Process and system for treating sludge by utilizing waste heat of boiler

A boiler waste heat and sludge system technology, applied in dehydration/drying/thickened sludge treatment, incinerator, lighting and heating equipment, etc., can solve the problem of air quality and water content in the power plant and its surroundings, blockage and dust in the power plant coal delivery system Emissions cannot meet the standards, etc., to achieve the effect of stabilizing operation, saving boiler coal resources, and eliminating exhaust gas pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The preferred embodiment of the present invention will be described below with reference to the drawings, and the specific embodiments herein are in detail, and it is not to be understood to limit the invention, without departing from the spirit and substances of the present invention. In the case of a range, various modifications and modifications can be made, which should be included within the scope of the invention.

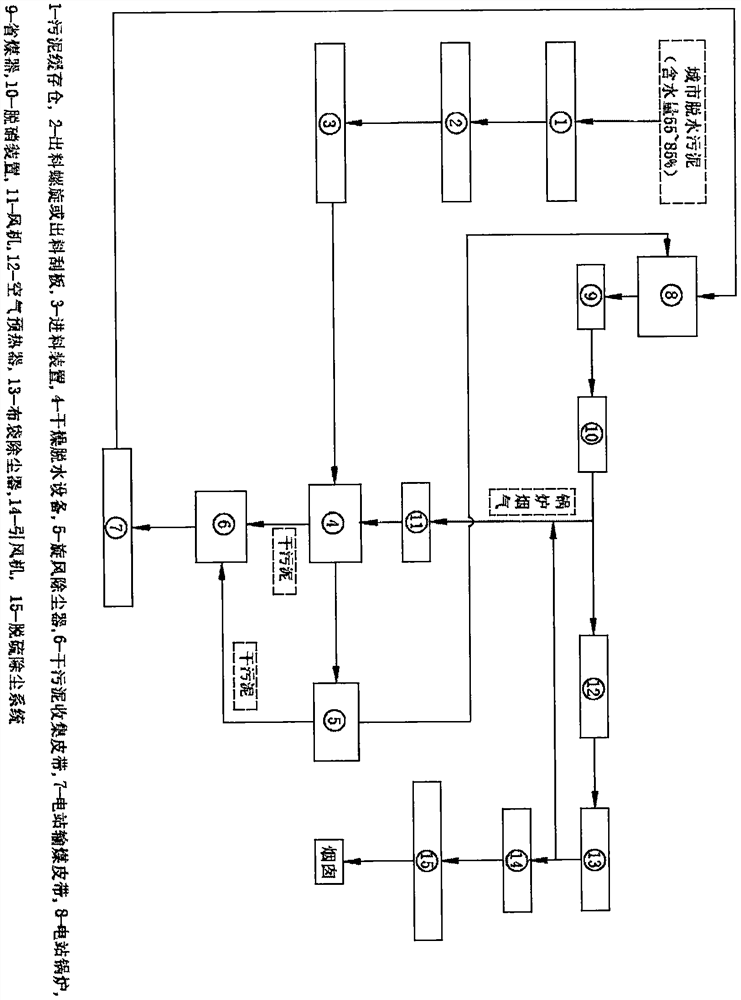

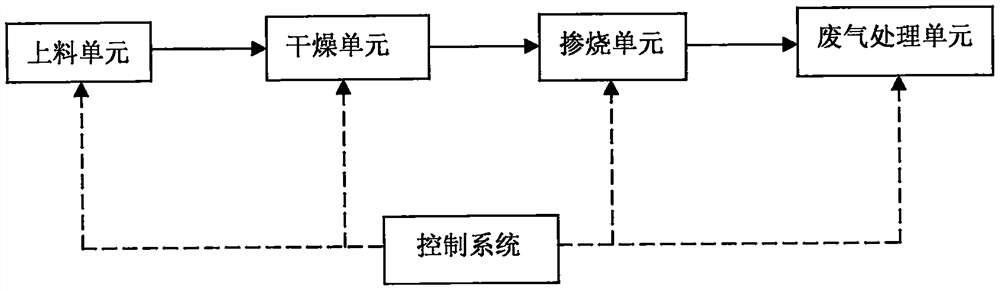

[0023] The present invention provides a sludge process using a power plant boiler residual heat, including: a feed step, derivation of the sludge after being transferred to the dry dewatering apparatus (4), so that it is suitable for drying properties; drying steps, boiler ( 8) A portion of the thermos and bag dust collector (13) Another part of the flue gas is introduced into the dry dewatering equipment (4) as a heat source, and the heat transfer is carried out by direct contact with sludge to dry the sludge dehydration; blending step, The dry sludge is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com