Novel method for synthesizing stearic acid-modified short oil glyptal resin

A technology of alkyd resin and stearic acid, which is applied in coatings, polyurea/polyurethane coatings, etc., can solve the problems of poor water resistance and adding more curing agents, and achieve good wettability, reduce reaction space resistance, and elasticity Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

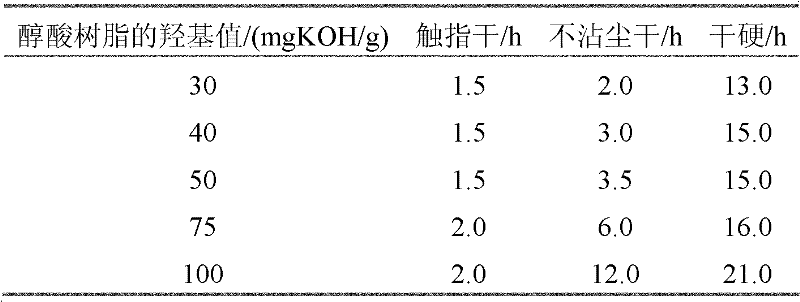

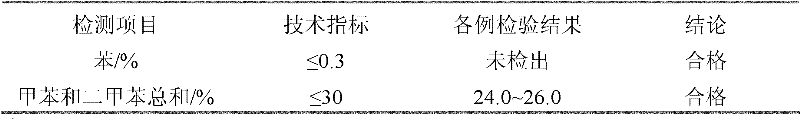

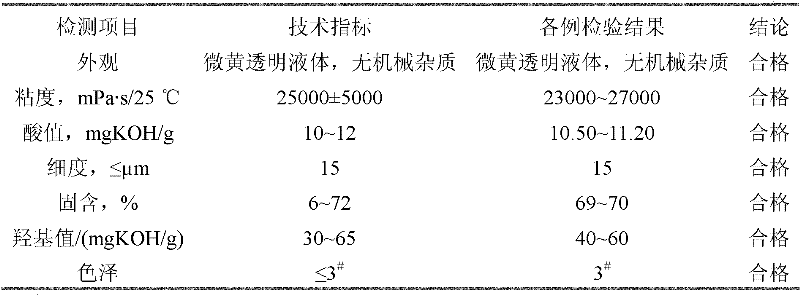

[0033] 596.05kg of refined oleic acid, 357.63kg of 1081 stearic acid, 157.36kg of benzoic acid, 298.03kg of diethylene glycol, 59.06kg of TMP, 298.03kg of glycerin (95.0%), and 576.44kg of pentaerythritol were put into the reactor, and then 1788.15kg of phthalic anhydride was added. Afterwards, when the temperature is lower than 80°C, add 5.96kg antioxidant, reflux with 119.21kg xylene, heat up, and pass carbon dioxide (when the temperature rises to 170°C, stop ventilation), when the temperature rises to 120°C, start stirring At the same time turn on the return cooling water. Control the voltage so that it takes 2.0 hours to rise to 170°C and keep it warm for 1.0 hours. Continue to raise the temperature so that it takes 2.5 hours to rise to 200°C, then rise to 210°C, and reflux at a constant temperature. After the reaction until the acid value is ≤12mgKOH / g, lower the temperature. When the temperature dropped to 190° C., add 953.68 kg of xylene and 119.21 kg of toluene to di...

Embodiment 2

[0035]937.52kg refined oleic acid, 250.00kg1081 stearic acid, 143.75kg benzoic acid, 506.26kg diethylene glycol, 56.88kgTMP, 318.76kg glycerin (95.0%), 451.07kg pentaerythritol were put into the reactor, and then 1562.53kg phthalic anhydride was added, Afterwards, when the temperature is lower than 80°C, add 12.50kg antioxidant, reflux with 200.00kg xylene, heat up, and pass carbon dioxide (when the temperature rises to 170°C, stop ventilation), when the temperature rises to 120°C, start stirring Turn on the reflux cooling water. Control the voltage so that it takes 2.0 hours to rise to 170°C and keep it warm for 1.0 hours. Continue to raise the temperature so that it takes 2.5 hours to rise to 200°C, then rise to 210°C, and reflux at a constant temperature. After the reaction until the acid value is less than or equal to 12mgKOH / g, lower the temperature. When the temperature dropped to 190°C, add 1043.77kg of xylene and 62.50kg to dilute, and adjust the viscosity of the rea...

Embodiment 3

[0037] 1221.72kg refined oleic acid, 228.46kg1081 stearic acid, 299.32kg benzoic acid, 610.86kg diethylene glycol, 6.11kgTMP, 61.09kg glycerin (95.0%), 357.96kg pentaerythritol were put into the reactor, and then 1221.72kg phthalic anhydride was added, Afterwards, when the temperature is lower than 80°C, add 12.22kg antioxidant, reflux with 366.51kg xylene, heat up, and pass carbon dioxide (when the temperature rises to 170°C, stop ventilation), when the temperature rises to 120°C, start stirring At the same time turn on the return cooling water. Control the voltage so that it takes 2.0 hours to rise to 170°C and keep it warm for 1.0 hours. Continue to raise the temperature so that it takes 2.5 hours to rise to 200°C, then rise to 210°C, and reflux at a constant temperature. After the reaction until the acid value is less than or equal to 12mgKOH / g, lower the temperature. When the temperature dropped to 190° C., add 977.37 kg of xylene and 156.56 kg of toluene to dilute, and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com