Flow guiding tapering shape pure smokeless vertical type water heater boiler

A hot water boiler and deflector cone technology, which is applied to fluid heaters, water heaters, lighting and heating equipment, etc., can solve the problems of black smoke emission from coal combustion, and achieve the advantages of protecting the environment, high thermal efficiency and saving coal resources. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

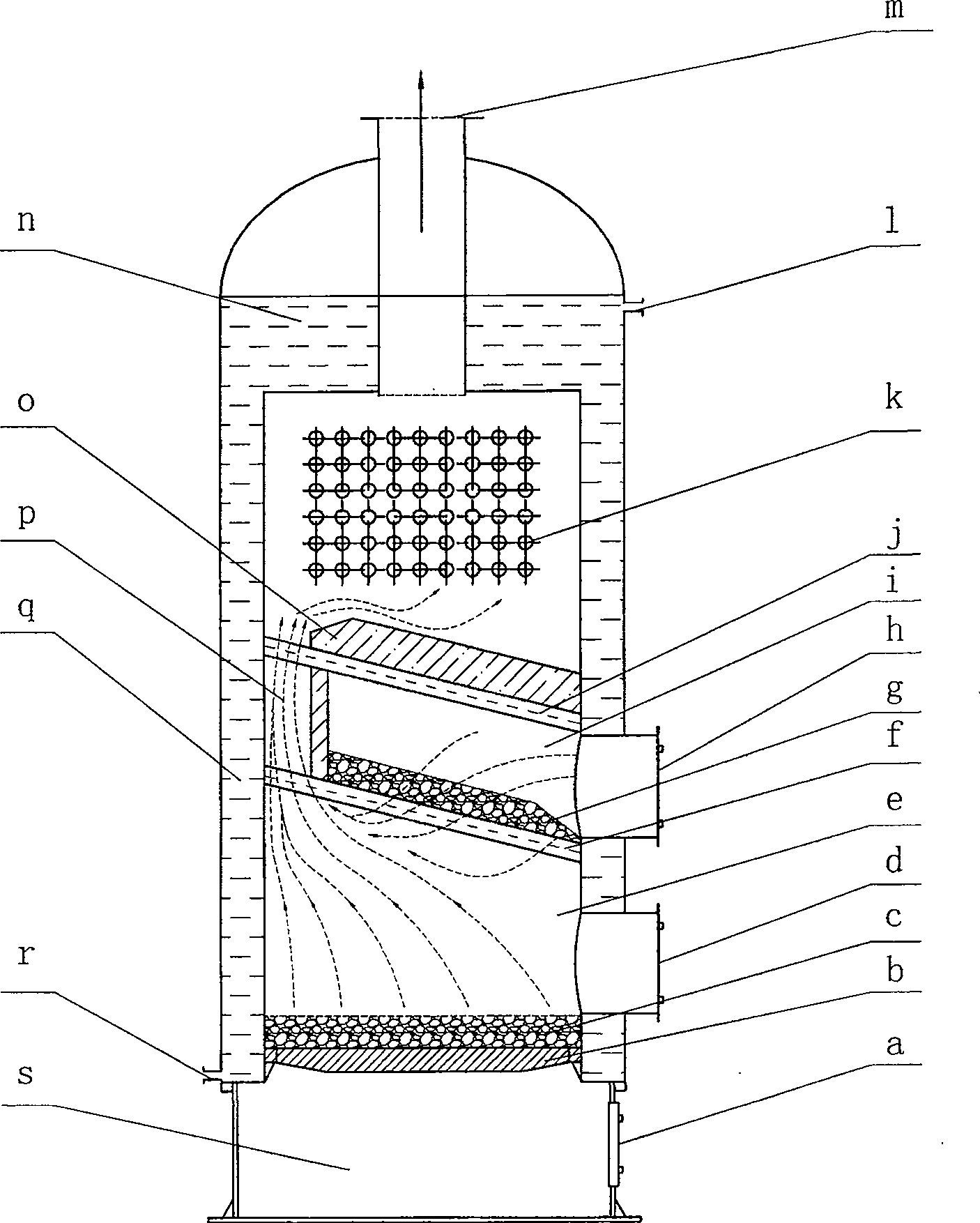

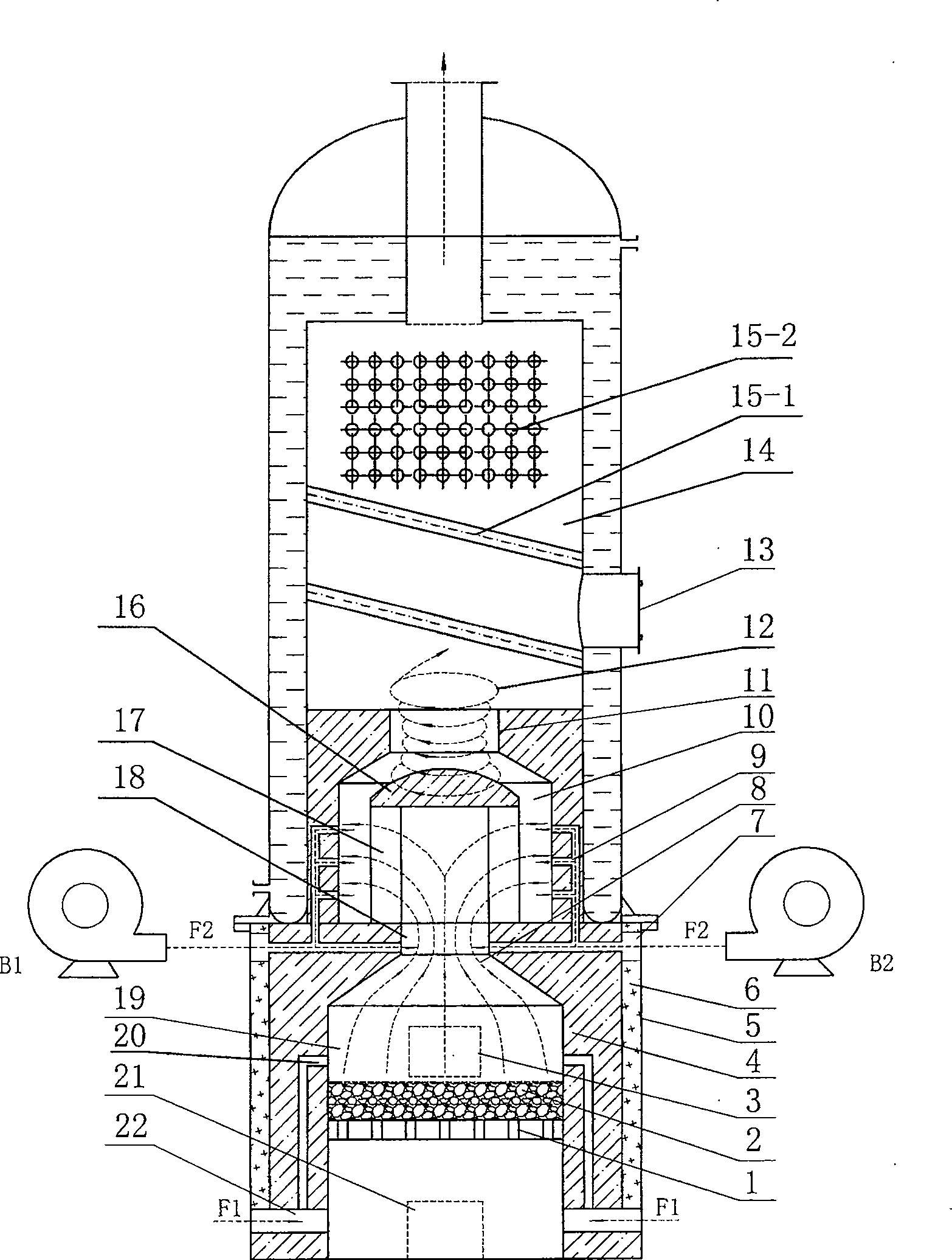

