Automatic pulsating MIG aluminium bronze surfacing method for upstream and downstream flanges

An upstream and downstream aluminum bronze technology, applied in welding equipment, arc welding equipment, program control manipulator, etc., can solve the problem of no manufacturing experience in automatic pulse MIG surfacing welding, high requirements for welding preheating temperature, and unstable quality of manual surfacing welding and other issues, to achieve the effect of improving the pass rate of flaw detection, shortening production time, and protecting health

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

[0031] The present invention provides a process method for automatic pulse MIG surfacing welding of aluminum bronze on upstream and downstream flanges. According to the technical solution proposed by the present invention, specific examples are as follows:

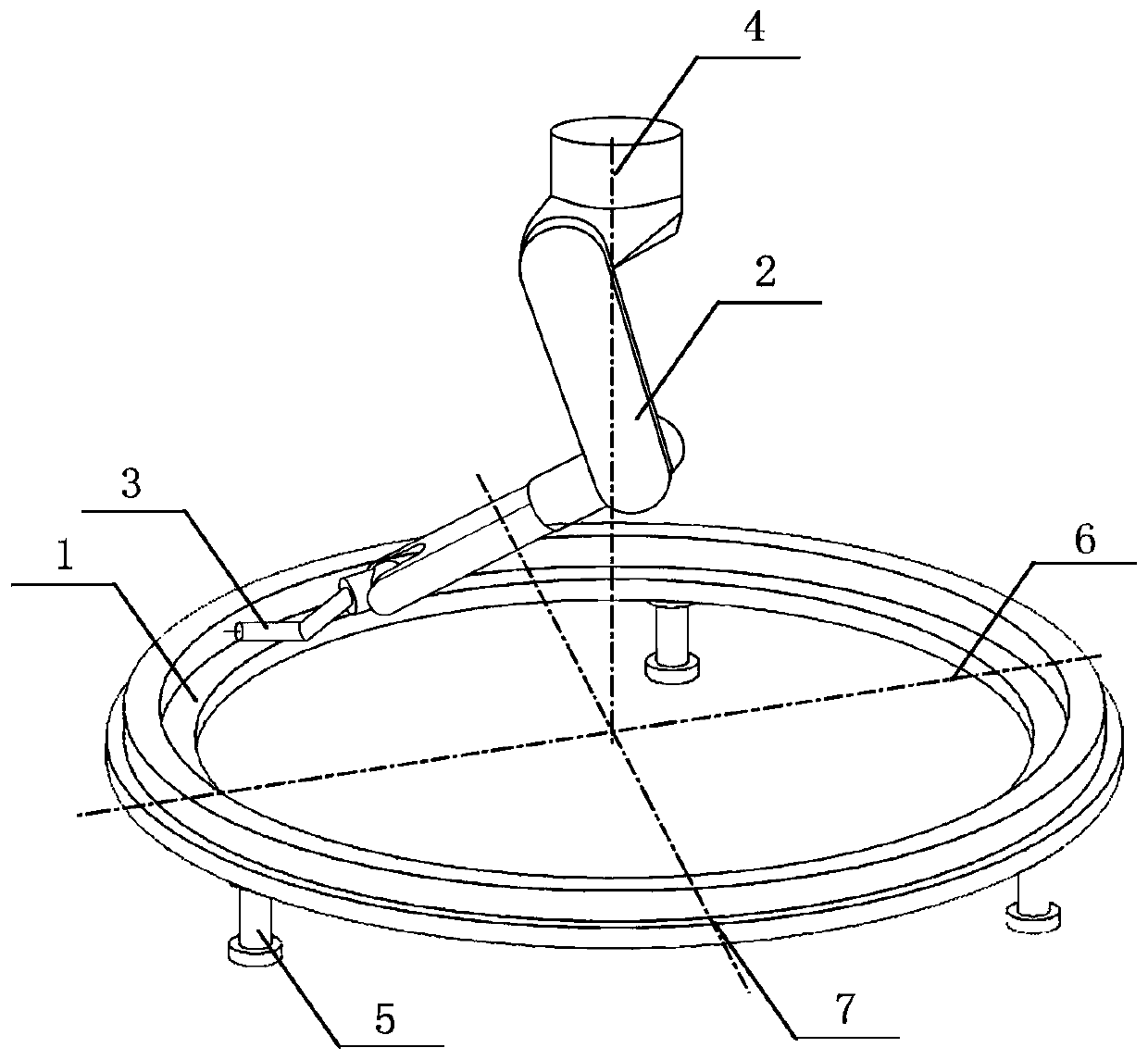

[0032] 1) if figure 1 As shown, level and pad the upstream and downstream flanges 1 stably: hang the upstream and downstream flanges 1 on the support pier 5, level them with a spirit level, and ensure the levelness of the upstream and downstream flanges 1 ± 2mm; adjust the position of the robot so that the welding robot The central axis 4 of the first axis coincides with the axis of the upstream and downstream flanges 1, and the concentricity is ±5mm;

