Method for separating iron, vanadium and titanium from schreyerite

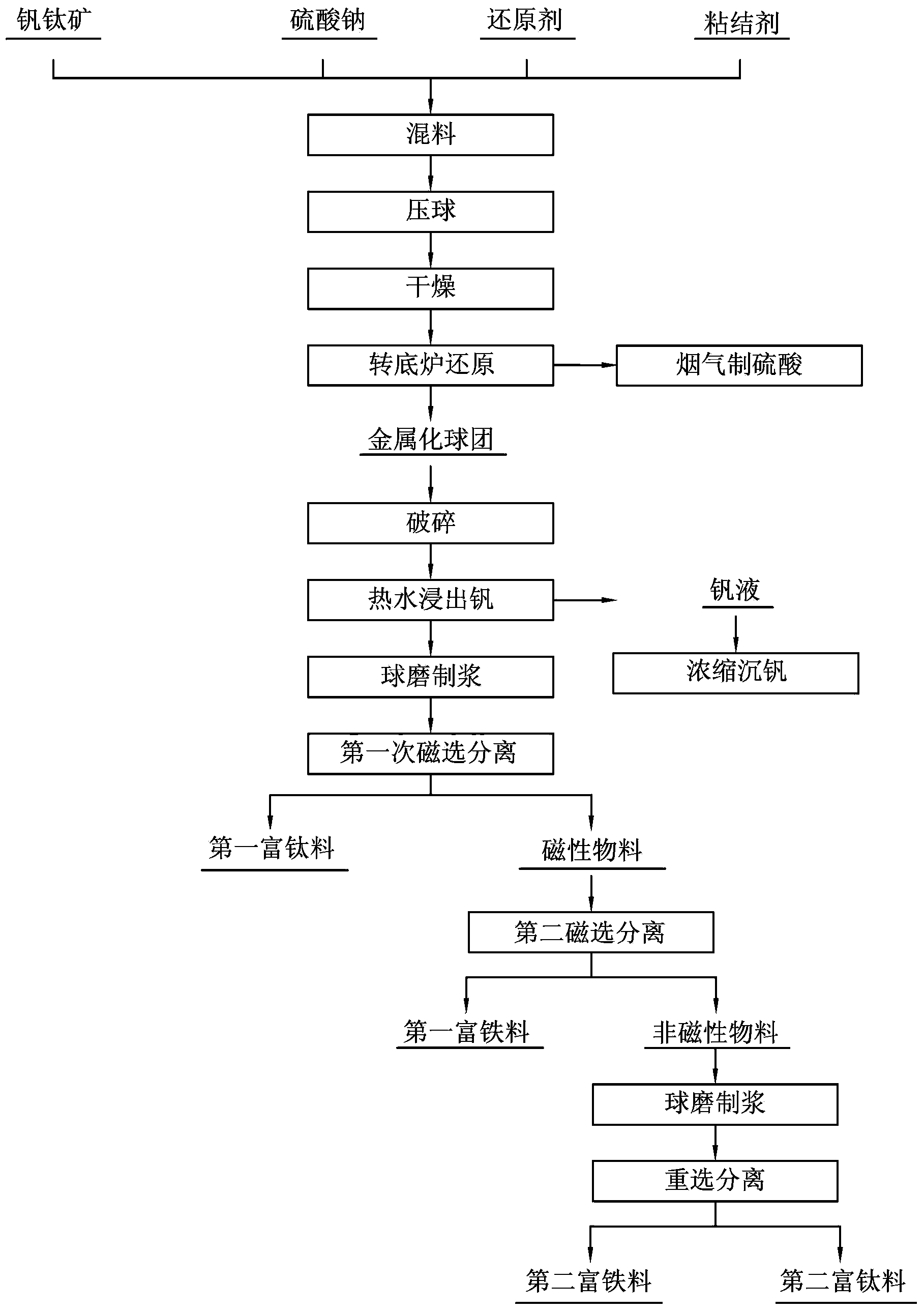

A separation method, technology of vanadium-titanium ore, applied in the separation of vanadium and titanium, iron in vanadium-titanium ore, can solve the problems of long process and high energy consumption, achieve high-efficiency separation, reduce energy consumption, and avoid high-temperature reduction and melting Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0031] Vanadium-titanium ore (containing TFe54.2%, V 2 o 5 0.62%, TiO 2 13.7%, particle size2 48.6%), the obtained magnetic material is separated by a second magnetic separation through a drum magnetic separator with a magnetic field strength of 0.03T to obtain a magnetic material (that is, the first iron-rich material, which contains TFe91.5%), and the obtained The non-magnetic material is re-selected by a shaker after being pulped by ball milling, and the second titanium-rich material (containing TiO 2 42.1%) and the second iron-rich material (which contains TFe55.7%).

example 2

[0033] Vanadium-titanium ore (containing TFe30.5%, TiO 2 47.2%, particle size 2 75.2%), and the obtained magnetic material is separated by a second magnetic separation through a drum magnetic separator with a magnetic field strength of 0.02T to obtain a magnetic material (that is, the first iron-rich material, which contains TFe87.5%), and the obtained The non-magnetic material is re-selected by a shaker after being pulped by ball milling, and the second titanium-rich material (containing TiO 2 57.5%) and the second iron-rich material (which contains TFe51.8%).

Embodiment 3

[0035] Vanadium-titanium ore (containing TFe53.1%, V 2 o 5 0.57%, TiO 2 12.8%, particle size2 52.0%), the obtained magnetic material is separated by a second magnetic separation through a drum magnetic separator with a magnetic field strength of 0.025T to obtain a magnetic material (that is, the first iron-rich material, which contains TFe90.2%), and the obtained The non-magnetic material is re-selected by a shaker after being pulped by ball milling, and the second titanium-rich material (containing TiO 2 43.7%) and the second iron-rich material (which contains TFe57.2%).

[0036] In summary, the vanadium-titanium magnetite, industrial sodium sulfate, coal powder and other raw materials used in the method for separating iron, vanadium and titanium in the vanadium-titanium ore of the present invention are cheap and easy to get, and the method can effectively convert vanadium-titanium The iron, vanadium and titanium resources in the mine are extracted, the process flow is sim...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com