A coal-fired marine power boiler

A boiler, marine technology, applied in the field of thermal energy engineering and engineering thermophysics, can solve the problem of wasting time and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

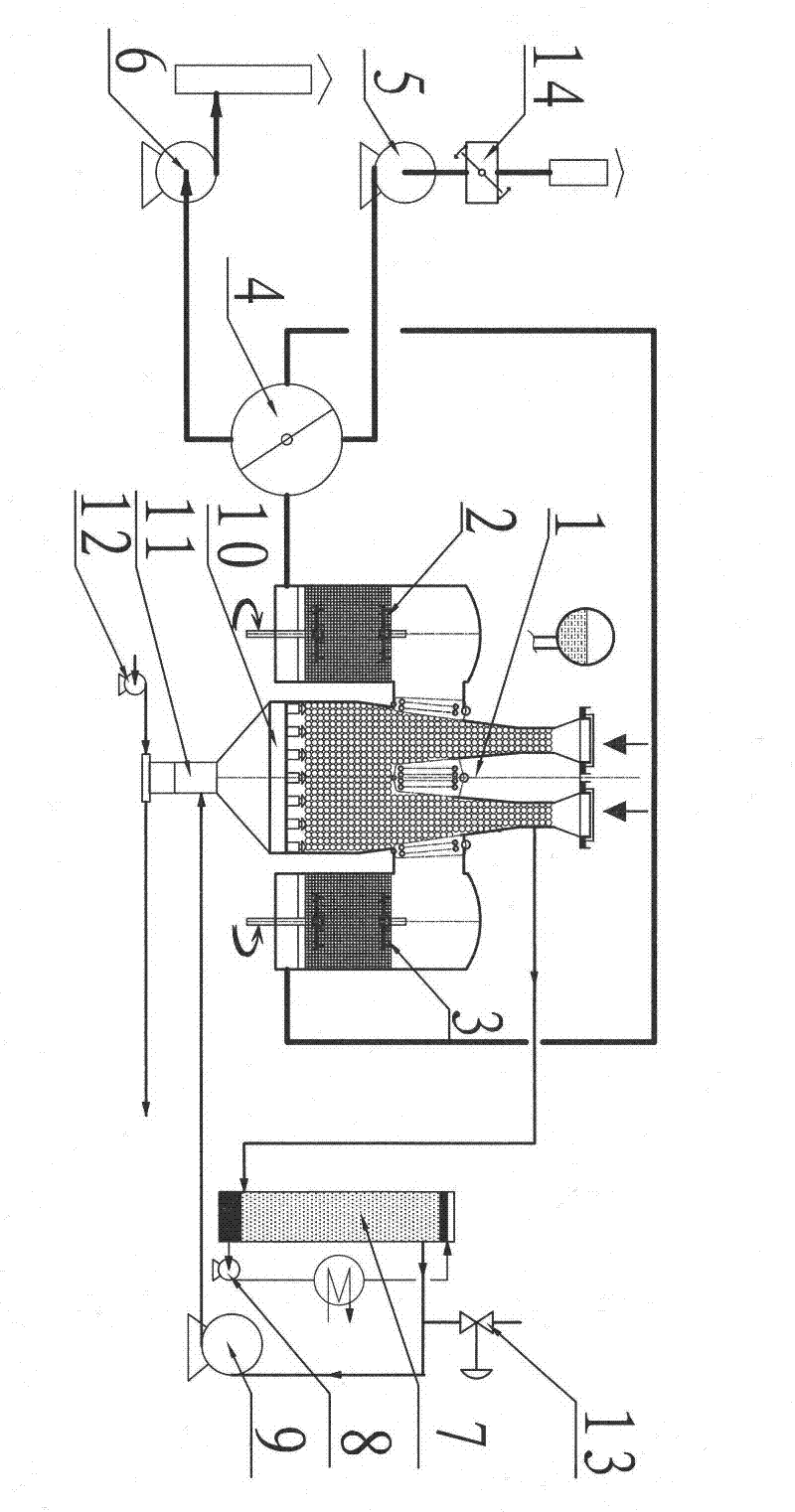

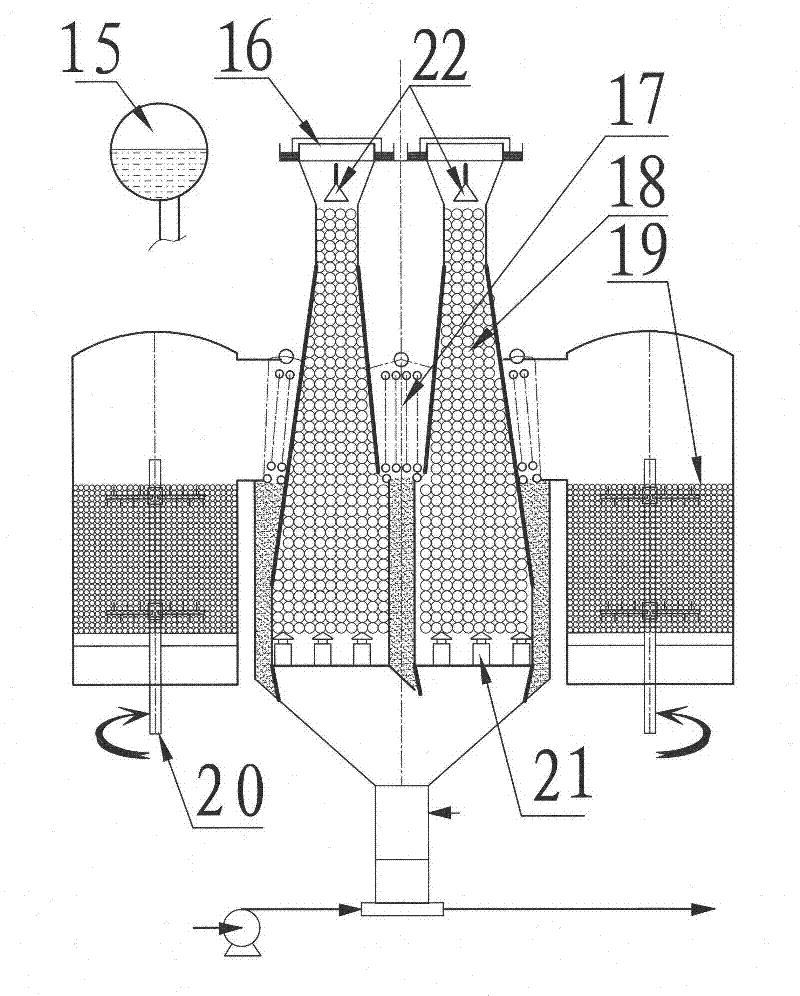

[0031] The structure of the marine power boiler is divided into two parts: the boiler main device and the auxiliary machinery.

[0032] 5.1 The structure of the boiler main device:

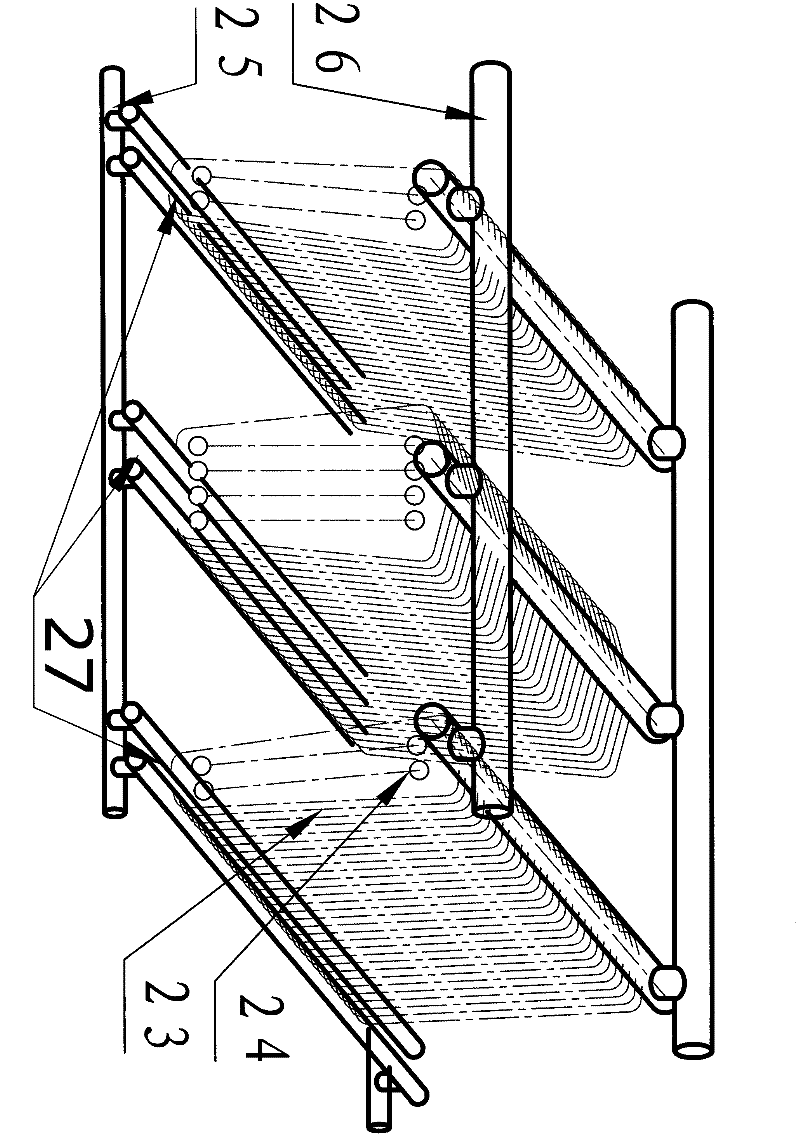

[0033] Such as figure 1 As shown, the main device of the boiler is composed of moving bed 1 and heat storage beds 2 and 3, heat storage beds 2 and 3 are arranged on both sides of 1, and 2, 1 and 3 are connected as a whole, and 2, 1 and 3 are reversing with four-way The valve 4 is communicated with the air duct, and the evaporation pipe and the superheating pipe 17 are divided into left, middle and right three components and placed in the left, right and left sides of the moving bed 1 and in the middle, and each pipe row is provided with a fine ash discharge port 27 to eliminate the waste that falls into the overheating pipe from between the pipes. The fine ash of heat pipe panel, steam drum 15 places outside furnace, forms a boiler. The name of this marine power boiler is heat storage moving be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com