A kind of acid and alkali wear-resistant polyurethane elastomer and preparation method thereof

A polyurethane elastomer, acid and alkali resistance technology, applied in the field of polymer materials, can solve the problems of poor acid and alkali resistance and wear resistance, and achieve good modification effect, excellent acid and alkali resistance, and excellent wear resistance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

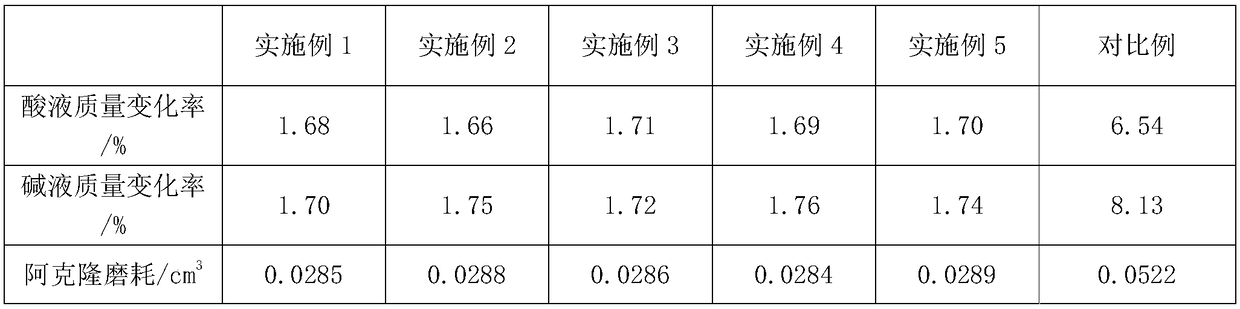

Examples

Embodiment 1

[0027] Acid, alkali and wear-resistant polyurethane elastomer, prepared from the following raw materials in parts by weight: 100 parts of PCL, 39 parts of hexamethylene diisocyanate, 0.2 parts of antioxidant 626, 5 parts of MOCA, triethylenediamine 1 part, 1.3 parts of carbodiimide, 0.6 parts of UV-531, 12 parts of diatomaceous earth, 13 parts of modified composite magnesium borate whiskers.

[0028] The steps of the preparation method of this polyurethane elastomer comprise:

[0029] (1) Magnesium chloride is added to water, after stirring until uniform, adjust the ph value with ammonia water to 10, continue stirring for 30 minutes, add boric acid, potassium chloride, obtain a mixed solution after stirring until uniform, add the mixed solution in the autoclave, and heat up React for 14 hours at 200°C, take out the product after cooling down to room temperature, wash with deionized water for 5 minutes after suction filtration, dry at 100°C to obtain the precursor, put the prec...

Embodiment 2

[0034] Acid, alkali and wear-resistant polyurethane elastomer, prepared from the following raw materials in parts by weight: 100 parts of PCL, 37 parts of hexamethylene diisocyanate, 0.4 parts of antioxidant 626, 7 parts of MOCA, triethylenediamine 0.8 parts, carbodiimide 1.5 parts, UV-531 0.4 parts, diatomaceous earth 14 parts, modified composite magnesium borate whiskers 11 parts.

[0035] The steps of the preparation method of the polyurethane elastomer are the same as in Example 1.

Embodiment 3

[0037] Acid, alkali and wear-resistant polyurethane elastomer, prepared from the following raw materials in parts by weight: 100 parts of PCL, 35 parts of hexamethylene diisocyanate, 0.6 parts of antioxidant 626, 9 parts of MOCA, triethylenediamine 0.6 parts, 1.1 parts of carbodiimide, 0.8 parts of UV-531, 16 parts of diatomaceous earth, 9 parts of modified composite magnesium borate whiskers.

[0038] The steps of the preparation method of the polyurethane elastomer are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com