Technology for preparing dipotassium phosphate through spray-drying method

A technology of dipotassium hydrogen phosphate and spray drying method, applied in the chemical industry, can solve the problems of increased transportation cost, limited use, waste of energy, etc., and achieves the effects of improving heat utilization rate, reducing environmental pollution and saving coal resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

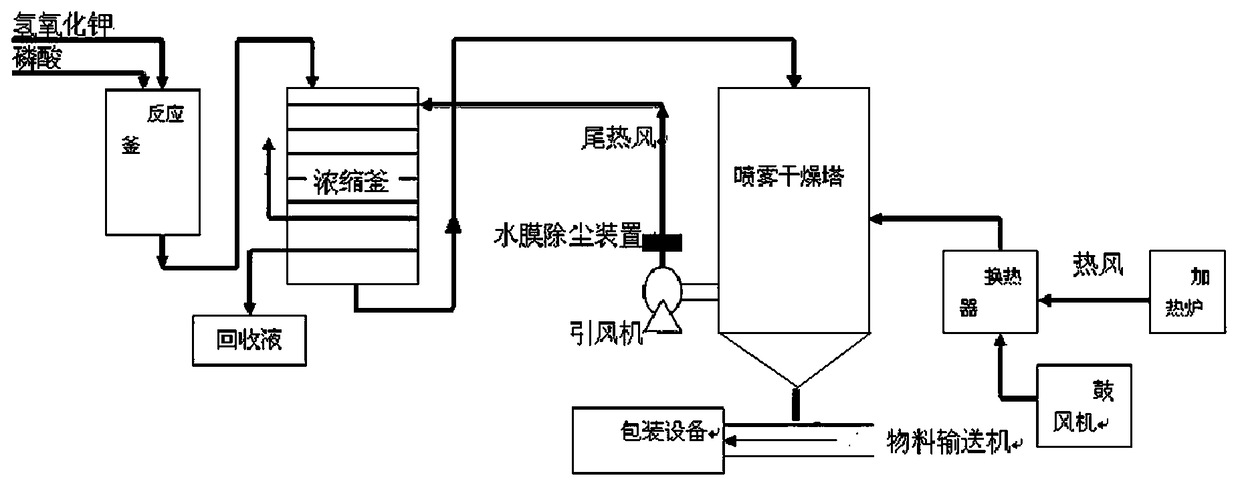

Image

Examples

Embodiment 1

[0022] A kind of spray-drying method prepares dipotassium hydrogen phosphate process, and the steps are as follows:

[0023] (1). Potassium hydroxide and phosphoric acid are neutralized in the reactor, and the pH value at the end of the reaction is 7.8;

[0024] (2). Concentrate the reaction solution prepared in step (1) in the concentration tank to reach saturation, and then enter the drying tower to spray dry;

[0025] (3). The clean air is sent to the heat exchanger by the blower to exchange heat with the hot air of the heating furnace, heated to 320°C, and then sent to the drying tower;

[0026] (4). The 320°C hot air sent into the drying tower is in full contact with the sprayed materials, and the water is evaporated instantly, and the solid product falls to the bottom of the tower in powder form, and the moisture content of the product is ≤0.5%, which ensures that the product does not agglomerate. Conveyor conveying and packaging;

[0027] (5). The induced draft fan di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com