

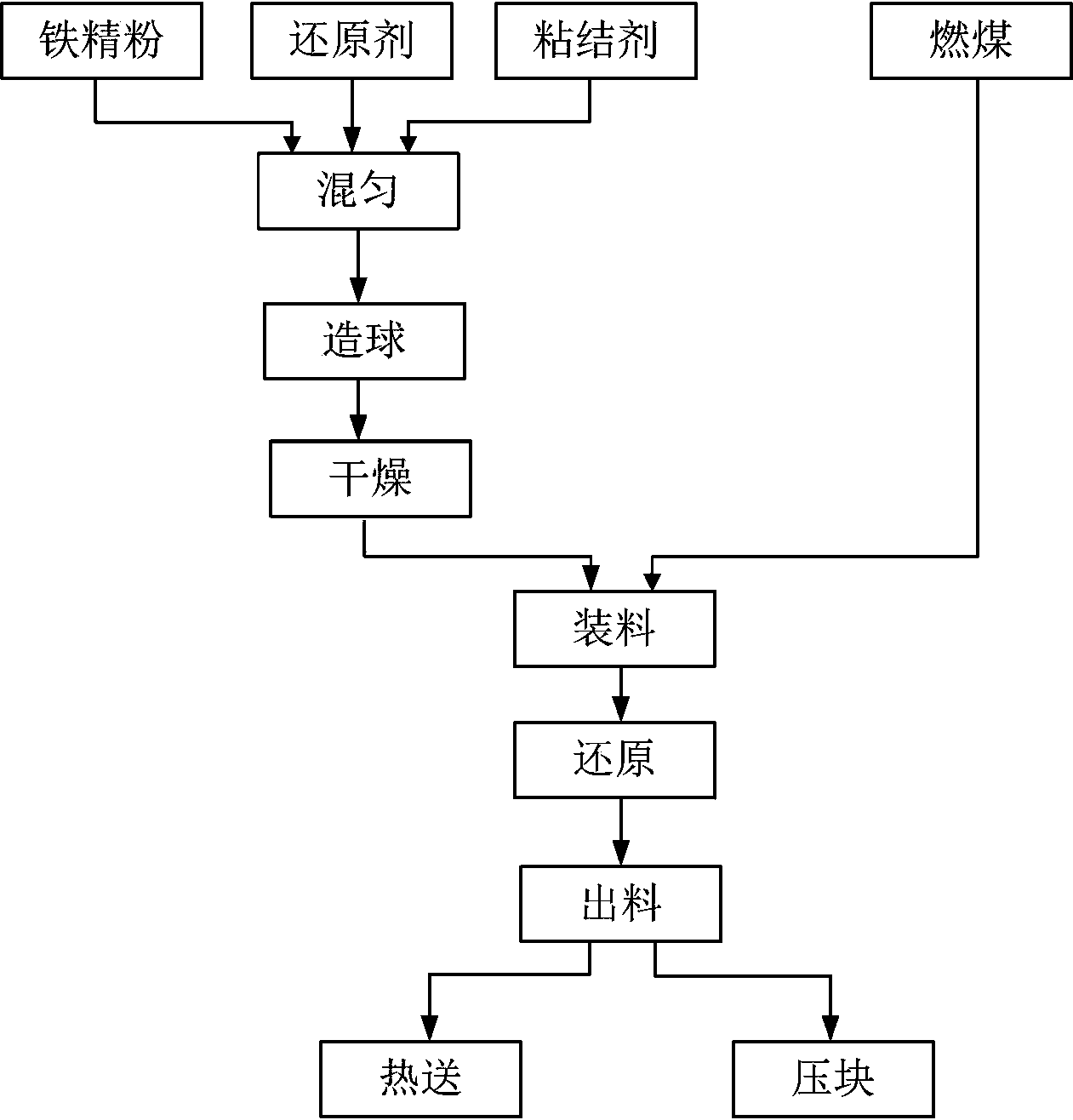

The invention provides a reducing furnace. The reducing furnace comprises a furnace wall, at least one reducing tank and at least one combustion tank, and the at least one reducing tank and the at least one combustion tank are alternately arranged. The top of each reducing tank is connected with a raw material feeding device, and the bottom of each reducing tank is provided with a material outlet. The top of each combustion tank is connected with a fuel feeding device, and the bottom of each combustion tank is provided with an ash outlet. The invention also provides a technology for directly heating coal-containing pellets through preheating outside a coal base. The technology comprises the following steps: 1, mixing and pelletizing an iron-containing raw material, coal dust and a binder to obtain coal pellets; and 2, providing the reducing furnace, adding the pellets to the reducing tank(s) through the raw material feeding device(s), adding fire coal to the combustion tank(s) through the fuel feeding device(s), allowing the pellets and the fire coal to independently move from top to bottom, heating and reducing the pellets to form spongy iron, and discharging the spongy iron. The reducing furnace and the reducing technology have the advantages of high shaft furnace productivity, adoption of non-coking coal as a reducing agent in coal base reduction, adoption of cheap coal as a heat source, and production of the direct reduction iron for steel making.

Owner:WISDRI ENG & RES INC LTD

High-efficiency energy-saving environment-friendly coal

The invention relates to a high-efficiency energy-saving environment-friendly coal, belonging to the energy source field; the coal is formed by the following raw materials by weight part: 92-97 percent of ground masses and 3-8 percent of sulphur-fixed smoke suppressors, the raw materials are uniformly mixed and crushed to be particles with less than 3mm, the 1-5 per thousand of sulphur-fixed smoke suppressors, which do not contain water weight parts is added when the particles are stirred, the mixture is casted and molded, dried naturally and encapsulated; according to the coal requirements, the ratio is adjusted, so as to lead the coal to be used as civil honeycomb briquette, coal balls for catering industry and boilers, more than 20 percent of coal is saved, and the sulphur fixation efficiency is 75-85 percent, thereby having good economic, social and environmental benefits and having high promotion value.

Owner:范泽文 +1

High-strength and high-water permeability ceramic water permeable brick and preparation method thereof

InactiveCN108341686AGood water permeabilityHigh strengthCeramic materials productionCeramicwareFiberBrick

The invention discloses a high-strength and high-water permeability ceramic water permeable brick and a preparation method thereof. The high-strength and high-water permeability ceramic water permeable brick comprises the following raw materials in part by weight: 60-80 parts of porous coarse aggregates, 30-40 parts of ceramsite, 20-30 parts of cement, 10-30 parts of calcined metakaolin powder, 10-20 parts of fly ash, 5-15 parts of coal gangue, 3-8 parts of coal ball micro-powder, 2-8 parts of fibers, 1-5 parts of a pore-forming agent, 0.3-0.8 part of a water reducer and 0.1-0.5 part of sintering aid. The water permeable brick disclosed by the invention is excellent in water permeability, high in strength, good in wear resistance, and convenient and quick to construct, also has the functions of water storage, dehumidification and humidification and is used on a pavement to relieve the pressure caused by too much rain to the urban pavement and reduce the urban surface temperature.

Owner:合肥慧林建材有限公司

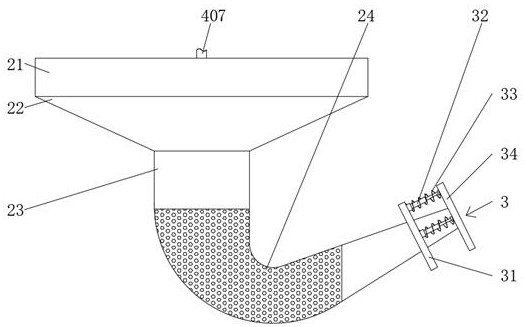

A coal-fired marine power boiler

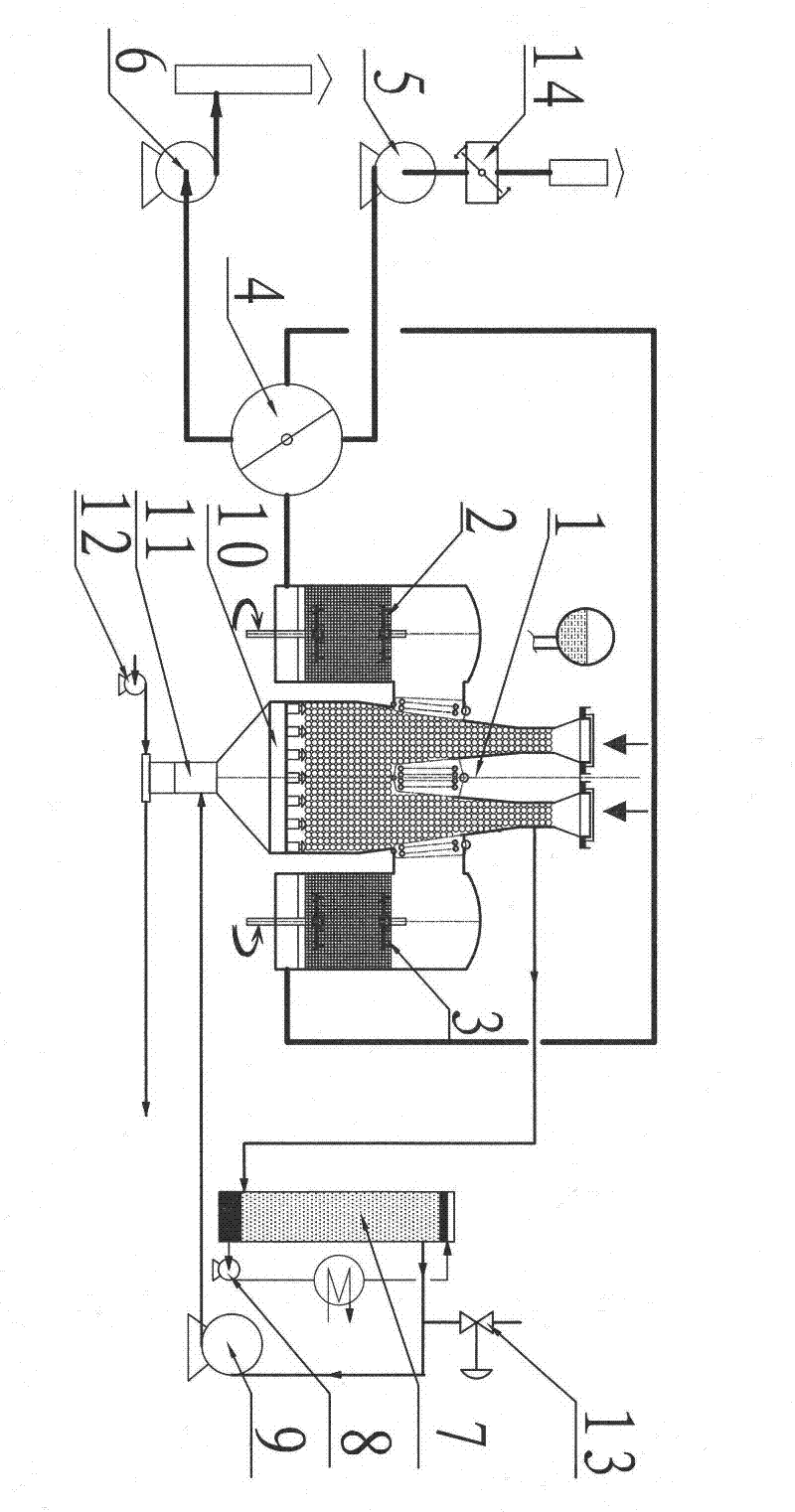

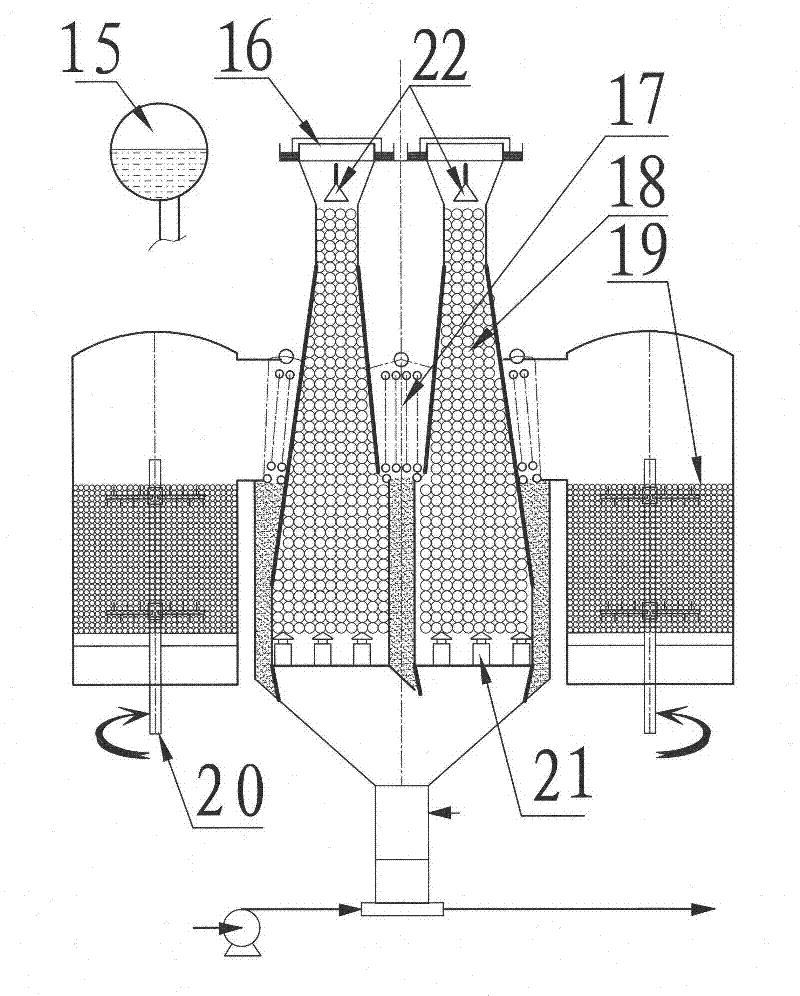

It is an innovative technology that adopts high-temperature air combustion technology to burn or gasify solid fuels such as coal and biomass. The boiler created by this technology is called regenerative moving bed, which includes two types of coal pellet moving bed and ceramic ball regenerative bed. Among the furnace types available for coal-fired ships, the heat-storage moving bed boiler may have the highest thermal efficiency of the unit, that is, it is the most suitable power boiler for coal-fired ships. The operation mode of the boiler is divided into combustion and cold slag carbonization time periods in time, and these two processes are operated alternately. During the combustion period, the four-way reversing valve 4 periodically switches the flow direction of exhaust gas and air, and the two heat storage beds 2 and 3 alternately store or release heat. The heat storage is to store the waste heat of high-temperature exhaust gas. The heat release is to use this waste heat to heat the incoming cold air to obtain high-temperature air above 600°C, so as to obtain a higher combustion temperature and a high radiation heat transfer rate. This is the core feature of the regenerative moving bed boiler. This feature This makes heat storage moving bed boilers more suitable for ships than other types of boilers.

