Anti-decarburization heat treatment method for hobbing cutter ring of shield tunneling machine

A heat treatment method and anti-decarburization technology, applied in heat treatment furnaces, heat treatment equipment, furnaces, etc., can solve the problems of high cost, poor strength, parameter design and complex operation of vacuum heat treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0069] The material of the hob cutter ring of the shield machine is 4Cr5MoSiV1, the element composition is C 0.42%, Cr 5.36%, Mo1.40%, Si 1.14%, V 0.83%, and the balance is Fe and unavoidable impurities;

[0070] Composition of the first anti-oxidation coating: Na 2 O 2SiO 2 20%;Al 2 o 3 20%;Cr 2 o 3 10%; NaF 5%; TiO 2 5%; V 2 o 5 4%; water balance;

[0071] The second anti-oxidation coating composition: SiC 3%; Graphite powder (1000 orders) 30%; Poly-internal olefin 30%; Water surplus;

[0072] The composition of briquettes is: 30% sodium nitrate, 2% potassium nitrate, 20% charcoal powder, 30% anthracite, 15% carbonized sawdust, 1% tungsten oxide, and 2% yellow mud;

[0073] The coal briquettes are honeycomb briquettes, and the size conditions are as follows: the diameter is 120mm, the height is 75mm, the honeycomb aperture is 12mm, and the number of holes is 12.

[0074] Coat the surface of the hob cutter ring of the shield machine to be heat treated with the first...

Embodiment 2

[0084] The material of the hob cutter ring of the shield machine is 4Cr5MoSiV1, the element composition is C 0.39%, Cr 5.1%, Mo1.20%, Si 1.1%, V 0.9%, and the balance is Fe and unavoidable impurities; other technical means and Application example 1 is the same.

Embodiment 3

[0091] The material of the hob cutter ring of the shield machine is 4Cr5MoSiV1, the element composition is C 0.47%, Cr 4.9%, Mo1.0%, Si 1.1%, V 1%, and the balance is Fe and unavoidable impurities; other technical means and Application example 1 is the same.

[0092] Comparative example 2

[0093] The material of the hob cutter ring of the shield machine is 4Cr5MoSiV1, the element composition is C 0.47%, Cr 4.9%, Mo1.0%, Si 1.1%, V 1%, and the balance is Fe and unavoidable impurities; other technical means and Consistent with Comparative Example 1.

[0094] The hardness of the surface of the hob cutter ring obtained by heat treatment in Comparative Example 3 and Example 3 was tested, and the hardness of the surface of the hob cutter ring obtained in Comparative Example 3 was 47HRC, and the hardness of the surface of the hob cutter ring obtained in Example 3 was 59HRC.

