Method for preparing synthesis gas by co-gasifying livestock and poultry waste hydrothermal carbon and pulverized coal

A technology of livestock and poultry waste and hydrothermal carbon, which is applied in the field of resource utilization and livestock and poultry waste cleaning, can solve the problems of high moisture content of livestock and poultry waste, poor environmental and economic benefits, and low energy density, and achieve saving Coal resources, large scale of raw material processing, and high reaction conversion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

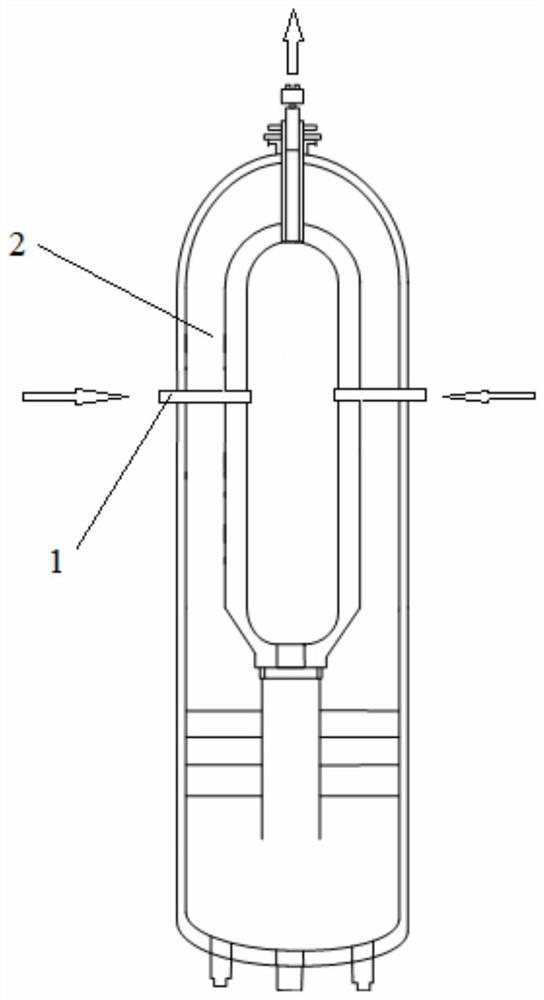

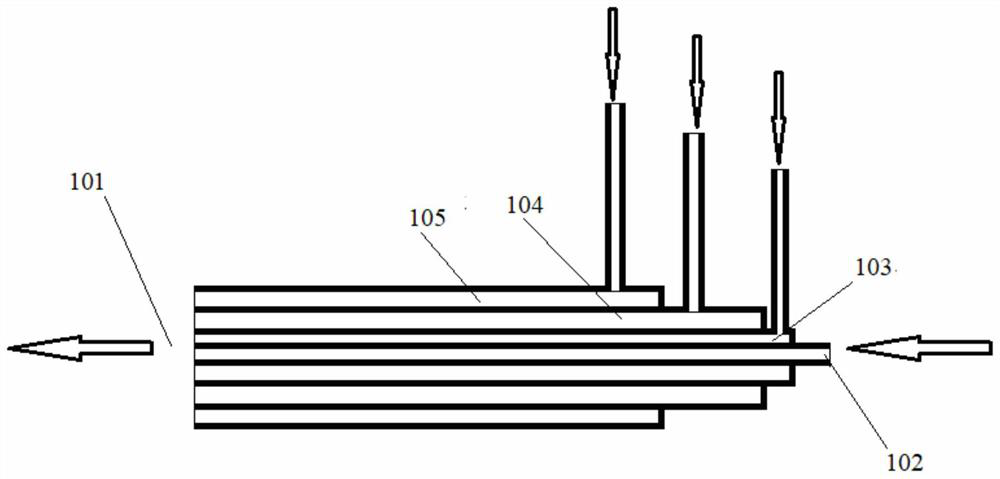

[0037] use figure 1 The entrained bed gasifier device and figure 2 The multi-channel nozzle is used to prepare synthetic gas from livestock and poultry waste and coal water slurry.

[0038] (1) Collect fresh livestock and poultry waste, and dry them naturally until the moisture content is 16%;

[0039] (2) The product of step (1) was hydrothermally carbonized at 200°C and 2MPa for 2.5 hours to obtain hydrothermal carbon with a particle size of 60 microns, a water content of 8% (weight), and a calorific value of about 20MJ / kg;

[0040] (3) adding water to the hydrothermal carbon obtained in step (2) and beating to obtain a hydrothermal carbon slurry with a carbon matrix weight concentration of 60%;

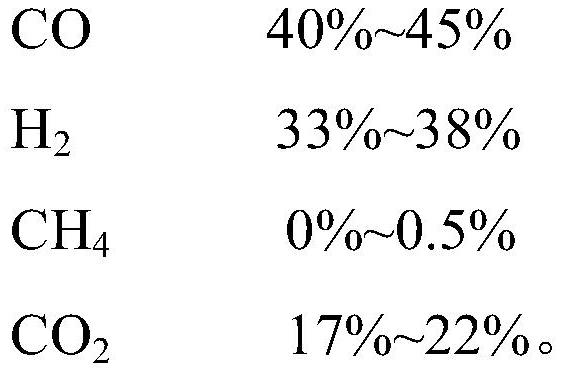

[0041] (4) the hydrothermal carbon slurry of step (3), the carbon matrix weight concentration being 60% coal water slurry, hydrothermal carbon slurry oxidant and coal water slurry oxidant, are sent into by the respective runners of the multi-channel nozzle respectively Gasifica...

Embodiment 2

[0058] use figure 1 The entrained bed gasifier device and figure 2The multi-channel nozzle is used to prepare synthetic gas from livestock and poultry waste and coal water slurry.

[0059] (1) Collect fresh livestock and poultry waste, and dry them naturally until the moisture content is 12%;

[0060] (2) The product of step (1) was hydrothermally carbonized for 2 hours at 250° C. and 2.5 MPa anaerobic conditions to obtain a particle size of 50 microns, a moisture content of 5% (weight), and a low calorific value of about 25 MJ / kg. hydrothermal carbon;

[0061] (3) adding water to the hydrothermal carbon obtained in step (2) and beating to obtain a hydrothermal carbon slurry with a carbon substrate weight concentration of 65%;

[0062] (4) the hydrothermal carbon slurry of step (3), the carbon matrix weight concentration being 65% coal water slurry, hydrothermal carbon slurry oxidant and coal water slurry oxidant, are sent into by the respective runners of the multi-channe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| heating value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com