Owner:梁兆志

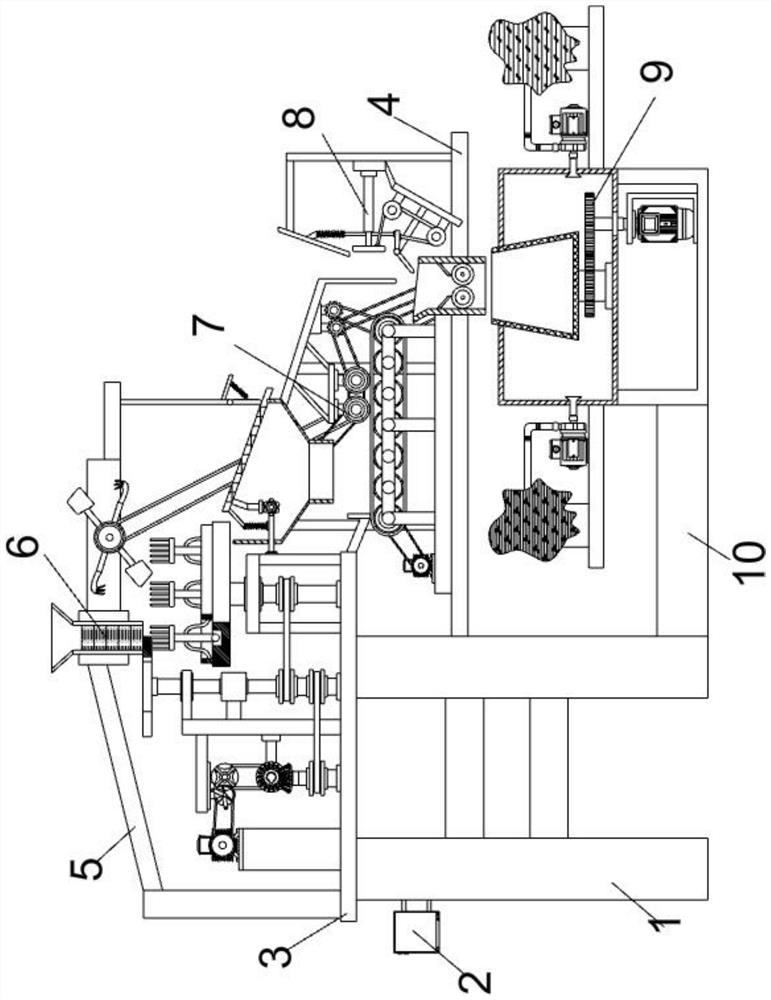

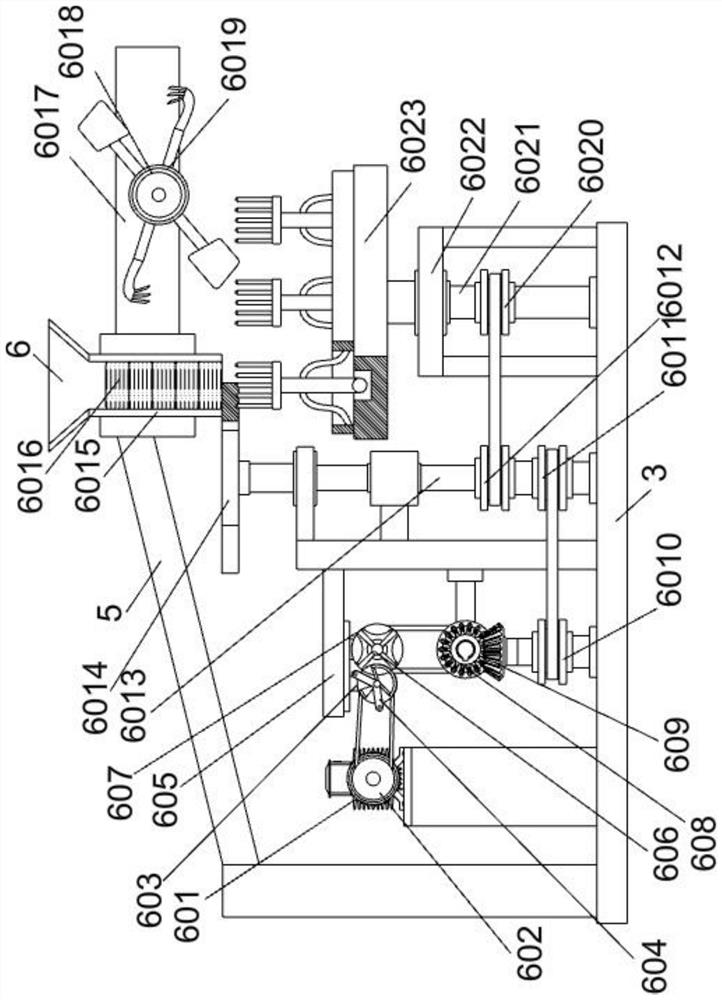

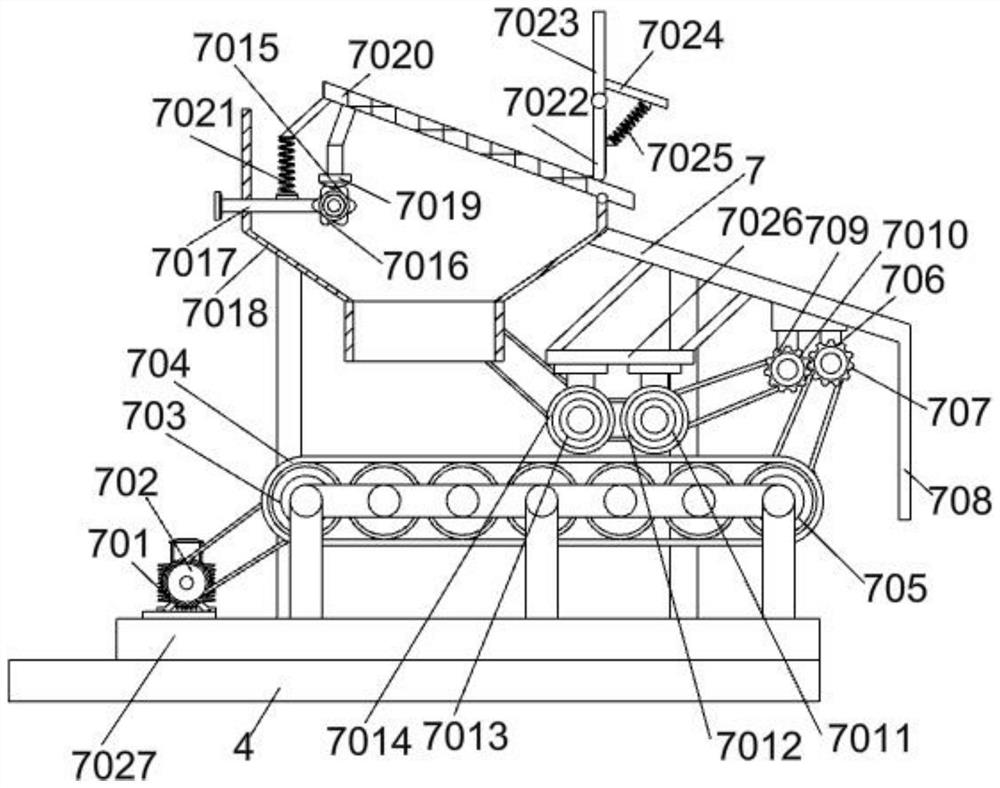

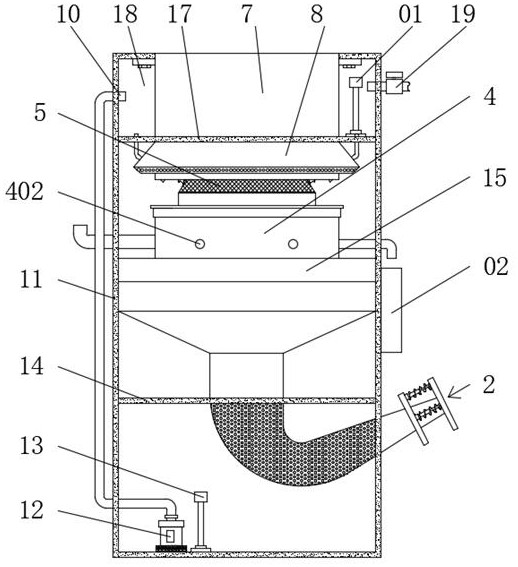

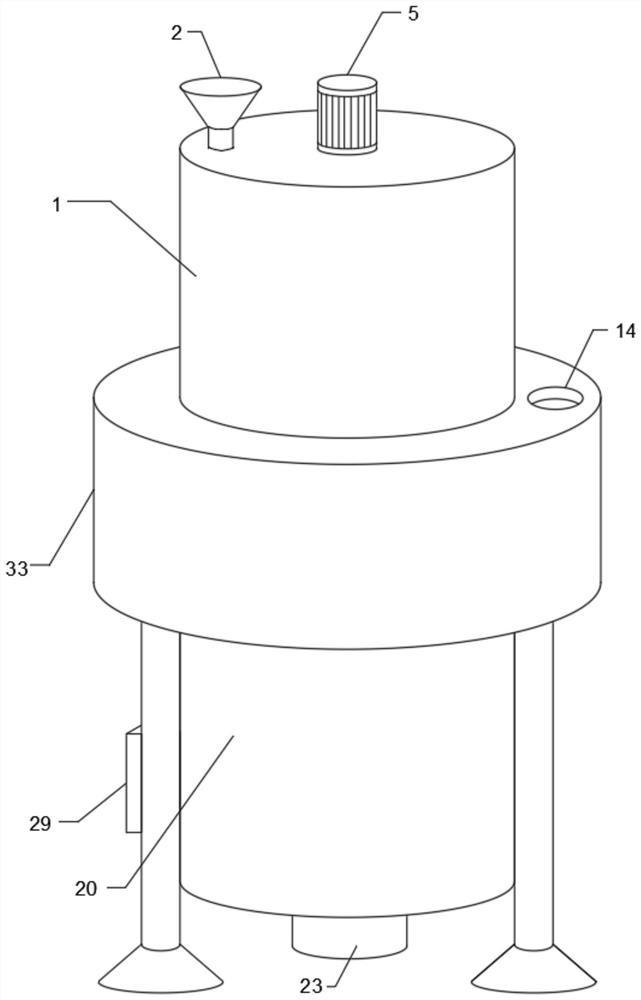

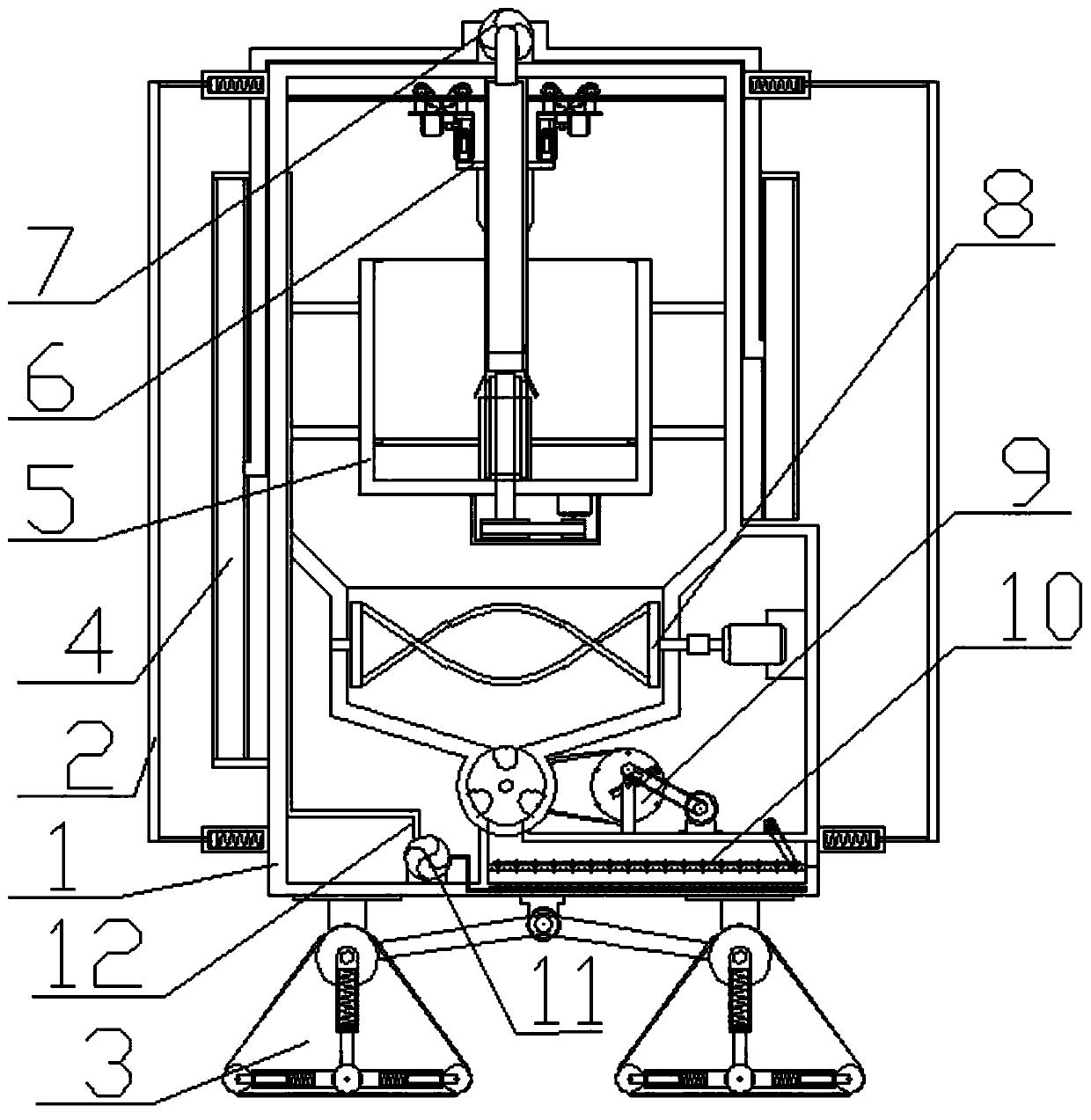

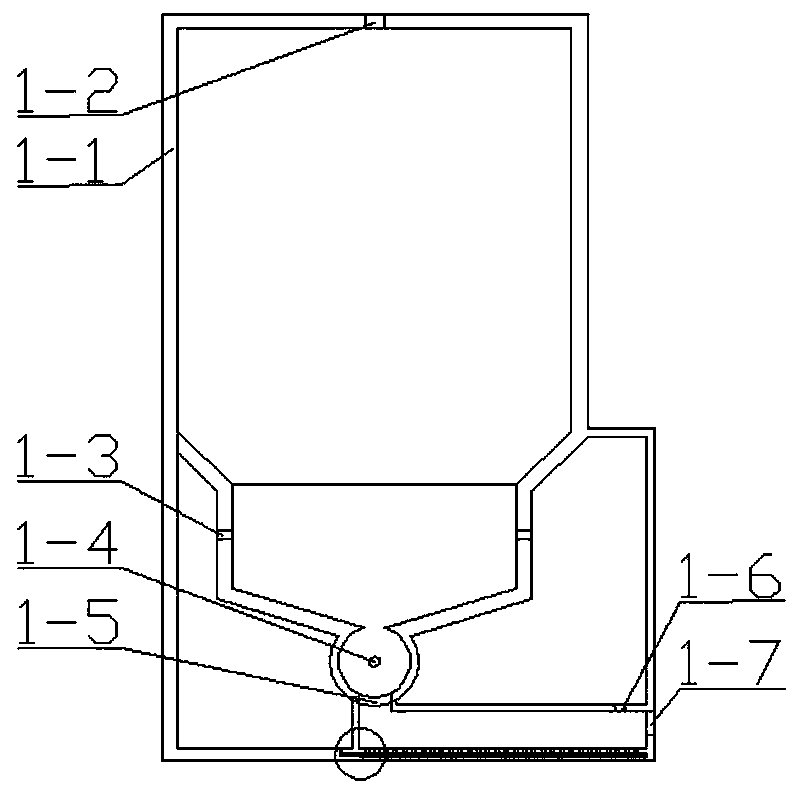

Fly ash extraction device

The invention relates to fly ash, in particular to a fly ash extraction device. The technical problem is to provide the fly ash extraction device. According to the technical scheme, the fly ash extraction device comprises a breaking separation treatment mechanism, a peripheral block grinding mechanism and the like; the other sides of machine tool supporting bottom feet are sequentially welded witha second machine tool plate and a machine tool connecting bottom plate; and a first machine tool plate is welded to the upper parts of the machine tool supporting bottom feet. The fly ash extractiondevice realizes the affects that burnt-out honeycomb coal balls are broken up and crushed one by one, peripheral parts and inner layer parts of the burnt-out honeycomb coal balls are separated to be ground and crushed respectively to obtain powder with the same particle size, and fly ash is separated from a mixture through rotation of a screen, so that the light fly ash with the small particle size floats out to be separated from the mixture, and floats to air for simultaneous collecting of gas and the fly ash, and the pure fly ash is obtained.

Owner:包头冀东水泥有限公司

Preparation method of laser pulse perforation assisted diffusion high-coercivity neodymium iron boron

ActiveCN112382500AImprove coercive forceLarge specific surface areaInductances/transformers/magnets manufactureMagnetic materialsRare-earth elementAlloy

The invention discloses a preparation method of laser pulse perforation assisted diffusion high-coercivity neodymium iron boron, which comprises the following steps: smelting Dy and other heavy rare earth metals and Al and other low-melting-point metals according to an atomic ratio to form a mother alloy, carrying out high-energy ball milling on the mother alloy to form nano-scale to micron-scalepowder, and mixing the powder with an organic solvent to form a diffusion source mixed solution; perforating the surface of the neodymium-iron-boron magnet by using femtosecond to nano laser pulses toform a coal ball-shaped magnet; immersing the coal ball-shaped magnet into the diffusion source mixed solution, taking out the magnet, and presintering at low temperature under the protection of nitrogen to obtain a magnet with a diffusion source coating inside and on the surface of the magnet; and finally, carrying out heat treatment on the magnet under argon protection and a strong magnetic field to obtain the neodymium-iron-boron magnet with high coercive force. According to the method, the specific surface area of the coating layer and the magnet is increased, the heavy rare earth elements are subjected to three-dimensional diffusion in the magnet, the distribution uniformity of the heavy rare earth elements in the magnet is effectively improved, the coercive force of the neodymium-iron-boron permanent magnet is improved, and the method is simple in process, easy to operate and suitable for batch production.

Owner:CHINA JILIANG UNIV

Environment-friendly pulverized coal collecting equipment for coal mine construction site

ActiveCN112316611AImprove permeabilityCoagulation stabilityDispersed particle filtrationTransportation and packagingMining engineeringProcess engineering

The invention discloses environment-friendly pulverized coal collecting equipment for a coal mine construction site, which comprises an isolation device, and a compression device is arranged in the isolation device; a filtering device is driven by a driving device to rotate quickly, so that pulverized coal on the filtering device can do centrifugal motion under the action of centrifugal force, thepulverized coal in centrifugal motion can impact the inner wall of a blower device, the pulverized coal is prevented from staying on the filtering device for a long time and being accumulated, and the filtering device keeps good permeability; shut-down for cleaning is not required, time and effort can be saved, the cleaning device is driven by the filtering device to quickly rotate, so that the cleaning device can scrape off pulverized coal adhered to the inner wall of the air blowing device, the scraped pulverized coal falls on the surface of the filtering device again, and the pulverized coal is repeatedly beaten to be compacted into large-particle coal balls; and it is ensured that discharged pulverized coal cannot form flying dust pollution again, and the practicability of the environment-friendly pulverized coal collecting equipment for the coal mine construction site is improved.

