A kind of high-efficiency energy-saving coal-fired manufacturing method with network structure

A high-efficiency, energy-saving, network-like structure technology, applied in the combustion method, block/powder fuel preparation, fuel, etc., can solve the problem of affecting the production efficiency and economic benefits of thermal power plants, reducing the combustion efficiency of coal combustion, and reducing the combustion heat of coal combustion. Value and other problems, to achieve the effect of difficult production efficiency and economic benefits, difficult to large particle dust, and full combustion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

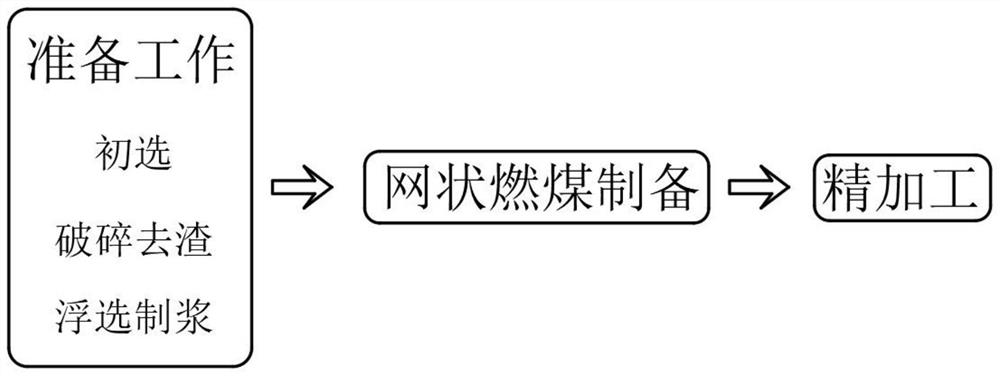

[0039] see figure 1 , a high-efficiency energy-saving coal-fired manufacturing method with a network structure, the main steps of which include:

[0040]S1, primary selection, primary selection of candidate coal, removal of large particle impurities mixed in coal, to facilitate follow-up work;

[0041] S2, crushing and removing slag, sending the primary selected coal to a pulverizer for crushing, and sieving the crushed coal to remove large-diameter and high-strength impurities to obtain powdered coal;

[0042] S3, flotation pulping, the powdered coal that has been crushed and slag removed is subjected to flotation, and the purity of coal is further improved by flotation, and at the same time, desulfurization and denitrification of coal are carried out by adjusting the flotation liquid, especially, coal flotation desulfurization and denitrification It is a well-known technology for those skilled in the art, and those skilled in the art can reasonably select flotation equipmen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com