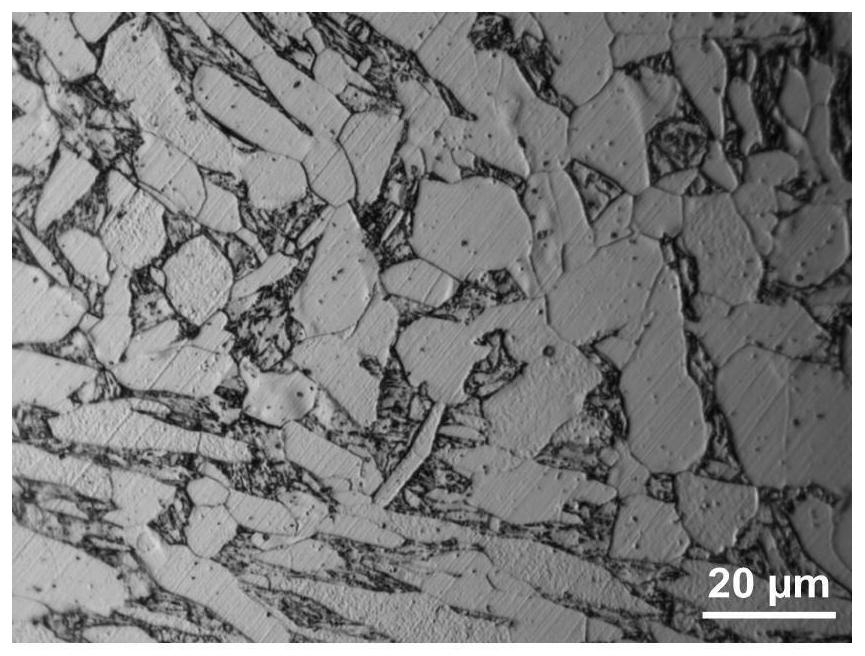

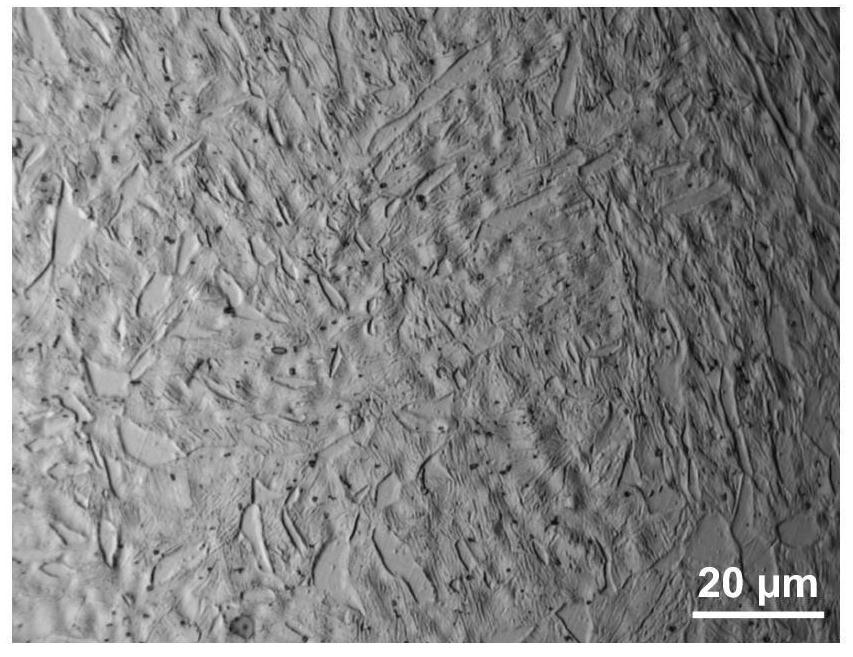

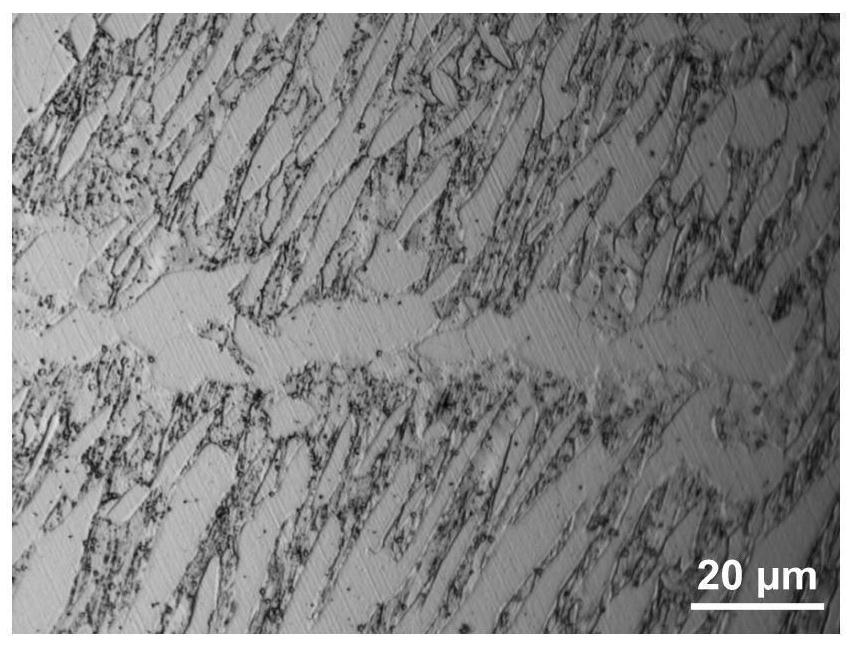

[0095] The metallographic structure of the surface of the hob cutter ring obtained by heat treatment in Co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com