Owner:ZAOZHUANG BAI LUN IND CO LTD

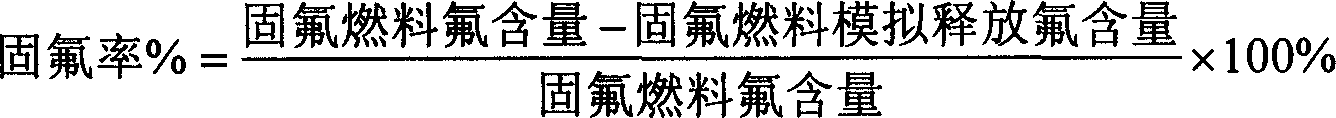

Fluorine capturing shaped coal fuel for stone coal and its production method

InactiveCN1546618AHigh sulfur removal rateImprove dust removal rateFuel additivesCoal dustAir pollution

The invention discloses a fluorine capturing shaped coal fuel for stone coal and its production method, wherein the fluorine capturing fuel comprises stone coal dust, anthracite duff, fluorine capturing addition agent and clay, wherein the fluorine capturing additive is burned dolomitite or burned limestone or lime, the preparation process includes mixing the cured fluorine capturing additive with anthracite duff, clay and stone coal dust based on proportion and grain diameter range, charging right amount of water, stirring homogeneously artificially or by machine. The invention realizes high fluorine capturing rate, sulfur capturing rate and dust depositing rate.

Owner:INST OF GEOGRAPHICAL SCI & NATURAL RESOURCE RES CAS

Bio-fuel coal briquettes

InactiveCN103805303AReduce the impactSimple processing technologyBiofuelsSolid fuelsCoal briquetteBiofuel

The invention relates to the treatment and utilization of wastes and particularly relates to bio-fuel coal briquettes. Firstly plastic bags are sent into a crusher and crushed into pieces, then sent into a melting device and molten into plastic liquid, firstly straw plants and wood wastes are crushed by using the crusher, and then sent into a dryer to be dried, then fly ash, gravel and dried granular straw plants and wood wastes are evenly mixed and stirred with the plastic liquid to form a coal briquette mixture, and then the coal briquette mixture is sent into a coal briquette forming machine to be extruded and formed. The bio-fuel coal briquettes provided by the invention are low in production cost, and all raw materials are from plastic products, straw crops and the fly ash which are easily abandoned by people in life, so that the influence of the wastes on the environment can be effectively reduced, and the bio-fuel coal briquettes have very good energy-saving and environment-protecting effects.

Owner:王立才

Preparation method of high-coercivity diffusion samarium-cobalt composite permanent magnet

ActiveCN112382497AGuaranteed MagneticValid entryInductances/transformers/magnets manufactureMagnetic materialsMagnetic phaseAlloy

Owner:CHINA JILIANG UNIV

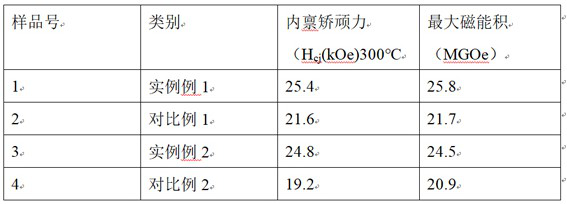

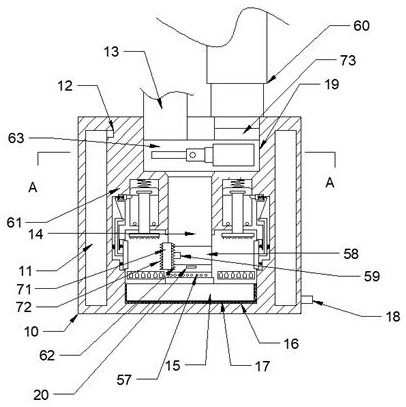

Novel stamping rod structure of coal compression machine

InactiveCN110802867AQuality assuranceGuaranteed processing efficiencyPress ramShaping pressCoal briquetteStamping

The invention relates to the technical field of mechanical equipment and discloses a novel stamping rod structure of a coal compression machine. The structure comprises a machine body, wherein supports are fixedly connected to two sides of the top face of the machine body; a cinder outlet is formed in the middle of the front face of the machine body; a discharge hole is formed in the front face ofthe machine body and is located on the left side of the cinder outlet; and a mold is movably connected to the top face of the machine body and is located above the cinder outlet. The novel stamping rod structure disclosed by the invention has the beneficial effects that through adjustment of the height of a stamping rod and interactions between a screw rod and a screw, a baseplate can be driven by the screw rod to move up and down, and a stamping head is driven by the baseplate to move up and down, so the height is adjusted; problems that the height of a conventional stamping rod cannot be adjusted, acting force of stamping cannot be controlled during stamping and thus coal is crushed due to high stamping force and compression fails, or shaping cannot be realized when the stamping force is too small can be solved; and processing efficiency and quality of coal briquettes are ensured.

