Coal gangue-based industrial environment-friendly coal

A technology for coal gangue and base industry, which is applied in the field of environmental protection briquette of coal gangue base industry, can solve the problem of high cost of briquette, and achieve the effects of low price, cost reduction and wide source.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

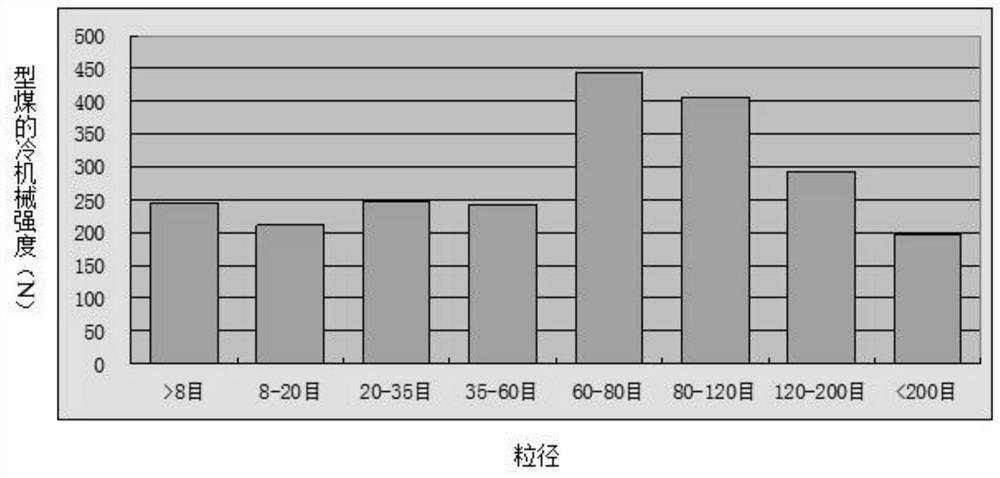

[0040] (1) Crush 25kg of coal gangue, 30kg of coal slime and 40kg of raw coal to a particle size of 60-80 mesh, and stir to mix, then add 3kg of 80-120-mesh straw powder, 1.5kg of polyvinyl alcohol and 0.5kg of ferric oxide and stir Mix, and finally add 10kg of boiling water and knead;

[0041] (2) Put the briquette raw material uniformly kneaded into the forming machine, extrude under 24MPa pressure to obtain oval briquettes, and dry at 120° C. for 6 hours to obtain the briquette product.

Embodiment 2

[0043] (1) Crush 15kg of coal gangue, 40kg of coal slime and 30kg of raw coal to a particle size of 60-80 mesh, and stir and mix, then add 2kg of 80-120 mesh straw powder, 1kg of polyvinyl alcohol and 0.5kg of ferric oxide and stir and mix , and finally add 95°C 8kg hot water and knead;

[0044] (2) Put the briquette raw material uniformly kneaded into the forming machine, extrude under 26MPa pressure to obtain oval briquettes, and dry at 130° C. for 5.5 hours to obtain the briquette product.

Embodiment 3

[0046] (1) Crush 35kg of coal gangue, 20kg of coal slime and 50kg of raw coal to a particle size of 60-80 mesh, and stir and mix, then add 4kg of 80-120 mesh straw powder, 2kg of polyvinyl alcohol and 0.5kg of ferric oxide and stir and mix , and finally add 15kg of boiling water and knead;

[0047] (2) Put the briquette raw material uniformly kneaded into the molding machine, extrude under 28MPa pressure to obtain oval briquettes, and dry at 150° C. for 4.5 hours to obtain the briquette product.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com