Coal ball replacing device for coal ball stove

A technology of coal ball furnace and briquettes, which is applied in the field of coal ball furnaces, can solve problems such as troublesome and unsanitary, and achieve the effects of convenient use and simple structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

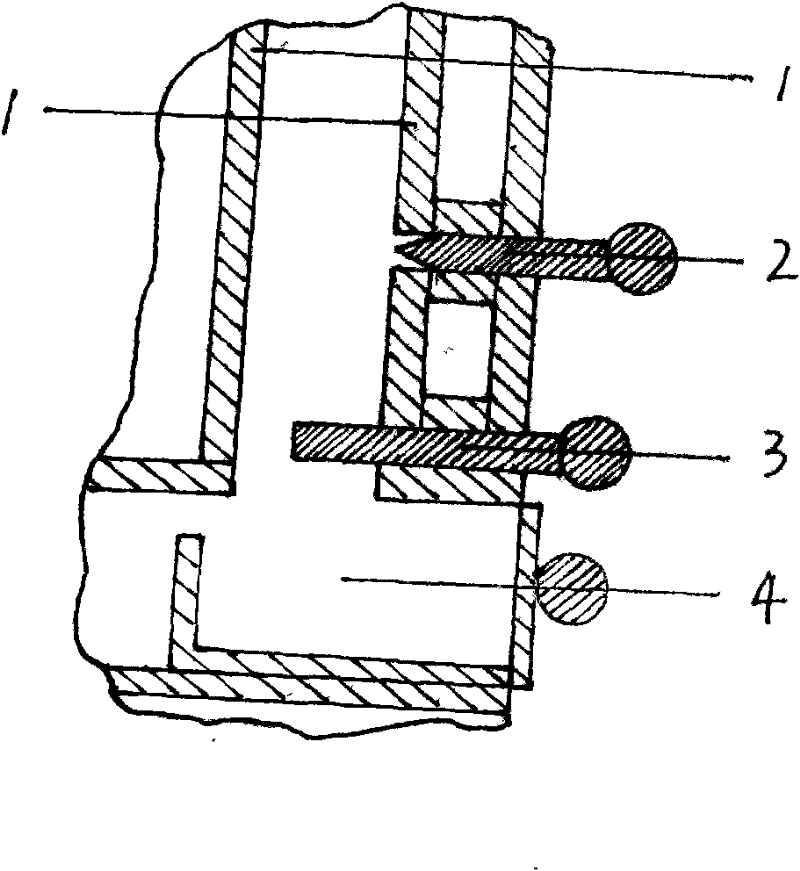

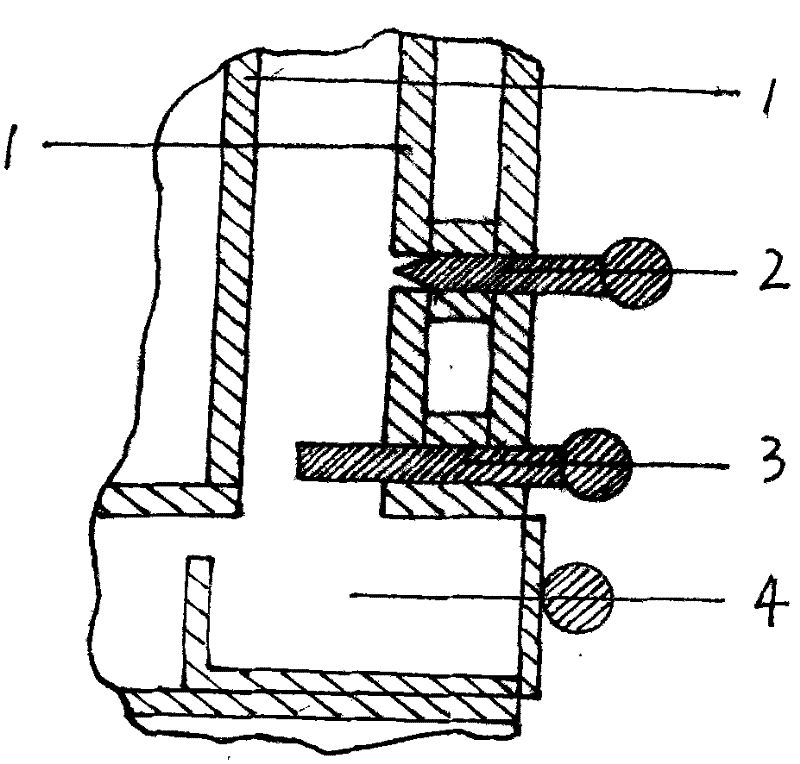

[0008] When changing briquettes, first push the control separation rod 2 in the furnace 1 toward the briquette furnace, separate the briquettes at the bottom and control the briquettes on the top not to fall, and then pull the discharge rod outward so that the burned briquettes fall into the furnace. In the drawer, push the discharge rod into the briquette furnace, and then pull the control separation rod outward, the briquettes in the briquette furnace will automatically fall down to the height of a briquette, and then put unburned coal on the top of the briquette furnace mouth. For briquettes, pull out the drawer and take out or dump the burnt briquettes that fell into the drawer, that is, the task is completed.

[0009] Of course, the lower end of the discharge rod is not limited to be provided with a drawer, and a pull-out plate can also be provided, as long as these transformations of controlling the separation rod and the discharge rod are arranged on the furnace inner wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com