Owner:江门健维自动化设备有限公司

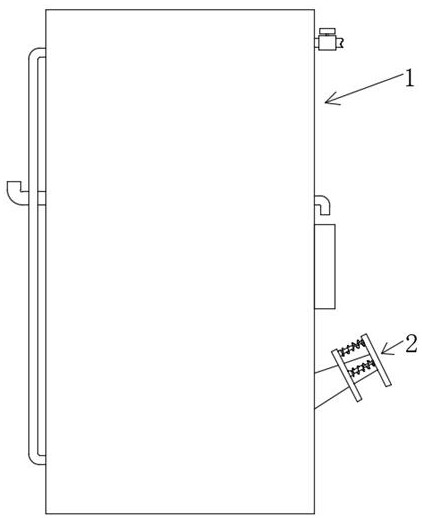

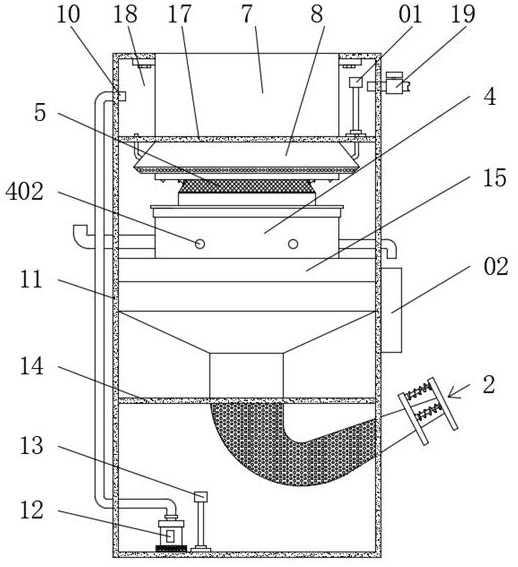

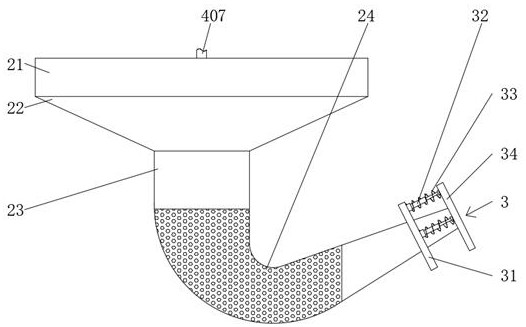

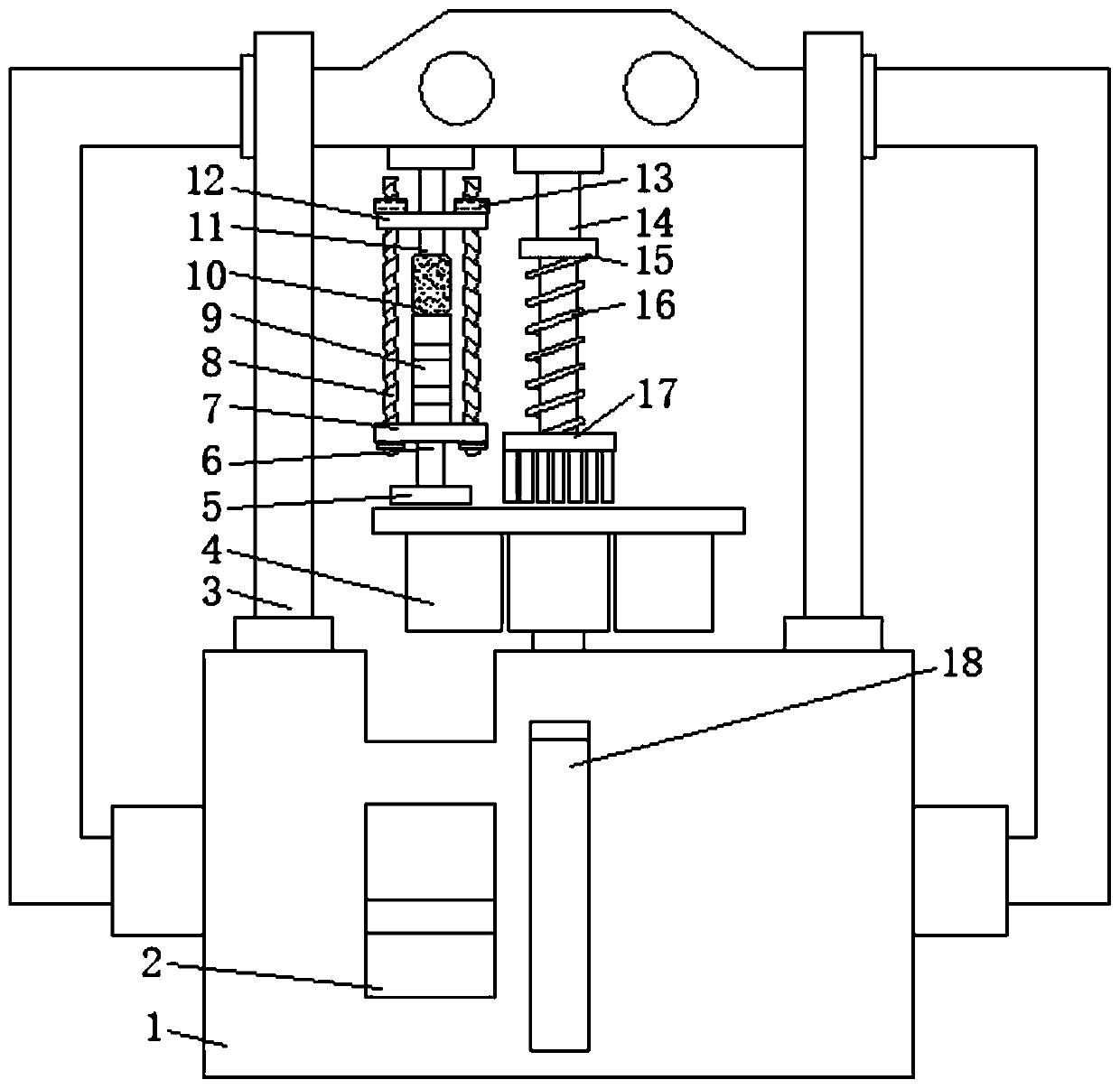

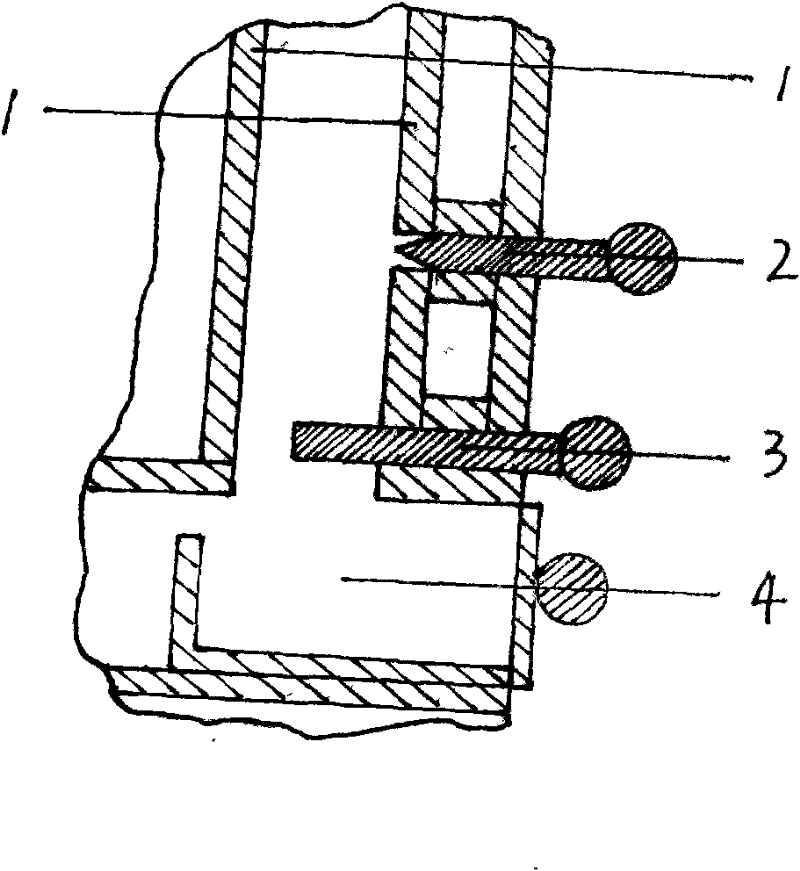

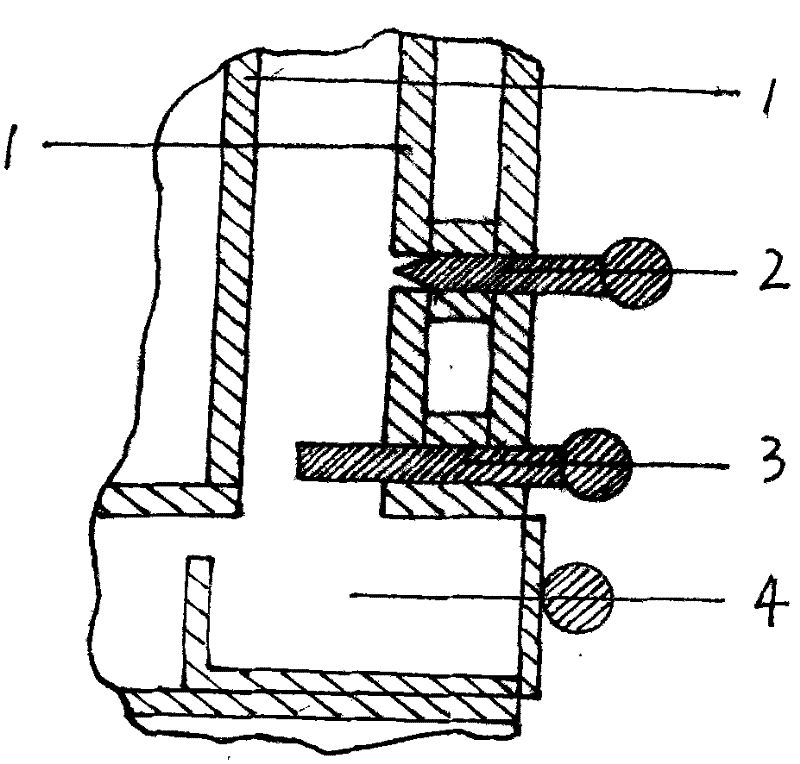

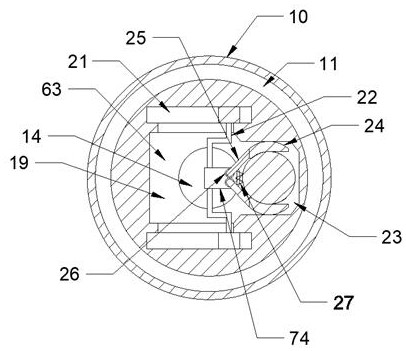

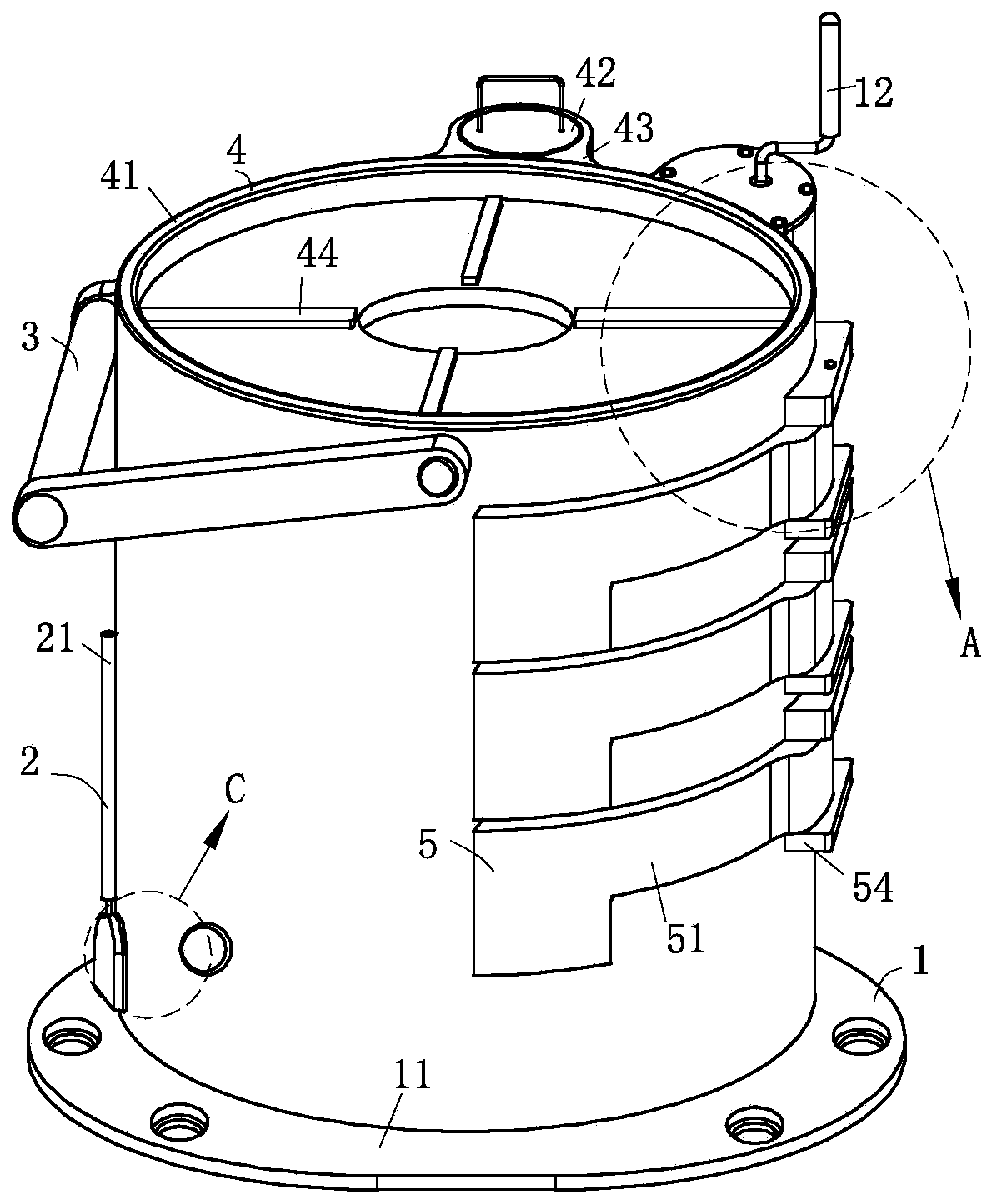

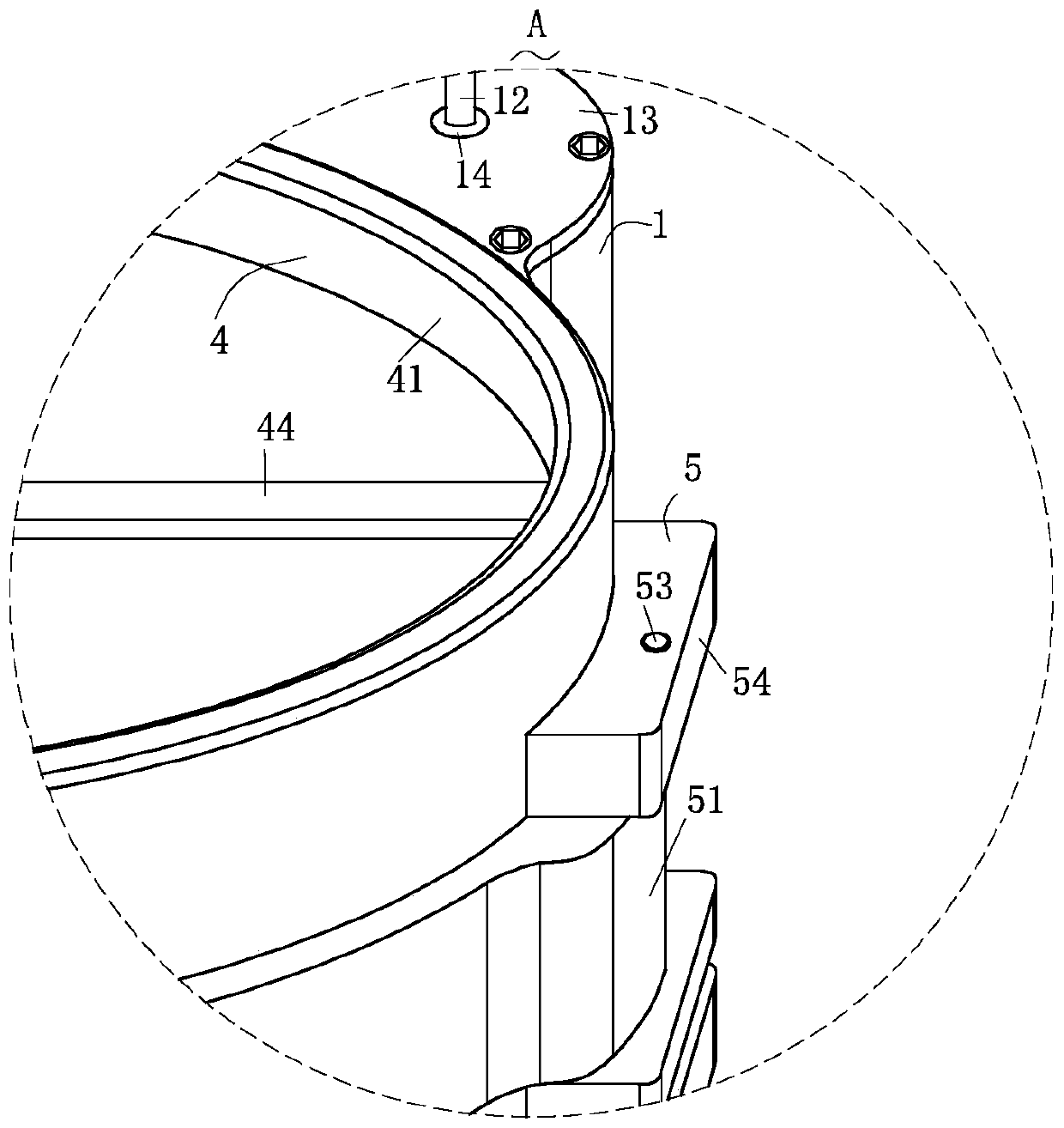

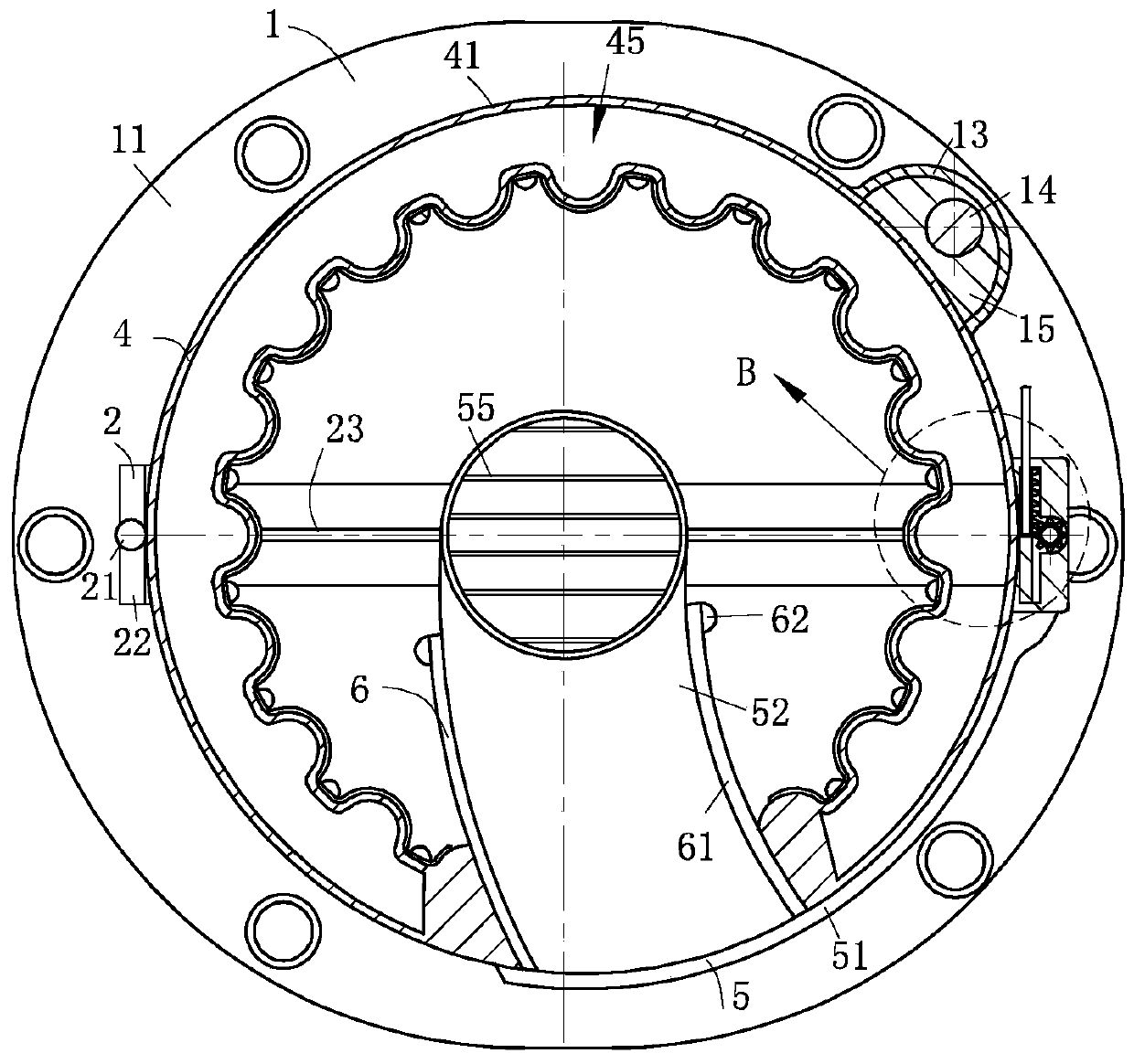

Coal ball replacing device for coal ball stove

InactiveCN102345882ASimple structureEasy to useDomestic stoves or rangesLighting and heating apparatusCoalCoal ball

The invention relates to a coal ball replacing device for a coal ball stove. In the coal ball replacing device, two round holes are formed in the wall of a stove lining; the lateral surface of a stove body is provided with a control separating rod and a discharging rod; the sizes of the two round holes on the wall of the stove lining are equal to those of the control separating rod and the discharging rod; the control separating rod is arranged in the round hole on the upper side of the stove lining; the discharging rod is arranged in the round hole on the lower side of the stove lining; a drawer is arranged below the discharging rod; the control separating rod is used for separating burning coal balls which are connected together and controlling the coal balls on the upper side not to fall; and the discharging rod is used for discharging burnt coal balls into the drawer.

Owner:闫子玲

Coal gangue-based industrial environment-friendly coal

PendingCN113322113AExtensive sourcesLow priceSolid fuelsFuel additivesPolyvinyl alcoholPhysical chemistry

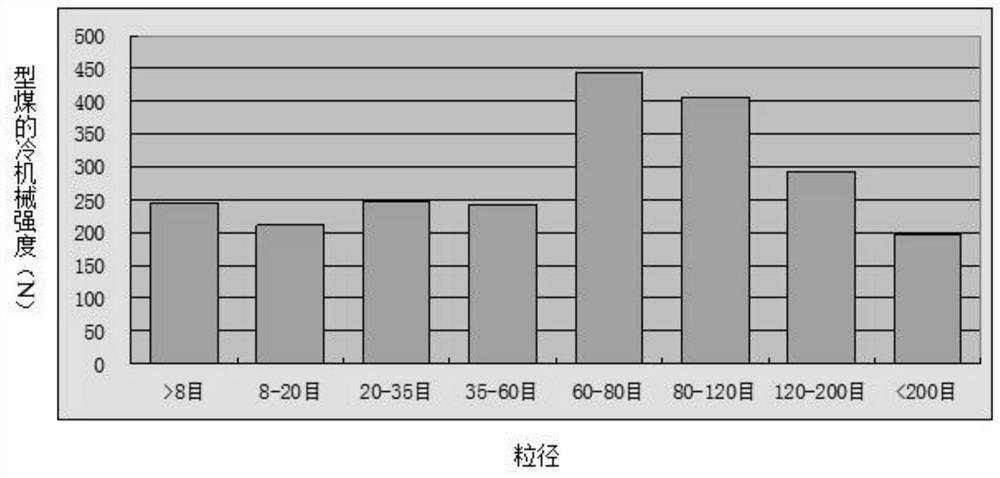

The invention discloses coal gangue-based industrial environment-friendly coal which comprises the following raw materials in percentage by weight: 15-35% of coal gangue, 20-40% of coal slime, 30-50% of raw coal, 2-4% of straw powder, 1-2% of polyvinyl alcohol and 0.5% of ferric oxide. The invention also discloses a preparation method of the coal gangue-based industrial environment-friendly coal, which comprises the following steps: (1) crushing the coal gangue, the coal slime and the raw coal until the particle size is 60-80 meshes, conducting stirring and mixing, then adding the straw powder, the polyvinyl alcohol and the ferric oxide, conducting stirring and mixing, and finally adding hot water for mixing and kneading; and (2) adding the briquette raw material formed by uniform mixing and kneading into a forming machine, then carrying out extrusion forming to obtain elliptical briquettes, and conducting drying to obtain a briquette product. According to the industrial environment-friendly coal prepared by the invention, wastes can be utilized to the greatest extent, the cost of the briquette coal is further reduced, and meanwhile, the prepared briquette coal is high in strength and high in coal saving rate.

Owner:宁夏亘峰嘉能能源科技股份有限公司

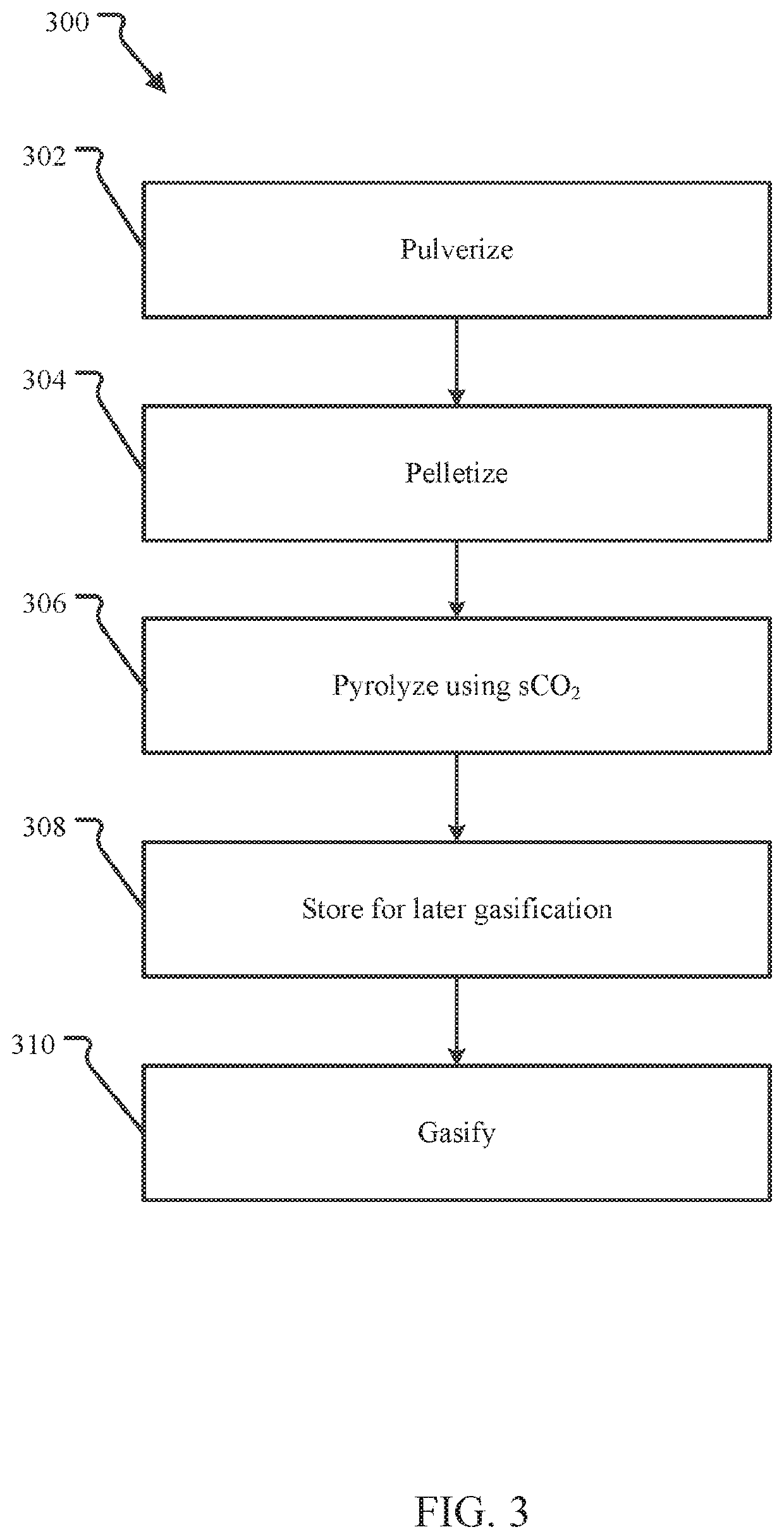

Beneficiation of coal for storage, transportation, and gasification

ActiveUS11421169B2Resistant to crumblingIncrease energy densitySolvent extractionSolid fuelsThermodynamicsCarbonization

