Coal-saving combustion mechanism for industrial boiler

A technology for industrial boilers and coal is applied in the field of coal-saving combustion mechanisms for industrial boilers, which can solve the problems of low utilization rate of coal combustion and unfavorable combustion and utilization of coal slag, and achieve the effects of high utilization efficiency, convenient collection, and improved combustion utilization rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

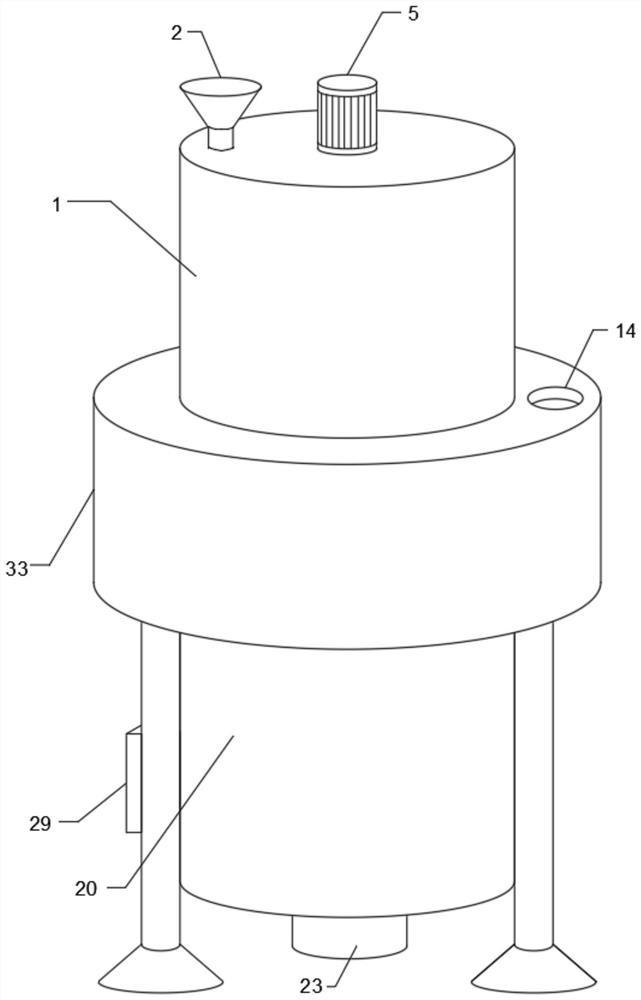

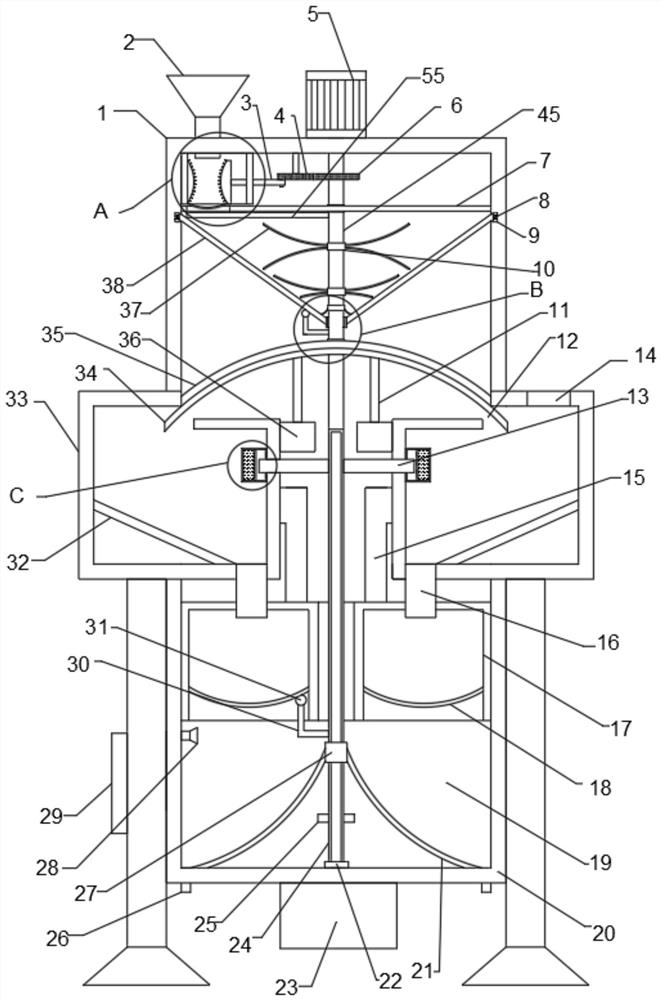

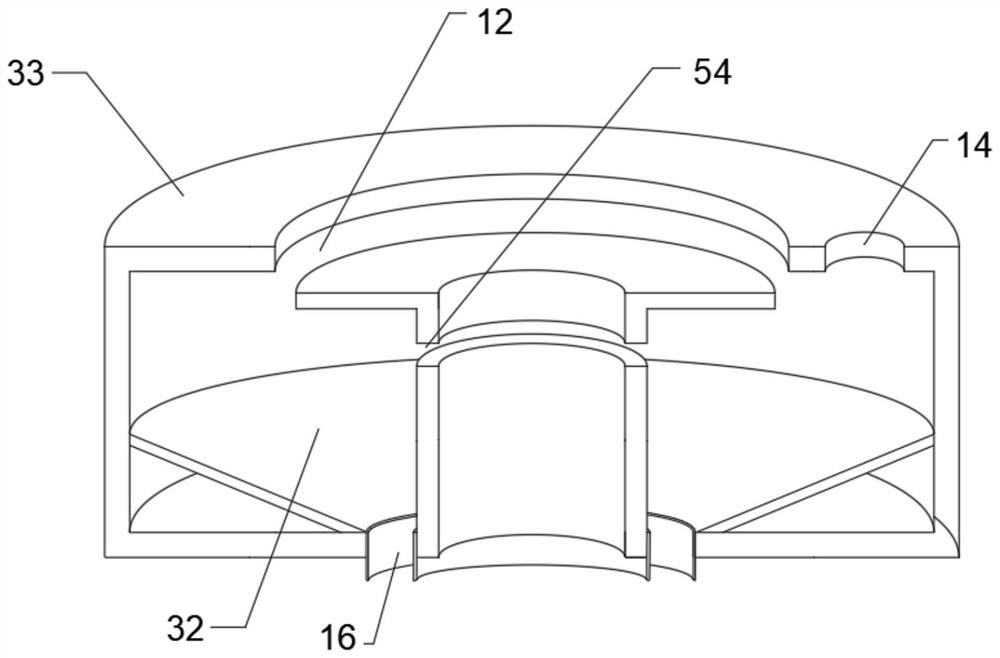

[0029] refer to Figure 1-7 , a coal-saving combustion mechanism for an industrial boiler, comprising a box body 1, a feed channel 2 is fixedly connected to the top outer wall of the box body 1, a motor 5 is fixedly connected to the top outer wall of the box body 1, and a rotating shaft 45 is fixedly connected to the bottom of the motor 5, A crushing mechanism is arranged inside the box body 1, and the crushing mechanism is located at the bottom of the feeding passage 2. A crushing box 38 is arranged at the bottom of the crushing mechanism. The outer wall of the top of the first combustion box 33 is provided with a heat outlet 14, the inner wall of the first combustion box 33 is provided with an oxygen supply mechanism, the bottom of the first combustion box 33 is fixedly connected with the bottom box 20, and the inner wall of the bottom box 20 is fixedly connected with the second combustion box 17 , the bottom of the first combustion box 17 is fixedly connected with a dischar...

Embodiment 2

