Preparation method of high-coercivity diffusion samarium-cobalt composite permanent magnet

A high coercivity, permanent magnet technology, used in magnetic objects, inductor/transformer/magnet manufacturing, magnetic materials, etc., can solve problems such as uneven distribution of soft and hard magnetic phases, and achieve improved coercivity and maximum magnetic energy product. , The experimental method is simple, and the effect of maintaining the magnetic properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

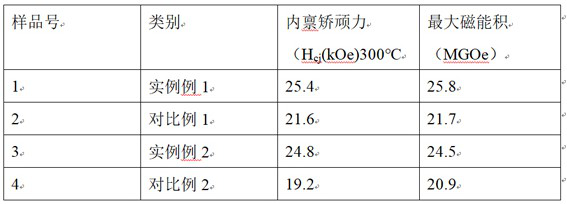

Examples

Embodiment 1

[0021] Embodiment 1: a kind of preparation method of high coercive force diffused samarium cobalt permanent magnet, comprises the following steps:

[0022] Step (1) Preparation of diffusion source:

[0023] Mixing soft magnetic phase nanoscale Fe powder with organic solvent acetone to form a mixed solution of diffusion source;

[0024] Step (2) Preparation of samarium cobalt hard magnetic phase permanent magnet:

[0025] Preparation of samarium cobalt hard magnetic phase permanent magnet: according to (Sm, Tb) 1 (Co,Fe,Ni,Cu) 5 After the alloy components are mixed, the samarium cobalt permanent magnet is obtained through melting, hot pressing and heat treatment, in which the atomic ratio of Sm:Tb is 1:0.04, (Co,Fe,Ni,Cu) 5 The atomic proportion of Co in the medium is 70%;

[0026] Step (3) Laser perforation of samarium cobalt permanent magnet:

[0027] Using femtosecond to nanometer laser pulses, the laser wavelength is 820nm, the pulse duration is 300fs, the pulse intens...

Embodiment 2

[0035] Step (1) Preparation of diffusion source:

[0036] Mixing soft magnetic phase nanoscale Fe powder with organic solvent acetone to form a mixed solution of diffusion source;

[0037] Step (2) Preparation of samarium cobalt hard magnetic phase permanent magnet:

[0038] Preparation of samarium cobalt hard magnetic phase permanent magnet: according to (Sm, Gd) 1 (Co,Fe,Ni,Cu) 5 After the alloy components are mixed, the samarium-cobalt permanent magnet is obtained through smelting, hot pressing and heat treatment, in which the atomic ratio of Sm:Tb is 1:0.08, (Co,Fe,Ni,Cu) 5 The atomic proportion of Co in the medium is 90%;

[0039] Step (3) Laser perforation of samarium cobalt permanent magnet:

[0040] Using femtosecond to nanometer laser pulses, the laser wavelength is 820nm, the pulse duration is 300fs, the pulse intensity is 200uJ, the spot size is 7μm, and the surface of a samarium cobalt magnet with a size of 20mm×20mm×20mm is perforated. The shape of the hole is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com