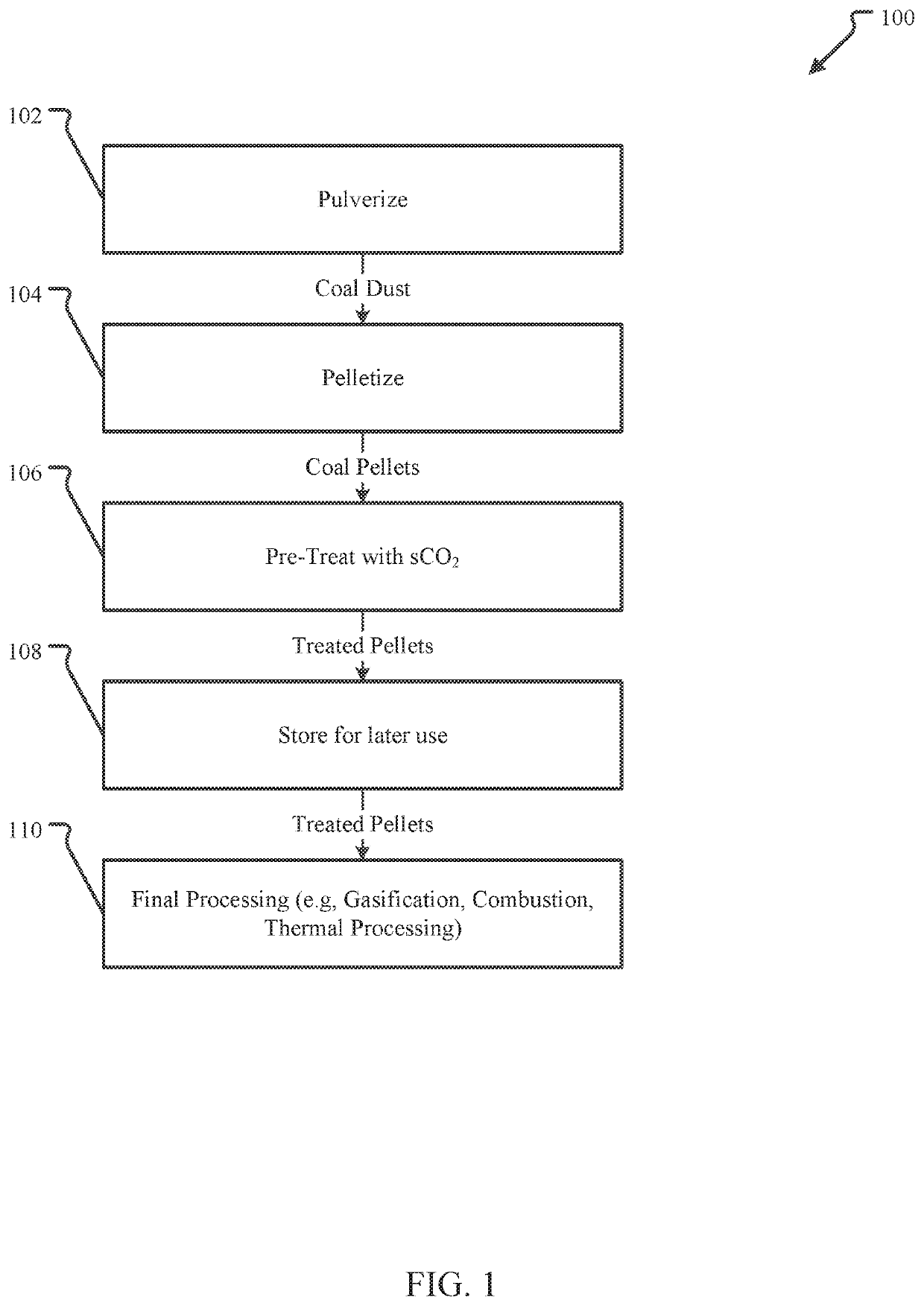

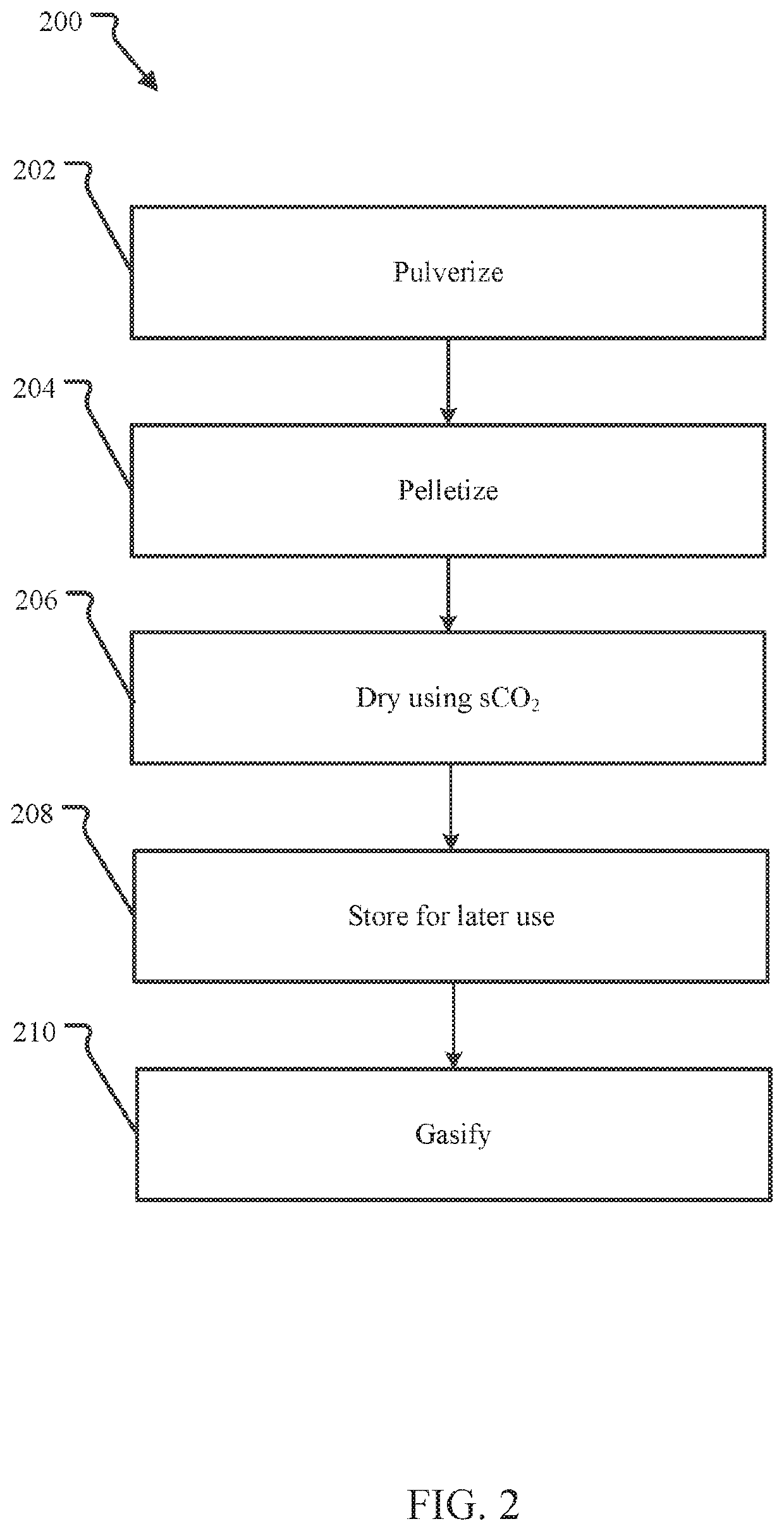

This document describes methods for pretreating coal to create either a dried coal or a char product that is stable in the outdoor environment and is more efficient as a feedstock for gasification or other processes than the original coal. Embodiments of the methods include pulverizing and pelletizing the coal, and pretreating the coal pellets to obtain a stable pellet of either dried coal or a stable pellet of chared coal (coal char). The pellets created by the described methods have undergone deoxygenation and carbonization improving their handling and storage properties and, in some cases, energy density. Pore structures within the pellets are stabilized physically and chemically so that the uptake of moisture into dry coal, that leads to internal heat generation, is greatly reduced. Chars are also, therefore, stable against transitions from a dry state to a wet state and less prone to self-ignition.

