A nitrogen-containing dual-phase corrosion-resistant and wear-resistant hot-rolled steel and its production method

A corrosion-resistant, hot-rolled steel technology, applied in the direction of improving process efficiency, can solve the problems of high production cost, difficult processing and forming, long production cycle, etc., and achieve the effect of low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention is described in detail below:

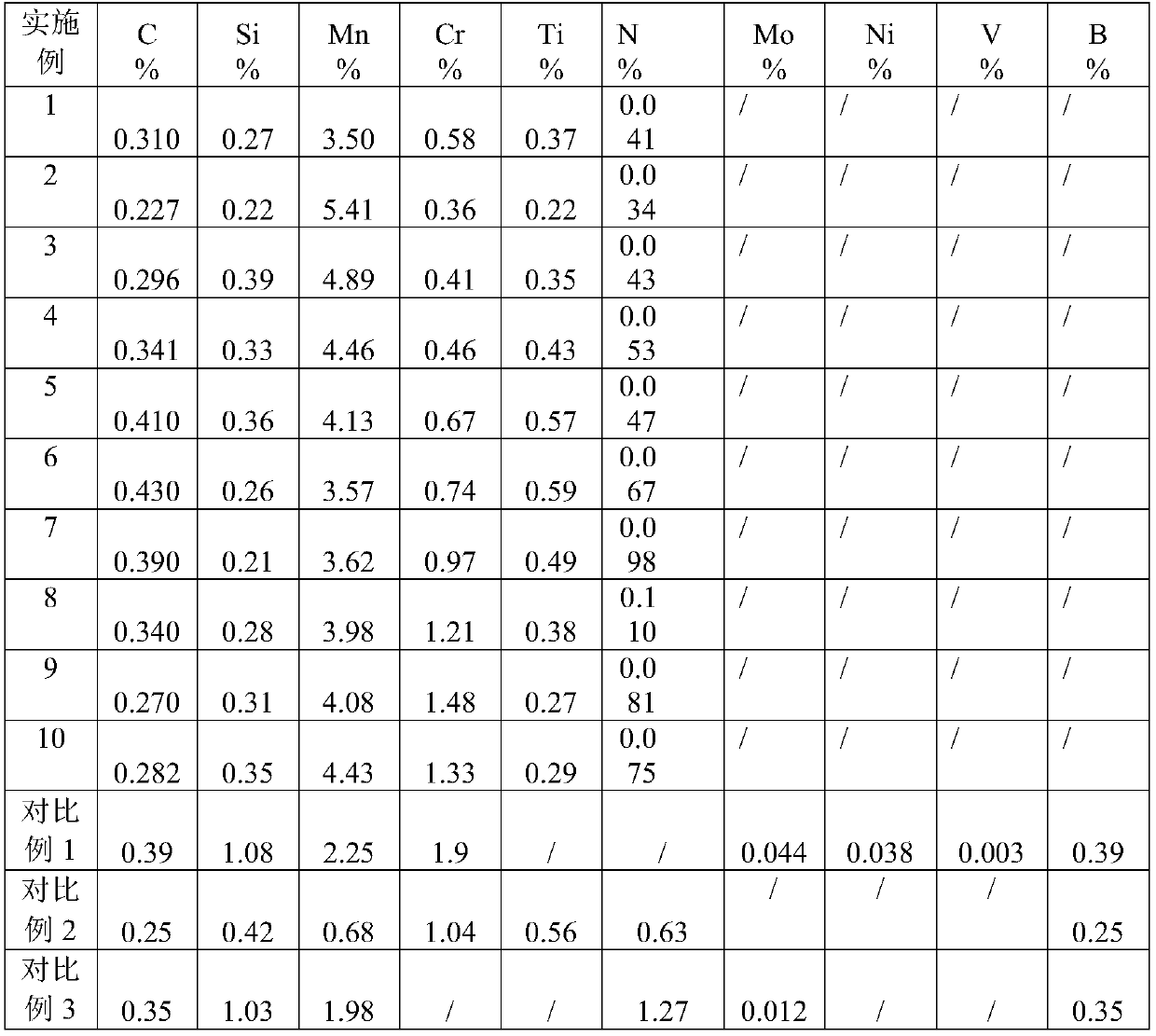

[0036] Table 1 is the chemical composition list of each embodiment of the present invention and comparative example;

