A method of utilizing corex melting to reduce dedusting coal powder

A technology for pulverized coal and anthracite, which is applied in the field of using COREX smelting reduction and dedusting pulverized coal, can solve the problems of complex process and high cost, achieve high value, save the cost of blast furnace coal, and achieve good economic and environmental benefits.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

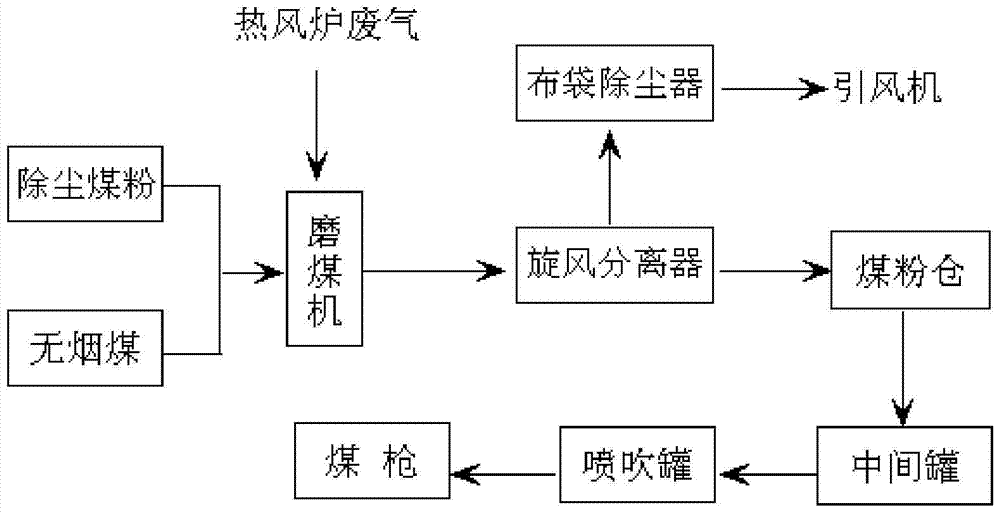

[0021] The dedusted coal powder (Ad=11%, VMd=32%) less than 1mm and the anthracite (Ad=6%, VMd=6%) less than 10mm are mixed in proportion, and the proportion of dedusted coal powder accounts for the proportion of dedusted powder 5% of the mass ratio of the mixture of dust-removed coal and anthracite, put the mixture of dedusted coal powder and anthracite into the coal pulverizer to fully grind, and transport the pulverized coal to the cyclone separator through the exhaust gas of the hot blast stove and the pneumatic conveying pipeline, and then enter the coal The powder silo, then enters the tundish tank and the injection tank, and then injects the pulverized coal into the blast furnace through the coal injection gun for coal injection operation. After testing the performance of the pulverized coal, its injection performance is as follows: pulverized coal grindability index HGI 70, the combustion rate of pulverized coal is 65, and the conveying speed of pulverized coal is 265g / ...

Embodiment 2

[0023] The dedusted coal powder (Ad=13%, VMd=35%) smaller than 1mm and the anthracite (Ad=10%, VMd=7%) smaller than 10mm are mixed in proportion, and the ratio of the dedusted coal powder accounts for the dedusted powder 10% of the mass ratio of the mixture of dust-removed coal and anthracite, put the mixture of dust-removed coal powder and anthracite into the coal pulverizer and grind it fully, and the pulverized coal will be transported to the cyclone separator through the exhaust gas of the hot blast stove and the pneumatic conveying pipeline, and then enter the coal The powder silo, then enters the tundish tank and the injection tank, and then injects the pulverized coal into the blast furnace through the coal injection gun for coal injection operation. After testing the performance of the pulverized coal, its injection performance is as follows: pulverized coal grindability index HGI 67, the combustion rate of pulverized coal is 63, and the pulverized coal delivery speed i...

Embodiment 3

[0025] The dedusted coal powder (Ad=14%, VMd=34%) smaller than 1mm and the anthracite (Ad=8%, VMd=8%) smaller than 10mm are mixed in proportion, and the proportion of dedusted coal powder accounts for the dedusted powder 15% of the mass ratio of the mixture of dust-removed coal and anthracite, put the mixture of dust-removed coal powder and anthracite into the coal pulverizer and grind it fully, and the pulverized coal will be transported to the cyclone separator through the exhaust gas of the hot blast stove and the pneumatic conveying pipeline, and then enter the coal The powder silo, then enters the tundish tank and the injection tank, and then injects the pulverized coal into the blast furnace through the coal injection gun for coal injection operation. After testing the performance of the pulverized coal, its injection performance is as follows: pulverized coal grindability index HGI 64, the combustion rate of pulverized coal is 61, and the conveying speed of pulverized co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| combustion efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com