Owner:TERRAPOWER

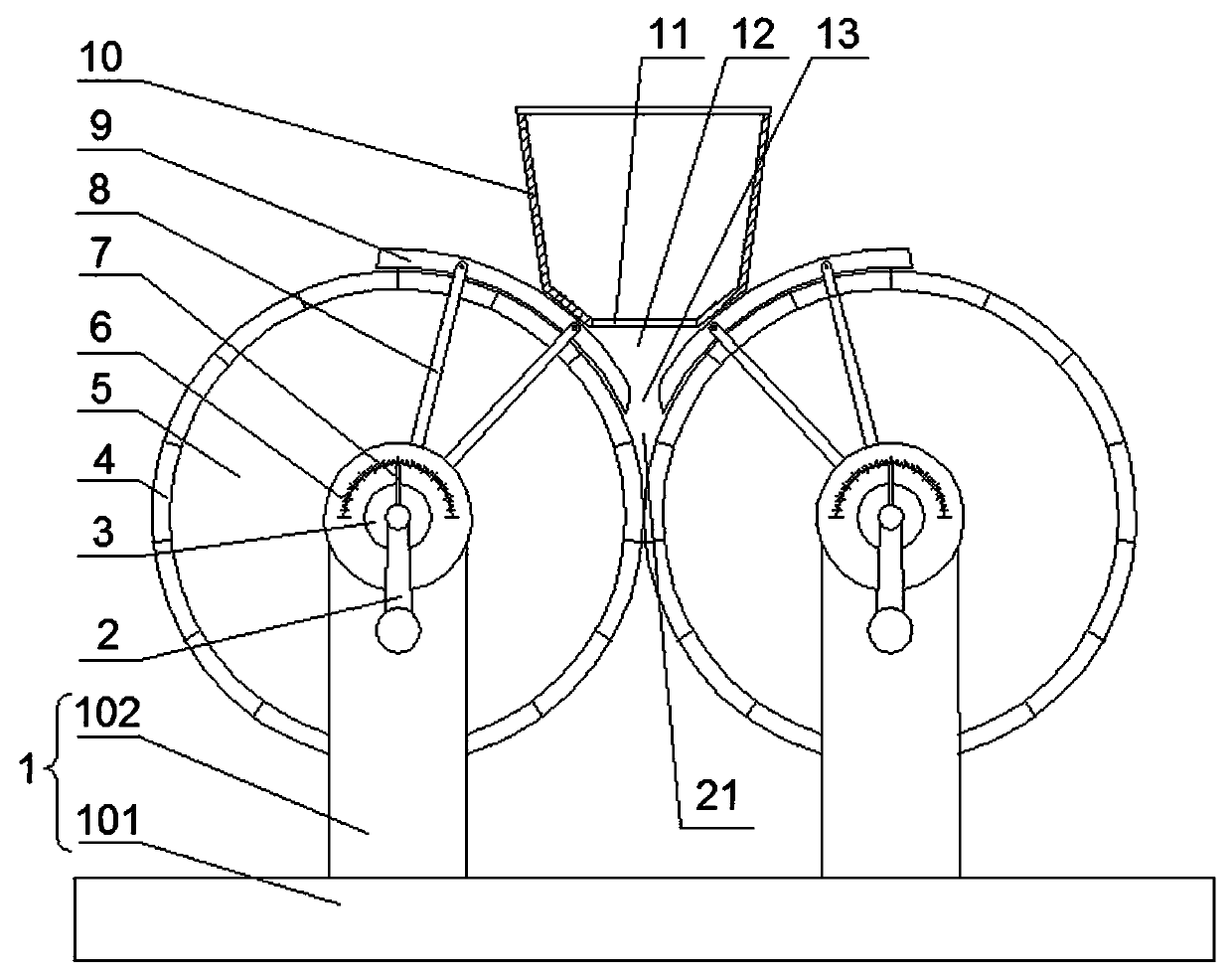

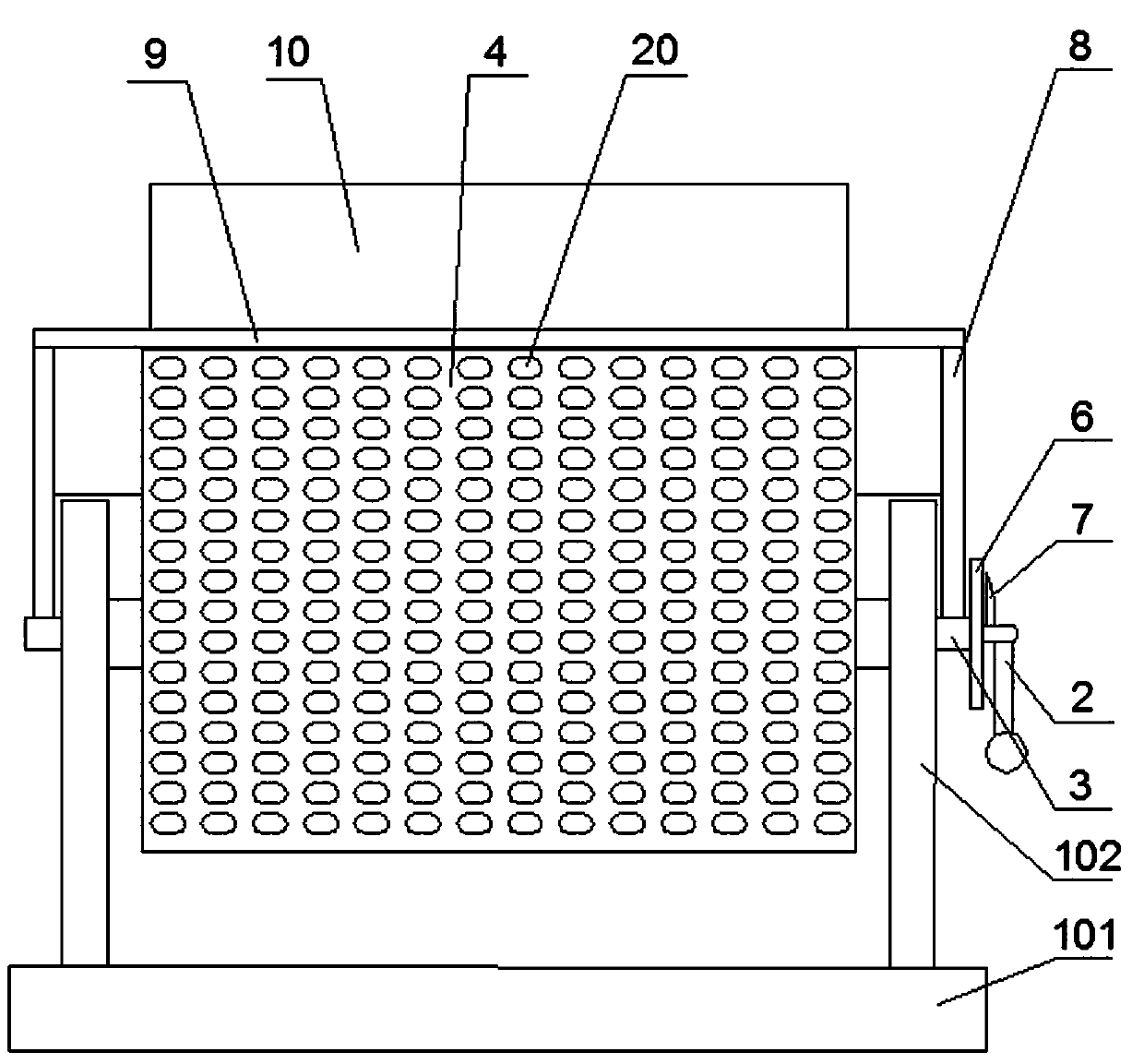

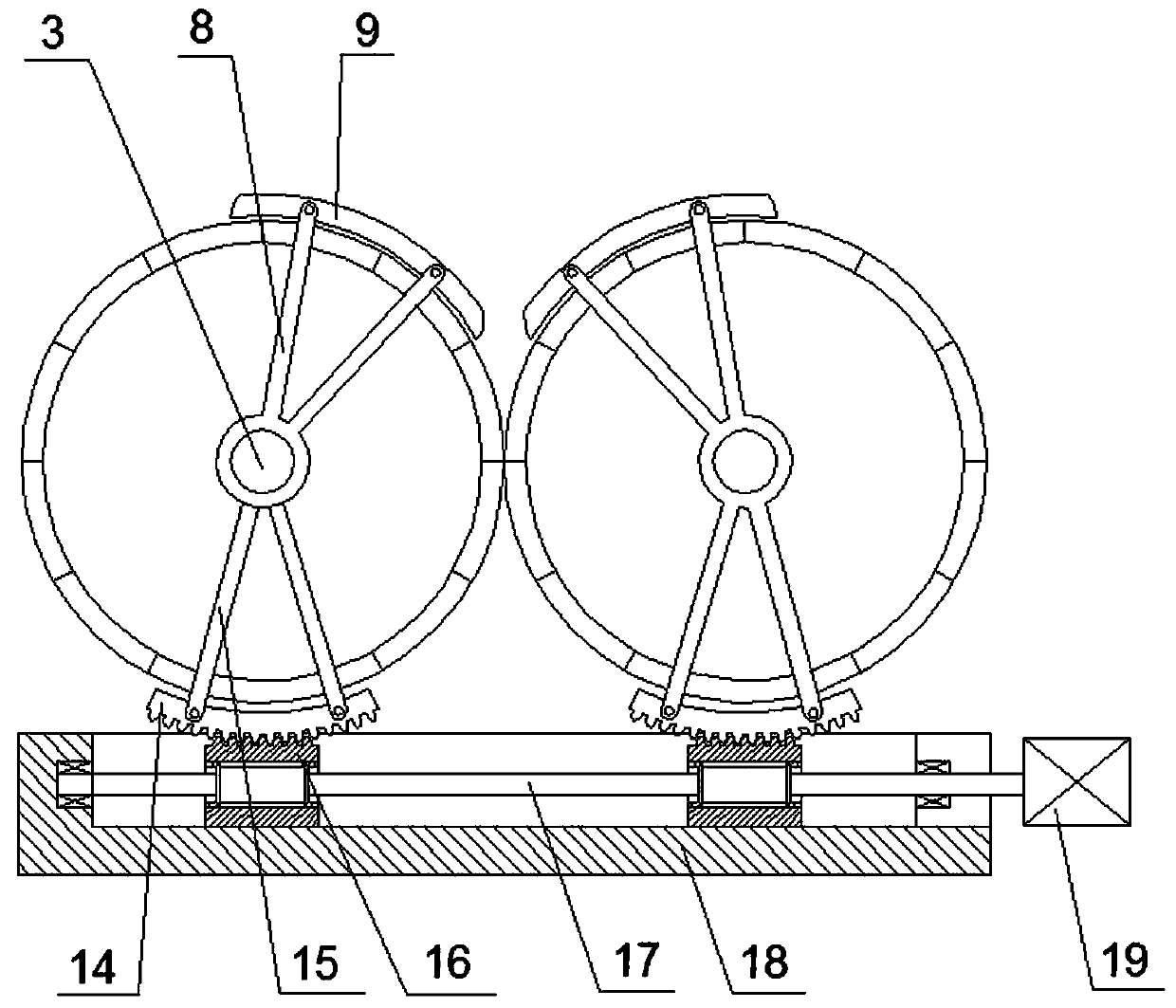

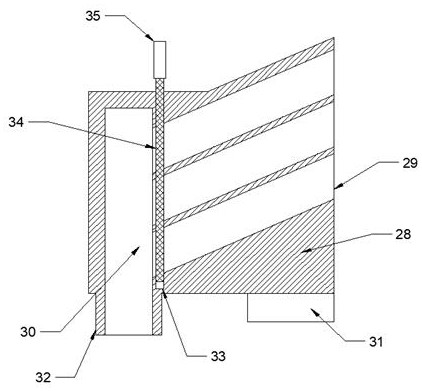

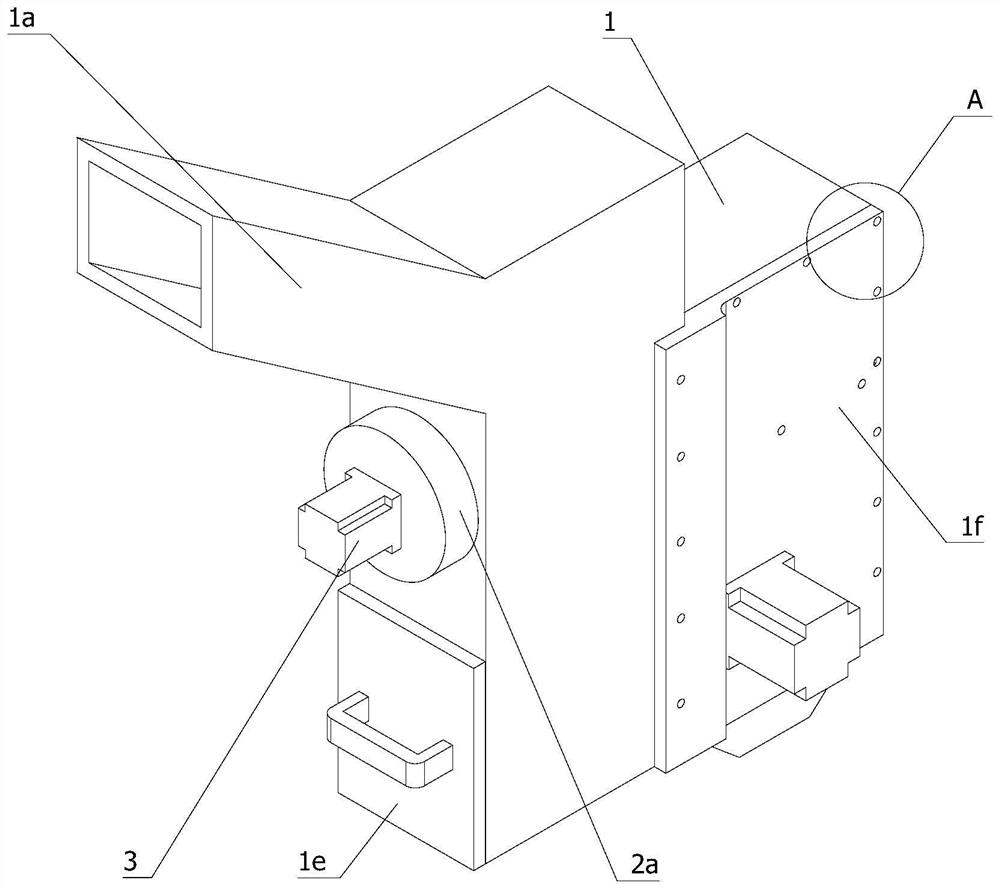

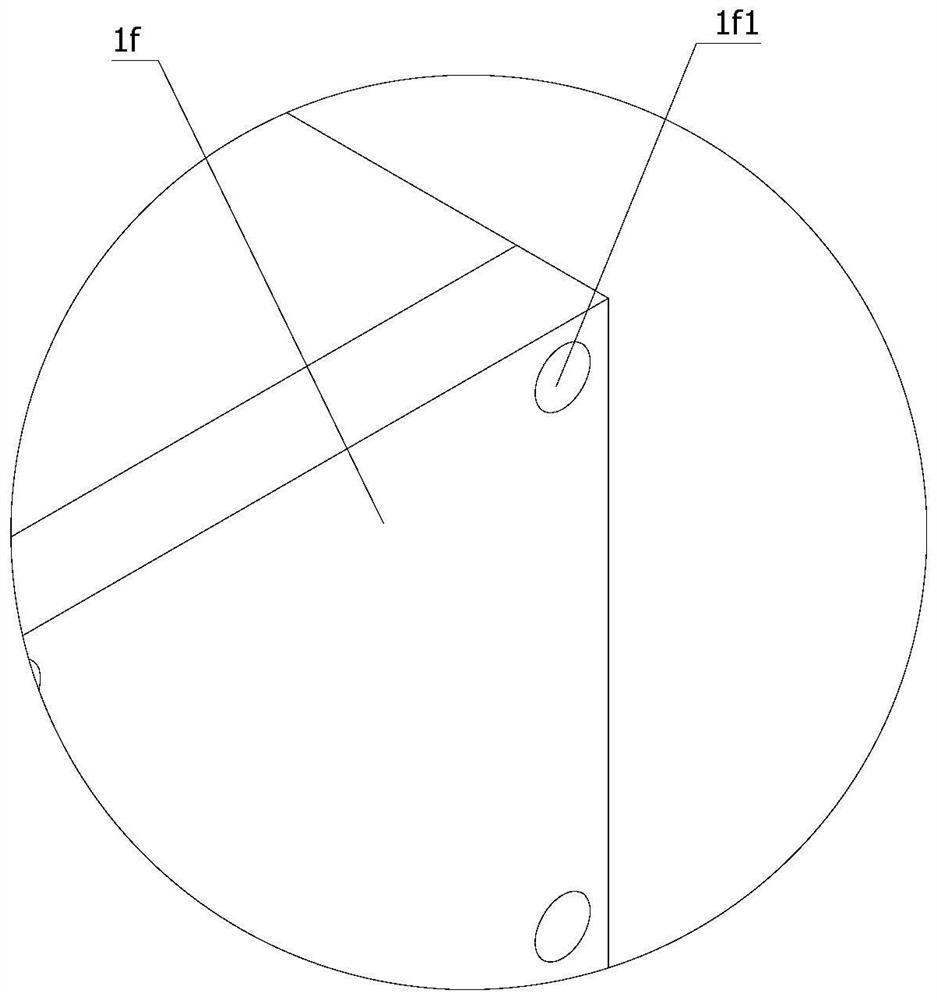

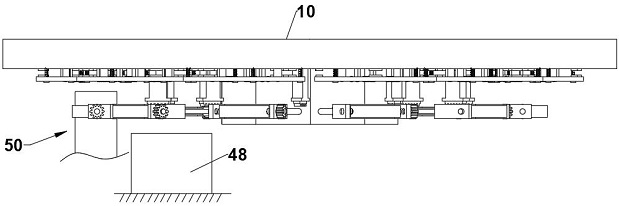

A non-screw self-feeding ball pressing machine

ActiveCN109774226BReasonable compression ratioImprove productivityShaping pressCoal briquetteThermodynamics

The invention relates to the field of coal briquette processing equipment, in particular to a ball press machine featuring non-spiral self discharging. The ball press machine comprises a rack and twoball press rollers arranged on the rack in parallel. A plurality of semispherical forming cavities used for pressing pulverized coal into coal briquettes are formed in roller skins of the two ball press rollers correspondingly. The ball press machine further comprises a self-discharging storage box and two pulverized coal isolation plates which are arranged on the rack from top to bottom in sequence and located above the two ball press rollers. A first-stage discharging port is formed in the bottom of the self-discharging storage box. The two pulverized coal isolation plates cover the upper portions of the two ball press rollers correspondingly. A pulverized coal temporary storage cavity is formed in a space between the two pulverized coal isolation plates and located below the first-stagedischarging port. A second-stage discharging port is formed in a gap between the two pulverized coal isolation plates. The two pulverized coal isolation plates can rotate in the circumferential directions of the corresponding ball press rollers, so that the width of the second-stage discharging port is adjustable. According to the ball press machine featuring non-spiral self discharging, electricenergy consumption can be reduced, the ball press rollers are prevented from being subjected to unnecessary acting force in the coal briquette pressing process, and accordingly, the service life is prolonged.

Owner:HENAN UNIV OF SCI & TECH

Heating equipment capable of automatically replacing coal briquettes

InactiveCN112648641ASave storage spaceImprove crushing effectLighting and heating apparatusStove/ranges for heating waterCoal briquetteCombustion chamber

The invention discloses heating equipment capable of automatically replacing coal briquettes. The heating equipment capable of automatically replacing the coal briquettes comprises a heating body, wherein a collecting sliding cavity is formed in the middle of the heating body; a collecting drawer is arranged in the collecting sliding cavity in a front-back sliding mode; the collecting drawer is provided with a waste collecting cavity with an upward opening; vent holes are formed in the front part and the rear part of the collecting drawer; and a combustion chamber is arranged on the upper side of the collecting sliding cavity in a communicating mode. When using the heating equipment capable of automatically replacing the coal briquettes, by arranging a coal supplementing mechanism and a discharging mechanism, the device can automatically remove burnt coal briquettes and place the coal briquettes to be used in a combustion area; the device can automatically replace the coal briquettes, so that personnel participation is not needed, the device is conveniently used at night, heating equipment can continuously supply heat; and in addition, the device extrudes and crushes the burnt coal briquettes by utilizing heat energy generated by the device, and the coal briquettes are rotationally crushed in the extrusion process, so that the crushing effect is good, and the waste storage space is saved.

Owner:南京优玖如贸易有限公司

An environmentally friendly coal dust collection equipment for coal mine sites

ActiveCN112316611BImprove permeabilityCoagulation stabilityDispersed particle filtrationTransportation and packagingMining engineeringProcess engineering

Owner:ZAOZHUANG BAI LUN IND CO LTD

Low-pollution coal pulverizing system for thermal power generation

ActiveCN114534896AAvoid blockingSolve technical problemsCombined combustion mitigationGrain treatmentsThermodynamicsElectric machine

The invention relates to the field of coal pulverizing for thermal power generation, in particular to a low-pollution coal pulverizing system for thermal power generation, which comprises a rack, a raw coal hopper, a coal feeder and a coal mill, a discharging device is further arranged at the output end of the coal mill and comprises a connecting shell, a rotating shaft, a first motor, air blowing blades and a filter screen. The discharging device is connected with the output end of a coal mill through a first conveying channel on a connecting shell to convey powdery coal powder, the coal powder is conveyed into a second conveying channel through the first conveying channel, at the moment, a first motor drives a rotating shaft and an air blowing blade to rotate, the air blowing blade blows air to blow the powder to a filter screen in front, and then the powder is conveyed into the second conveying channel. Large briquettes are blocked through the first through holes with the fixed diameter in the filter screen, the large briquettes and a small amount of processed pulverized coal are conveyed from the first discharging port, qualified powdery pulverized coal can penetrate through the filter screen to be conveyed through the second discharging port, and the technical problem of how to screen the briquettes which are not powdery is solved.

Owner:山西大唐国际云冈热电有限责任公司

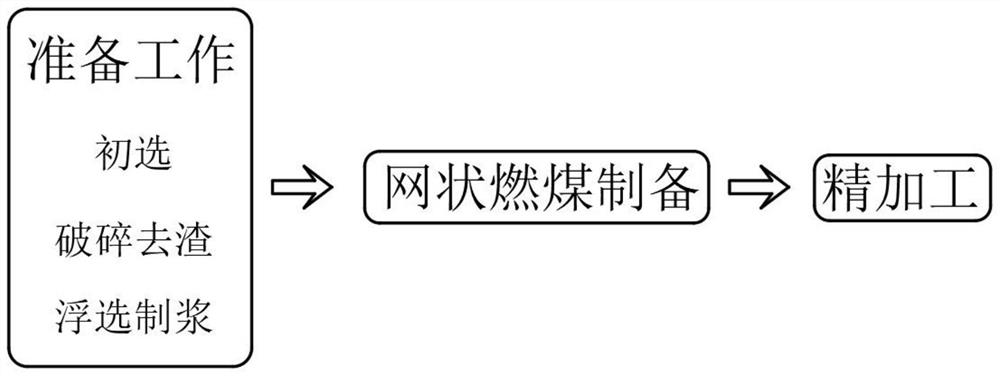

A kind of high-efficiency energy-saving coal-fired manufacturing method with network structure

ActiveCN112500898BBurn fullyImprove combustion efficiencySolid fuelsLump/pulverulent fuel preparationCombustionProcess engineering

Owner:DATANG HUANGDAO POWER GENERATION

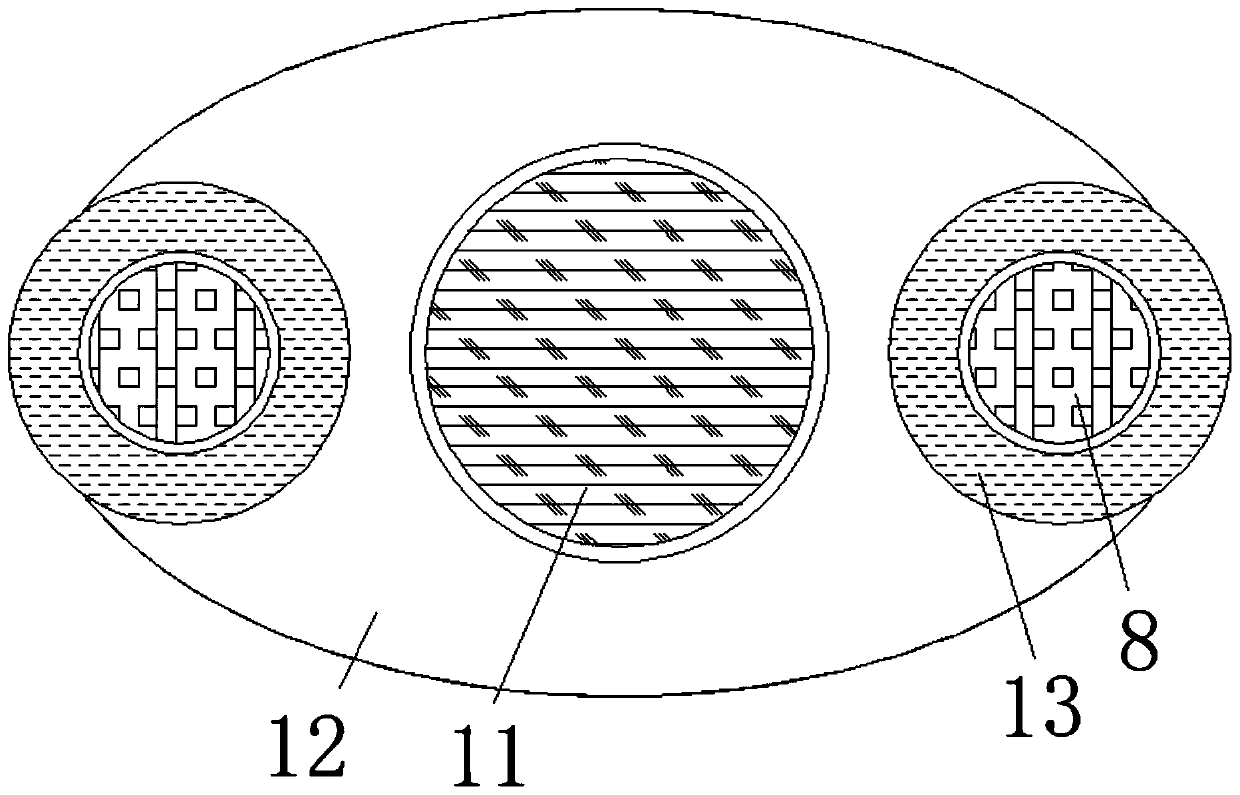

Method for ensuring smooth gas extraction channel of soft coal seam

ActiveCN111255508ASmooth extractionImprove extraction efficiencyGas removalSealing/packingThermodynamicsEngineering