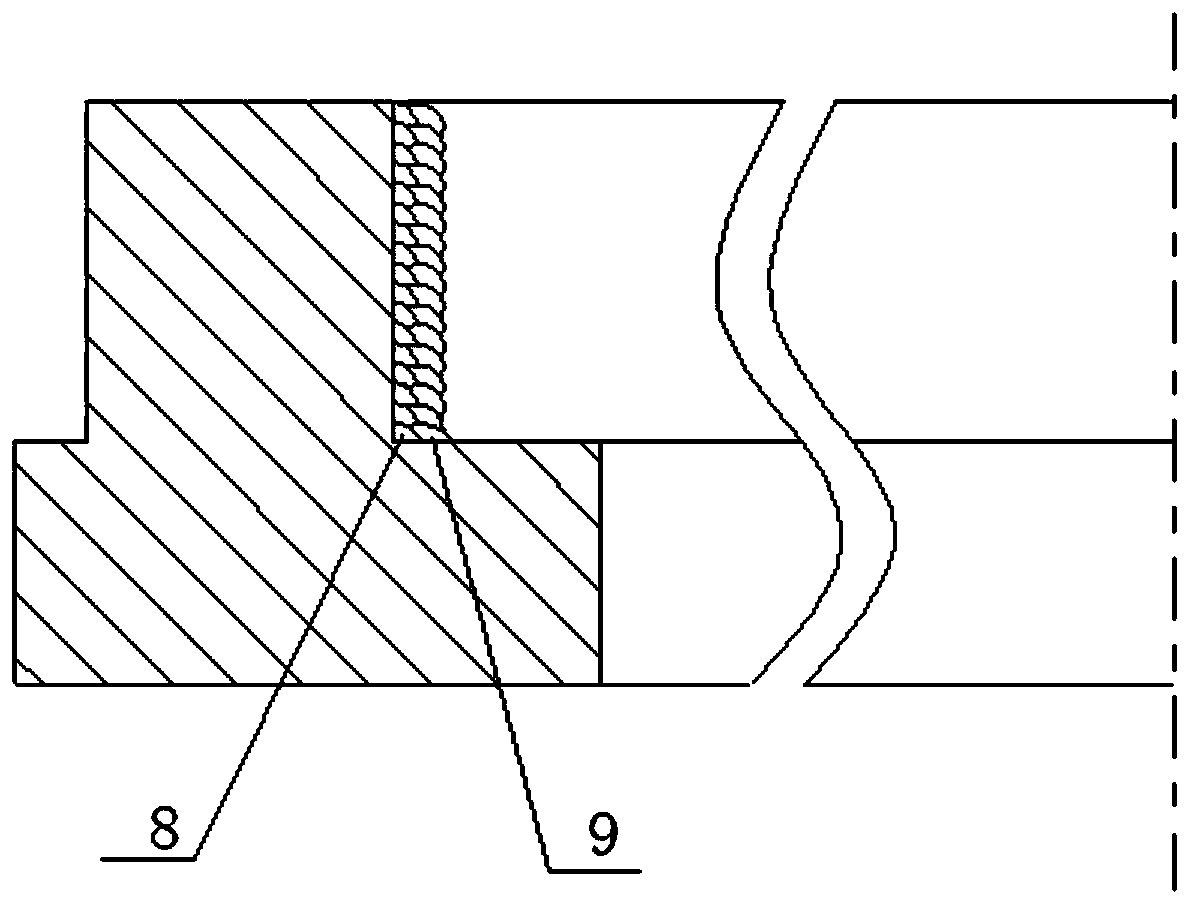

[0033] 2) Teach the welding robot 2 for the bottoming first weld 8 of the upstream and downstream flanges 1. The teaching track is circular, and the teaching points include the absolute coordinate system X axis 6 and the absolute coordinate system Y of the welding robot 2. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com