[0039] refer to figure 2 and Figure 8 , a coal-saving combustion mechanism for an industrial boiler, comprising a nickel powder box 51 fixedly connected to the inner wall of the first combustion box 33, the nickel powder box 51 being arranged in a ring shape, the first gas distribution pipe 13 passing through the nickel powder box 51, and the nickel powder box 51 The inner wall is fixedly connected with a ventilating plate 53, and the end of the venting plate 53 away from the first air distribution pipe 13 is provided with nickel powder 52, and the outer wall of the nickel powder box 51 is provided with a plurality of powder outlet holes.

[0040] During use, by arranging the first air distribution pipe 13 into the nickel powder box 51, the nickel powder is blown out from the nickel powder box 51 through the air-permeable plate 53, and the carbon monoxide in the combustion waste gas is absorbed by the nickel powder. Heating releases carbon monoxide and re-combustion makes c...

Embodiment 3

[0042] refer to figure 2 , a coal-saving combustion mechanism for industrial boilers, the inner wall of the dust removal bin 19 is provided with a second connecting block 27, the second connecting block 27 is rotationally connected with the air guide pipe 24, and the outer wall of the second connecting block 27 is fixedly connected with a partition 21, the partition 21 The bottom is fixedly connected to the inner wall of the bottom box 20, the partition 21 is arranged in an arc shape, the outer wall of the partition 21 is provided with a plurality of through holes, and the end of the partition 21 away from the atomizing nozzle 28 is provided with a plurality of second air distribution pipes 25, the second The trachea 25 is fixedly connected with the airway tube 24.

[0043] During use, by setting up the air pump 23 and utilizing the delivery of the air guide pipe 24, the second air distribution pipe 25 will eject gas, so that the partition plate 21 can be rotated and sprayed,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com