Coal ash blending combustion and gasification process and system for pulverized coal furnace

A pulverized coal furnace and coal ash technology, which is applied in the field of solid waste disposal, can solve the problems of restricting and affecting the utilization of gasification coal ash resources, etc., and achieves the elimination of environmental pollution, the obvious effect of energy saving and emission reduction, and the reliable combustion. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Below in conjunction with accompanying drawing, describe the best implementation mode of the present invention through preferred embodiment, the specific implementation mode here is to illustrate the present invention in detail, and should not be interpreted as the limitation of the present invention, without departing from the spirit and essence of the present invention Various changes and modifications can be made within the scope of the present invention, and these should be included in the protection scope of the present invention.

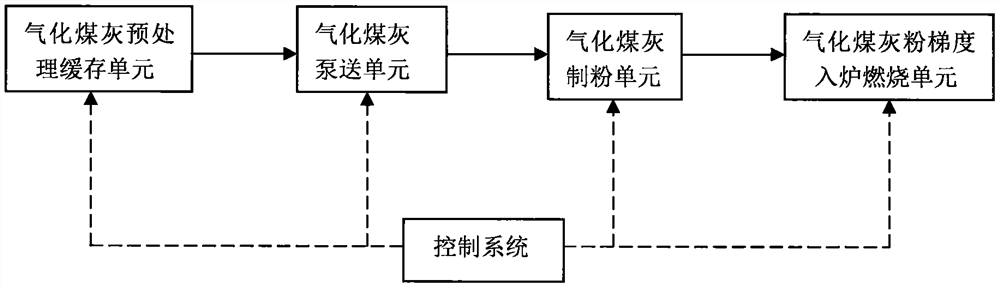

[0024] The present invention provides a pulverized coal furnace mixed combustion gasification coal ash process, including the gasification coal ash pretreatment buffer step, the gasification coal ash is removed, and then sent to the receiving bin with anti-corrosion function to prevent segregation and buffer, so that It has the characteristics of pumping; the gasification coal ash pumping step adopts anti-corrosion treated positive press...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com