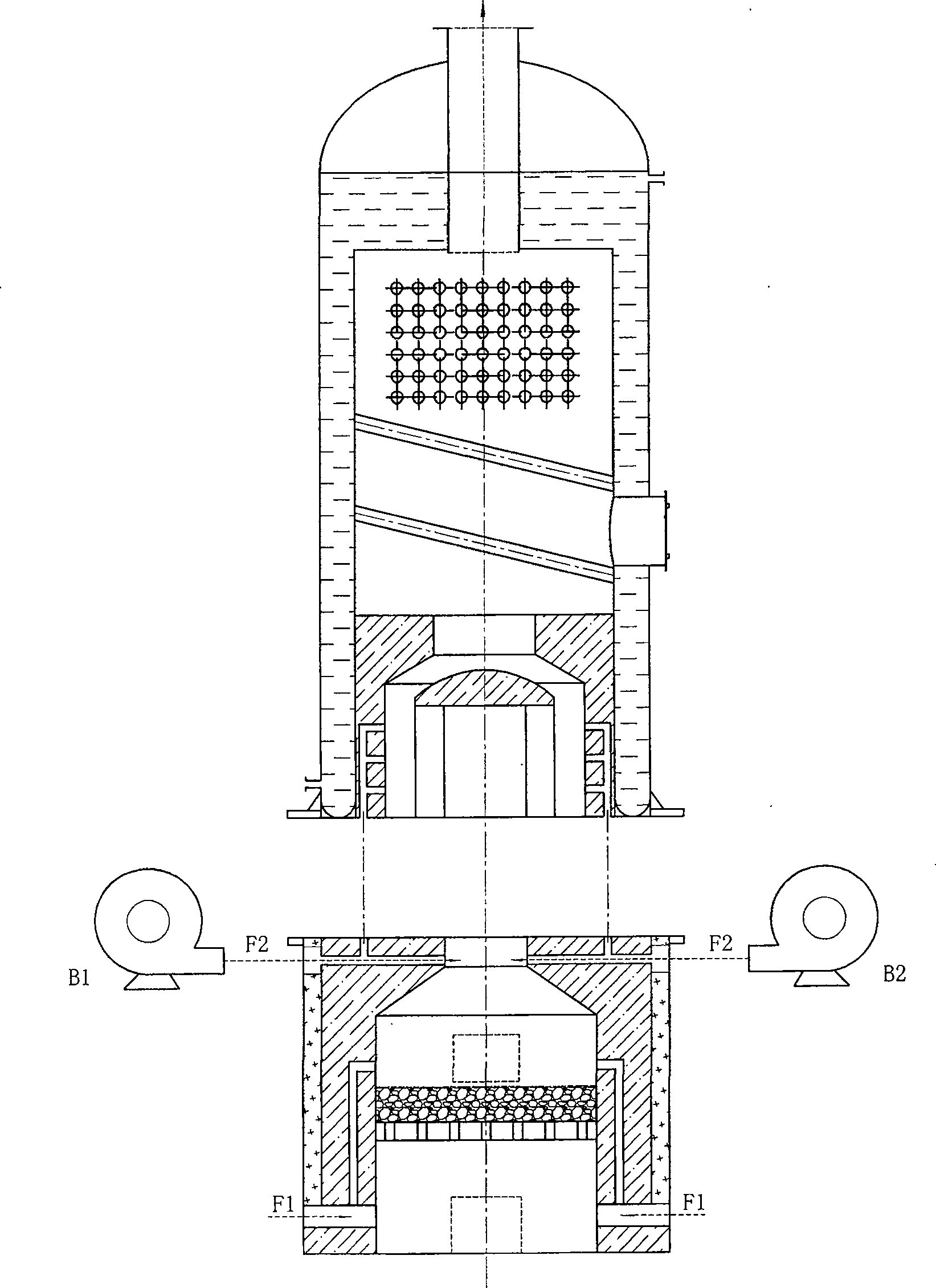

[0037] The present invention will be further described in conjunction with the accompanying drawings of the above-mentioned embodiments.

[0038] figure 2 Shown is the embodiment 1 of the diversion cone type pure smokeless vertical hot water boiler according to the present invention, including the upper sandwich casing, the lower metal casing 5 of the combustion device, the boiler tube group 15-2 and the combustion device, The boiler tube group 15-2 is placed in the hot gas chamber 14 above the combustion device. The furnace grate 1 is below the combustion furnace 19 of the combustion device. Corresponding to the ash chamber, an ash door 21 is provided, and the ash chamber is equipped with a primary combustion-supporting tuyere. The primary combustion-supporting air auxiliary tuyere 20 is also distributed around the furnace wall of the combustion furnace 19. The combustion-supporting air is provided by the air duct 22, and the combustion-supporting air is provided on the top ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com