Preparation method of laser pulse perforation assisted diffusion high-coercivity neodymium iron boron

A laser pulse, high coercivity technology, used in the manufacture of inductors/transformers/magnets, magnetic objects, magnetic materials, etc., can solve the problems of broken magnet structure, reduction of magnet coercivity, uneven distribution of heavy rare earth elements, etc. , to achieve the effect of improving uniformity, increasing coercivity, and increasing specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Embodiment 1: A preparation method of laser pulse perforation assisted diffusion high coercive force NdFeB, comprising the following steps:

[0021] Step (1) Preparation of diffusion source:

[0022] The heavy rare earth metal Tb and the low melting point metal Al are smelted at an atomic ratio of 0.3:1 to form a master alloy, and the master alloy is high-energy ball milled for 12 hours to form a nanometer to micron powder, and the powder is mixed with an acetone solution to form a mixed solution of a diffusion source;

[0023] Step (2) NdFeB laser perforation:

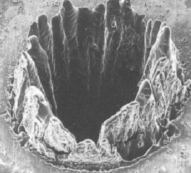

[0024] Using femtosecond to nanometer laser pulses, the laser wavelength is 800nm, the pulse duration is 300fs, the pulse intensity is 150uJ, the spot size is 10μm, and the surface of the NdFeB magnet with a size of 10mm×10mm×10mm is perforated. The shape of the hole is as follows figure 1 As shown, the distance between the holes is 0.5mm, and a coal ball-shaped magnet is formed;

[0025] Step (3) NdFeB surfa...

Embodiment 2

[0032] Step (1) Preparation of diffusion source:

[0033] The heavy rare earth metal Dy and the low melting point metal Al are smelted at an atomic ratio of 0.5:1 to form a master alloy, and the master alloy is high-energy ball milled for 24 hours to form a nanometer to micrometer powder, and the powder is mixed with an acetone solution to form a mixed solution of a diffusion source;

[0034] Step (2) NdFeB laser perforation:

[0035] Using femtosecond to nanometer laser pulses, the laser wavelength is 800nm, the pulse duration is 1ns, the pulse intensity is 100uJ, the spot size is 25μm, and the surface of the NdFeB magnet with a size of 20mm×20mm×20mm is perforated, and the distance between the holes is 1mm, forming a briquette magnet;

[0036] Steps (3 NdFeB surface and internal coating:

[0037] Immerse the briquette-shaped magnet in the mixed solution of the diffusion source, take it out, and pre-fire it at 100°C for 4 hours under the protection of nitrogen to obtain a m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com