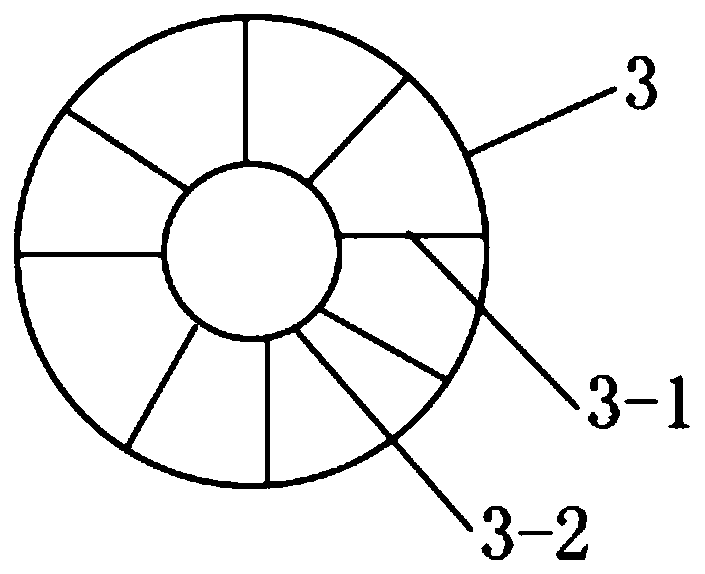

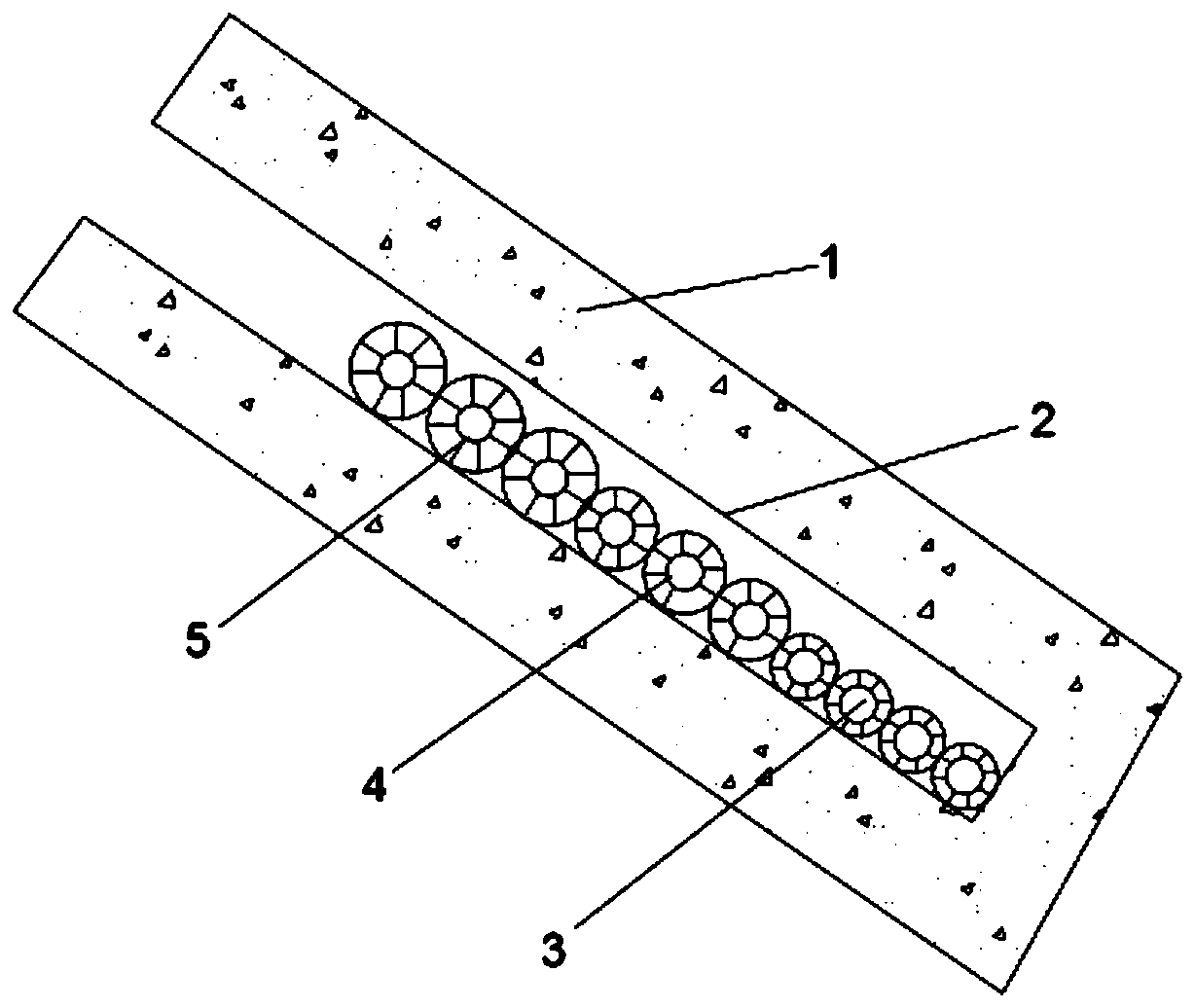

The invention discloses a method for ensuring a smooth gas extraction channel of a soft coal seam. The method is characterized in that a downward drilling hole is sequentially filled with small-numberperforated coal balls, medium-number perforated coal balls and large-number perforated coal balls, wherein the interiors of the perforated coal balls of various models are provided with spherical hollow structures and communicate with the outside through vent holes, and after the drilling hole is filled with the perforated coal balls of various models, a certain supporting effect can be achievedon the downward drilling hole, and the possibility of collapse and deformation of the downward drilling hole is reduced; in addition, due to the fact that the coal balls are spherical, gaps still exist after the coal balls make direct contact with each other in the drilling hole, at the moment, gas in the coal seam forms the gas extraction channel through the perforated coal ball gaps, vent holesand inner spherical hollow structures of various models, so that the gas extraction is smooth; and the coal balls rely on the inclination angle of the downward drilling hole during filling, and roll into the drilling hole under the action of the gravity of the coal balls so as to conduct protection support, and special installation equipment is not needed, so that field use is facilitated, and wide practicability is achieved.

Owner:XUZHOU UNIV OF TECH

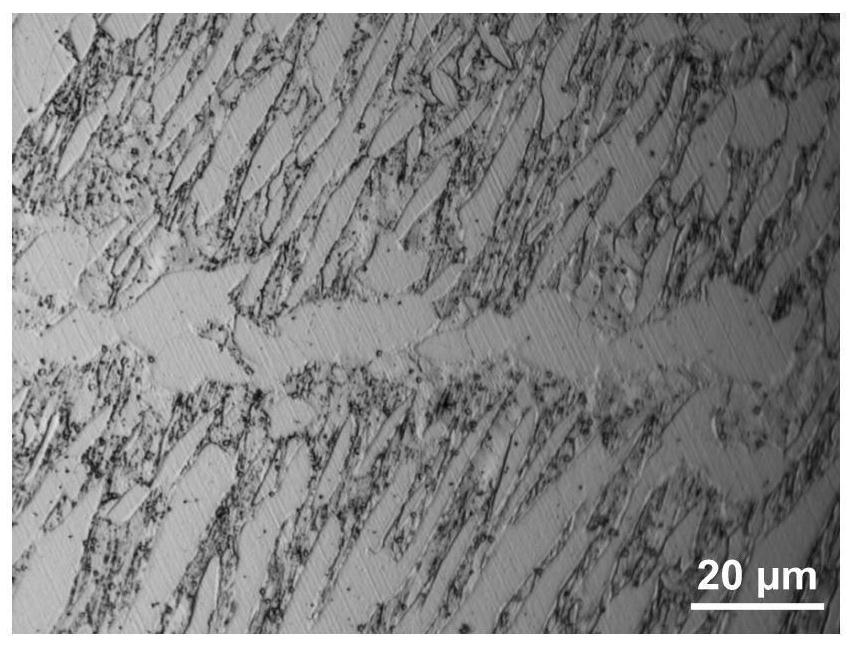

Anti-decarburization heat treatment method for hobbing cutter ring of shield tunneling machine

ActiveCN112143863AMitigation of oxidative decarburization behaviorReduce oxygen contentFurnace typesHeat treatment furnacesHobbingEngineering

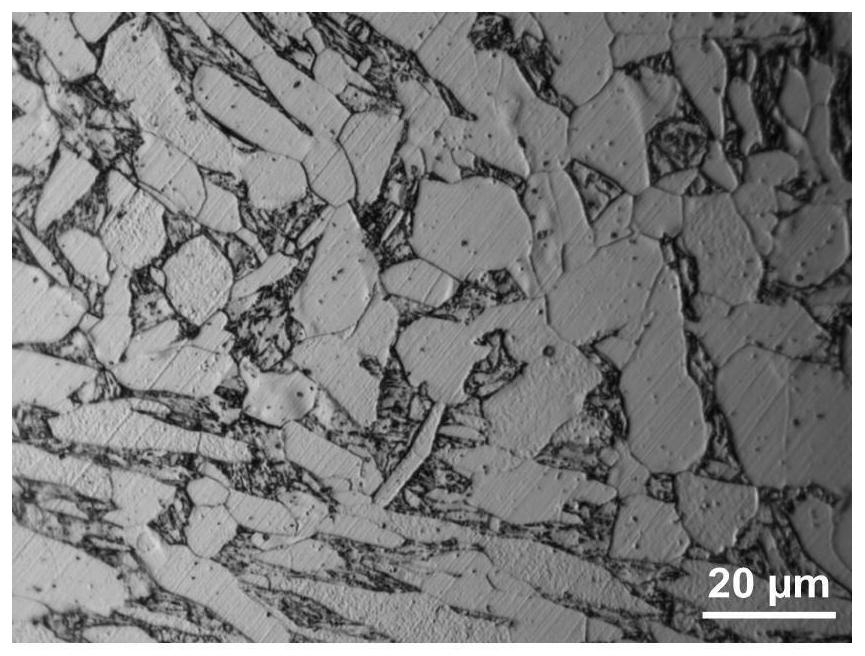

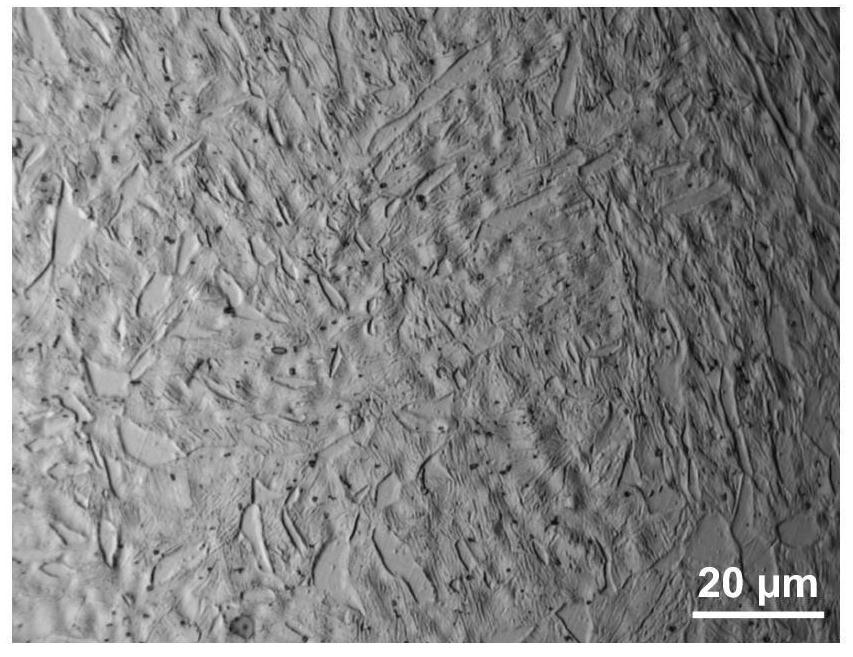

The invention belongs to the technical field of cutters of shield tunneling machines, and particularly relates to an anti-decarburization heat treatment method for a hobbing cutter ring of a shield tunneling machine. The anti-decarburization heat treatment method of the hobbing cutter ring of the shield tunneling machine comprises the following steps of: placing the hobbing cutter ring with the surface coated with an oxidation coating, of the the shield tunneling machine in a cavity of heat treatment equipment, and raising the temperature to the final temperature under the normal pressure, performing heat preservation and heat treatment, wherein coal balls are placed in the cavity of the heat treatment equipment; the oxidation coating comprises a first anti-oxidation coating and a second anti-oxidation coating in sequence from inside to outside; the first anti-oxidation coating is prepared from Na2O. 2SiO2, Al2O3, Cr2O3, NaF, TiO2 and V2O5; and the second anti-oxidation coating is prepared from SiC, graphite powder and polyinternalolefin. Test results show that the surface structure of the hobbing cutter ring treated by the anti-decarburization heat treatment method provided by theinvention is a large amount of lath martensite, and the hobbing cutter ring has obvious embossments on the surface and the hardness of 54 HRC.

Owner:广州鑫润丰东热处理有限公司

Heat exchanger core structure

InactiveCN111140877APrevent dumpingHas a limiting effectStove/ranges for heating waterWarming devicesCoal briquetteProcess engineering

The invention relates to heat exchangers, in particular to a heat exchanger core structure. The heat exchanger core structure comprises a support structure, an air door structure, a handle, a heat exchange structure, gathering structures, storage structures, clearing structures and supercharging structures, wherein the support structure is arranged on the heat exchange structure for heat exchangefor a water source through airflow produced by burning of coal briquettes, the heat exchange area is increased by means of the heat exchange structure, so that the heat exchange effect is better; theheight of the heat exchange structure is convenient to adjust by means of the support structure, the water source in the heat exchange structure can be completely discharged under the action of gravity, and the use comfort and space utilization efficiency are greatly improved; a plurality of gathering structures for storing coal briquettes in a classified manner are arranged on the heat exchange structure, the coal briquettes in any position in the heat exchange structure are convenient to replace, heat waste is reduced, and replacement of the coal briquettes is more convenient and rapider; and besides, air circulation between two adjacent coal briquettes is promoted, the burning effect is better, and chips of the coal briquettes are more convenient and rapider to store by cooperation withthe storage structures.

Owner:杭州翼兔网络科技有限公司

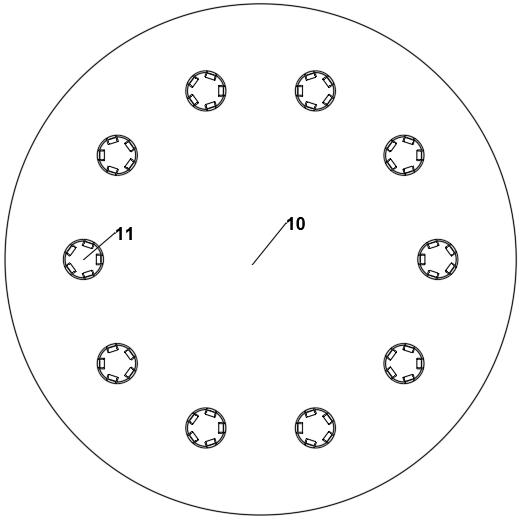

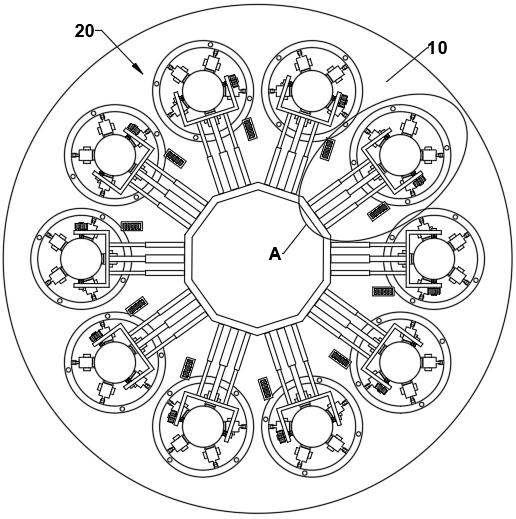

Automatic discharging mechanical device for briquette detection

ActiveCN114578076AIntegrity guaranteedNo risk of accidental dropsMaterial analysisRobot handStructural engineering

The invention relates to the technical field of briquette detection, and discloses an automatic blanking mechanical device for briquette detection, the automatic blanking mechanical device comprises a control box and a plurality of manipulators, the manipulators are all arranged at the bottom of a coal sample turntable, and each manipulator comprises a plurality of guide columns which are all arranged along the longitudinal direction; the lifting ring is in sliding connection with the multiple guide columns; the spring enables the lifting ring to have a trend of moving downwards; the multiple movable claws are arranged at equal intervals in the circumferential direction of the corresponding coal sample holes, the two sides of the middle of each movable claw are rotationally connected with the bottom of the coal sample rotating disc, the first end of each movable claw extends to the bottom of the corresponding coal sample hole, and the second end of each movable claw is movably connected with the lifting ring; the electromagnets are all mounted at the bottom of the coal sample turntable; and the plurality of permanent magnets are all mounted at the top of the lifting ring and are arranged in one-to-one correspondence with the plurality of electromagnets.

