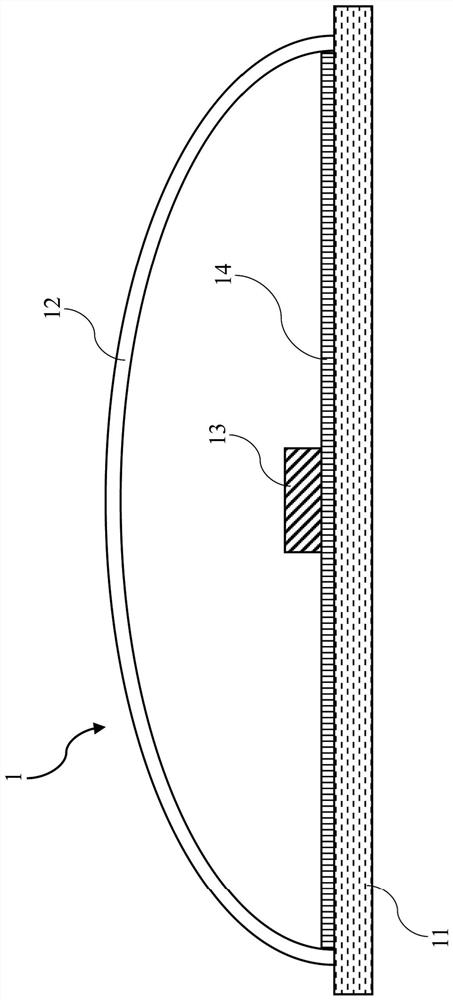

Light-emitting diode lamp with residual light prevention function

A technology of light-emitting diode lamps and functions, applied in the use of semiconductor lamps, electrical components, etc., can solve the problems of light-emitting diodes 13 afterglow, etc., achieve the effect of increasing costs, solving the problem of afterglow, and simple circuit design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to describe in detail the technical content, structural features, achieved objectives and effects of the technical solution, the following detailed description is given in conjunction with specific embodiments and accompanying drawings.

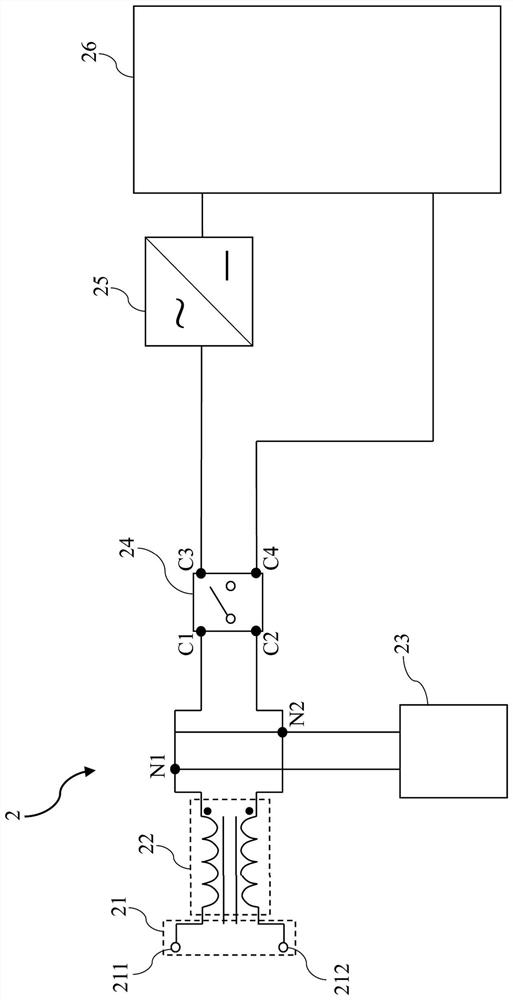

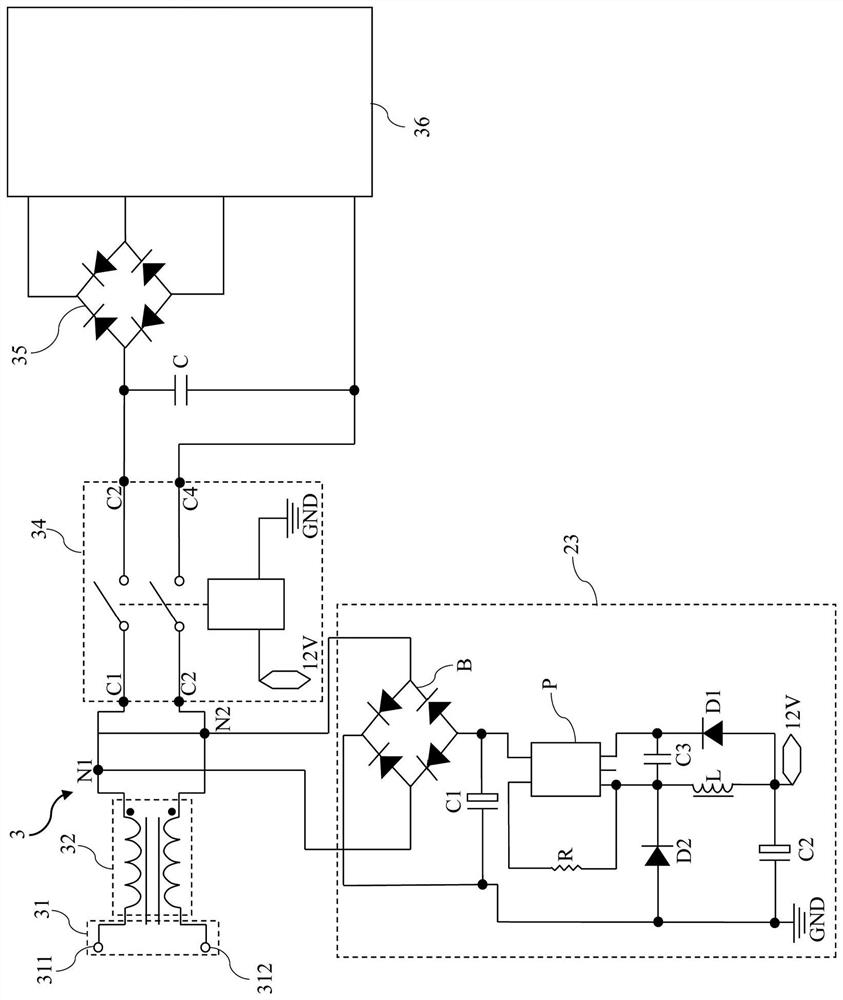

[0026] see figure 2 , which is a circuit diagram of the light-emitting diode lamp with the function of preventing afterglow according to the first embodiment of the present invention. As shown in the figure, the LED lamp 2 with the function of preventing afterglow includes a power supply input terminal 21 , a transformer circuit 22 , a control circuit 23 , a switch circuit 24 , a rectifier circuit 25 and a drive circuit 26 .

[0027] The power input terminal 21 includes a first power input terminal 211 and a second power input terminal 212 . In one embodiment, the first power input terminal 211 may be a live wire, and the second power input terminal 212 may be a neutral wire. In another embodiment, the first power input ter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com