Energy consumption difference analysis method for load varying of ultra-supercritical generating unit of thermal power plant

A generator set, ultra-supercritical technology, applied in the direction of electrical digital data processing, special data processing applications, instruments, etc., can solve the problems of lack of guidance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

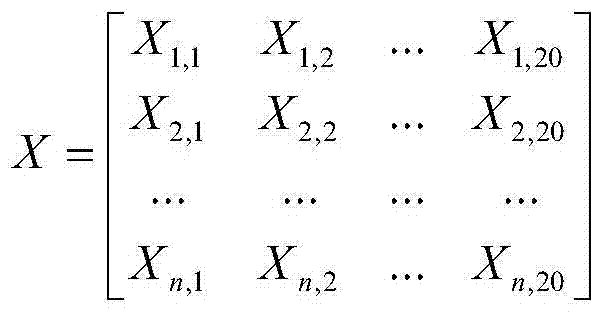

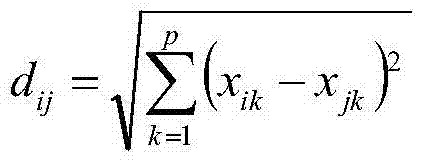

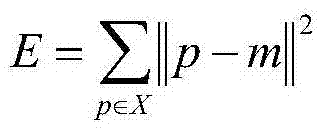

[0065] The invention provides a method for analyzing the variable load consumption difference of an ultra-supercritical generating set in a thermal power plant. First, 18 operating parameters that have a greater impact on the economy of the generating set are selected as the analysis objects. The 18 parameters are respectively: carbon content of fly ash , Furnace outlet flue gas contains O 2 volume, exhaust gas temperature, main steam pressure, main steam temperature, reheat steam temperature, feed water temperature, high temperature heater end difference, superheater desuperheating water, reheat desuperheating water, make-up water rate, condenser vacuum, condensate overheating Coldness, circulating cooling water temperature, coal quality characteristics, air leakage of air preheater, internal efficiency of steam turbine, power consumption rate of plant. By collecting the data of the power plant and using the clustering method to obtain an optimal operating condition, and use ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com