Owner:LOFON CONTROL EQUIP BEIJING

Coal-saving combustion mechanism for industrial boiler

PendingCN113701143AImprove combustion efficiencyEasy to collectSolid fuel combustionAir/fuel supply for combustionThermodynamicsElectric machine

The invention belongs to the technical field of combustion mechanisms, particularly relates to a coal-saving combustion mechanism for an industrial boiler, and aims to solve the problems that large-particle briquettes are easy to generate in the combustion process of existing coal cinder, and the combustion and utilization of the coal cinder are greatly not facilitated. The coal-saving combustion mechanism for the industrial boiler comprises a box body, and the outer wall of the top of the box body is fixedly connected with a feeding channel; and a motor is fixedly connected to the outer wall of the top of the box body, a rotating shaft is fixedly connected to the bottom of the motor, and a crushing mechanism is arranged in the box body. By arranging a first combustion box and a second combustion box, pulverized coal can be subjected to multi-stage combustion treatment, the combustion utilization rate of the coal is increased, an oxygen supply mechanism arranged in the first combustion box can supply oxygen to the interior of the first combustion box in time, and the coal combustion efficiency is further improved; and by arranging a heat outlet at the top of the first combustion box, heat in the coal combustion process can be conveniently collected, and the utilization efficiency is high.

Owner:李乐东

A multifunctional mine mining dust removal device

Owner:新疆亚克斯资源开发股份有限公司

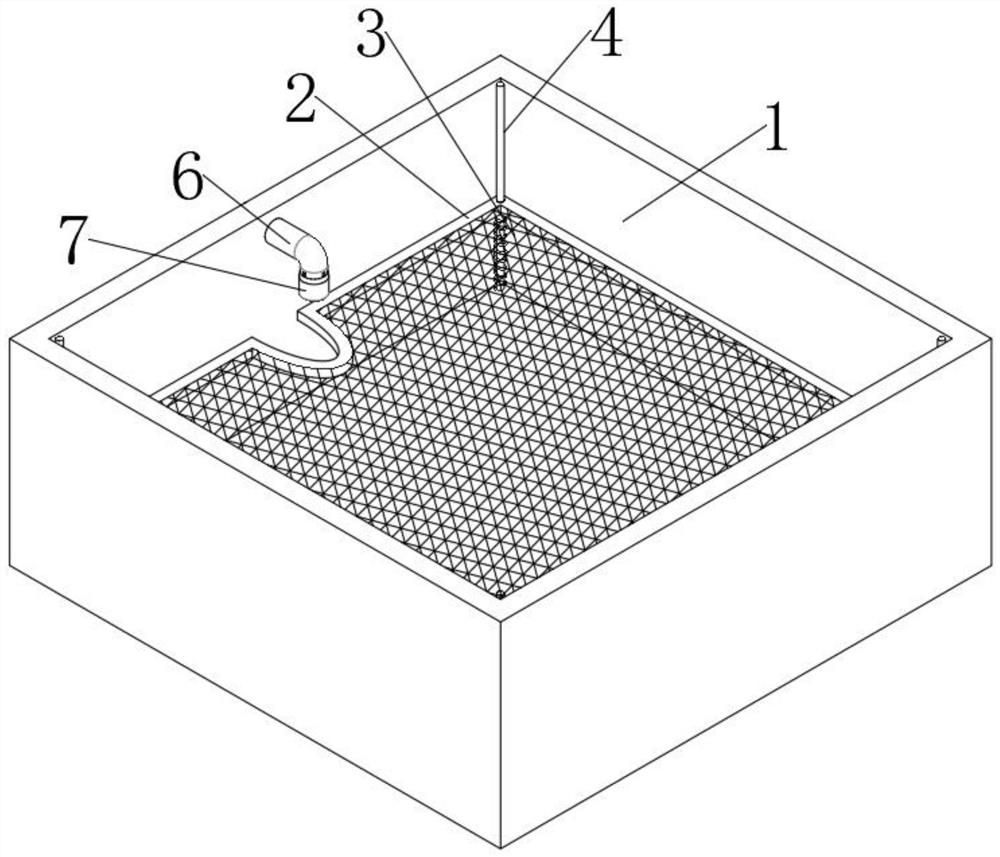

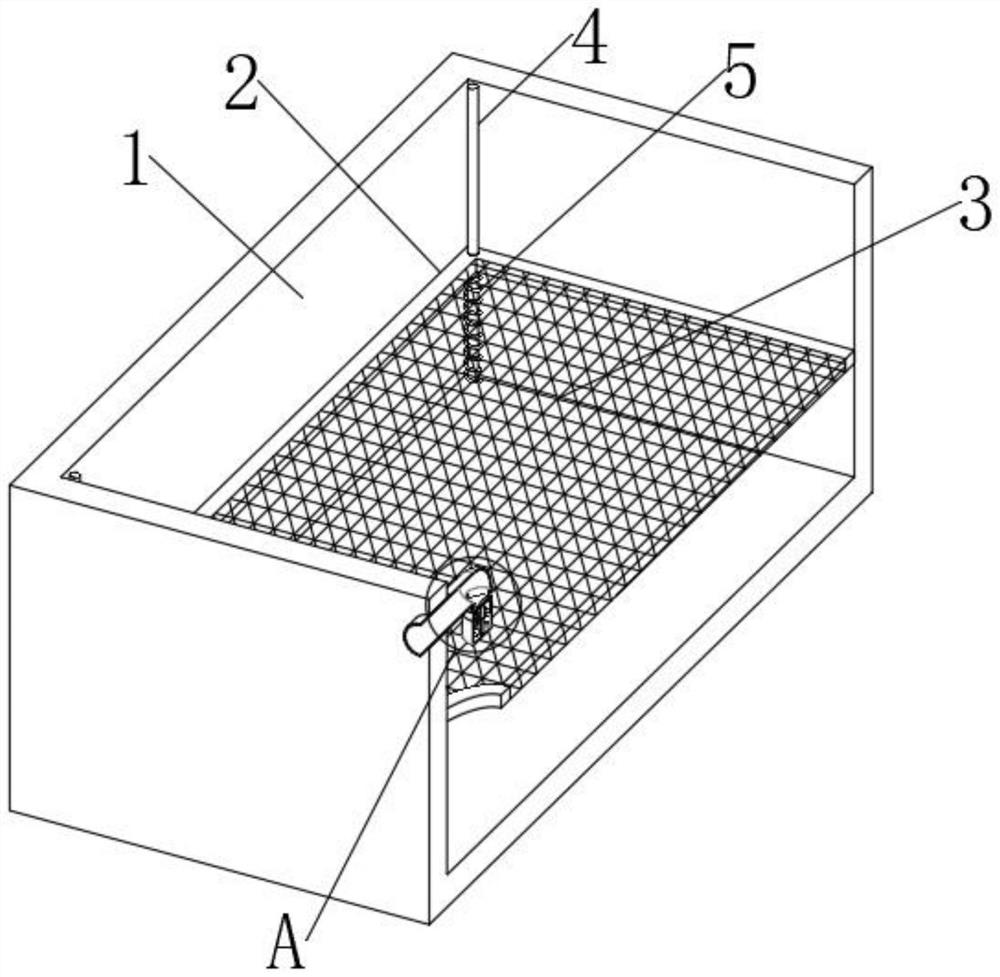

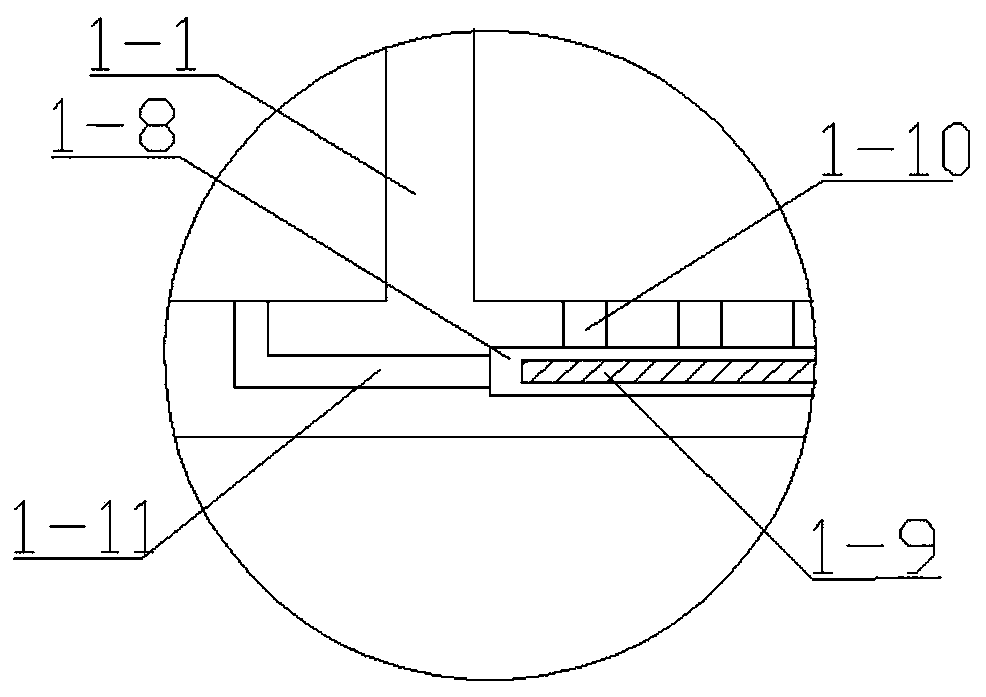

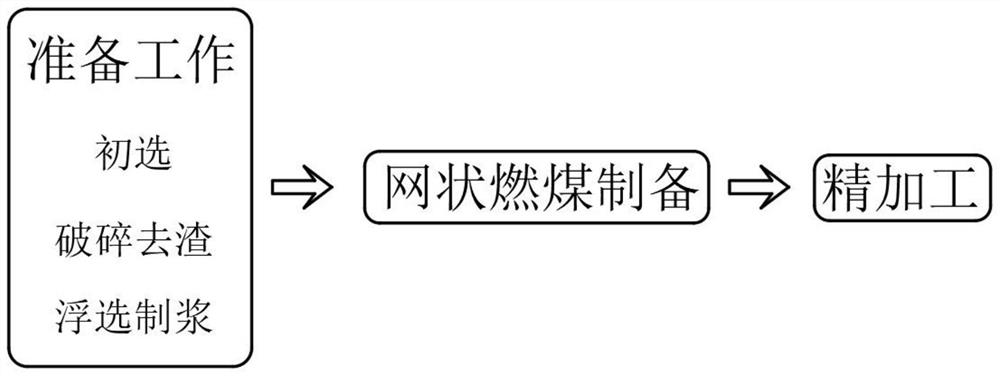

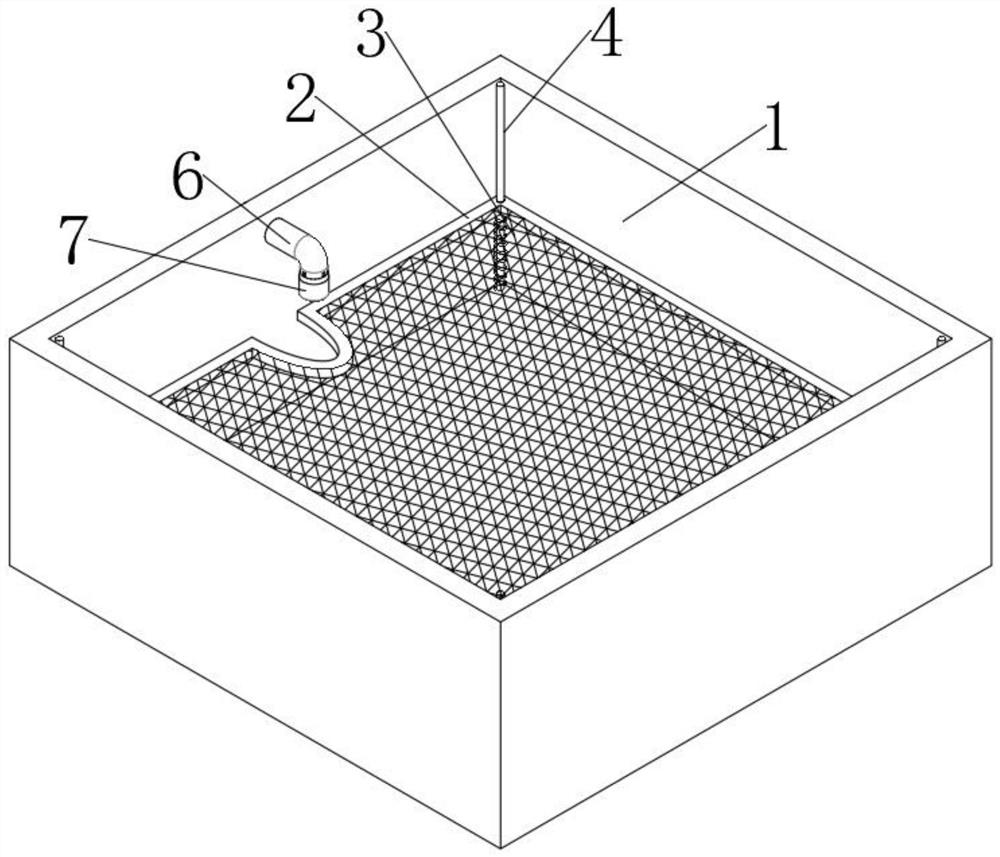

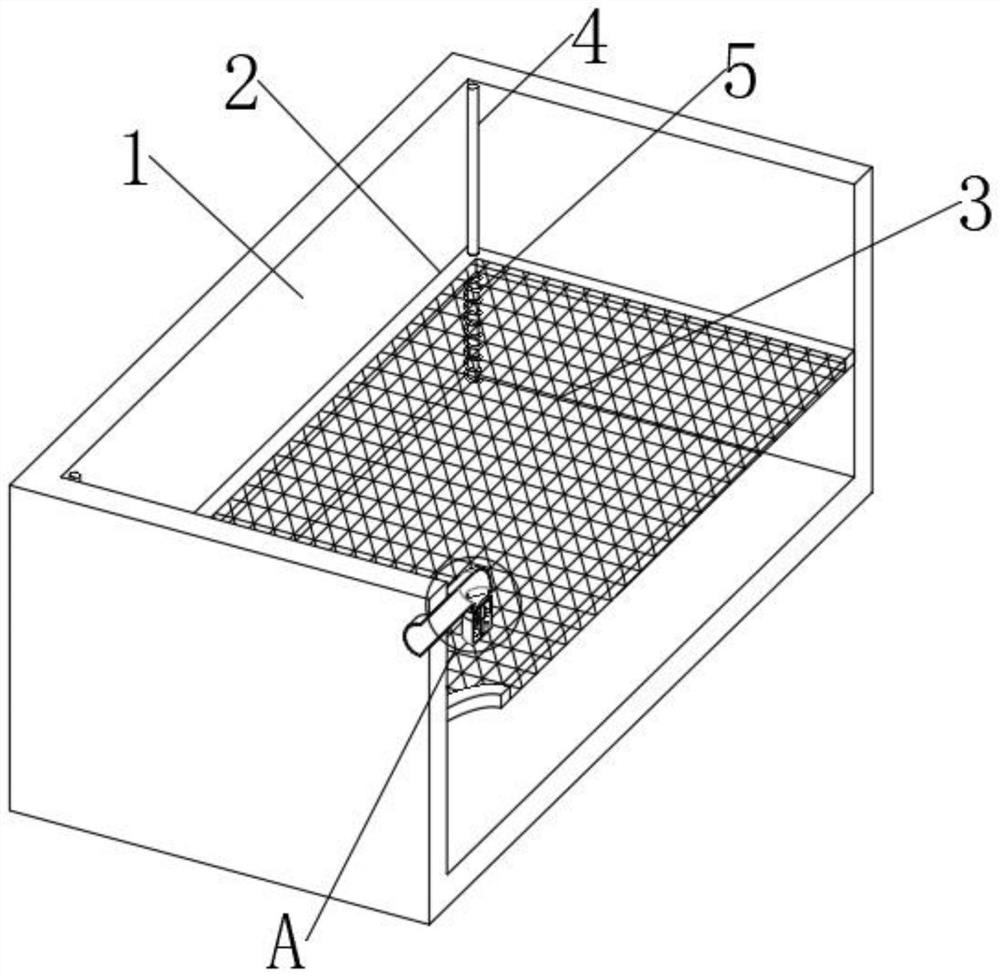

Manufacturing method of high-efficiency energy-saving fire coal with reticular structure

ActiveCN112500898ABurn fullyHigh calorific valueSolid fuelsLump/pulverulent fuel preparationCombustionEngineering

The invention discloses a manufacturing method of high-efficiency energy-saving fire coal with a reticular structure, belonging to the field of manufacturing methods of fire coal. According to the manufacturing method of the high-efficiency energy-saving fire coal with the reticular structure, in the preparation process of the reticular fire coal, attached branches are continuously washed by coalslurry under the action of a stirring device, the coal slurry is captured by closed compartments formed by interlacing, coal balls are gradually formed under the viscosity action of the coal slurry, and the outer side of outer protective skin is coated with the coal slurry; all the parts of an attachment net are made of combustible materials, and the ignition point of each part of the attachment net is lower than a coal combustion temperature; after a fixed frame and the attachment net are soaked in the coal slurry for a long time, the fixed frame and the attachment net are taken out of a preparation bed so as to obtain the reticular fire coal which grows naturally; and the fire coal can be fully combusted, large-particle dust is not prone to being formed, air is not prone to being polluted, the heat value of the fire coal can be kept at a high level, and the combustion efficiency of the coal is improved.

Owner:淮北德林机械设备有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com