Fly ash extraction device

An extraction device and fly ash technology, which is applied in the field of fly ash extraction devices, can solve the problems of difficulty in extracting fly ash, inability to extract fly ash, and high hardness of honeycomb coal, etc., and achieve easy breaking and fragmentation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

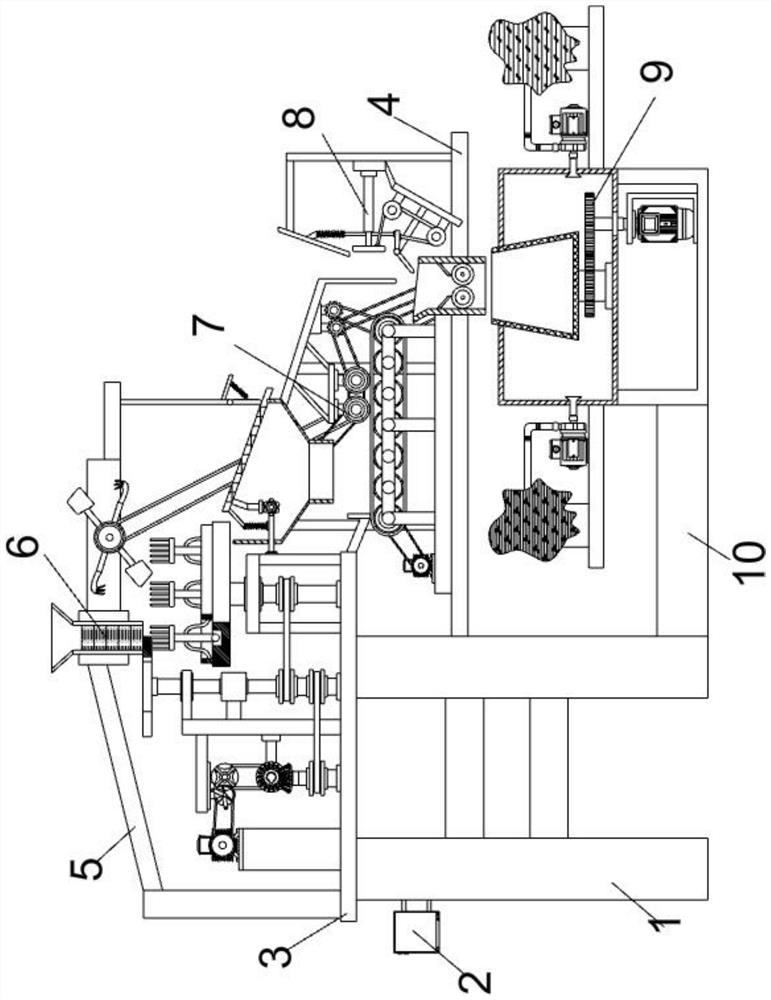

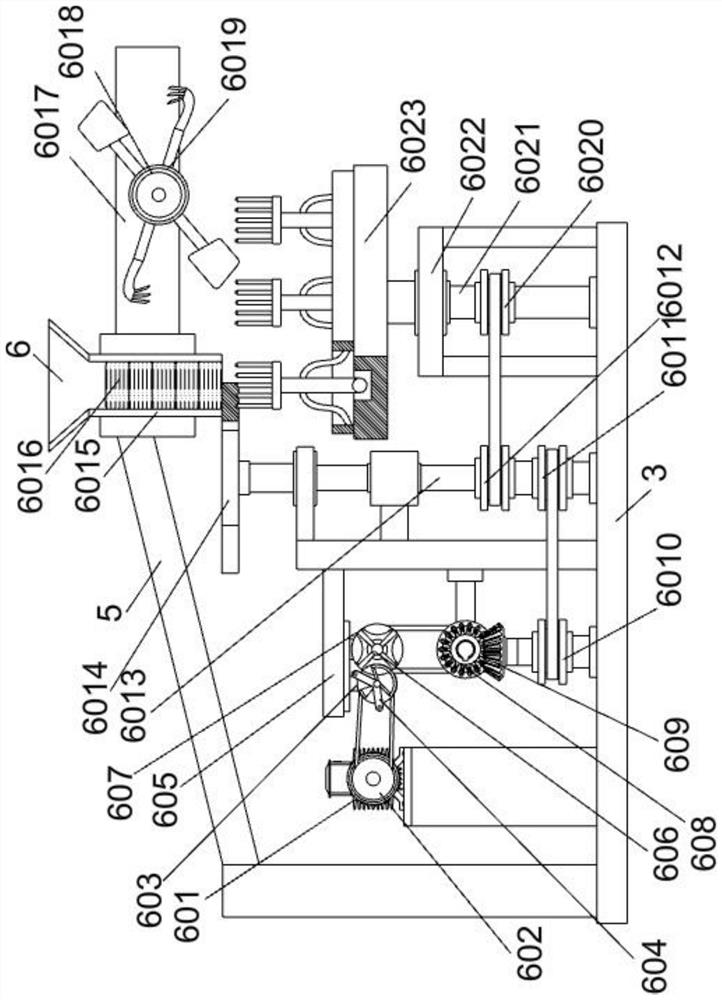

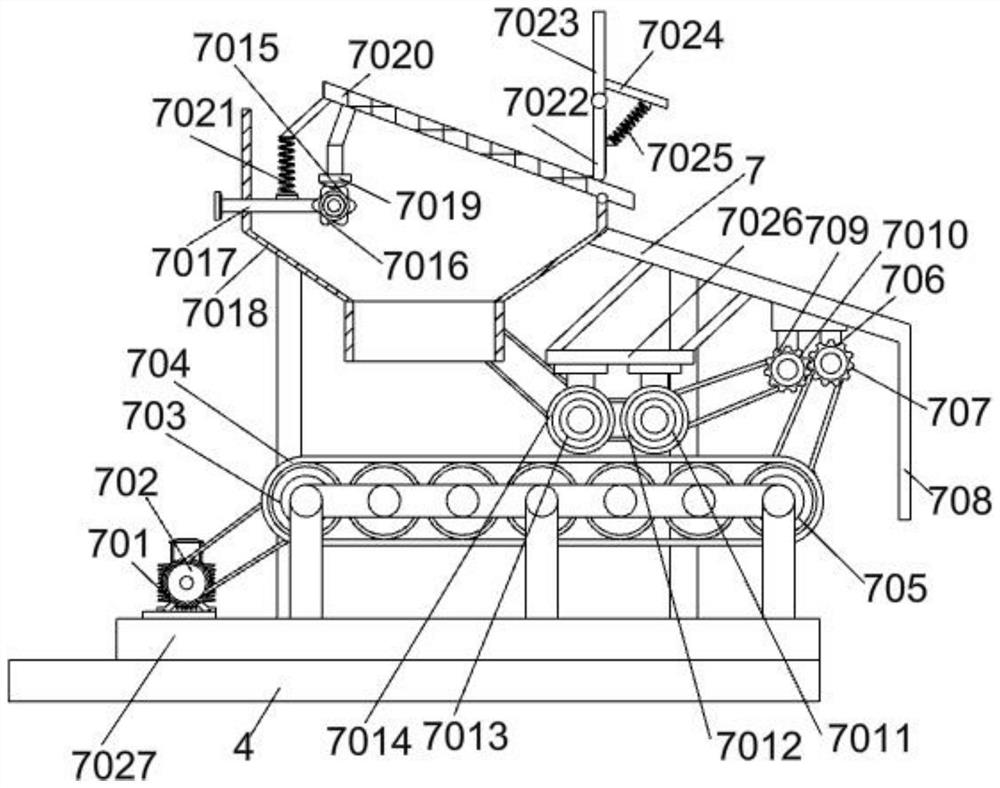

[0030] A fly ash extraction device, such as Figure 1-8 As shown, it includes machine tool support feet 1, real-time control panel 2, first machine tool board 3, second machine tool board 4, machine tool top board 5, breaking and separating processing mechanism 6, peripheral block crushing mechanism 7, inner layer block impact A crushing mechanism 8, a separation and collection mechanism 9, and a machine tool connection base plate 10; a real-time control panel 2 is provided on one side of the machine tool support foot 1, and the other side of the machine tool support foot 1 is sequentially connected with the second machine tool plate 4 and the machine tool connection base plate 10 Welding; the top of the machine tool support foot 1 is welded with the first machine tool plate 3; the top of the first machine tool plate 3 is connected with the machine tool top plate 5 and the breaking and separating processing mechanism 6; the top of the breaking and separating processing mechanis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com