Unpowered layered and lined coal feeding device of chain grate boiler

A technology of chain grate and coal feeding device, applied in the direction of block/powder supply/distribution, combustion method, combustion equipment, etc., can solve the problem of poor adaptability to changes in coal type and raw coal moisture, affecting boiler thermal efficiency and safety, and manufacturing , maintenance, high operating costs, etc., to achieve the effects of fast steam pressure and flow response, simple structure, and low operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

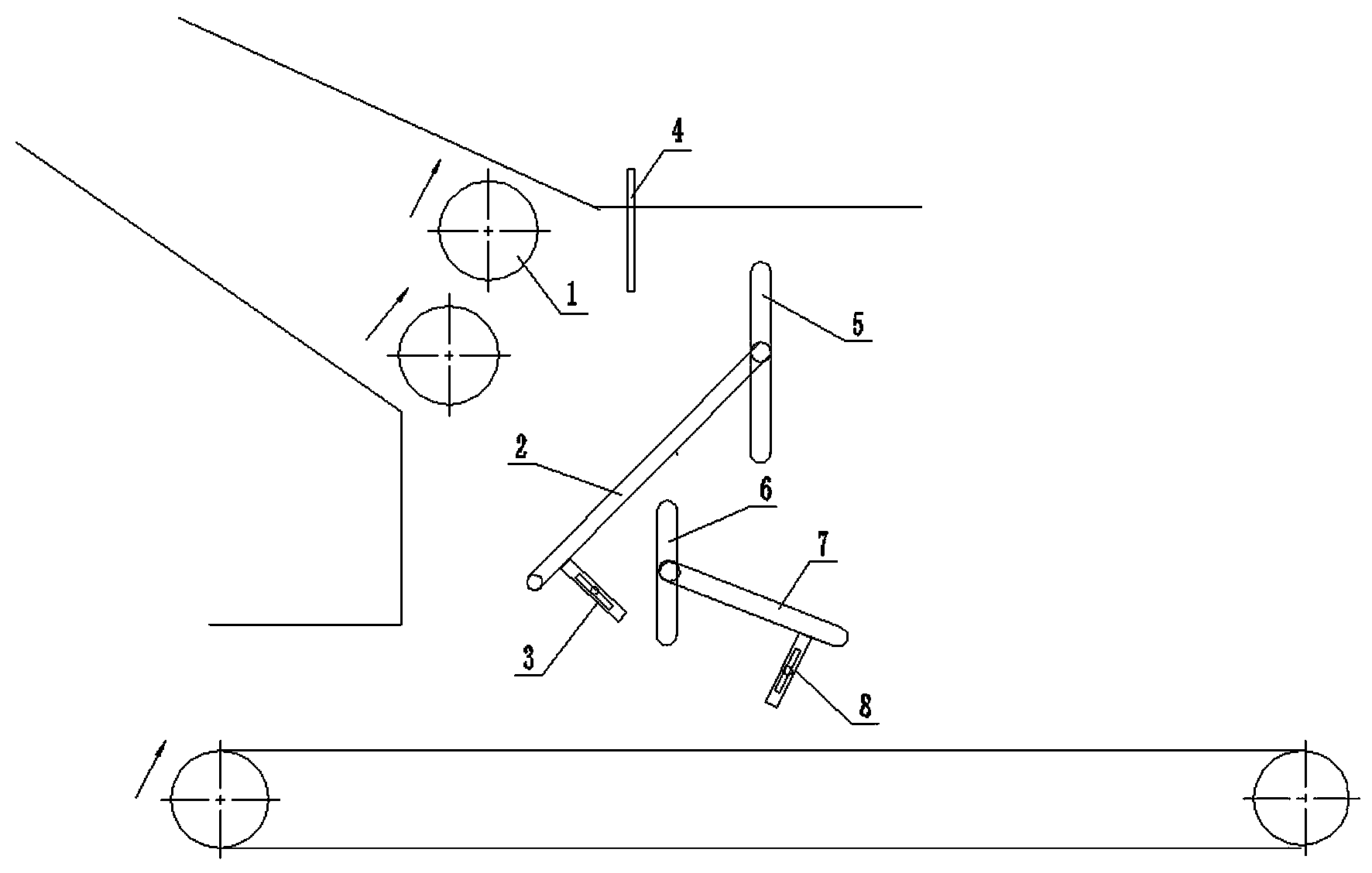

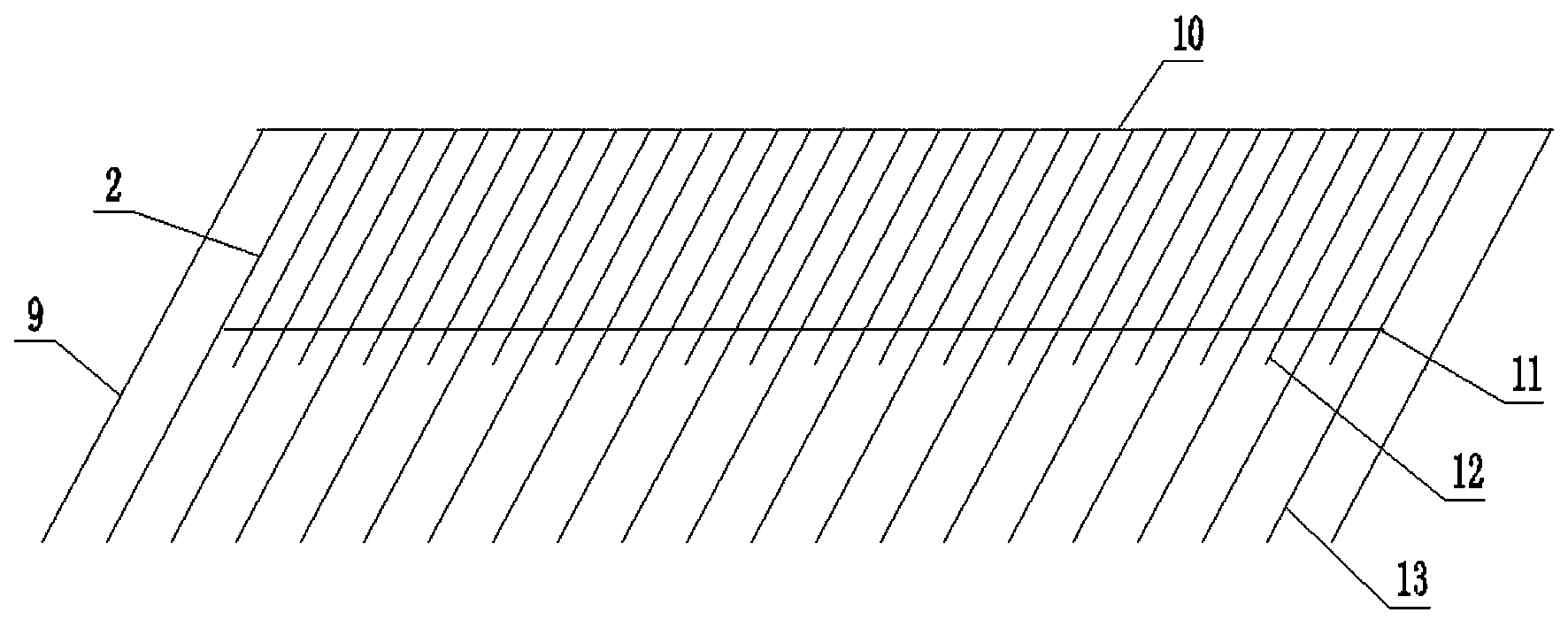

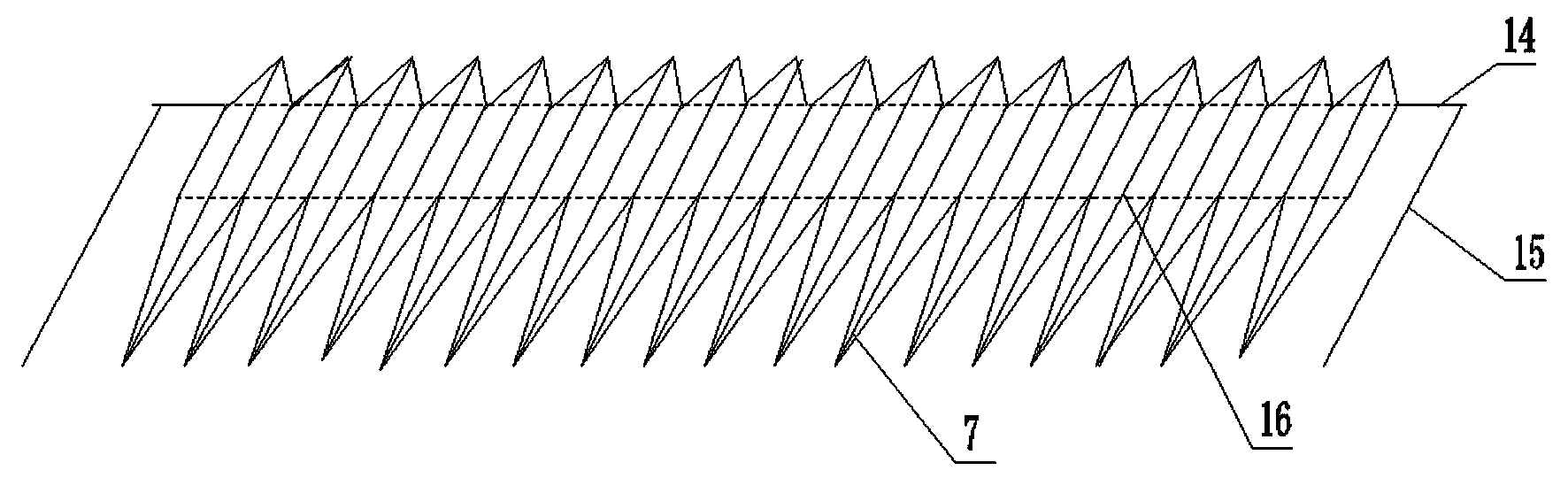

[0020] Example: such as Figure 1-7 As shown, a chain grate boiler unpowered layered branch coal feeding device includes a layered grid 2, a branch baffle 7 and its fixing and adjusting mechanism, and the layered grid 2 is divided into dense Rod area, bar thinning area and no rod area; the branch baffle plate 7 is arranged directly below the dense rod area of the layered grid 2, forming layered branches without power; the layered grid 2 is low in the front and high in the rear Inclined setting, the branch baffles 7 are set with a high front and a low slope at the rear, and adjustment mechanisms with adjustable inclination angles are respectively provided; the layered grid 2 and the branch baffles 7 are arranged between the front end of the boiler grate and the coal bunker outlet ( figure 1 Among them, 1 is the coal shifting roller, and 4 is the coal gate of the coal bunker), and the fixing mechanisms with adjustable installation heights are respectively set.

[0021] The g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com