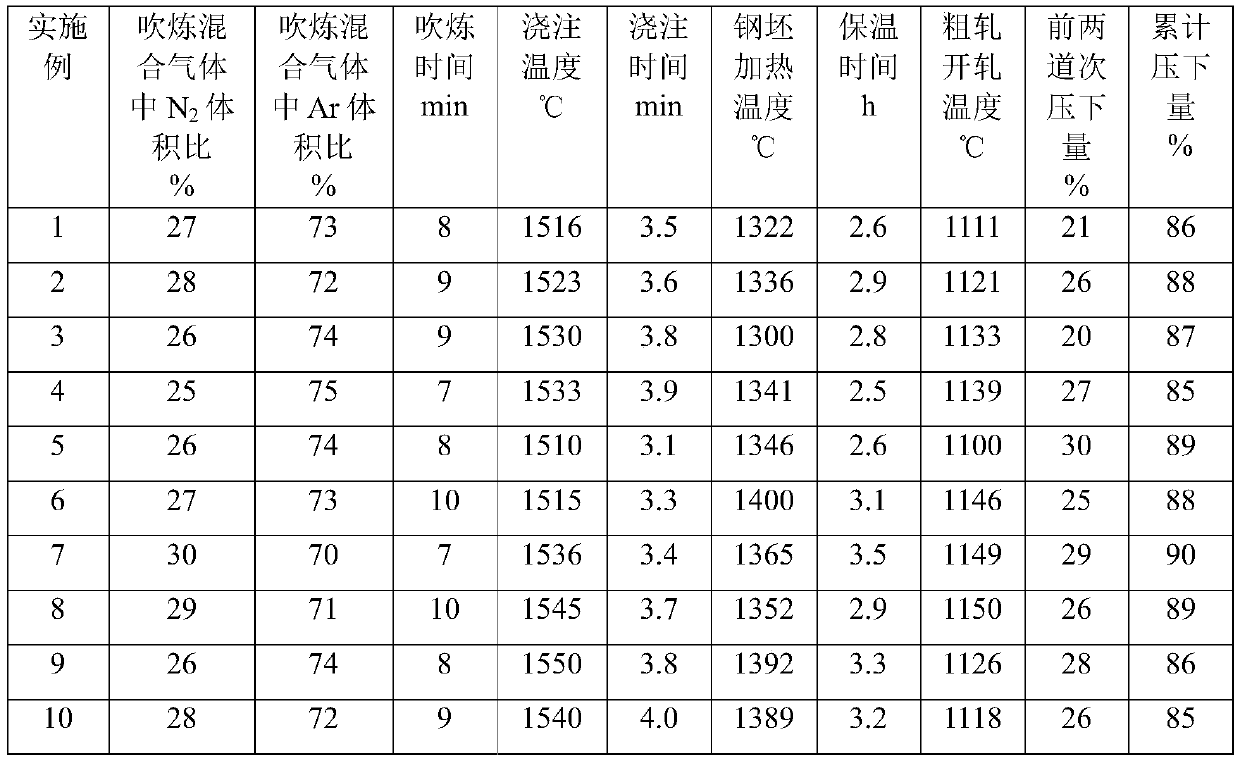

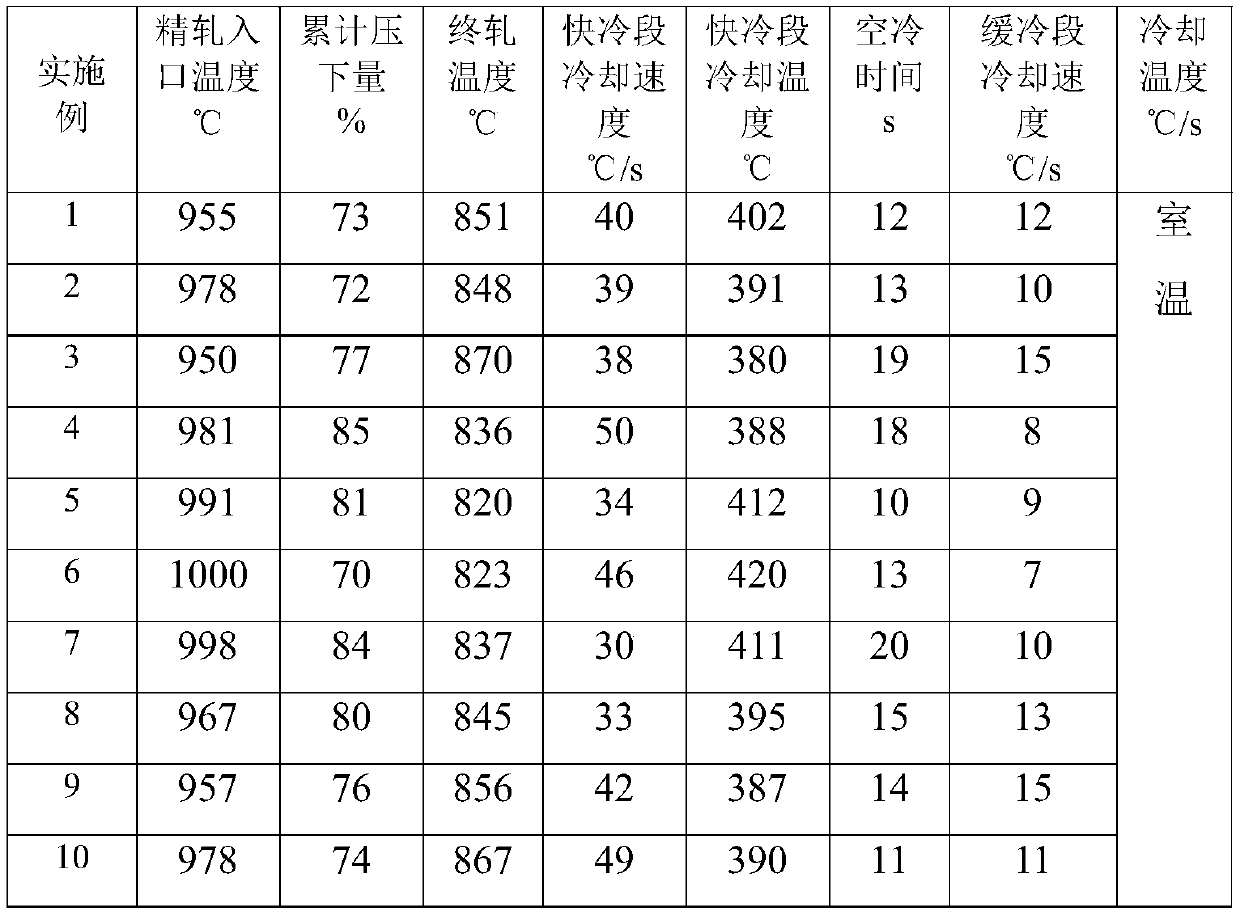

[0037] Table 2 is the main process parameter list of each embodiment of the present invention and comparative example;

[0038] Table 3 is the performance list of each embodiment of the present invention and comparative examples.

[0039] Each embodiment of the present invention all produces according to the following steps:

[0040] 1) After smelting in the electric furnace, enter the argon station, where the mixed gas of argon and nitrogen is used for blowing, and the blowing time is 7-10 minutes; in the mixed gas, nitrogen accounts for 25-30% by volume, and the rest is argon ; The added weight of steel scrap during smelting shall not exceed 10% of the total weight;

[0041] 2) Pouring after conventional vacuum treatment, the pouring temperature is 1510 ° C ~ 1550 ° C, and the pouring is complet...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com